ASTM E1106-86(2002)e1

(Test Method)Standard Method for Primary Calibration of Acoustic Emission Sensors

Standard Method for Primary Calibration of Acoustic Emission Sensors

SCOPE

1.1 This method covers the requirements for the absolute calibration of acoustic emission (AE) sensors. The calibration yields the frequency response of a transducer to waves, at a surface, of the type normally encountered in acoustic emission work. The transducer voltage response is determined at discrete frequency intervals of approximately 10 kHz up to 1 MHz. The input is a given well-established dynamic displacement normal to the mounting surface. The units of the calibration are output voltage per unit mechanical input (displacement, velocity, or acceleration).

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: E 1106 – 86 (Reapproved 2002)

Standard Method for

Primary Calibration of Acoustic Emission Sensors

This standard is issued under the fixed designation E1106; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorially replaced the term “inspection” with “examination” in 6.2 in June 2002.

1. Scope understood. If this can be established, the stated accuracy

should apply over the full frequency range up to 1 MHz.

1.1 This method covers the requirements for the absolute

calibration of acoustic emission (AE) sensors. The calibration

NOTE 1—The stated accuracy applies only if the transfer standard

yields the frequency response of a transducer to waves, at a

returns to quiescence, following the transient input, before any wave

reflected from the boundary of the calibration block returns to the transfer

surface, of the type normally encountered in acoustic emission

standard (;100 µs). For low frequencies with periods on the order of the

work. The transducer voltage response is determined at dis-

time window, this condition is problematical to prove.

crete frequency intervals of approximately 10 kHz up to 1

MHz. The input is a given well-established dynamic displace- 4.2 Applications Sensors—This method may also be used

for the calibration of AE sensors for use in nondestructive

ment normal to the mounting surface. The units of the

calibration are output voltage per unit mechanical input (dis- evaluation. Some of these sensors are less well behaved than

devicessuitableforatransferstandard.Thestatedaccuracyfor

placement, velocity, or acceleration).

1.2 This standard does not purport to address all of the such devices applies in the range of 100 kHz to 1 MHz and

with less accuracy below 100 kHz.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. General Requirements

priate safety and health practices and determine the applica-

5.1 Aprimary difficulty in any calibration of a mechanical/

bility of regulatory limitations prior to use.

electrical transduction device is the determination of the

2. Referenced Documents

mechanical-motion input to the device. Using this calibration

2.1 ASTM Standards: procedure, the motional input may be determined by two

different means: theoretical calculation and measurement with

E114 Practice for Ultrasonic Pulse-Echo Straight-Beam

Examination by the Contact Method an absolute displacement transducer.

E494 Practice for Measuring Ultrasonic Velocity in Mate- 5.2 Theoretical Calculation—Elasticity theory has been

usedtocalculatethedynamicdisplacementofthesurfaceofan

rials

E650 Guide for Mounting PiezoelectricAcoustic Emission infinite half-space due to a normal point-force step function in

time. The solutions give the displacement of any point on the

Sensors

E1316 Terminology for Nondestructive Examinations surface as a function of time, yielding a waveform for the

displacement called the seismic surface pulse.

3. Terminology

5.2.1 This calibration method uses an approximation to this

3.1 Refer to Terminology E1316 for terminology used in theoretical solution. See also Breckenridge and Hsu and

this method. Breckenridge . The half-space is approximated by a large

metalblockintheformofacircularcylinderandthepointforce

4. Significance and Use

stepfunctioniscloselyapproximatedbythebreakingofaglass

4.1 Transfer Standards—One purpose of this method is for capillary against the plane surface of the block. The displace-

the direct calibration of displacement transducers for use as

mentasafunctionoftimeshouldbecalculatedforthelocation

secondarystandardsforthecalibrationofAEsensorsforusein ofthedeviceundertest(onthesamesurfaceoftheblockasthe

nondestructive evaluation. For this purpose, the transfer stan-

input). This calculation should be performed using a measured

dard should be high fidelity and very well behaved and value of the step function force and the elastic constants that

are determined by speed of sound measurements on the block.

This method is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.04 on Breckenridge, F. R., “Acoustic Emission Transducer Calibration by Means of

Acoustic Emission. the Seismic Surface Pulse,” Journal of Acoustic Emission Vol 1, pp. 87–94.

Current edition approved April 25, 1986. Published June 1986. Hsu, N. N., and Breckenridge, F. R., “Characterization and Calibration of

Annual Book of ASTM Standards, Vol 03.03. Acoustic Emission Sensors,” Materials Evaluation, Vol 39, 1981, pp. 60–68.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

E 1106 – 86 (2002)

5.3 Absolute Displacement Measurement—An absolute polymethyl methacrylate block. In general, the sensitivity will

measurement of the dynamic normal surface displacement of be less if the block is made of a less rigid or less dense

the block is required for this calibration method. The trans- material.

ducer used for this measurement is a standard transducer 5.5.2 TheRayleighspeedinthematerialoftheblockaffects

against which the device under test is compared. The standard surface wave calibrations. For a sensor having a circular

transducer should meet or exceed the performance of the aperture (mounting face) with uniform sensitivity over the

capacitive transducer described by Breckenridge and face, the aperture effect predicts nulls at the zeroes of J (ka),

Greenspan . The important characteristics of the standard wherek=2pf/c, and f =frequency, c =Rayleigh speed, and

transducer include high fidelity, high sensitivity, and operating a =radius of the sensor face. Hence, the frequencies at which

characteristics amenable to theoretical calculation. It should the nulls occur are dependent upon the Rayleigh speed.

also present no appreciable dynamic loading to the surface it is

6. Description of Typical Apparatus

measuring.

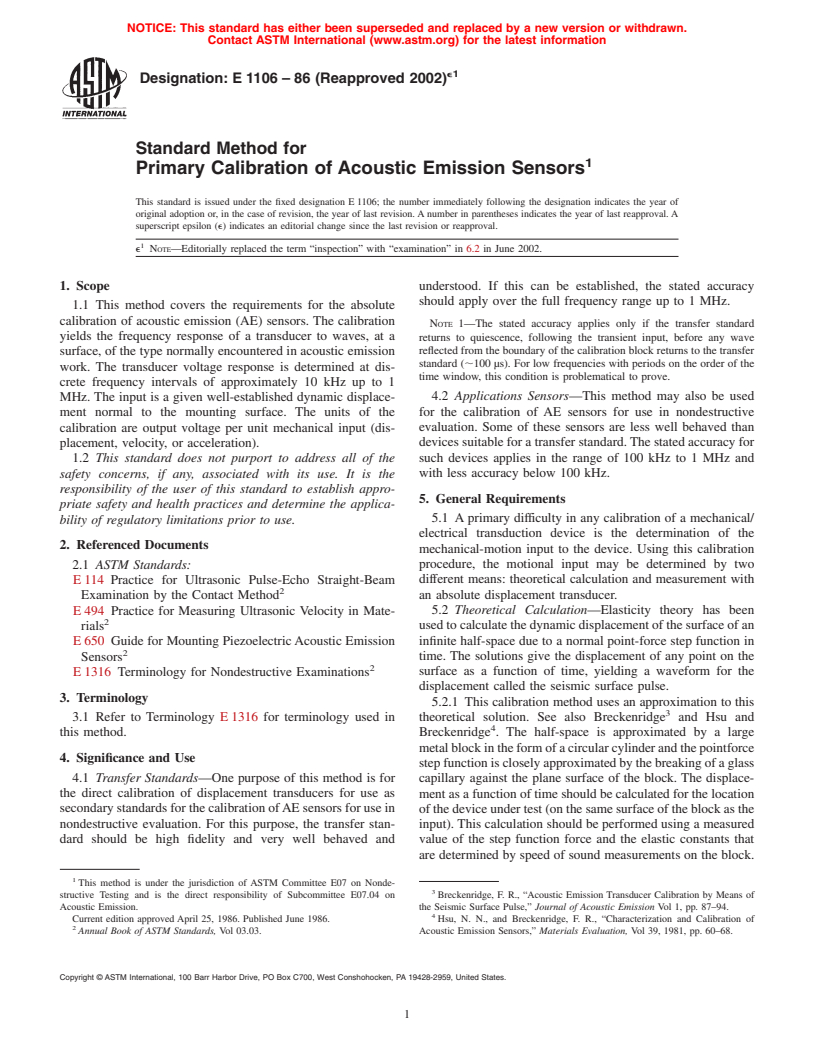

6.1 A typical basic scheme for the calibration is shown in

5.3.1 For a calibration, the standard transducer and the

Fig. 1. A glass capillary, B, of diameter about 0.2 mm, is

device to be calibrated are both placed on the same surface of

squeezedbetweenthetipoftheloadingscrew,C,andtheupper

the block as the mechanical input and equidistant in opposite

face of the large steel transfer block, A. When the capillary

directions from it. This guarantees that both experience the

breaks, the sudden release of force is a step function whose

same displacement-time history. Comparison of the output of

risetime is of the order of 0.1 µs. The magnitude of the force

the transfer standard or AE sensor with the output of the

step is measured by the combination of the PZTdisc, D, in the

standard transducer yields a calibration of the device under

loadingscrewandachargeamplifier, E,connectedtoastorage

test.

oscilloscope, F.The standard capacitive transducer, G, and the

5.3.2 Otherrelativegeometriesfortheinputandtransducers

device under test, H, are placed equally distant (usually 100

are possible, but results from other geometries should only be

mm) from the source and in opposite directions from it. It is

used to supplement results from the “same surface” geometry.

obvious from the symmetry that the surface displacements

AE waves in structures are most frequently dominated by

wouldbethesameatthetwotransducerlocationsifitwerenot

surface wave phenomena, and the calibration should be based

for the loading effects of the transducers. The loading effect of

on the transducer’s response to such waves.

the standard capacitive transducer is negligible and the loading

5.4 Units for the Calibration—An AE sensor may be

effect of the unknown sensor is part of its calibration.

considered to respond to either stress or strain at its front face.

6.1.1 Voltage transients from the two transducers are re-

The actual stress and strain at the front face of a mounted

corded simultaneously by digital recorders, I, and the informa-

sensor depend on the interaction between the mechanical

tion is stored for processing by the computer, J.

impedance of the sensor (load) and that of the mounting block

6.1.2 With such a system, it is possible to do the necessary

(driver). Neither the stress nor the strain is amenable to direct

comparison between the signal from the unknown sensor and

measurement at this location. However, the free displacement

that from the standard transducer or with the displacement

that would occur at the surface of the block in the absence of

waveform calculated by elasticity theory. A similar result

the sensor can be inferred from either elasticity theory calcu-

should be obtained either way.

lations or from measurements made elsewhere on the surface.

6.2 The Transfer Block—The transfer block must be made

SinceAE sensors are used to monitor motion at a free surface

from specially chosen material. It should be as defect-free as

of a structure and interactive effects between sensor and

possible and should undergo an ultrasonic longitudinal exami-

structure are generally of no interest, the free surface motion is

nation at 2.25 MHz. The method described in PracticeE114

the appropriate input variable. It is, therefore, recommended

should be used. The block should contain no flaws which give

that the units of calibration should be voltage per unit of free

a reflection larger than 10% of the first back wall reflection.

motion; for example, volts per metre.

The material should also be highly uniform as determined by

5.5 Block Material:

pulse-echo time of flight measurements through the block at a

5.5.1 Since the calibration depends on the interaction of the

minimumof15locationsregularlyspacedoverthesurface(see

mechanical impedance of the block and that of theAE sensor,

Practice E494). The individual values of the longitudinal and

a calibration procedure must specify the material of the block.

shear wave speed should differ from the average by no more

Calibrations performed on blocks of different materials will

than 61partand 63partsin10 ,respectively.Atransferblock

yield transducer sensitivity versus frequency curves that are

and calibration apparatus is shown in Fig. 2.

different in shape and in average magnitude. The amount by

6.3 The Step Function Source—The step function force

which such averages differ may be very large. A transducer

events are to be made by breaking glass capillary tubing (Fig.

calibrated on a glass or aluminum block will have an average

3). The capillaries are drawn down from ordinary laboratory

sensitivity that may be from 50 to 100% of the value obtained

glass tubing made of borosilicate glass. Sizes of the capillary

on steel, and will have an average sensitivity that may be as

may range from about 0.1 mm to 0.3 mm outside diameter,

little as 3% of the value obtained on steel if calibrated on a

with 0.2 mm being typical. A bore size equal to the wall

thickness gives the best results. The force obtained is usually

between 10 N and 30 N, with 20 N being typical.

Breckenridge, F. R., and Greenspan, M., “Surface-Wave Displacement: Abso-

6.3.1 The capillary is to be laid horizontally on a piece of

lute Measurements Using a Capacitive Transducer,” Journal, Acoustic Society of

America, Vol 69, pp 1177–1185. microscope cover glass (0.08 by 1.5 by 1.5 mm) which has

e1

E 1106 – 86 (2002)

A—steel transfer block

B—capillary source

C—loading screw

D—PZT disc

E—charge amplifier

F—storage oscilloscope

G—standard transducer

H—transducer under test

I—transient recorders

J—computer

FIG. 1 Schematic Diagram of the Apparatus

FIG. 2 Photograph of the Steel Block with the Calibration Apparatus in Place

e1

E 1106 – 86 (2002)

FIG. 3 Glass Capillary Source

been cemented to the top face of the steel block with salol the mass on its compliant supports (approximately 1 kHz), the

(phenyl salicylate) or cyanoacrylate cement. The force is brass cylinder remains approximately stationary. The brass

appliedtothecapillarybyasolidglassrod(2mmindiameter) cylinderispolarizedto100Vdcthroughalargevaluedresistor.

which has been laid horizontally on top of the capillary and at The large resistance causes the capacitor to operate essentially

right angles to it. The rod is forced downward by the loading in a fixed charge condition so that the voltage varies inversely

screw until the capillary breaks. The loading screw is to be with capacitance for the frequencies of interest.

threaded through a yoke above the calibration surface. The 6.4.1 For use as a primary standard, it is essential that the

loadingscrewshouldcontainaceramicforcetransducerwhich sensitivity of the transducer be calculable. To make the

hasbeencalibratedbydeadweights.Thus,althoughthesizeof calculations tractable, the cylinder is treated as a section of an

a source event cannot be predicted in advance, its magnitude infinite cylinder. Electrical guards are attached to each end to

may be measured and used for the elasticity theory calculation eliminate end effects that would otherwise be severe.

of the surface displacement. 6.4.2 The sensing area of the transducer is 12.4 mm long

6.3.2 Ideally, the capillary should rest directly on the steel and effectively less than 1 mm wide.The long axis of this area

with no cover glass interposed. It may be found necessary to istangenttoanadvancingwavefrontfromthecapillarysource.

usethecoverslidetopreventdamagetotheblocksurface.The 6.4.3 The sensitivity of the transducer is approximately

presence of the cover glass does alter the waveform very 12 310 V/mandtheminimumdetectablermsdisplacementis

−12

slightly; a slight ringing occurs due to reflections at its 4 310 m. The calculated frequency response of the trans-

boundaries. The ringing contains only frequencies above 2 ducer based on its effective aperture width and its deviation

MHz. Furthermore, the effects on both standard transducer and from the curvature of the wavefronts is shown in Fig. 6.At1

unknown sensor are the same; therefore, the calibration is not MHz the amplitude is down by less than 10% and the phase

affected. lag is about 8°. Expressions in Breckenridge and Greenspan

6.4 The Standard Transducer—The standard transducer to can be used to calculate the response at frequencies of interest.

be used for the absolute measurement of displacement in the The total estimated uncertainty in the displacement measure-

calibration is to have characteristic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.