ASTM C553-13(2019)

(Specification)Standard Specification for Mineral Fiber Blanket Thermal Insulation for Commercial and Industrial Applications

Standard Specification for Mineral Fiber Blanket Thermal Insulation for Commercial and Industrial Applications

ABSTRACT

This specification covers the classification, composition, physical properties, and dimensions of mineral fiber (rock, slag, or glass) blanket intended for use as thermal insulation on surfaces at certain temperatures. The orientation of the fibers within the blanket is primarily parallel to the principal surface (face). The mineral fiber blanket insulation shall be classified into seven types: Types I, II, III, IV, V, VI, and VII. The classification is based upon the insulations' maximum use temperature and apparent thermal conductivity. Mineral fiber blanket insulation shall be composed of rock, slag, or glass processed from the molten state into fibrous form bonded with an organic or inorganic binder, or both. Asbestos shall not be used as an ingredient or component part of the product. Different test methods shall be performed on the insulation to determine the following properties: odor emission, corrosiveness to steel, non-fibrous content, maximum use temperature, maximum exothermic temperature rise, apparent thermal conductivity, water vapor sorption, flexibility, rigidity, and surface burning characteristics.

SCOPE

1.1 This specification covers the classification, composition, physical properties, and dimensions of mineral fiber (rock, slag, or glass) blanket intended for use as thermal insulation on surfaces operating at temperatures between 0°F (–18°C) and 1200°F (649°C). For specific applications, the actual temperature limits shall be agreed upon between the supplier and the purchaser.

1.2 The orientation of the fibers within the blanket is primarily parallel to the principal surface (face). This specification does not cover fabricated pipe and tank wrap insulation where the insulation has been cut and fabricated to provide a fiber orientation that is perpendicular to the surface (face).

1.3 For satisfactory performance, properly installed protective vapor retarders must be used in below ambient temperature applications to reduce movement of water vapor through or around the insulation towards the colder surface. Failure to use a vapor retarder can lead to insulation and system damage. Refer to Practice C921 to aid material selection. Although vapor retarders are not part of this specification, properties required in Specification C1136 are pertinent to application or performance.

1.4 This standard does not purport to provide the performance requirements of hourly-rated fire systems. Consult the manufacturer for the appropriate system.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:C553 −13 (Reapproved 2019)

Standard Specification for

Mineral Fiber Blanket Thermal Insulation for Commercial

and Industrial Applications

This standard is issued under the fixed designation C553; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1.1 Thisspecificationcoverstheclassification,composition,

1.7 This international standard was developed in accor-

physical properties, and dimensions of mineral fiber (rock,

dance with internationally recognized principles on standard-

slag, or glass) blanket intended for use as thermal insulation on

ization established in the Decision on Principles for the

surfaces operating at temperatures between 0°F (–18°C) and

Development of International Standards, Guides and Recom-

1200°F (649°C). For specific applications, the actual tempera-

mendations issued by the World Trade Organization Technical

ture limits shall be agreed upon between the supplier and the

Barriers to Trade (TBT) Committee.

purchaser.

2. Referenced Documents

1.2 The orientation of the fibers within the blanket is

primarily parallel to the principal surface (face). This specifi-

2.1 ASTM Standards:

cation does not cover fabricated pipe and tank wrap insulation

C167 Test Methods for Thickness and Density of Blanket or

where the insulation has been cut and fabricated to provide a

Batt Thermal Insulations

fiber orientation that is perpendicular to the surface (face).

C168 Terminology Relating to Thermal Insulation

C177 Test Method for Steady-State Heat Flux Measure-

1.3 For satisfactory performance, properly installed protec-

ments and Thermal Transmission Properties by Means of

tivevaporretardersmustbeusedinbelowambienttemperature

the Guarded-Hot-Plate Apparatus

applications to reduce movement of water vapor through or

C390 Practice for Sampling and Acceptance of Thermal

around the insulation towards the colder surface. Failure to use

Insulation Lots

a vapor retarder can lead to insulation and system damage.

C411 Test Method for Hot-Surface Performance of High-

Refer to Practice C921 to aid material selection. Although

Temperature Thermal Insulation

vapor retarders are not part of this specification, properties

C447 Practice for Estimating the Maximum Use Tempera-

required in Specification C1136 are pertinent to application or

ture of Thermal Insulations

performance.

C518 Test Method for Steady-State Thermal Transmission

1.4 This standard does not purport to provide the perfor-

Properties by Means of the Heat Flow Meter Apparatus

mance requirements of hourly-rated fire systems. Consult the

C665 Specification for Mineral-Fiber Blanket Thermal Insu-

manufacturer for the appropriate system.

lation for Light Frame Construction and Manufactured

1.5 The values stated in inch-pound units are to be regarded Housing

as standard. The values given in parentheses are mathematical C680 Practice for Estimate of the Heat Gain or Loss and the

conversions to SI units that are provided for information only Surface Temperatures of Insulated Flat, Cylindrical, and

and are not considered standard. Spherical Systems by Use of Computer Programs

C795 Specification for Thermal Insulation for Use in Con-

1.6 This standard does not purport to address all of the

tact with Austenitic Stainless Steel

safety concerns, if any, associated with its use. It is the

C921 Practice for Determining the Properties of Jacketing

responsibility of the user of this standard to establish appro-

Materials for Thermal Insulation

C1045 Practice for Calculating Thermal Transmission Prop-

erties Under Steady-State Conditions

This specification is under the jurisdiction of ASTM Committee C16 on

Thermal Insulation and is the direct responsibility of Subcommittee C16.23 on

Blanket and Loose Fill Insulation. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2019. Published October 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1964. Last previous edition approved 2013 as C553 – 13. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C0553-13R19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C553−13 (2019)

A

TABLE 1 Physical Property Requirements

Properties Type I Type II Type III Type IV Type V Type VI Type VII

Maximum Use Temperature °F (°C) Up to 450 Up to 450 Up to 450 Up to 850 Up to 1000 Up to 1000 Up to 1200

See Paragraph 6.2.1 - Note 1 (232) (232) (232) (454) (538) (538) (649)

Apparent Thermal Conductivity

Max. Btu·in./h·ft ·°F (W/m·K)

Mean Temperatures

°F (°C)

25 (-4) 0.35 (0.051) 0.30 (0.043) 0.25 (0.036) 0.24 (0.035) 0.30 (0.043) 0.25 (0.036) 0.24 (0.035)

75 (24) 0.36 (0.052) 0.31 (0.045) 0.26 (0.038) 0.25 (0.036) 0.31 (0.045) 0.26 (0.038) 0.25 (0.036)

100 (38) 0.39 (0.056) 0.33 (0.048) 0.28 (0.040) 0.27 (0.039) 0.33 (0.048) 0.28 (0.040) 0.27 (0.039)

200 (93) 0.55 (0.079) 0.44 (0.063) 0.36 (0.052) 0.34 (0.049) 0.44 (0.063) 0.36 (0.052) 0.34 (0.049)

300 (149) 0.76 (0.110) 0.60 (0.087) 0.46 (0.066) 0.43 (0.062) 0.60 (0.087) 0.46 (0.066) 0.43 (0.062)

400 (204) 0.55 (0.079) 0.89 (0.128) 0.60 (0.087) 0.55 (0.079)

500 (260) 0.70 (0.101) 1.10 (0.159) 0.80 (0.115) 0.70 (0.101)

600 (316) 1.50 (0.216) 1.05 (0.151) 0.89 (0.128)

700 (371) 1.13 (0.163)

B

Water Vapor Sorption 5.0 5.0 5.0 5.0 5.0 5.0 5.0

% by Weight, max

Surface Burning Characteristics

Flame Spread Index, max 25 25 25 25 25 25 25

Smoke Developed Index, max 50 50 50 50 50 50 50

A

Additional physical property requirements, refer to Section 7.

B

It is possible that water sorption characteristics will change after the product is subject to elevated temperatures within normal service conditions.

C1058 Practice for Selecting Temperatures for Evaluating 3.2.2 shot—shot is defined, for the purposes of this

and Reporting Thermal Properties of Thermal Insulation document, as that material which cannot be brushed or me-

C1101/C1101M Test Methods for Classifying the Flexibility chanically shaken through No. 100 (150µm) sieve.

or Rigidity of Mineral Fiber Blanket and Board Insulation

C1104/C1104M Test Method for Determining the Water 4. Classification

Vapor Sorption of Unfaced Mineral Fiber Insulation

4.1 Mineral fiber blanket insulation covered by this speci-

C1114 Test Method for Steady-State Thermal Transmission

fication shall be classified into seven types shown in Table 1.

Properties by Means of the Thin-Heater Apparatus

The classification is based upon the maximum use temperature

C1136 Specification for Flexible, Low Permeance Vapor

and apparent thermal conductivity of the insulations.

Retarders for Thermal Insulation

C1304 Test Method for Assessing the Odor Emission of

5. Ordering Information

Thermal Insulation Materials

5.1 The type, dimensions, maximum use temperature, and

C1335 Test Method for Measuring Non-Fibrous Content of

facing shall be specified by the purchaser. A product certifica-

Man-Made Rock and Slag Mineral Fiber Insulation

tion (if required) shall be specified in the purchase order.

C1338 Test Method for Determining Fungi Resistance of

Insulation Materials and Facings

6. Materials and Manufacture

C1617 Practice for Quantitative Accelerated Laboratory

Evaluation of Extraction Solutions Containing Ions

6.1 Composition—Mineral fiber blanket insulation shall be

Leached from Thermal Insulation on Aqueous Corrosion

composed of rock, slag, or glass processed from the molten

of Metals

state into fibrous form bonded with an organic or inorganic

E84 Test Method for Surface Burning Characteristics of

binder, or both. Asbestos shall not be used as an ingredient or

Building Materials

component part of the product.

2.2 Other Referenced Documents:

6.2 Facings:

CAN/ULC-S102 Standard Method ofTest for Surface Burn-

3 6.2.1 The purchaser shall specify whether the insulation

ing Characteristics of Building Materials andAssemblies

shall be supplied plain or with facing, and if faced, shall

specify the type and its requirements.

3. Terminology

NOTE1—Theuserofthisspecificationisadvisedthatthemaximumuse

3.1 Definitions—For definitions used in this specification,

temperature of facing and adhesives may be lower than the maximum use

refer to Terminology C168.

temperature of the insulation. The user of this specification shall ensure

that sufficient insulation thickness is installed so that none of these

3.2 Definitions of Terms Specific to This Standard:

accessory items (facings and adhesives) are exposed to temperatures

3.2.1 mean temperature—the sum of the cold surface tem-

above their maximum use temperature. Practice C680 can be used to

perature and the hot surface temperature divided by two.

determine surface temperatures.

6.2.2 The vapor retarder facings shall be in accordance with

3 specification C1136.

Available from Underwriters Laboratories (UL), 2600 N.W. Lake Rd., Camas,

WA 98607-8542, http://www.ul.com. 6.2.3 Typical facing is as follows (others are available):

C553−13 (2019)

A

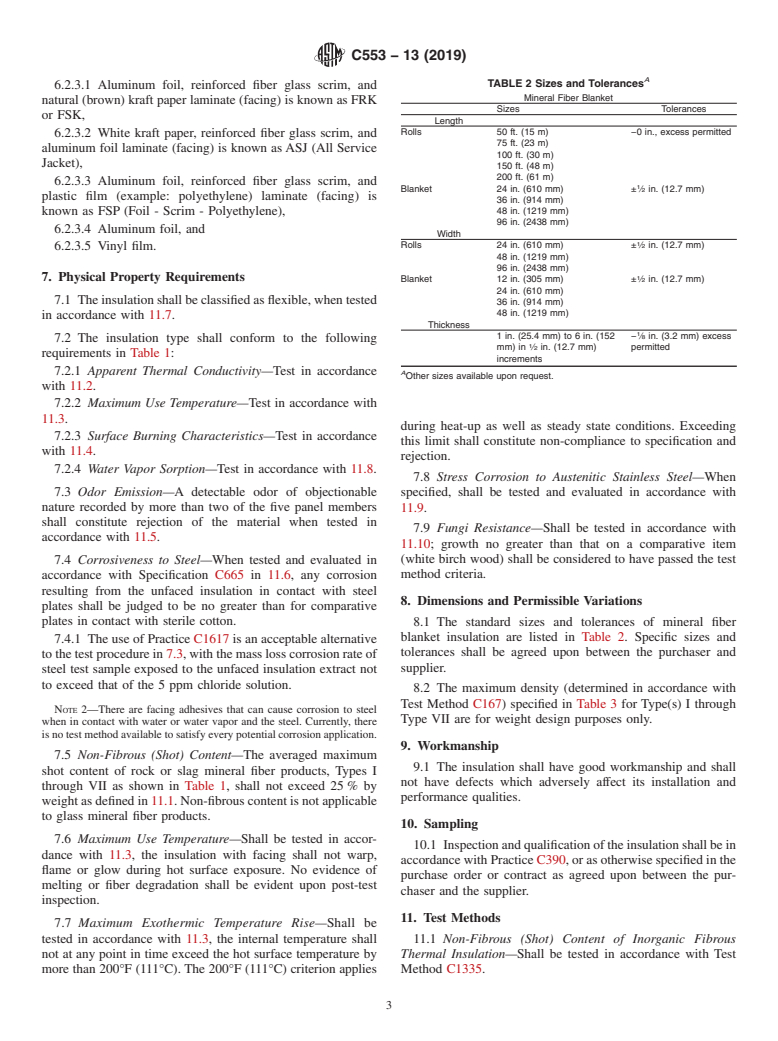

TABLE 2 Sizes and Tolerances

6.2.3.1 Aluminum foil, reinforced fiber glass scrim, and

Mineral Fiber Blanket

natural (brown) kraft paper laminate (facing) is known as FRK

Sizes Tolerances

or FSK,

Length

Rolls 50 ft. (15 m) −0 in., excess permitted

6.2.3.2 White kraft paper, reinforced fiber glass scrim, and

75 ft. (23 m)

aluminum foil laminate (facing) is known as ASJ (All Service

100 ft. (30 m)

Jacket),

150 ft. (48 m)

200 ft. (61 m)

6.2.3.3 Aluminum foil, reinforced fiber glass scrim, and

Blanket 24 in. (610 mm) ± ⁄2 in. (12.7 mm)

plastic film (example: polyethylene) laminate (facing) is

36 in. (914 mm)

48 in. (1219 mm)

known as FSP (Foil - Scrim - Polyethylene),

96 in. (2438 mm)

6.2.3.4 Aluminum foil, and

Width

Rolls 24 in. (610 mm) ± ⁄2 in. (12.7 mm)

6.2.3.5 Vinyl film.

48 in. (1219 mm)

96 in. (2438 mm)

7. Physical Property Requirements

Blanket 12 in. (305 mm) ± ⁄2 in. (12.7 mm)

24 in. (610 mm)

7.1 Theinsulationshallbeclassifiedasflexible,whentested

36 in. (914 mm)

48 in. (1219 mm)

in accordance with 11.7.

Thickness

1 in. (25.4 mm) to 6 in. (152 − ⁄8 in. (3.2 mm) excess

7.2 The insulation type shall conform to the following

mm) in ⁄2 in. (12.7 mm) permitted

requirements in Table 1:

increments

7.2.1 Apparent Thermal Conductivity—Test in accordance A

Other sizes available upon request.

with 11.2.

7.2.2 Maximum Use Temperature—Test in accordance with

11.3.

during heat-up as well as steady state conditions. Exceeding

7.2.3 Surface Burning Characteristics—Test in accordance

this limit shall constitute non-compliance to specification and

with 11.4.

rejection.

7.2.4 Water Vapor Sorption—Test in accordance with 11.8.

7.8 Stress Corrosion to Austenitic Stainless Steel—When

7.3 Odor Emission—A detectable odor of objectionable specified, shall be tested and evaluated in accordance with

nature recorded by more than two of the five panel members

11.9.

shall constitute rejection of the material when tested in

7.9 Fungi Resistance—Shall be tested in accordance with

accordance with 11.5.

11.10; growth no greater than that on a comparative item

(white birch wood) shall be considered to have passed the test

7.4 Corrosiveness to Steel—When tested and evaluated in

method criteria.

accordance with Specification C665 in 11.6, any corrosion

resulting from the unfaced insulation in contact with steel

8. Dimensions and Permissible Variations

plates shall be judged to be no greater than for comparative

plates in contact with sterile cotton. 8.1 The standard sizes and tolerances of mineral fiber

blanket insulation are listed in Table 2. Specific sizes and

7.4.1 The use of Practice C1617 is an acceptable alternative

tolerances shall be agreed upon between the purchaser and

to thetestprocedurein7.3,withthemasslosscorrosion rate of

supplier.

steel test sample exposed to the unfaced insulation extract not

to exceed that of the 5 ppm chloride solution.

8.2 The maximum density (determined in accordance with

Test Method C167) specified in Table 3 for Type(s) I through

NOTE 2—There are facing adhesives that can cause corrosion to steel

Type VII are for weight design purposes only.

when in contact with water or water vapor and the steel. Currently, there

is no test method available to satisfy every potential corrosion application.

9. Workmanship

7.5 Non-Fibrous (Shot) Content—The averaged maximum

9.1 The insulation shall have good workmanship and shall

shot content of rock or slag mineral fiber products, Types I

not have defects which adversely affect its installation and

through VII as shown in Table 1, shall not exceed 25 % by

performance qualities.

weightasdefinedin11.1.Non-fibrouscontentisnotapplicable

to glass mineral fiber products.

10. Sampling

7.6 Maximum Use Temperature—Shall be tested in accor-

10.1 Inspectionandqualificationoftheinsulationshallbein

dance with 11.3, the insulation with facing shall not warp,

accordance with Practice C390, or as otherwise specified in the

flame or glow during hot surface exposure. No evidence of

purchase order or contract as agreed upon between the pur-

melting or fiber degradation shall be evident upon post-test

chaser and the supplier.

inspection.

11. Test Methods

7.7 Maximum Exothermic Temperature Rise—Shall be

tested in accordance with 11.3, the internal temperature shall 11.1 Non-Fibrous (Shot) Content of Inorganic Fibrous

not at any point in time exceed the hot surface temperature by Thermal Insulation—Shall be tested in accordance with Test

more than 200°F (111°C). The 200°F (111°C) criterion applies Method C1335.

C553−13 (2019)

TABLE 3 Maximum Density for Weight Design Purposes Only

Type I Type II Type III Type IV Type V Type VI Type VII

Maximum density, lb/ft

(kg/m ), for weight design 6.0 (96) 6.0 (96) 6.0 (96) 8.0 (128) 10 (160) 10 (160) 12 (192)

purposes only

11.2 Apparent Thermal Conductivity: heat-up shall be specified by the manufacturer to qualify

11.2.1 The thermal conductivity as a function of tempera- product compliance with either maximum use temperature or

ture for the representative specimens shall be determined with maximum exo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.