ASTM D6112-97(2005)

(Test Method)Standard Test Methods for Compressive and Flexural Creep and Creep-Rupture of Plastic Lumber and Shapes

Standard Test Methods for Compressive and Flexural Creep and Creep-Rupture of Plastic Lumber and Shapes

SIGNIFICANCE AND USE

Data from creep and creep-rupture tests are necessary to predict the creep modulus and strength of materials under long-term loads and to predict dimensional changes that may occur as a result of such loads.

Data from these test methods can be used to characterize plastic lumber: for comparison purposes, for the design of fabricated parts, to determine long-term performance under constant load, and under certain conditions, for specification purposes.

For many products, there may be a specification that requires the use of this test method, but with some procedural modifications that take precedence when adhering to the specification. Therefore, it is advisable to refer to that product specification before using this test method. Table 1 in Classification D 4000 lists the ASTM materials standards that currently exist.

SCOPE

1.1 These test methods cover the determination of the creep and creep-rupture properties of plastic lumber and shapes, when loaded in compression or flexure under specified environmental conditions. Test specimens in the "as-manufactured" form are employed. As such, these are test methods for evaluating the properties of plastic lumber or shapes as a product and not material property test methods.

1.2 Plastic lumber and plastic shapes are currently made predominantly with recycled plastics. However, this test method would also be applicable to similar manufactured plastic products made from virgin resins where the product is non-homogenous in the cross-section.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in brackets are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.Note 1

There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6112 – 97 (Reapproved 2005)

Standard Test Methods for

Compressive and Flexural Creep and Creep-Rupture of

Plastic Lumber and Shapes

This standard is issued under the fixed designation D6112; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4000 Classification System for Specifying Plastic Materi-

als

1.1 These test methods cover the determination of the creep

D5033 Guide for Development of ASTM Standards Relat-

and creep-rupture properties of plastic lumber and shapes,

ing to Recycling and Use of Recycled Plastics

when loaded in compression or flexure under specified envi-

D5947 Test Methods for Physical Dimensions of Solid

ronmentalconditions.Testspecimensinthe“as-manufactured”

Plastics Specimens

form are employed. As such, these are test methods for

E4 Practices for Force Verification of Testing Machines

evaluating the properties of plastic lumber or shapes as a

product and not material property test methods.

3. Terminology

1.2 Plastic lumber and plastic shapes are currently made

3.1 Definitions:

predominantly with recycled plastics. However, this test

3.1.1 compression—in a compressive creep test, the de-

method would also be applicable to similar manufactured

crease in length produced in the gage length or the total length

plastic products made from virgin resins where the product is

of a test specimen.

non-homogenous in the cross-section.

3.1.2 creep modulus—the ratio of initial applied stress to

1.3 Thevaluesstatedininch–poundunitsaretoberegarded

creep strain.

as standard. The values given in parentheses are for informa-

3.1.3 creep strain—the total strain, at any given time,

tion only.

produced by the applied stress during a creep test.

1.4 This standard does not purport to address all of the

3.1.3.1 Discussion—The term creep, as used in this test

safety concerns, if any, associated with its use. It is the

method,reflectscurrentplasticsengineeringusage.Inscientific

responsibility of the user of this standard to establish appro-

practice, creep is often defined to be the nonelastic portion of

priate safety and health practices and determine the applica-

strain. However, this definition is not applicable to existing

bility of regulatory limitations prior to use.

engineering formulas. Plastics have a wide spectrum of retar-

NOTE 1—There is no similar or equivalent ISO standard.

dation times, and elastic portions of strain cannot be separated

in practice from nonelastic. Therefore, wherever “strain” is

2. Referenced Documents

mentioned in these test methods, it refers to the sum of elastic

2.1 ASTM Standards:

strain plus the additional strain with time.

D543 Practices for Evaluating the Resistance of Plastics to

3.1.4 deflection—in a flexural creep test, the change in

Chemical Reagents

mid-span position of a test specimen.

D883 Terminology Relating to Plastics

3.1.5 deformation—a change in shape, size or position of a

D2990 Test Methods for Tensile, Compressive, and Flex-

test specimen as a result of compression, deflection, or exten-

ural Creep and Creep-Rupture of Plastics

sion:

3.1.6 plastic lumber, n—a manufactured product composed

ofmorethan50weightpercentresin,andinwhichtheproduct

These test methods are under the jurisdiction of ASTM Committee D20 on

Plastics and are the direct responsibility of Subcommittee D20.20 on Plastic generally is rectangular in cross-section and typically supplied

Products (Section D20.20.01).

in board and dimensional lumber sizes, may be filled or

Current edition approved Nov. 1, 2005. Published January 2006. Originally

unfilled, and may be composed of single or multiple resin

approved in 1997. Last previous edition approved in 1997 as D6112-97. DOI:

blends.

10.1520/D6112-97R05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6112 – 97 (2005)

3.1.7 plastic shape, n—a manufactured product composed to other specimens undergoing testing. The accuracy of the

ofmorethan50weightpercentresin,andinwhichtheproduct loading system shall be verified at least once each year in

generally is not rectangular in cross-section, may be filled or accordance with Practices E4.

unfilled, and may be composed of single or multiple resin 6.1.1.2 Loading systems that provide a mechanical advan-

blends. tage require careful design to maintain constant load through-

3.1.8 resin, n—a solid or pseudo-solid organic material out the test. For example, lever systems must be designed so

oftenofhighmolecularweight,thatexhibitsatendencytoflow thattheloaddoesnotchangeastheleverarmmovesduringthe

when subjected to stress, usually has a softening or melting test.

range, and usually fractures conchoidally. (See Terminology 6.1.2 Compression and Deflection Measurements:

D883.) 6.1.2.1 The accuracy of the deformation measuring device

3.1.8.1 Discussion—In a broad sense, the term is used to shall be within 61% of the deformation to be measured.

designate any polymer that is a basic material for plastics. 6.1.2.2 Deformation measuring devices shall be calibrated

3.1.9 stress—for compressive creep, the ratio of the applied againstaprecisionmicrometerscreworothersuitablestandard

load to the initial cross-sectional area. For flexural creep, under conditions are nearly identical as possible with those

maximum fiber stress is calculated according to Eq 1. encountered in the test. Caution is necessary when using

3.1.10 Additional definition of terms applying to this test

deformation measuring devices whose calibration is subject to

method appear in Terminology D883 and Guide D5033. drifting with time and is dependent on temperature and

humidity.

4. Summary of Test Method 6.1.2.3 Deformation measuring devices shall be firmly at-

tached to or seated on the specimen so that no slippage occurs.

4.1 These test methods consist of measuring the deflection

Electrical resistance gages are suitable only if the material

or compression as a function of time and time-to-rupture, or

tested will permit perfect adhesion to the specimen and if they

failure of a specimen subject to constant flexural or compres-

are consistent with 6.2.1

sive load under specified environmental conditions.

6.1.3 Time Measurement—The accuracy of the time mea-

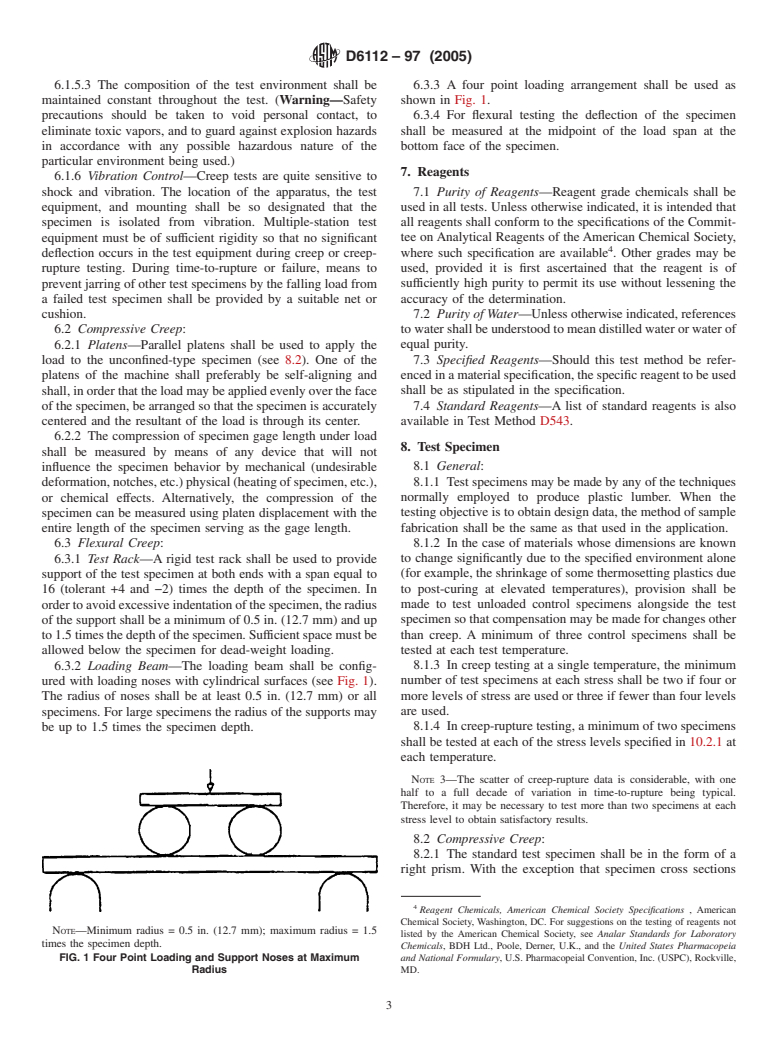

4.2 Thefour-pointloadingaoutlinedinthistestingstandard

suringdeviceshallbe 61%ofthetime-to-ruptureorfailureor

shall be used for the flexural creep tests.

the elapsed time of each creep measurement, or both.

4.3 Compressive loading as outlined in this testing standard

6.1.4 Temperature Control and Measurement:

shall be used for the compressive creep tests.

6.1.4.1 Thetemperatureofthetestspace,especiallycloseto

4.4 These test methods represent modifications of the com-

the gage length of the specimen, shall be maintained within

pressive and flexural creep and creep rupture test methods

62°C by a suitable automatic device and shall be stated in

specified in Test Methods D2990.

reporting the results.

5. Significance and Use

NOTE 2—The thermal contraction and expansion associated with small

temperature changes during the test may produce changes in the apparent

5.1 Datafromcreepandcreep-rupturetestsarenecessaryto

creep rate, especially near transition temperatures.

predict the creep modulus and strength of materials under

long-term loads and to predict dimensional changes that may

6.1.4.2 Care must be taken to ensure accurate temperature

occur as a result of such loads.

measurementsoverthegagelengthofthespecimenthroughout

5.2 Datafromthesetestmethodscanbeusedtocharacterize

the test. The temperature measuring devices shall be checked

plastic lumber: for comparison purposes, for the design of

regularly against temperature standards and shall indicate the

fabricated parts, to determine long-term performance under

temperature of the specimen gage area.

constant load, and under certain conditions, for specification

6.1.4.3 Temperature measurements shall be made at fre-

purposes.

quent intervals, or continuously recorded to ensure an accurate

5.3 For many products, there may be a specification that

determination of the average test temperature and compliance

requires the use of this test method, but with some procedural

with 6.1.5.

modifications that take precedence when adhering to the

6.1.5 Environmental Control and Measurements:

specification. Therefore, it is advisable to refer to that product

6.1.5.1 Whenthetestenvironmentisair,therelativehumid-

specification before using this test method. Table 1 in Classi-

ity shall be controlled to 50 6 5% during the test unless

fication D4000 lists the ASTM materials standards that cur-

otherwise specified, or unless the creep behavior of the

rently exist.

material under testing has been shown to be unaffected by

humidity. The controlling and measuring instruments shall be

6. Apparatus

stable for long time intervals and accurate to within 61%.

6.1 General: (The control of relative humidity is known to be difficult at

6.1.1 Loading System: temperatures much outside the range from 50 to 104°F (10 to

40°C).)

6.1.1.1 The loading system must be so designed that the

load applied and maintained on the specimen is within 61% 6.1.5.2 If, for any reason, the specified relative humidity

of the desired load. The loading mechanism must allow cannot be achieved or the test is conducted to determine the

reproductivelyrapidandsmoothloadingasspecifiedin11.1.3. sensitivity of the product to high humidity, the actual average

In creep-rupture tests, provision must be made to ensure that value and fluctuation of relative humidity used should be

shock loading, caused by a specimen failure, is not transferred reported.

D6112 – 97 (2005)

6.1.5.3 The composition of the test environment shall be 6.3.3 A four point loading arrangement shall be used as

maintained constant throughout the test. (Warning—Safety shown in Fig. 1.

precautions should be taken to void personal contact, to 6.3.4 For flexural testing the deflection of the specimen

eliminate toxic vapors, and to guard against explosion hazards shall be measured at the midpoint of the load span at the

in accordance with any possible hazardous nature of the bottom face of the specimen.

particular environment being used.)

7. Reagents

6.1.6 Vibration Control—Creep tests are quite sensitive to

7.1 Purity of Reagents—Reagent grade chemicals shall be

shock and vibration. The location of the apparatus, the test

equipment, and mounting shall be so designated that the used in all tests. Unless otherwise indicated, it is intended that

all reagents shall conform to the specifications of the Commit-

specimen is isolated from vibration. Multiple-station test

equipment must be of sufficient rigidity so that no significant tee onAnalytical Reagents of theAmerican Chemical Society,

where such specification are available . Other grades may be

deflection occurs in the test equipment during creep or creep-

rupture testing. During time-to-rupture or failure, means to used, provided it is first ascertained that the reagent is of

sufficiently high purity to permit its use without lessening the

preventjarringofothertestspecimensbythefallingloadfrom

a failed test specimen shall be provided by a suitable net or accuracy of the determination.

cushion. 7.2 PurityofWater—Unlessotherwiseindicated,references

6.2 Compressive Creep: towatershallbeunderstoodtomeandistilledwaterorwaterof

6.2.1 Platens—Parallel platens shall be used to apply the equal purity.

load to the unconfined-type specimen (see 8.2). One of the 7.3 Specified Reagents—Should this test method be refer-

platens of the machine shall preferably be self-aligning and encedinamaterialspecification,thespecificreagenttobeused

shall,inorderthattheloadmaybeappliedevenlyovertheface shall be as stipulated in the specification.

ofthespecimen,bearrangedsothatthespecimenisaccurately 7.4 Standard Reagents—A list of standard reagents is also

centered and the resultant of the load is through its center. available in Test Method D543.

6.2.2 The compression of specimen gage length under load

8. Test Specimen

shall be measured by means of any device that will not

influence the specimen behavior by mechanical (undesirable 8.1 General:

8.1.1 Testspecimensmaybemadebyanyofthetechniques

deformation,notches,etc.)physical(heatingofspecimen,etc.),

or chemical effects. Alternatively, the compression of the normally employed to produce plastic lumber. When the

testingobjectiveistoobtaindesigndata,themethodofsample

specimen can be measured using platen displacement with the

entire length of the specimen serving as the gage length. fabrication shall be the same as that used in the application.

8.1.2 In the case of materials whose dimensions are known

6.3 Flexural Creep:

6.3.1 Test Rack—A rigid test rack shall be used to provide to change significantly due to the specified environment alone

(forexample,theshrinkageofsomethermosettingplasticsdue

support of the test specimen at both ends with a span equal to

16 (tolerant +4 and −2) times the depth of the specimen. In to post-curing at elevated temperatures), provision shall be

ordertoavoidexcessiveindentationofthespecimen,theradius made to test unloaded control specimens alongside the test

of the support shall be a minimum of 0.5 in. (12.7 mm) and up specimensothatcompensationmaybemadeforchangesother

to1.5timesthedepthofthespecimen.Sufficientspacemustbe than creep. A minimum of three control specimens shall be

tested at each test temperature.

allowed below the specimen for dead-weight loading.

6.3.2 Loading Beam—The loading beam shall be config- 8.1.3 In creep testing at a single temperature, the minimum

number of test specimens at each stress shall be two if four or

ured with loading noses with cylindrical surfaces (see Fig. 1).

The radius of noses shall be at least 0.5 in. (12.7 mm) or all more levels of stress are used or three if fewer than four levels

are used.

specimens. For large specimens the radius of the supports may

be up to 1.5 times the specimen depth. 8.1.4 Increep-rupturetesting,aminimumoftwospecimens

shall be tested at each of the stress levels specified in 10.2.1 at

each temperature.

NOTE 3—The scatter of creep-rupture data is considerable, with one

half to a full decade of va

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.