ASTM E2954-15(2022)

(Test Method)Standard Test Method for Axial Compression Test of Reinforced Plastic and Polymer Matrix Composite Vertical Members

Standard Test Method for Axial Compression Test of Reinforced Plastic and Polymer Matrix Composite Vertical Members

SIGNIFICANCE AND USE

5.1 The compressive properties obtained by axial compression will provide information such as: modulus of elasticity, stress at proportional limit and compressive strength for the end support, and lateral bracing condition tested.

5.2 This test method addresses only full-sized specimens for determination of compressive strength and compressive modulus of elasticity intended for application to actual length members with end conditions and lateral bracing as intended.

Note 1: The effective length of the column with respect to buckling is affected by the end conditions. A fixed end condition results in an effective length for buckling that is less than the actual length of the column, by as much as 50 %.

SCOPE

1.1 This test method covers the evaluation of vertical members in axial compression for “full-sized” specimens with various end conditions with constant cross-sections throughout the length.

1.2 This test method is limited to reinforced plastic and polymer matrix composite materials and covers the determination of the compressive properties of structural members. The method is intended primarily for members of rectangular cross section, but is also applicable to irregularly shaped studs, round posts, or special sections.

1.3 This test method covers short-term axial load testing under standard indoor atmospheric conditions. It does not address: sampling, the ability of the material to carry a sustained long-term load, design load derivations, temperature effects, performance under freeze/thaw or salt spray exposure conditions, chemical/UV exposure effects, or engineering analysis/modeling needed to extrapolate the results to conditions other than those tested. Each of these factors, and potentially others, need to be considered by the design professional or product standard development committee before using the information generated by this test method to assess structural adequacy.

1.4 Short sections are not covered in this test method and should be tested using a material test standard such as Test Method D6108 or Test Methods D198.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2954 − 15 (Reapproved 2022)

Standard Test Method for

Axial Compression Test of Reinforced Plastic and Polymer

Matrix Composite Vertical Members

This standard is issued under the fixed designation E2954; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1.1 This test method covers the evaluation of vertical

1.7 This international standard was developed in accor-

members in axial compression for “full-sized” specimens with

dance with internationally recognized principles on standard-

various end conditions with constant cross-sections throughout

ization established in the Decision on Principles for the

the length.

Development of International Standards, Guides and Recom-

1.2 This test method is limited to reinforced plastic and

mendations issued by the World Trade Organization Technical

polymer matrix composite materials and covers the determina-

Barriers to Trade (TBT) Committee.

tion of the compressive properties of structural members. The

method is intended primarily for members of rectangular cross 2. Referenced Documents

section,butisalsoapplicabletoirregularlyshapedstuds,round 2

2.1 ASTM Standards:

posts, or special sections.

D198 Test Methods of Static Tests of Lumber in Structural

1.3 This test method covers short-term axial load testing

Sizes

under standard indoor atmospheric conditions. It does not D883 Terminology Relating to Plastics

address: sampling, the ability of the material to carry a D2915 Practice for Sampling and Data-Analysis for Struc-

sustained long-term load, design load derivations, temperature tural Wood and Wood-Based Products

effects, performance under freeze/thaw or salt spray exposure D3878 Terminology for Composite Materials

conditions, chemical/UV exposure effects, or engineering D6108 Test Method for Compressive Properties of Plastic

analysis/modeling needed to extrapolate the results to condi- Lumber and Shapes

tions other than those tested. Each of these factors, and E4 Practices for Force Calibration and Verification of Test-

potentially others, need to be considered by the design profes- ing Machines

sional or product standard development committee before

E6 Terminology Relating to Methods of Mechanical Testing

using the information generated by this test method to assess E83 Practice for Verification and Classification of Exten-

structural adequacy.

someter Systems

E575 Practice for Reporting Data from Structural Tests of

1.4 Short sections are not covered in this test method and

Building Constructions, Elements, Connections, and As-

should be tested using a material test standard such as Test

semblies

Method D6108 or Test Methods D198.

E631 Terminology of Building Constructions

1.5 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical 3. Terminology

conversions to SI units that are provided for information only

3.1 Definitions—Terminology D3878 defines terms relating

and are not considered standard.

to high-modulus fibers and their composites. Terminology

1.6 This standard does not purport to address all of the

D883definestermsrelatingtoplastics.TerminologyE6defines

safety concerns, if any, associated with its use. It is the

terms relating to mechanical testing. In the event of a conflict

responsibility of the user of this standard to establish appro-

between terms, Terminology D3878 shall have precedence

over the other standards.

3.1.1 For definitions of terms in this standard, see Termi-

nology E631.

This test method is under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.11

on Horizontal and Vertical Structures/Structural Performance of Completed Struc-

tures. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2022. Published May 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2015. Last previous edition approved in 2015 as E2954–15. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E2954-15R22. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2954 − 15 (2022)

3.2 Definitions of Terms Specific to This Standard: 5. Significance and Use

3.2.1 full-sized specimen—full-sized specimens (meaning

5.1 The compressive properties obtained by axial compres-

full cross-sectional area) tested with standard lengths with

sion will provide information such as: modulus of elasticity,

various end conditions and bracing conditions about the weak

stress at proportional limit and compressive strength for the

and strong member axes. The end conditions addressed in-

end support, and lateral bracing condition tested.

clude: eccentricity, fixed, pinned.

5.2 Thistestmethodaddressesonlyfull-sizedspecimensfor

3.2.2 short sections (not considered in this test method)—

determination of compressive strength and compressive modu-

compressive test sections having a maximum length, L, less

lus of elasticity intended for application to actual length

than 17 times the least radius of gyration, r, where r = √(I/A).

members with end conditions and lateral bracing as intended.

3.3 Symbols:

NOTE 1—The effective length of the column with respect to buckling is

3.3.1 σ = compressive strength.

affectedbytheendconditions.Afixedendconditionresultsinaneffective

3.3.2 σ' = compressive stress at proportional limit. length for buckling that is less than the actual length of the column, by as

much as 50 %.

3.3.3 E = compressive modulus of elasticity.

3.3.4 E' = apparent modulus of elasticity.

6. Apparatus

3.3.5 A = cross-sectional area.

6.1 Drive Mechanism—Adrive mechanism for imparting to

3.3.6 ∆ = change in length from original gage length at

a movable loading head a uniform controlled velocity with

L

proportional limit.

respect to the stationary base.

3.3.7 L = gage length of compression column.

G

6.2 Load Indicator—A load-indicating mechanism capable

3.3.8 P = maximum load borne by column loaded to of showing the total compressive force on the specimen. This

max

failure.

force-measuring system shall be calibrated to ensure accuracy

in accordance with Practices E4.Aschematic representation of

3.3.9 P' = applied load at proportional limit, lbf (N).

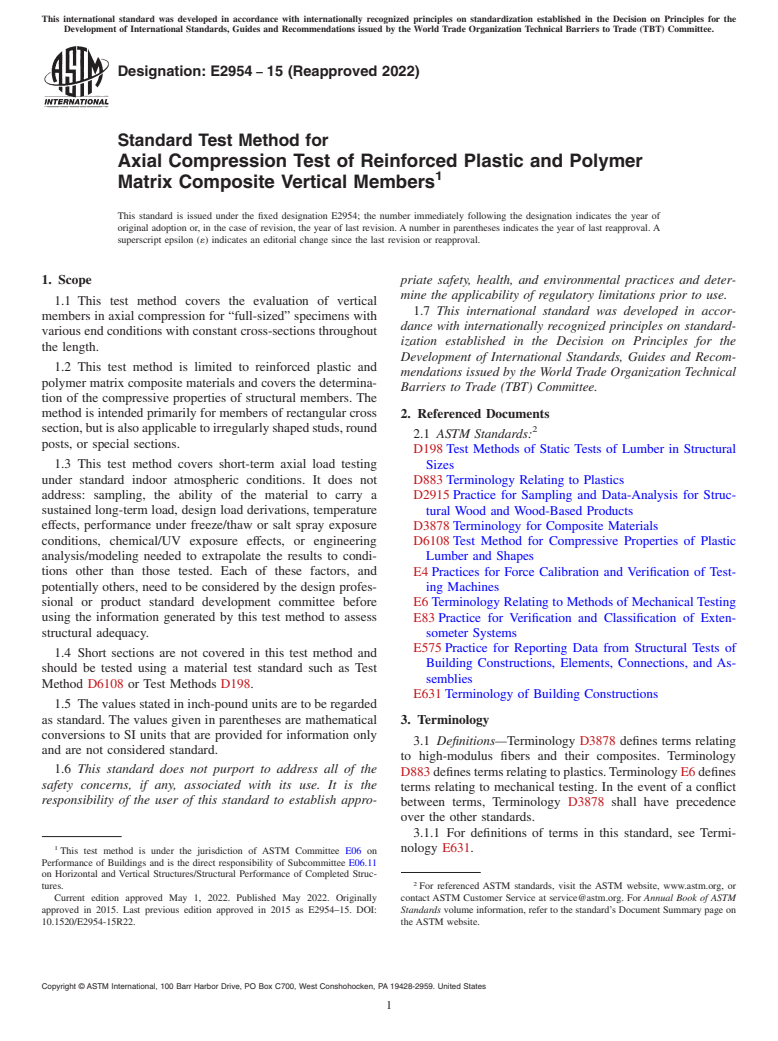

the typical test set up is shown in Fig. 1.

4. Summary of Test Method

6.3 End Conditions—The end conditions used for the test

shall be chosen to satisfy the experimental objectives. Options

4.1 The structural member is subjected to a compressive

force distributed on the contact surface of the specimen in a include:

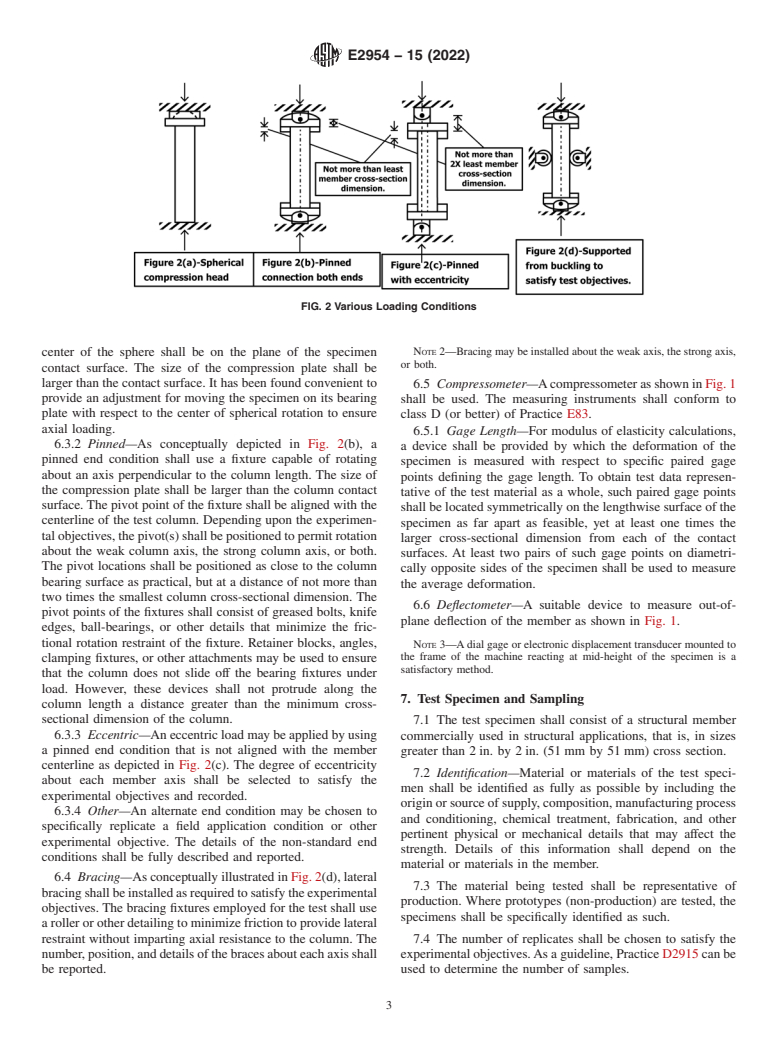

direction generally parallel to the longitudinal axis. The speci- 6.3.1 Fixed—With a fixed end condition as conceptually

mens are either loaded to failure or proof loaded. The test depicted in Fig. 2(a), a spherical bearing block may be used at

method is intended to determine the axial compressive strength either end of the column to ensure uniform contact. When

of standard full-size specimens tested with various end condi- spherical bearing blocks are used, the radius of the sphere shall

tions including: built-in eccentricity, pinned, fixed, or as be as small as practicable, in order to facilitate adjustment of

required to accomplish the experimental objective. Lateral the bearing plate to the specimen, and yet large enough to

bracing may be installed as required to accomplish the experi- provide adequate spherical bearing area. This radius is usually

mental objective. one to two times the greatest cross-section dimension. The

FIG. 1 Test Set-Up

E2954 − 15 (2022)

FIG. 2 Various Loading Conditions

NOTE 2—Bracing may be installed about the weak axis, the strong axis,

center of the sphere shall be on the plane of the specimen

or both.

contact surface. The size of the compression plate shall be

larger than the contact surface. It has been found convenient to

6.5 Compressometer—AcompressometerasshowninFig.1

provide an adjustment for moving the specimen on its bearing shall be used. The measuring instruments shall conform to

plate with respect to the center of spherical rotation to ensure

class D (or better) of Practice E83.

axial loading.

6.5.1 Gage Length—For modulus of elasticity calculations,

6.3.2 Pinned—As conceptually depicted in Fig. 2(b), a

a device shall be provided by which the deformation of the

pinned end condition shall use a fixture capable of rotating

specimen is measured with respect to specific paired gage

about an axis perpendicular to the column length. The size of

points defining the gage length. To obtain test data represen-

the compression plate shall be larger than the column contact

tative of the test material as a whole, such paired gage points

surface. The pivot point of the fixture shall be aligned with the

shall be located symmetrically on the lengthwise surface of the

centerline of the test column. Depending upon the experimen-

specimen as far apart as feasible, yet at least one times the

talobjectives,thepivot(s)shallbepositionedtopermitrotation

larger cross-sectional dimension from each of the contact

about the weak column axis, the strong column axis, or both.

surfaces. At least two pairs of such gage points on diametri-

The pivot locations shall be positioned as close to the column

cally opposite sides of the specimen shall be used to measure

bearing surface as practical, but at a distance of not more than

the average deformation.

two times the smallest column cross-sectional

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.