ASTM D523-14(2018)

(Test Method)Standard Test Method for Specular Gloss

Standard Test Method for Specular Gloss

SIGNIFICANCE AND USE

5.1 Gloss is associated with the capacity of a surface to reflect more light in directions close to the specular than in others. Measurements by this test method correlate with visual observations of surface shininess made at roughly the corresponding angles.

5.1.1 Measured gloss ratings by this test method are obtained by comparing the specular reflectance from the specimen to that from a black glass standard. Since specular reflectance depends also on the surface refractive index of the specimen, the measured gloss ratings change as the surface refractive index changes. In obtaining the visual gloss ratings, however, it is customary to compare the specular reflectances of two specimens having similar surface refractive indices.

5.2 Other visual aspects of surface appearance, such as distinctness of reflected images, reflection haze, and texture, are frequently involved in the assessment of gloss (1), (6), (7). Test Method E430 includes techniques for the measurement of both distinctness-of-image gloss and reflection haze. Test Method D4039 provides an alternative procedure for measuring reflection haze.

5.3 Little information about the relation of numerical-to-perceptual intervals of specular gloss has been published. However, in many applications the gloss scales of this test method have provided instrumental scaling of coated specimens that have agreed well with visual scaling (10).

5.4 When specimens differing widely in perceived gloss or color, or both, are compared, nonlinearity may be encountered in the relationship between visual gloss difference ratings and instrumental gloss reading differences.

SCOPE

1.1 This test method covers the measurement of the specular gloss of nonmetallic specimens for glossmeter geometries of 60, 20, and 85° (1-7).2

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D523 − 14 (Reapproved 2018)

Standard Test Method for

1

Specular Gloss

This standard is issued under the fixed designation D523; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope E97 Method of Test for Directional Reflectance Factor,

45-Deg 0-Deg, of Opaque Specimens by Broad-Band

1.1 Thistestmethodcoversthemeasurementofthespecular

4

Filter Reflectometry (Withdrawn 1991)

gloss of nonmetallic specimens for glossmeter geometries of

2 E430 TestMethodsforMeasurementofGlossofHigh-Gloss

60, 20, and 85° (1-7).

Surfaces by Abridged Goniophotometry

1.2 The values stated in inch-pound units are to be regarded

3. Terminology

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

3.1 Definitions:

and are not considered standard.

3.1.1 relative luminous reflectance factor, n—the ratio of the

luminous flux reflected from a specimen to the luminous flux

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the reflected from a standard surface under the same geometric

conditions. For the purpose of measuring specular gloss, the

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- standard surface is polished glass.

mine the applicability of regulatory limitations prior to use.

3.1.2 specular gloss, n—the relative luminous reflectance

1.4 This international standard was developed in accor-

factor of a specimen in the mirror direction.

dance with internationally recognized principles on standard-

4. Summary of Test Method

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

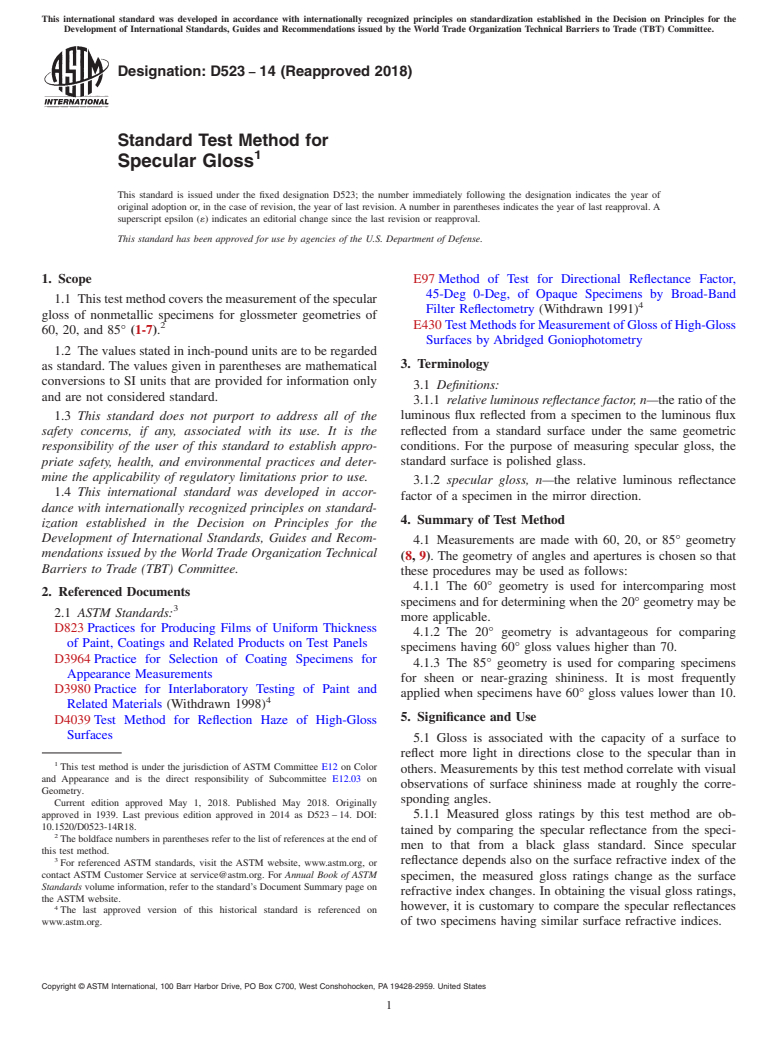

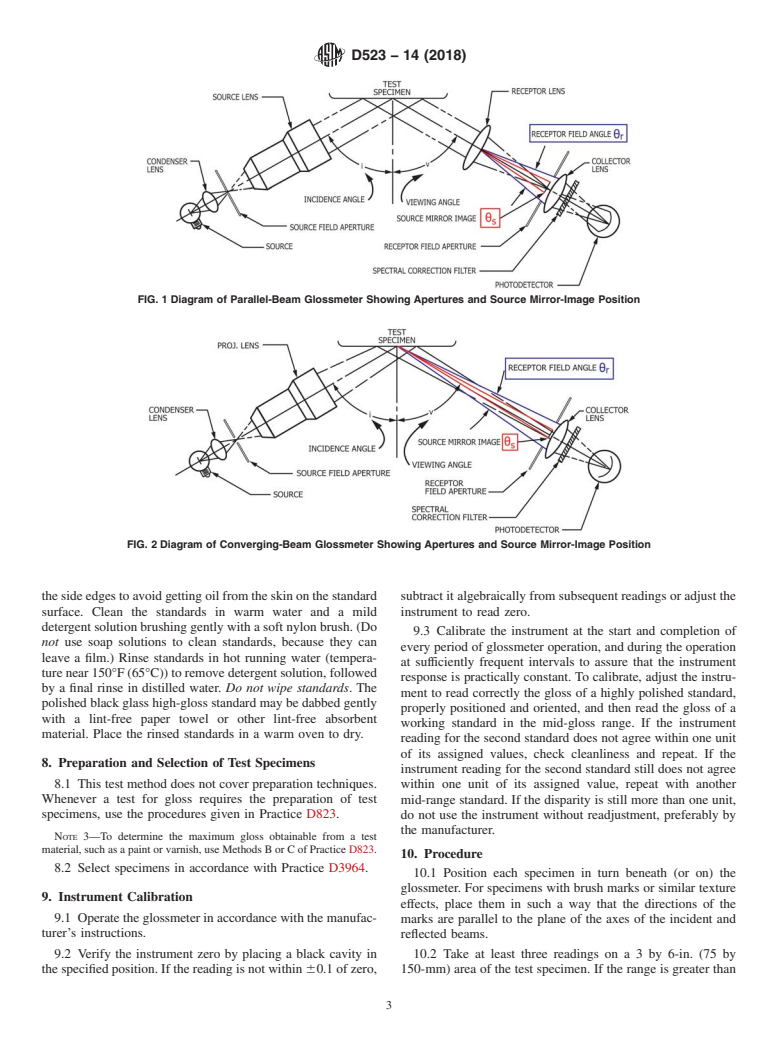

4.1 Measurements are made with 60, 20, or 85° geometry

mendations issued by the World Trade Organization Technical

(8, 9). The geometry of angles and apertures is chosen so that

Barriers to Trade (TBT) Committee.

these procedures may be used as follows:

4.1.1 The 60° geometry is used for intercomparing most

2. Referenced Documents

specimens and for determining when the 20° geometry may be

3

2.1 ASTM Standards:

more applicable.

D823 Practices for Producing Films of Uniform Thickness

4.1.2 The 20° geometry is advantageous for comparing

of Paint, Coatings and Related Products on Test Panels

specimens having 60° gloss values higher than 70.

D3964 Practice for Selection of Coating Specimens for

4.1.3 The 85° geometry is used for comparing specimens

Appearance Measurements

for sheen or near-grazing shininess. It is most frequently

D3980 Practice for Interlaboratory Testing of Paint and

applied when specimens have 60° gloss values lower than 10.

4

Related Materials (Withdrawn 1998)

5. Significance and Use

D4039 Test Method for Reflection Haze of High-Gloss

Surfaces

5.1 Gloss is associated with the capacity of a surface to

reflect more light in directions close to the specular than in

1

This test method is under the jurisdiction of ASTM Committee E12 on Color

others. Measurements by this test method correlate with visual

and Appearance and is the direct responsibility of Subcommittee E12.03 on

observations of surface shininess made at roughly the corre-

Geometry.

sponding angles.

Current edition approved May 1, 2018. Published May 2018. Originally

approved in 1939. Last previous edition approved in 2014 as D523 – 14. DOI:

5.1.1 Measured gloss ratings by this test method are ob-

10.1520/D0523-14R18.

tained by comparing the specular reflectance from the speci-

2

The boldface numbers in parentheses refer to the list of references at the end of

men to that from a black glass standard. Since specular

this test method.

3

reflectance depends also on the surface refractive index of the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

specimen, the measured gloss ratings change as the surface

Standards volume information, refer to the standard’s Document Summary page on

refractive index changes. In obtaining the visual gloss ratings,

the ASTM website.

4 however, it is customary to compare the specular reflectances

The last approved version of this historical standard is referenced on

www.astm.org. of two specimens having similar surface refractive indices.

Copyri

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.