ASTM D3796-90(1998)

(Practice)Standard Practice for Calibration of Type S Pitot Tubes

Standard Practice for Calibration of Type S Pitot Tubes

SCOPE

1.1 This practice covers the determination of Type S pitot tube coefficients in the gas velocity range from 305 to 1524 m/min or 5.08 to 25.4 m/s (1000 to 5000 ft/min). The method applies both to the calibration of isolated Type S pitot tubes (see 5.1), and pitobe assemblies (see 5.2).

1.2 This practice outlines procedures for obtaining Type S pitot tube coefficients by calibration at a single-velocity setting near the midpoint of the normal working range (see 5.3). Type S pitot coefficients obtained by this method will generally be valid to within +3% over the normal working range. If a more precise correlation between Type S pitot tube coefficient and velocity is desired, multivelocity calibration technique (Annex A1) should be used.

1.3 This practice may be used for the calibration of thermal anemometers for gas velocities in excess of 3 m/s (10 ft/s).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 3796 – 90 (Reapproved 1998)

Standard Practice for

Calibration of Type S Pitot Tubes

This standard is issued under the fixed designation D 3796; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.3 pitobe assembly—any Type S pitot tube that is cali-

brated or used while attached to a conventional isokinetic

1.1 This practice covers the determination of Type S pitot

source-sampling probe (designed according to Martin (1) or

tube coefficients in the gas velocity range from 305 to 1524

allowable modifications thereof; see also Fig. 7).

m/min or 5.08 to 25.4 m/s (1000 to 5000 ft/min). The method

applies both to the calibration of isolated Type S pitot tubes

4. Summary of Practice

(see 5.1), and pitobe assemblies (see 5.2).

4.1 The coefficients of a given Type S pitot tube are

1.2 This practice outlines procedures for obtaining Type S

determined from alternate differential pressure measurements,

pitot tube coefficients by calibration at a single-velocity setting

made first with a standard pitot tube, and then with the Type S

near the midpoint of the normal working range (see 5.3). Type

pitot tube, at a predetermined point in a confined, flowing gas

S pitot coefficients obtained by this method will generally be

stream. The Type S pitot coefficient is equal to the product of

valid to within 63 % over the normal working range. If a more

the standard pitot tube coefficient, C (std), and the square root

p

precise correlation between Type S pitot tube coefficient and

of the ratio of the differential pressures indicated by the

velocity is desired, multivelocity calibration technique (Annex

standard and Type S pitot tubes.

A1) should be used.

1.3 This practice may be used for the calibration of thermal

5. Significance and Use

anemometers for gas velocities in excess of 3 m/s (10 ft/s).

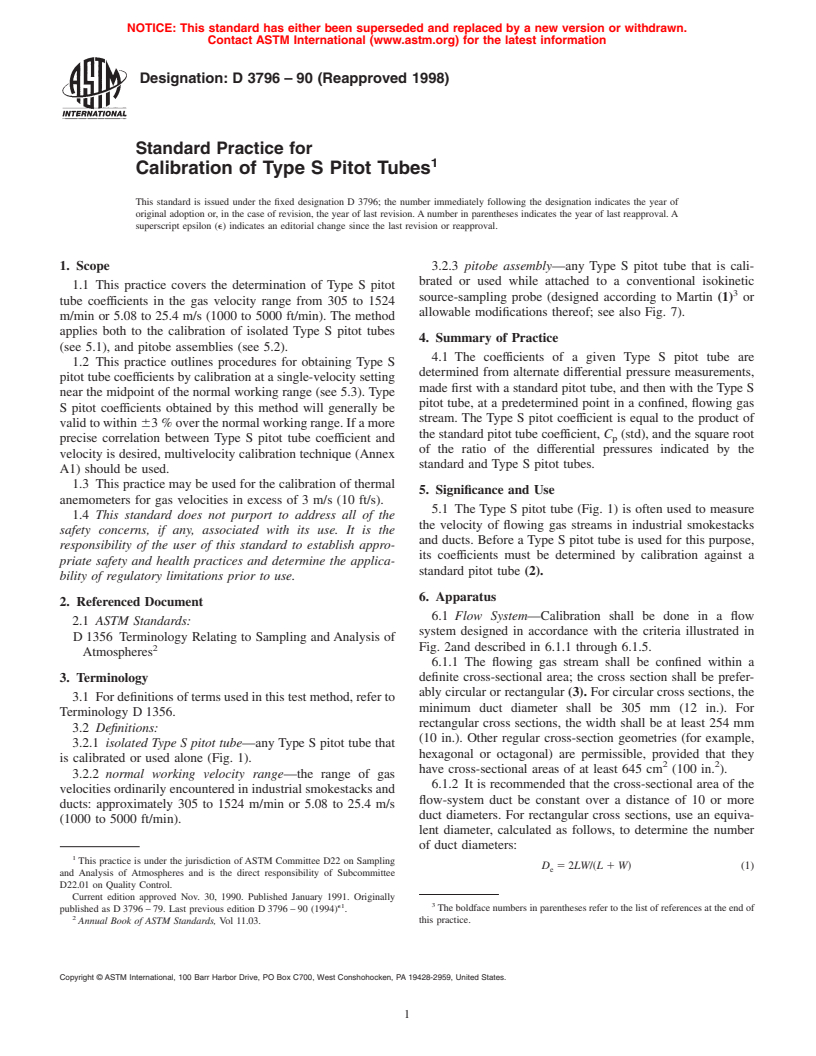

5.1 The Type S pitot tube (Fig. 1) is often used to measure

1.4 This standard does not purport to address all of the

the velocity of flowing gas streams in industrial smokestacks

safety concerns, if any, associated with its use. It is the

and ducts. Before a Type S pitot tube is used for this purpose,

responsibility of the user of this standard to establish appro-

its coefficients must be determined by calibration against a

priate safety and health practices and determine the applica-

standard pitot tube (2).

bility of regulatory limitations prior to use.

6. Apparatus

2. Referenced Document

6.1 Flow System—Calibration shall be done in a flow

2.1 ASTM Standards:

system designed in accordance with the criteria illustrated in

D 1356 Terminology Relating to Sampling and Analysis of

Fig. 2and described in 6.1.1 through 6.1.5.

Atmospheres

6.1.1 The flowing gas stream shall be confined within a

definite cross-sectional area; the cross section shall be prefer-

3. Terminology

ably circular or rectangular (3). For circular cross sections, the

3.1 For definitions of terms used in this test method, refer to

minimum duct diameter shall be 305 mm (12 in.). For

Terminology D 1356.

rectangular cross sections, the width shall be at least 254 mm

3.2 Definitions:

(10 in.). Other regular cross-section geometries (for example,

3.2.1 isolated Type S pitot tube—any Type S pitot tube that

hexagonal or octagonal) are permissible, provided that they

is calibrated or used alone (Fig. 1).

2 2

have cross-sectional areas of at least 645 cm (100 in. ).

3.2.2 normal working velocity range—the range of gas

6.1.2 It is recommended that the cross-sectional area of the

velocities ordinarily encountered in industrial smokestacks and

flow-system duct be constant over a distance of 10 or more

ducts: approximately 305 to 1524 m/min or 5.08 to 25.4 m/s

duct diameters. For rectangular cross sections, use an equiva-

(1000 to 5000 ft/min).

lent diameter, calculated as follows, to determine the number

of duct diameters:

This practice is under the jurisdiction of ASTM Committee D22 on Sampling

D 5 2LW/~L 1 W! (1)

e

and Analysis of Atmospheres and is the direct responsibility of Subcommittee

D22.01 on Quality Control.

Current edition approved Nov. 30, 1990. Published January 1991. Originally

e1 3

published as D 3796 – 79. Last previous edition D 3796 – 90 (1994) . The boldface numbers in parentheses refer to the list of references at the end of

Annual Book of ASTM Standards, Vol 11.03. this practice.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 3796 – 90 (1998)

FIG. 1 Isolated Type-S Pitot Tube

FIG. 2 Pitot Tube Calibration System

6.4 Differential Pressure Gage—An inclined manometer, or

where:

equivalent device, shall be used to measure differential pres-

D = equivalent diameter,

e

sure. The gage shall be capable of measuring DP to within

L = length of cross section, and

W = width of cross section.

60.13 mm water or 1.2 Pa (60.005 in. water).

For regular polygonal ducts, use an equivalent diameter, 6.5 Pitot Lines—Flexible lines, made of poly(vinyl chlo-

equal to the diameter of the inscribed circle, to determine the ride) (or similar material) shall be used to connect the standard

number of duct diameters. and Type S pitot tubes to the differential-pressure gage.

6.1.3 To ensure the presence of stable, well-developed flow

7. Procedure

patterns at the calibration site (test section), it is recommended

that the site be located at least 8 duct diameters (or equivalent 7.1 Assign a permanent identification number to the Type S

diameters) downstream and 2 diameters upstream from the pitot tube. Mark or engrave this number on the body of the

nearest flow disturbances. If the 8 and 2-diameter criteria tube. Mark one leg of the tube “A,” and the other, “B.”

cannot be met, the existence of stable, developed flow at the 7.2 Prepare the differential-pressure gage for use. If an

test site must be adequately demonstrated. inclined manometer is to be used, be sure that it is properly

6.1.4 The flow-system fan shall have the capacity to gener- filled, and that the manometer fluid is free of contamination.

ate a test-section velocity of about 909 m/min or 15.2 m/s 7.3 Level and zero the manometer (if used). Inspect all pitot

(3000 ft/min); this velocity should be constant with time. The lines and check for leaks; repair or replace lines if necessary.

fancanbelocatedeitherupstream(Fig.2)ordownstreamfrom 7.4 Turn on the flow system fan and allow the flow to

the test-section. stabilize; the test section velocity should be about 909 m/min

6.1.5 Two entry ports, one each for the Type S and standard or 15.2 m/s (3000 ft/min). Seal the Type S entry port.

pitot tubes, shall be cut in the test section. The standard pitot 7.5 Determine an appropriate calibration point. Use the

tube entry port shall be located slightly downstream of the following guidelines:

Type S port, so that the standard and Type S impact openings 7.5.1 For isolated Type S pitot tubes (or pitot tube-

will lie in the same plane during calibration. To facilitate thermocouple combinations), select a calibration point at or

alignment of the pitot tubes during calibration, it is advisable near the center of the duct.

that the test section be constructed of acrylic or similar 7.5.2 For pitobe assemblies, choose a point for which probe

transparent material. blockage effects are minimal; the point should be as close to

6.2 Standard Pitot Tube, used to calibrate the Type S pitot thecenteroftheductaspossible.Todeterminewhetheragiven

tube. The standard pitot tube shall have a known coefficient, point will be acceptable for use as a calibration point, make a

obtained preferably directly from the National Institute of projected-area model of the pitobe assembly (Fig. 5), with the

Standards and Technology in Gaithersburg, MD.Alternatively, impact openings of the Type S pitot tube centered at the point.

a modified ellipsoidal-nosed pitot static tube, designed as For assemblies without external sheaths (Fig. 5(a)), the point

showninFig.3maybeused(4).Notethatthecoefficientofthe will be acceptable if the theoretical probe blockage, calculated

ellipsoidal-nosed tube is a function of the stem/static hole as shown in Fig. 5, is less than or equal to 2 %. For assemblies

distance; therefore, Fig. 4 should be used as a guide for with external sheaths (Fig. 5(b)), the point will be acceptable if

determining the precise coefficient value. the theoretical probe blockage is 3 % or less (5).

6.3 Type S Pitot Tube, (isolated pitot or pitobe assembly) 7.6 Connect the standard pitot tube to the differential-

either a commercially available model or constructed accord- pressure gage. Position the standard tube at the calibration

ing to Martin (1) or allowable modifications thereof. point; the tip of the tube should be pointed directly into the

D 3796 – 90 (1998)

FIG. 3 Ellipsoidal Nosed Pitot-Static Tube

flow. Particular care should be taken in aligning the tube, to ordinarilyusedforisokineticsamplingatvelocitiesaround909

avoid yaw and pitch angle errors. Once the standard pitot tube m/min or 15.2 m/s (3000 ft/min).

is in position, seal the entry port surrounding the tube.

7.7 Take a differential-pressure reading with the standard

8. Calculation

pitot tube; record this value in a data table similar to the one

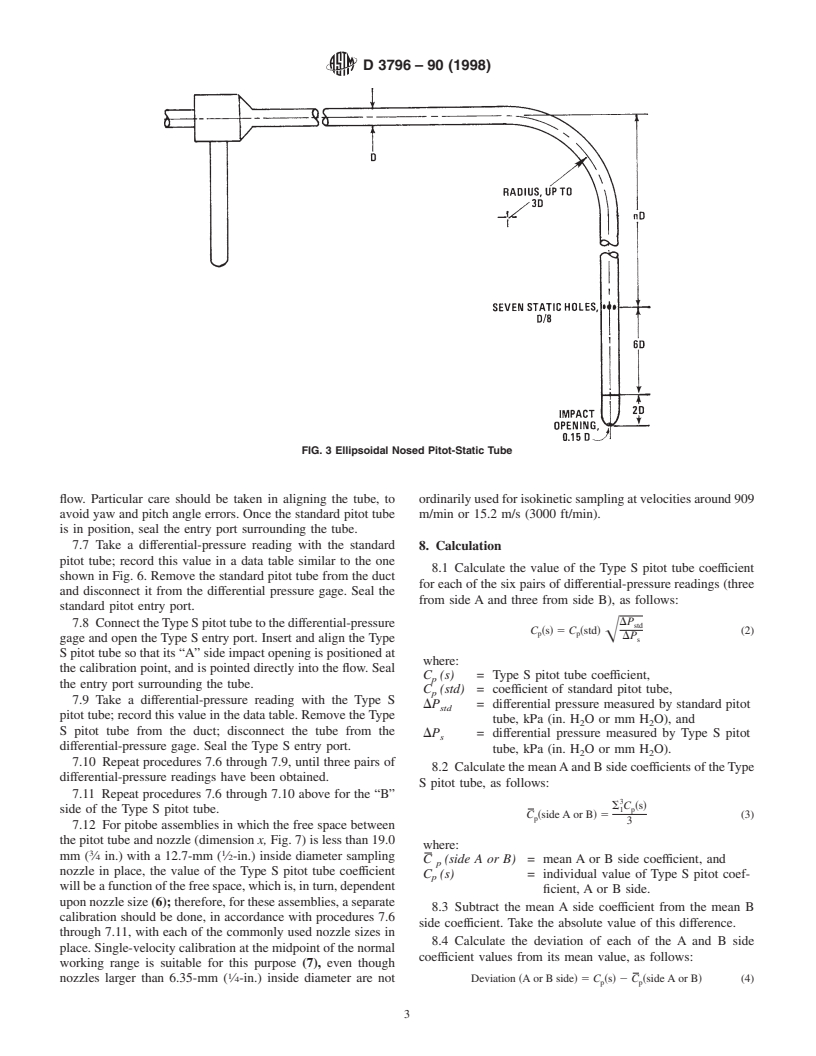

8.1 Calculate the value of the Type S pitot tube coefficient

shown in Fig. 6. Remove the standard pitot tube from the duct

for each of the six pairs of differential-pressure readings (three

and disconnect it from the differential pressure gage. Seal the

from side A and three from side B), as follows:

standard pitot entry port.

DP

7.8 ConnecttheTypeSpitottubetothedifferential-pressure

std

C ~s!5 C ~std! (2)

Œ

p p

DP

gage and open the Type S entry port. Insert and align the Type s

S pitot tube so that its “A” side impact opening is positioned at

where:

the calibration point, and is pointed directly into the flow. Seal

C (s) = Type S pitot tube coefficient,

p

the entry port surrounding the tube.

C (std) = coefficient of standard pitot tube,

p

7.9 Take a differential-pressure reading with the Type S

DP = differential pressure measured by standard pitot

std

pitot tube; record this value in the data table. Remove the Type

tube, kPa (in. HOormmH O), and

2 2

S pitot tube from the duct; disconnect the tube from the

DP = differential pressure measured by Type S pitot

s

differential-pressure gage. Seal the Type S entry port.

tube, kPa (in. HOormmH O).

2 2

7.10 Repeat procedures 7.6 through 7.9, until three pairs of

8.2 Calculate the meanAand B side coefficients of theType

differential-pressure readings have been obtained.

S pitot tube, as follows:

7.11 Repeat procedures 7.6 through 7.10 above for the “B”

S C ~s!

1 p

side of the Type S pitot tube.

C ~sideAorB!5 (3)

p

7.12 For pitobe assemblies in which the free space between

the pitot tube and nozzle (dimension x, Fig. 7) is less than 19.0

where:

3 1

mm ( ⁄4 in.) with a 12.7-mm ( ⁄2-in.) inside diameter sampling

C (side A or B) = mean A or B side coefficient, and

p

nozzle in place, the value of the Type S pitot tube coefficient

C (s) = individual value of Type S pitot coef-

p

willbeafunctionofthefreespace,whichis,inturn,dependent

ficient, A or B side.

upon nozzle size(6); therefore, for these assemblies, a separate

8.3 Subtract the mean A side coefficient from the mean B

calibration should be done, in accordance with procedures 7.6

side coefficient. Take the absolute value of this difference.

through 7.11, with each of the commonly used nozzle sizes in

8.4 Calculate the deviation of each of the A and B side

place. Single-velocity calibration at the midpoint of the normal

coefficient values from its mean value, as follows:

working range is suitable for this purpose (7), even though

nozzles larger than 6.35-mm ( ⁄4-in.) inside diameter are not Deviation ~A or B side!5 C ~s!2 C ~sideAorB! (4)

p p

D 3796 – 90 (1998)

FIG. 4 Effect of Stem/Static Hole Distance on Basic Coefficient, C (std), of Standard Pitot-Static Tubes with Ellipsoidal Nose

p

FIG. 5 Projected-Area Models for Typical Pitobe Assemblies

8.5 Calculate the average deviation from the mean, for both the mean, A or B side.

the A and B sides of the pitot tube, as follows:

3 9. Precision and Bias

S @C ~s!2 C ~sideAorB!#

1 p p

s~sideAorB!5 (5)

9.1 Precision—The results of the calibration should not be

considered suspect unless the following criteria fail to be met:

where s(sideAor B) = average deviation of C (s) values from

p

D 3796 – 90 (1998)

NOTE—1 in. H O = 0.249 kPa; 1 mm H O = 0.0098 kPa.

2 2

FIG. 6 Calibration Data Table, Single-Velocity Calibration

3 1

NOTE—This figure shows pitot tube-nozzle separation distance (x); the Type S pitot tube coefficient is a function of x, if x < ⁄4 in. where D = ⁄2 in.

n

FIG. 7 Typical Pitobe Assembly

mm in.

13 ⁄2

19 ⁄4

76 3

9.1.1 The absolute value of the difference between the mean 9.1.2 The A and B side values of average deviation are less

Aand B side coefficients (see 8.3) is less than or equal to 0.01. than or equal to 0.01.

D 3796 – 90 (1998)

9.1.3 If criterion 9.1.1, or 9.1.2, or both, are not met, the 9.2.2 AType S pitot tube shall be calibrated before its initial

Type S pitot tube may not be suitable for use. In such cases, use. Thereafter, if the tube has been significantly damaged by

repeat the calibration procedure two more times; do not use the

field use (for example, if the impact openings are noticeably

Type S pitot tube unless both of these runs give satisfactory

bent out of shape, nicked, or misaligned), it should be repaired

results.

and recalibrated. The data collected should be evaluated in the

9.2 Bias—In general, the mean A and B side coefficient

light of this recalibration.

values obtained by this method will be accurate to within

9.2.3 The coefficient of a calibrated isolated Type S pitot

63 % over the normal working range (7).

tube may change if the isolated tube is attached to a source

9.2.1 When a calibrated pitobe assembly is used to measure

samplingprobeandusedasapitobeassembly.Theisolatedand

velocity in ducts having diameters (or equivalent diameters)

assembly coefficient values can only be considered equal when

between 305 and 915 mm (12 and 36 in.), the calibration

the intercomponent spacing requirements illustrated in Figs.

coefficients may need to be adjusted slightly to compensate for

8-10 and are met.

probe blockag

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.