ASTM E1867-06

(Test Method)Standard Test Method for Temperature Calibration of Dynamic Mechanical Analyzers

Standard Test Method for Temperature Calibration of Dynamic Mechanical Analyzers

SIGNIFICANCE AND USE

Dynamic mechanical analyzers monitor changes in the viscoelastic properties of a material as a function of temperature and frequency, providing a means to quantify these changes. In most cases, the value to be assigned is the temperature of the transition (or event) under study. Therefore, the temperature axis (abscissa) of all DMA thermal curves must be accurately calibrated by adjusting the apparent temperature scale to match the actual temperature over the temperature range of interest.

SCOPE

1.1 This test method describes the temperature calibration of dynamic mechanical analyzers (DMA) from -150 to 500°C.

1.2 SI units are the standard

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Note 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1867–06

Standard Test Method for

1

Temperature Calibration of Dynamic Mechanical Analyzers

This standard is issued under the fixed designation E1867; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

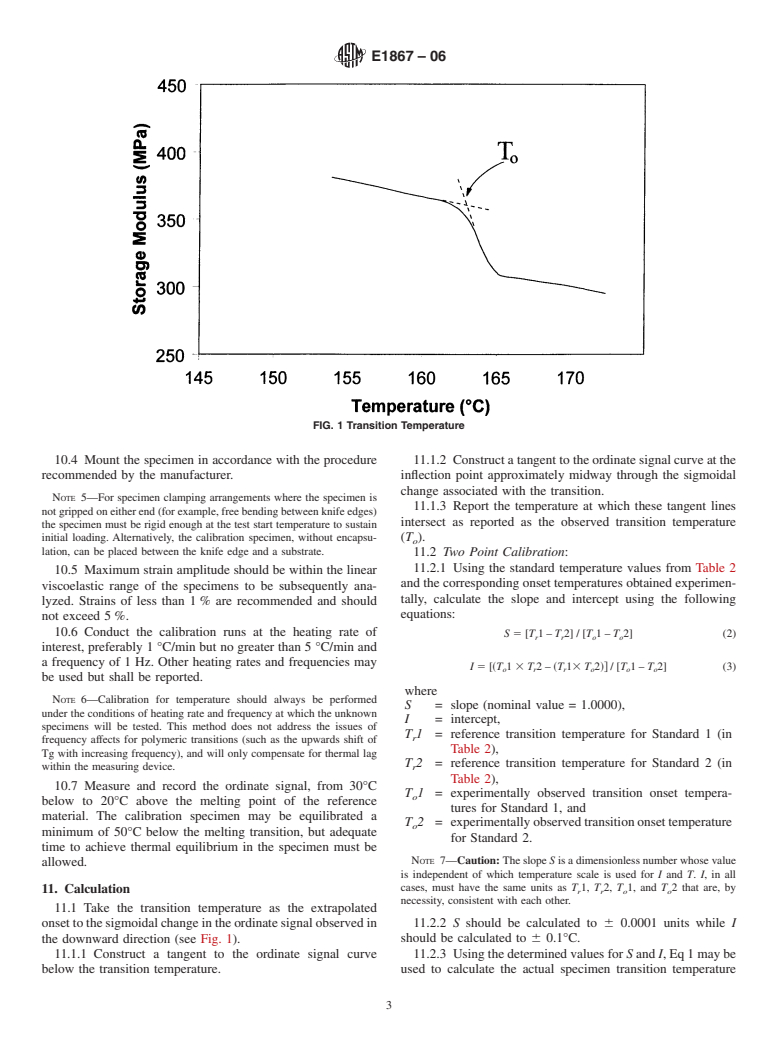

1. Scope melting is identified by a rapid decrease in the ordinate signal

(the apparent storage modulus, stress, inverse strain or probe

1.1 This test method describes the temperature calibration

position). This onset is used for temperature calibration with

of dynamic mechanical analyzers (DMA) from –150 to 500°C.

two melting point reference materials.

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

5. Significance and Use

standard.

5.1 Dynamic mechanical analyzers monitor changes in the

1.3 This standard does not purport to address all of the

viscoelastic properties of a material as a function of tempera-

safety concerns, if any, associated with its use. It is the

ture and frequency, providing a means to quantify these

responsibility of the user of this standard to establish appro-

changes. In most cases, the value to be assigned is the

priate safety and health practices and determine the applica-

temperature of the transition (or event) under study. Therefore,

bility of regulatory limitations prior to use. Specific precau-

the temperature axis (abscissa) of all DMA thermal curves

tionary statements are given in Note 7.

must be accurately calibrated by adjusting the apparent tem-

2. Referenced Documents perature scale to match the actual temperature over the

2

temperature range of interest.

2.1 ASTM Standards:

E473 Terminology Relating to Thermal Analysis and Rhe-

6. Interferences

ology

6.1 An increase or decrease in heating rates or change in

E1142 Terminology Relating to Thermophysical Properties

purge gas type or rate from those specified may alter results.

3. Terminology 6.2 Once the temperature calibration procedure has been

executed, the measuring temperature sensor position shall not

3.1 Definitions:

be changed, nor shall it be in contact with the specimen or

3.1.1 The technical terms used in this test method are

specimen holder in a way that would impede movement. If the

defined in Terminology E473 and Terminology E1142.

temperature sensor position is changed or is replaced, then the

4. Summary of Test Method entire calibration procedure shall be repeated.

6.3 Once the temperature calibration has been executed, the

4.1 An equation is developed for the linear correlation of

geometry deformation (bending study, versus tensile, and the

experimentally observed program or sensor temperature and

like) shall not be changed. If the specimen testing geometry

the actual melting temperature for known melting reference

differs significantly from that of the calibrants, then the

materials. This is accomplished by loading melting point

calibration shall be repeated in the geometry matching that of

referencematerialsintoapolymertube,orwrappingthemwith

specimen testing.

polymer tape and subjecting it to a mechanical oscillation at

6.4 This method does not apply to calibration for shear or

either fixed or resonant frequency. The extrapolated onset of

compressive geometries of deformation.

1

This test method is under the jurisdiction ofASTM Committee E37 onThermal 7. Apparatus

Measurements and is the direct responsibility of Subcommittee E37.10 on Funda-

7.1 The function of the apparatus is to hold a specimen of

mental, Statistical and Mechanical Properties.

uniform dimension so that the specimen acts as the elastic and

Current edition approved Sept. 1, 2006. Published November 2006. Originally

approved in 1997. Last previous edition approved in 2001 as E1867 – 01. DOI:

dissipative element in a mechanically oscillated system. Dy-

10.1520/E1867-06.

namic mechanic analyzers typically operate in one of several

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

modes as outlined in Table 1.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on 7.1.1 The apparatus shall consist of the following:

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1867–06

TABLE 1 Dynamic Mechanical Analyzer Modes of Operation TABLE 2 Calibration Materials

A

Mechanical Response Transition Temperature

Mode Material Reference

Tension Flexural Torsion Compression °C K

A

Free/dec . . X . Cyclopentan

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.