ASTM F2730/F2730M-13

(Specification)Standard Specification for Silicon Nitride Cylindrical Bearing Rollers

Standard Specification for Silicon Nitride Cylindrical Bearing Rollers

SCOPE

1.1 This specification covers the establishment of the basic quality, physical/mechanical property, and test requirements for silicon nitride rollers Classes I, II, and III to be used for cylindrical roller bearings.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2730/F2730M −13

StandardSpecification for

1

Silicon Nitride Cylindrical Bearing Rollers

ThisstandardisissuedunderthefixeddesignationF2730/F2730M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope R 1607Testing Method for Fracture Toughness of High

Performance Ceramics

1.1 This specification covers the establishment of the basic

5

2.5 CEN Standards:

quality, physical/mechanical property, and test requirements

EN 843-1 Advanced Technical Ceramics—Monolithic

for silicon nitride rollers Classes I, II, and III to be used for

Ceramics—Mechanical Properties at Room Temperature,

cylindrical roller bearings.

Part 1, Determination of Flexural Strength

1.2 The values stated in either SI units or inch-pound units

ENV 843-5 Advanced Technical Ceramics—Monolithic

are to be regarded separately as standard. The values stated in

Ceramics—Mechanical Properties at Room Temperature,

each system are not exact equivalents; therefore, each system

Part 5, Statistical Analysis

must be used independently of the other. Combining values

6

2.6 ISO Standard:

from the two systems may result in nonconformance with the

Hardmetals-Metallographic determination of porosity and

specification.

uncombined carbon

2. Referenced Documents

3. Terminology

2.1 Order of Precedence:

3.1 Definitions of Terms Specific to This Standard:

2.1.1 In the event of a conflict between the text of this

3.1.1 ceramic second phase, n—additive phases, for ex-

document and the references herein, the text of this document

ample yttria and alumina, which appear darkeror lighter than

takes precedence. Nothing in this document, however, super-

thesiliconnitridematrixbutarenothighlyreflectiveinnature.

sedes applicable laws and regulations unless a specific exemp-

3.1.2 chips, n—break-outs of material greater in extent than

tion has been obtained.

0.25 mm [0.1 in.] typically at the corner chamfers or the

2

2.2 ASTM Standards:

junction of the chamfers with the cylindrical surface or end

C1161Test Method for Flexural Strength of Advanced

face.

Ceramics at Ambient Temperature

3.1.3 cracks, n—irregular, narrow breaks in the surface of

C1421Test Methods for Determination of Fracture Tough-

the roller typically having a visible width of less than 0.002

ness of Advanced Ceramics at Ambient Temperature

3

mm. [0.00008 in.]

2.3 ASME Standard:

3.1.3.1 Discussion—Mostcracksareformedafterdensifica-

B 46.1Surface Texture (Surface Roughness, Waviness, and

tion but occasionally may be present as material faults. Some

Lay)

4

cracks may not be visible with normal white light microscopy

2.4 JIS Standards:

and may only show up under ultraviolet light after processing

R 1601Testing Method for Flexural Strength (Modulus of

with a suitable fluorescent penetrant.

Rupture) of High Performance Ceramics

3.1.4 cuts, n—shortlinearorcircumferentialgrooveshaving

a width of more than 0.005 mm [0.002 in.] and a length of

1

ThisspecificationisunderthejurisdictionofASTMCommitteeF34onRolling

more than 0.20 mm [0.008 in.]. Cuts are normally assessed

Element Bearings and is the direct responsibility of Subcommittee F34.01 on

Rolling Element.

under roller surface appearance but large or numerous cuts, or

Current edition approved Oct. 1, 2013. Published October 2013. Originally

both can be considered defects.

approved in 2008. Last previous edition approved in 2011 as F2708/F2708M–11.

DOI: 10.1520/F2730_F2730M-13.

3.1.5 flats, n—flat bands running along the length of the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

cylindrical part of the roller, usually caused by a stop in

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

rotation of the roller during machining.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3

Available from American Society of Mechanical Engineers (ASME), ASME

5

International Headquarters, Three Park Ave., New York, NY 10016-5990, http:// Available from European Committee for Standardization (CEN), 36 rue de

www.asme.org. Stassart, B-1050, Brussels, Belgium, http://www.cenorm.be.

6

4

Available from Japanese Standards Organization (JSA), 4-1-24 Akasaka Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Minato-Ku, Tokyo, 107-8440, Japan, http://www.jsa.or.jp. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

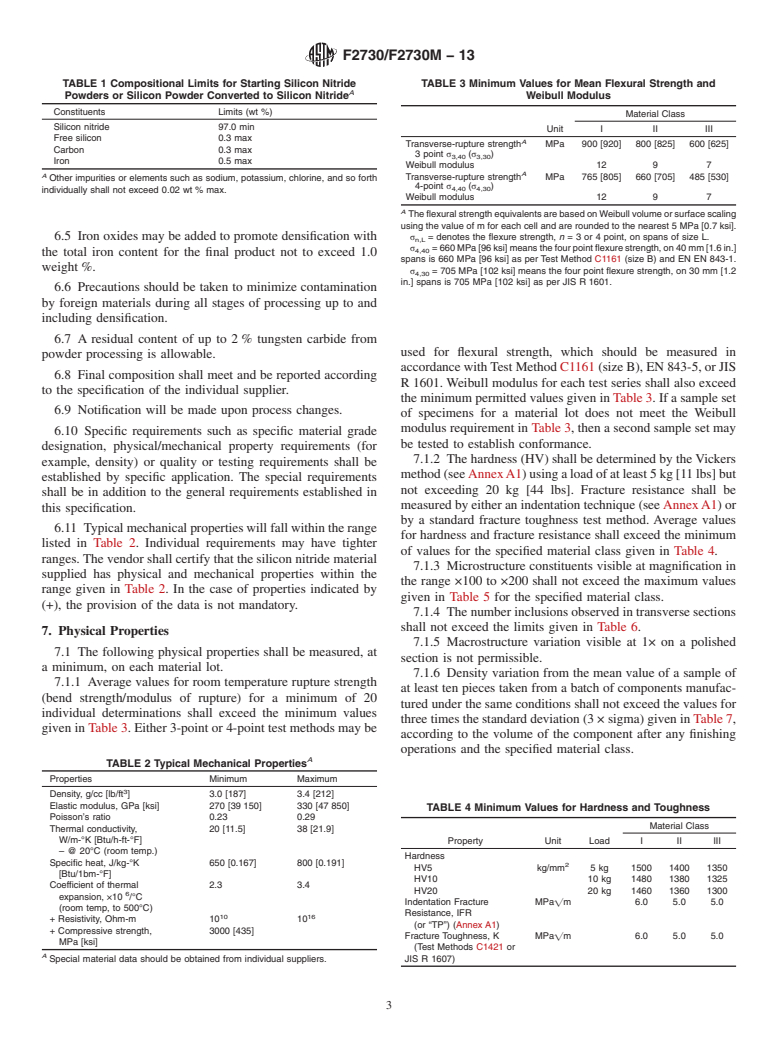

F2730/F2730M−13

3.1.5.1 Discussion—Flats can also be formed at one end have not been

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2730/F2730M − 11 F2730/F2730M − 13

Standard Specification for

1

Silicon Nitride Cylindrical Bearing Rollers

This standard is issued under the fixed designation F2730/F2730M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the establishment of the basic quality, physical/mechanical property, and test requirements for

silicon nitride rollers Classes I, II, and III to be used for cylindrical roller bearings.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two

systems may result in nonconformance with the specification.

2. Referenced Documents

2.1 Order of Precedence:

2.1.1 In the event of a conflict between the text of this document and the references herein, the text of this document takes

precedence. Nothing in this document, however, supersedes applicable laws and regulations unless a specific exemption has been

obtained.

2

2.2 ASTM Standards:

C1161 Test Method for Flexural Strength of Advanced Ceramics at Ambient Temperature

C1421 Test Methods for Determination of Fracture Toughness of Advanced Ceramics at Ambient Temperature

3

2.3 ASME Standard:

B 46.1 Surface Texture (Surface Roughness, Waviness, and Lay)

4

2.4 JIS Standards:

R 1601 Testing Method for Flexural Strength (Modulus of Rupture) of High Performance Ceramics

R 1607 Testing Method for Fracture Toughness of High Performance Ceramics

5

2.5 CEN Standards:

EN 843-1 Advanced Technical Ceramics—Monolithic Ceramics—Mechanical Properties at Room Temperature, Part 1,

Determination of Flexural Strength

ENV 843-5 Advanced Technical Ceramics—Monolithic Ceramics—Mechanical Properties at Room Temperature, Part 5,

Statistical Analysis

6

2.6 ISO Standard:

Hardmetals-Metallographic determination of porosity and uncombined carbon

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 ceramic second phase, n—additive phases, for example yttria and alumina, which appear darkeror lighter than the silicon

nitride matrix but are not highly reflective in nature.

1

This specification is under the jurisdiction of ASTM Committee F34 on Rolling Element Bearings and is the direct responsibility of Subcommittee F34.01 on Rolling

Element.

Current edition approved June 1, 2011Oct. 1, 2013. Published June 2011October 2013. Originally approved in 2008. Last previous edition approved in 20082011 as

F2708/F2708M–08.–11. DOI: 10.1520/F2730_F2730M-11.10.1520/F2730_F2730M-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

www.asme.org.

4

Available from Japanese Standards Organization (JSA), 4-1-24 Akasaka Minato-Ku, Tokyo, 107-8440, Japan, http://www.jsa.or.jp.

5

Available from European Committee for Standardization (CEN), 36 rue de Stassart, B-1050, Brussels, Belgium, http://www.cenorm.be.

6

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2730/F2730M − 13

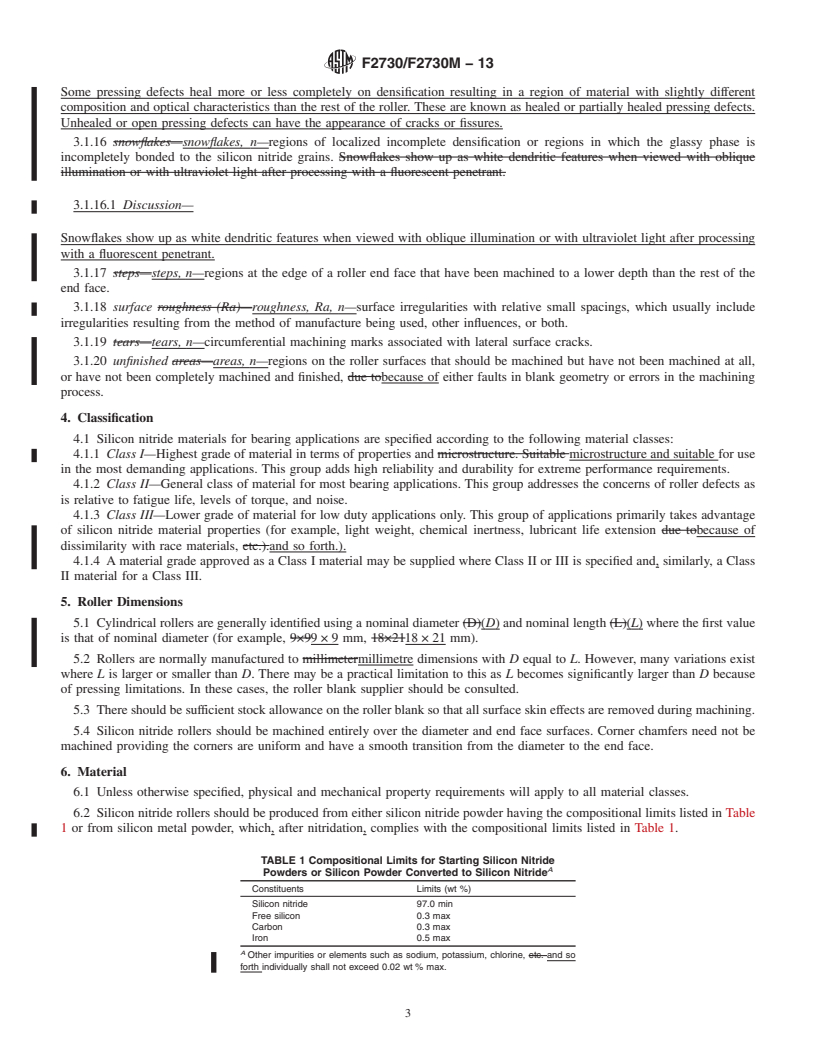

3.1.2 chips—chips, n—break-outs of material greater in extent than 0.25 mm [0.1 in.] typically at the corner chamfers or the

junction of the chamfers with the cylindrical surface or end face.

3.1.3 cracks—cracks, n—irregular, narrow breaks in the surface of the roller typically having a visible width of less than 0.002

mm. Most cracks are formed after densification but occasionally may be present as material faults. Some cracks may not be visible

with normal white light microscopy and may only show up under ultraviolet light after processing with a suitable fluorescent

penetrant.[0.00008 in.]

3.1.3.1 Discussion—

Most cracks are formed after densification but occasionally may be present as materi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.