ASTM E3301-22

(Test Method)Standard Test Method for Temperature Calibration of Dynamic Mechanical Analyzers Using Thermal Lag

Standard Test Method for Temperature Calibration of Dynamic Mechanical Analyzers Using Thermal Lag

SIGNIFICANCE AND USE

5.1 Dynamic mechanical analysis monitors changes in the viscoelastic properties (that is, storage modulus, loss modulus, tangent angle delta) of a material as a function of temperature and frequency, providing a means to quantify these changes. In many cases, the value to be assigned is the temperature of the transition or event under study. Therefore, the temperature axis (abscissa) of the dynamic mechanical analysis thermal curve must be accurately calibrated by adjusting the measured temperature scale to match the assumed specimen temperature over the temperature range of interest.

SCOPE

1.1 This test method describes the temperature calibration of a dynamic mechanical analyzer using thermal lag over the temperature range of –100 °C to 300 °C.

1.2 This standard may be compared to Test Methods E1867.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E3301 − 22

Standard Test Method for

Temperature Calibration of Dynamic Mechanical Analyzers

1

Using Thermal Lag

This standard is issued under the fixed designation E3301; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope namic Mechanical Analyzers

E1970 PracticeforStatisticalTreatmentofThermoanalytical

1.1 This test method describes the temperature calibration

Data

of a dynamic mechanical analyzer using thermal lag over the

E2161 Terminology Relating to Performance Validation in

temperature range of –100 °C to 300 °C.

Thermal Analysis and Rheology

1.2 This standard may be compared toTest Methods E1867.

E2877 Guide for Digital Contact Thermometers

1.3 The values stated in SI units are to be regarded as E3142 Test Method for Thermal Lag of Thermal Analysis

Apparatus

standard. No other units of measurement are included in this

standard.

3. Terminology

1.4 This standard does not purport to address all of the

3.1 Definitions:

safety concerns, if any, associated with its use. It is the

3.1.1 The technical terms used in this test method are

responsibility of the user of this standard to establish appro-

defined in Terminologies D4092, E473, E1142, and E2161

priate safety, health, and environmental practices and deter-

including calibration, Celsius, damping, dissipative, elastic,

mine the applicability of regulatory limitations prior to use.

frequency, loss modulus, peak, storage modulus, strain, stress

1.5 This international standard was developed in accor-

tan δ, tan delta, tangent delta.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3.2 Definitions of Terms Specific to This Standard:

Development of International Standards, Guides and Recom- 3.2.1 dew point, n—the temperature below which conden-

mendations issued by the World Trade Organization Technical sation of water vapor begins when the atmosphere is cooled.

Barriers to Trade (TBT) Committee.

3.2.2 relaxation, n—in a glass or viscous liquid, the change

in any material property (such as density, enthalpy, etc.) with

2. Referenced Documents

timefollowingaperturbation(suchasachangeintemperature,

2

2.1 ASTM Standards: stress. etc.).

D4092 Terminology for Plastics: Dynamic Mechanical

4. Summary of Test Method

Properties

E473 Terminology Relating to Thermal Analysis and Rhe- 4.1 In dynamic mechanical analysis, large (for example, 1 g

ology to 10 g), low thermal conductivity test specimens are charac-

E1142 Terminology Relating to Thermophysical Properties terized. These specimens are mechanically supported using

E1356 Test Method for Assignment of the Glass Transition high thermal conductivity materials of construction. A free-

Temperatures by Differential Scanning Calorimetry floatingtemperaturesensorisplacedascloseaspracticaltothe

E1640 Test Method for Assignment of the Glass Transition specimen. Under conditions of temperature change, where the

Temperature By Dynamic Mechanical Analysis

system atmosphere surrounding the specimen is heated or

E1867 Test Methods for Temperature Calibration of Dy- cooled at rates up to 5 °C/min, the temperature of the specimen

will lead or lag that of the temperature sensor. It is the purpose

of this standard to calibrate the dynamic mechanical analyzer

1

temperature signal so that the measured temperature more

ThistestmethodisunderthejurisdictionofASTMCommitteeE37onThermal

Measurements and is the direct responsibility of Subcommittee E37.10 on

closely approximates that of the assumed test specimen.

Fundamental, Statistical and Mechanical Properties.

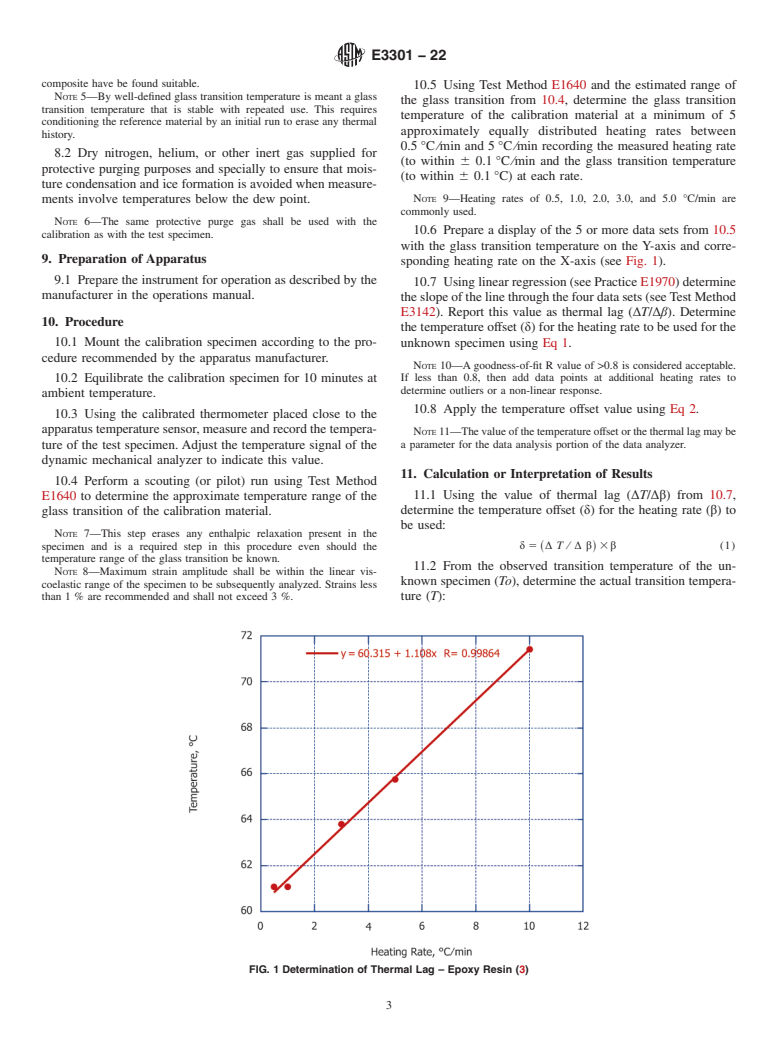

4.2 The thermal lag between the temperature sensor and the

Current edition approved Jan. 1, 2022. Published January 2022. DOI: 10.1520/

E3301-22.

testspecimenisdeterminedasafunctionoftemperaturerateof

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

change. This value is then used to adjust the indicated

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

temperature following calibration under isothermal ambient

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. temperature conditions.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E3301 − 22

5. Significance and Use 7. Apparatus

7.1 Dynamic Mechanical Analyzer—The

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.