ASTM D2187-94(2004)

(Test Method)Standard Test Methods for Physical and Chemical Properties of Particulate Ion-Exchange Resins

Standard Test Methods for Physical and Chemical Properties of Particulate Ion-Exchange Resins

SIGNIFICANCE AND USE

The ionic form of an ion-exchange material affects both its equivalent mass and its equilibrium water content. These in turn influence the numerical values obtained in exchange capacity determinations, in density measurements, and in the size of the particles. To provide a uniform basis for comparison, therefore, the sample should be converted to a known ionic form before analysis. This procedure provides for the conversion of cation-exchange materials to the sodium form and anion-exchange materials to the chloride form prior to analysis. These forms are chosen since they permit samples to be weighed and dried without concern for air contamination or decomposition. If other ionic forms are used this fact should be noted in reporting the results.

SCOPE

1.1 These test methods cover the determination of the physical and chemical properties of ion-exchange resins when used for the treatment of water. They are intended for use in testing both new and used materials.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Note 1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D 2187–94 (Reapproved 2004)

Standard Test Methods for

Physical and Chemical Properties of Particulate Ion-

Exchange Resins

This standard is issued under the fixed designation D 2187; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 These test methods cover the determination of the 2.1 ASTM Standards:

physical and chemical properties of ion-exchange resins when D 1129 Terminology Relating to Water

used for the treatment of water. They are intended for use in D 1193 Specification for Reagent Water

testingbothnewandusedmaterials.Thefollowingthirteentest D 1293 Test Methods for pH of Water

methods are included: D 2687 Practices for Sampling Particulate Ion-Exchange

Materials

D 2777 Practice for Determination of Precision and Bias of

Sections

Test MethodA—Pretreatment 6-10

Applicable Methods of Committee D19 on Water

Test Method B—Water Retention Capacity 11-17

E11 Specification for Wire Cloth and Sieves for Testing

Test Method C—Backwashed and Settled Density 18-24

Purposes

Test Method D—Particle Size Distribution 25-32

Test Method E—Salt-Splitting Capacity of Cation- 33-41

Exchange Resins

3. Terminology

Test Method F—Total Capacity of Cation-Exchange 42-50

3.1 Definitions—For definitions of terms used in these test

Resins

Test Method G—Percent Regeneration of Hydrogen- 51-58

methods refer to Terminology D1129.

Form Cation-Exchange Resins

3.2 Definitions of Terms Specific to This Standard:

Test Method H—Total and Salt-Splitting Capacity of 59-66

3.2.1 anion-exchange material—an ion-exchange material

Anion-Exchange Resins

Test Method I—Percent Regeneration ofAnion 67-75

capable of the reversible exchange of negatively charged ions.

Exchange Resins

3.2.2 cation-exchange material—an ion-exchange material

Test Method J—Ionic Chloride Content ofAnion- 76-83

capable of the reversible exchange of positively charged ions.

Exchange Resins

Test Method K—Carbonate Content ofAnion- 84-91

3.2.3 ion-exchange resin—asyntheticorganicion-exchange

Exchange Resins

material.

Test Method L—Sulfate Content ofAnion Exchange 92-99

Resins 3.2.4 mixed bed—a physical mixture of anion-exchange

Test Method M—TotalAnion Capacity ofAnion- 100-108

material and cation-exchange material.

Exchange Resins

4. Reagents

1.2 The values stated in SI units are to be regarded as the

standard. The inch-pound units given in parentheses are for

4.1 Purity of Reagents—Reagent grade chemicals shall be

information only.

used in all tests. Unless otherwise indicated, it is intended that

1.3 This standard does not purport to address all of the

all reagents shall conform to the specifications of the Commit-

safety concerns, if any, associated with its use. It is the

tee onAnalytical Reagents of theAmerican Chemical Society,

responsibility of the user of this standard to establish appro-

where such specifications are available. Other grades may be

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific precau-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

tionary statements are given in Note 1.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Reagent Chemicals, American Chemical Society Specifications, American

These test methods are under the jurisdiction of ASTM Committee D19 on Chemical Society, Washington, DC. For suggestions on the testing of reagents not

Water and are the direct responsibility of Subcommittee D19.08 on Membranes and listed by the American Chemical Society, see Analar Standards for Laboratory

Ion Exchange Materials. Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Current edition approved June 1, 2004. Published June 2004. Originally and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

approved in 1963. Last previous edition approved in 1998 as D2187–94 (1998). MD.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

D 2187–94 (2004)

used, provided it is first ascertained that the reagent is of

sufficiently high purity to permit its use without lessening the

accuracy of the determination.

4.2 Purity of Water— Unless otherwise indicated, refer-

ences to water shall be understood to mean Type IV reagent

water described in Specification D1193.

5. Sampling

5.1 Obtain a representative sample of the ion-exchange

resin in accordance with Practices D2687.

5.2 A minimum sample size of 1 L is recommended for a

complete testing program.

TEST METHOD A—PRETREATMENT

6. Scope

6.1 This test method covers the conversion of ion-exchange

resins to a known ionic form and is intended for application to

both new and used material.

7. Significance and Use

7.1 The ionic form of an ion-exchange material affects both

its equivalent mass and its equilibrium water content. These in

turn influence the numerical values obtained in exchange

capacity determinations, in density measurements, and in the

size of the particles. To provide a uniform basis for compari-

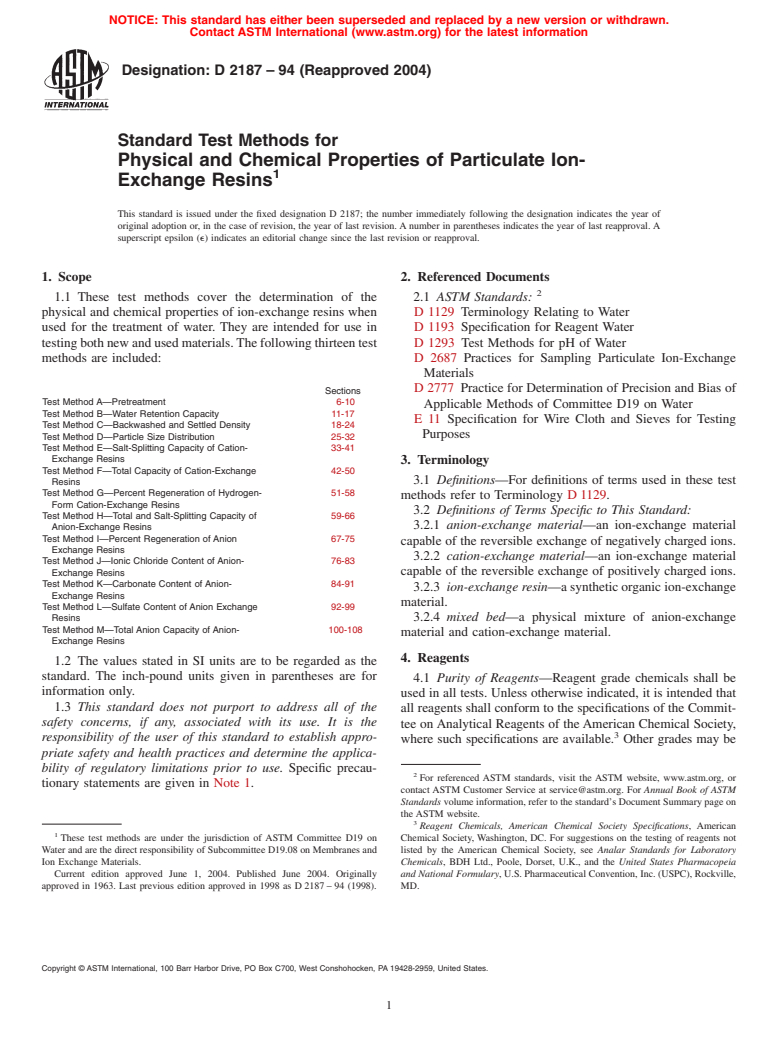

FIG. 1 Typical Arrangement of Apparatus for Pretreatment of Ion-

son, therefore, the sample should be converted to a known

Exchange Materials

ionic form before analysis. This procedure provides for the

conversion of cation-exchange materials to the sodium form

8.2.4 Vacuum Pump, capable of creating a pressure differ-

and anion-exchange materials to the chloride form prior to

ential 40 mm Hg below atmospheric pressure.

analysis. These forms are chosen since they permit samples to

be weighed and dried without concern for air contamination or 9. Reagents

decomposition.Ifotherionicformsareusedthisfactshouldbe

9.1 Hydrochloric Acid (1 + 9)—Carefully pour 100 mL of

noted in reporting the results.

hydrochloric acid (HCl, sp gr 1.19) into 900 mL of water,

stirring constantly. Cool to 25 6 5°C.

8. Apparatus

9.2 Sodium Chloride Solution (100 g/L)—Dissolve 100.0 g

8.1 Pretreatment Apparatus (See Fig. 1): of sodium chloride (NaCl) in 800 mL of water and dilute to 1

8.1.1 Column, transparent, vertically-supported, 25 6 2.5 L.

mm (1.0 6 0.1 in.) inside diameter and approximately 1500 9.3 Sodium Chloride Solution (240 g/L)—Dissolve240gof

mm(60in.)long.Thebottomofthecolumnshallbeclosedand sodium chloride (NaCl) in 800 mL of water and dilute to 1 L.

provided with an outlet of approximately 6-mm inside diam- 9.4 Sodium Hydroxide Solution (40 g/L)—Dissolve 40.0 g

eter. Connections shall be provided at top and bottom for

of sodium hydroxide (NaOH) in 800 mL of water. Cool and

admissionandremovalofsolutionsasdescribedinSection10. dilute to 1 L.

Adequate means for measuring and regulating flow shall be

9.5 Thymol Blue Indicator Solution—Dissolve 0.1 g of

provided. Calibrate the column in such a manner that the thymol blue (thymol sulfonphthalein) in 10.75 mL of 0.02 N

volumereadingsrequiredbythemethodcanbemade.Makeall

NaOH solution. Dilute to 250 mL with water.

measurements at 25 6 5°C. 9.6 Tropaeolin O Indicator Solution—Dissolve 0.10 g of

8.1.2 Support, for the sample, so designed that the distance

tropaeolin O (p-benzene-sulfonic acid-azoresorcinol) in 50 mL

from the sample to the column outlet is at least 50 mm. of water and dilute to 100 mL in a volumetric flask.

Suggested supports are corrosion-resistant screen or porous

10. Procedure

plate.

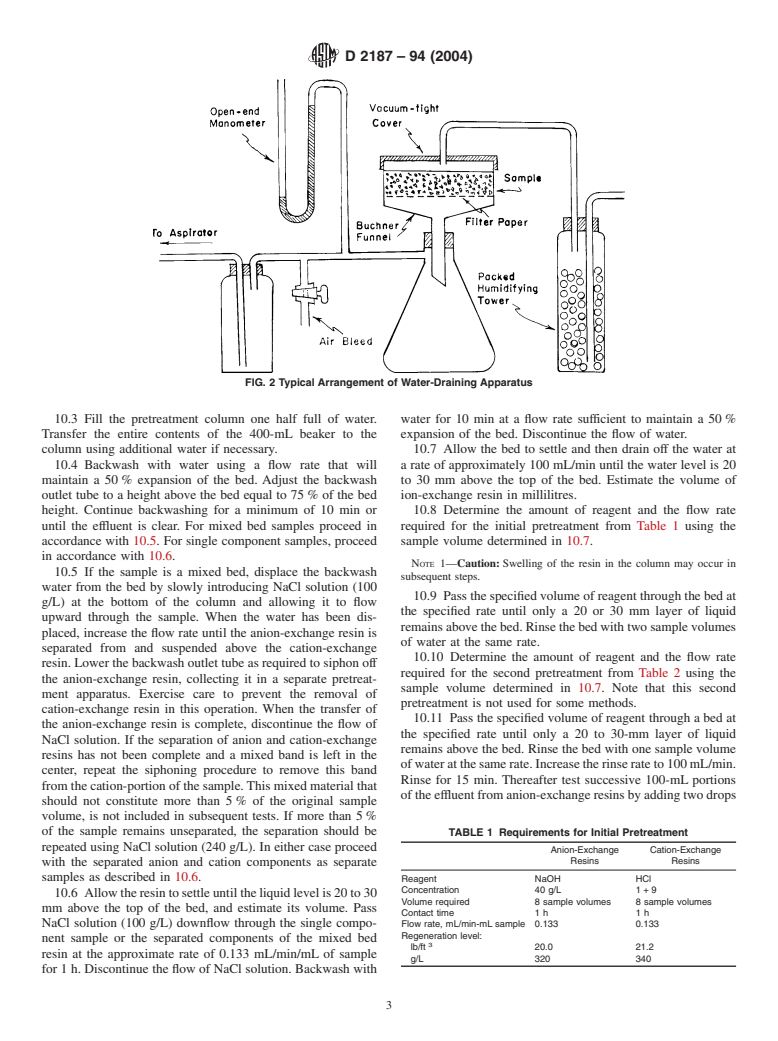

8.2 Draining Apparatus (Fig. 2): 10.1 Adjustthetemperatureofthewaterandallsolutionsto

8.2.1 Buchner-Type Funnel, containing a 125-mm filter be used in the procedure to 25 6 5°C and maintain this

paper and supported in a 1-L suction flask. temperature throughout the test.

8.2.2 Open-Arm Mercury Manometer, connected by a 10.2 Transfer the entire sample as received to a 2-L beaker

T-tube to a vacuum train. using water to rinse out the container.Adjust the water level to

8.2.3 Gas-Humidifying Tower, of at least 500 mL capacity, the sample level. Let stand a minimum of 1 h. Mix thoroughly

two thirds filled with glass beads or similar material. and transfer a representative sample to fill a 400-mL beaker.

D 2187–94 (2004)

FIG. 2 Typical Arrangement of Water-Draining Apparatus

10.3 Fill the pretreatment column one half full of water. water for 10 min at a flow rate sufficient to maintain a 50%

Transfer the entire contents of the 400-mL beaker to the expansion of the bed. Discontinue the flow of water.

column using additional water if necessary. 10.7 Allow the bed to settle and then drain off the water at

10.4 Backwash with water using a flow rate that will a rate of approximately 100 mL/min until the water level is 20

maintain a 50% expansion of the bed. Adjust the backwash to 30 mm above the top of the bed. Estimate the volume of

outlet tube to a height above the bed equal to 75% of the bed ion-exchange resin in millilitres.

height. Continue backwashing for a minimum of 10 min or 10.8 Determine the amount of reagent and the flow rate

until the effluent is clear. For mixed bed samples proceed in required for the initial pretreatment from Table 1 using the

accordance with 10.5. For single component samples, proceed sample volume determined in 10.7.

in accordance with 10.6.

NOTE 1—Caution:Swelling of the resin in the column may occur in

10.5 If the sample is a mixed bed, displace the backwash

subsequent steps.

water from the bed by slowly introducing NaCl solution (100

10.9 Passthespecifiedvolumeofreagentthroughthebedat

g/L) at the bottom of the column and allowing it to flow

the specified rate until only a 20 or 30 mm layer of liquid

upward through the sample. When the water has been dis-

remainsabovethebed.Rinsethebedwithtwosamplevolumes

placed, increase the flow rate until the anion-exchange resin is

of water at the same rate.

separated from and suspended above the cation-exchange

10.10 Determine the amount of reagent and the flow rate

resin.Lowerthebackwashoutlettubeasrequiredtosiphonoff

required for the second pretreatment from Table 2 using the

the anion-exchange resin, collecting it in a separate pretreat-

sample volume determined in 10.7. Note that this second

ment apparatus. Exercise care to prevent the removal of

pretreatment is not used for some methods.

cation-exchange resin in this operation. When the transfer of

10.11 Pass the specified volume of reagent through a bed at

the anion-exchange resin is complete, discontinue the flow of

the specified rate until only a 20 to 30-mm layer of liquid

NaCl solution. If the separation of anion and cation-exchange

remains above the bed. Rinse the bed with one sample volume

resins has not been complete and a mixed band is left in the

ofwateratthesamerate.Increasetherinserateto100mL/min.

center, repeat the siphoning procedure to remove this band

Rinse for 15 min. Thereafter test successive 100-mL portions

fromthecation-portionofthesample.Thismixedmaterialthat

oftheeffluentfromanion-exchangeresinsbyaddingtwodrops

should not constitute more than 5% of the original sample

volume, is not included in subsequent tests. If more than 5%

of the sample remains unseparated, the separation should be TABLE 1 Requirements for Initial Pretreatment

repeated using NaCl solution (240 g/L). In either case proceed

Anion-Exchange Cation-Exchange

Resins Resins

with the separated anion and cation components as separate

samples as described in 10.6.

Reagent NaOH HCl

Concentration 40 g/L 1+9

10.6 Allowtheresintosettleuntiltheliquidlevelis20to30

Volume required 8 sample volumes 8 sample volumes

mm above the top of the bed, and estimate its volume. Pass

Contact time 1 h 1 h

NaCl solution (100 g/L) downflow through the single compo- Flow rate, mL/min-mL sample 0.133 0.133

Regeneration level:

nent sample or the separated components of the mixed bed

lb/ft 20.0 21.2

resin at the approximate rate of 0.133 mL/min/mL of sample

g/L 320 340

for 1 h. Discontinue the flow of NaCl solution. Backwash with

D 2187–94 (2004)

TABLE 2 Requirements for Second Pretreatment

14. Procedure

Anion-Exchange Cation-Exchange

14.1 Weigh three approximately 5-g representative samples

Resins Resins

of material pretreated in accordance with Section 10 to the

Reagent HCl NaOH

nearest 1 mg into previously tared weighing vessels.

Concentration 1+9 40 g/L

14.2 Dry the samples for 18 62hat104 6 2°C.

Volume required 8 sample volumes 4 sample volumes

Contact time 1 h 0.5 h

14.3 Remove the samples from the oven. Cool 30 min in a

Flow rate, mL/min-mL sample 0.133 0.133

desiccator, and reweigh.

Regeneration level:

lb/ft 21.2 10.0

15. Calculation

g/L 340 160

15.1 Calculate the water retention capacity, in percent, as

follows:

waterretained,% 5[~A 2 B!/A] 3100 (1)

of thymol blue indicator solution. Continue rinsing until a 100

mL portion of the effluent remains yellow (pH > 2.5) on the

where:

addition of the indicator. Test the effluent from the cation-

A = amount of wet sample used, g, and

exchange resins in the same manner with two drops of

B = amount of dry sample obtained, g.

tropaeolin-O indicator solution. Continue rinsing until a

3 16. Report

100-mLportion of the effluent remains yellow (pH < 11.0) on

the addition of the indicator. 16.1 Report the percent water retained as the average of the

10.12 Removetheion-exchangeresinfromthepretreatment three values obtained.

column, discarding any extraneous material that may have

17. Precision and Bias

accumulated at the bottom of the bed. Transfer the resin to the

17.1 Precision—The precision of this test method of deter-

Buchner funnel of the draining apparatus that has been fitted

mining water retention capacity of ion exchange resins may be

with a medium porosity filter paper. Drain the water to the top

expressed as follows:

of the sample using suction if required. Cover the funnel with

a suitable vacuum-tight cover, which is fitted with an inlet for

S 50.017x

T

air from the water-filled humidifying tower. Apply sufficient

S 50.004x

o

suction to maintain a pressure differential of 40 65mmHg

below atmospheric pressure. Continue passing humidified air where:

through the sample for 10 min. S = overall precision,

T

10.13 Transfertheentiredrainedsampletoaclean,dry,1-L S = single-operator precision, and

o

x = water retention capacity determined in percent.

(1-qt.), wide-mouthed bottle with a screw top or other vapor-

17.1.1 Information given for the precision statement is

tight closure.

derived from round robin testing in which eight laboratories,

i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.