ASTM E571-98(2003)e1

(Practice)Standard Practice for Electromagnetic (Eddy-Current) Examination of Nickel and Nickel Alloy Tubular Products

Standard Practice for Electromagnetic (Eddy-Current) Examination of Nickel and Nickel Alloy Tubular Products

SIGNIFICANCE AND USE

Eddy-current examination is a nondestructive method of locating discontinuities in metallic materials. Signals can be produced by discontinuities originating on either the external or internal surfaces of the tube or by discontinuities totally contained within the wall. Since the density of eddy currents decreases nearly exponentially with increasing distance from the surface nearest the coil, the response to deep-seated defects decreases correspondingly. Phase changes are also associated with changes in depth, allowing the use of phase analysis techniques.

The response from natural discontinuities can be significantly different than that from artificial discontinuities, such as drilled holes or notches. For this reason, sufficient work should be done to establish the sensitivity level and setup required to detect natural discontinuities of consequence to the end use of the product.

Some indications obtained by this method may not be relevant to product quality; for example, an irrelevant indication may be caused by minute dents or tool chatter marks, which are not detrimental to the end use of the product. Irrelevant indications can mask unacceptable discontinuities. Relevant indications are those which result from discontinuities. Any indication that exceeds the rejection level shall be treated as a relevant indication until it can be demonstrated that it is irrelevant.

Generally, eddy-current examination systems are not sensitive to discontinuities adjacent to the ends of the tube (end effect).

Discontinuities such as scratches or seams that are continuous and uniform over the full length of the tube may not always be detected with differential encircling coils or probes scanned along the tube length.

For material that is magnetic, a strong magnetic field shall be placed in the region of the examining coil. A magnetic field may also be used to improve the signal-to-noise ratio in tubing that exhibits slight residual magnetism.

SCOPE

1.1 This practice covers the procedures for eddy-current testing of nickel and nickel alloy tubes. These procedures are applicable for tubes with outside diameters up to 2 in. (50.8 mm), incl, and wall thicknesses from 0.035 to 0.120 in. (0.889 to 3.04 mm), incl. These procedures may be used for tubes beyond the size range recommended, by contractual agreement between the purchaser and the producer.

1.2 The procedures described in this practice make use of fixed encircling test coils or probe systems.

1.3 The values stated in inch-pound units are to be regarded as the standard.

Note 1-- For convenience, the term "tube" or "tubular product" will hereinafter be used to refer to both pipe and tubing.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: E 571 – 98 (Reapproved 2003)

Standard Practice for

Electromagnetic (Eddy-Current) Examination of Nickel and

Nickel Alloy Tubular Products

This standard is issued under the fixed designation E 571; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial changes made throughout the standard in July 2003.

1. Scope Certification of Nondestructive Testing Personnel

2 NAS-410 Certification and Qualification of Nondestructive

1.1 This practice covers the procedures for eddy-current

Personnel (Quality Assurance Committee)

examination of nickel and nickel alloy tubes.These procedures

are applicable for tubes with outside diameters up to 2 in. (50.8

3. Terminology

mm), incl, and wall thicknesses from 0.035 to 0.120 in. (0.889

3.1 Standard terminology relating to electromagnetic ex-

to 3.04 mm), incl. These procedures may be used for tubes

amination may be found in Terminology E 1316, Section C,

beyond the size range recommended, by contractual agreement

Electromagnetic Testing.

between the purchaser and the producer.

1.2 The procedures described in this practice make use of

4. Summary of Practice

fixed encircling coils or probe systems.

4.1 Examination is usually performed by the use of one of

1.3 The values stated in inch-pound units are to be regarded

two general techniques:

as the standard.

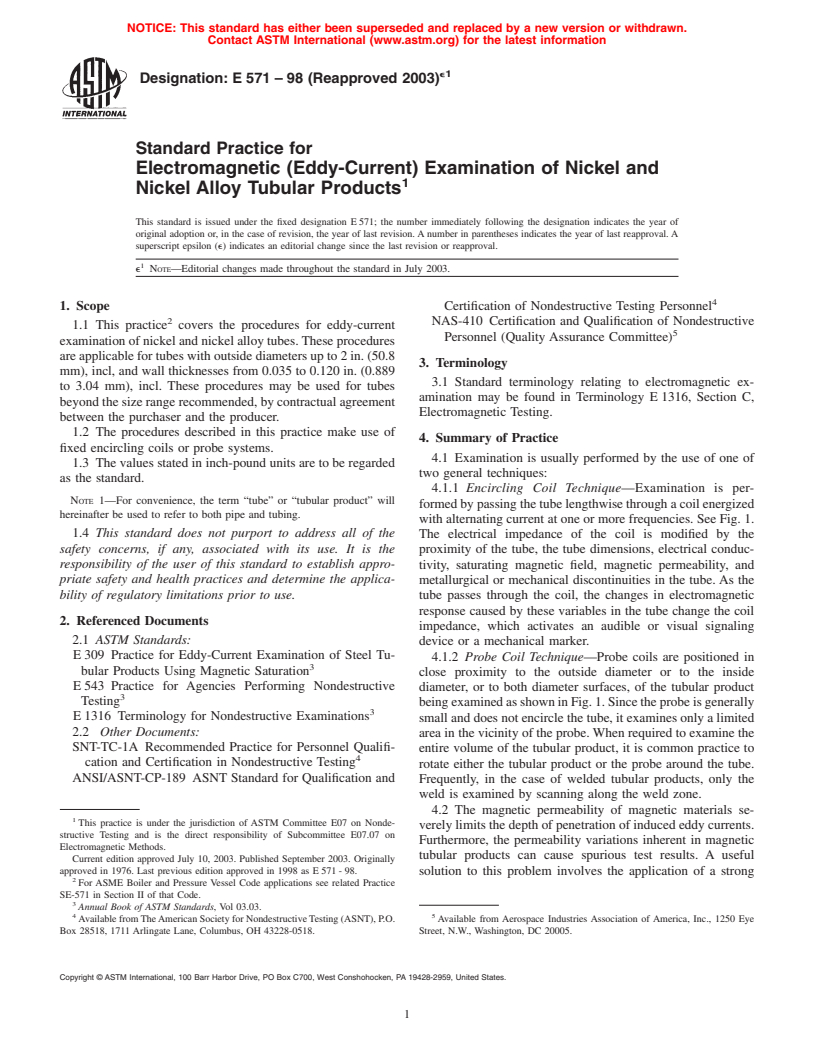

4.1.1 Encircling Coil Technique—Examination is per-

NOTE 1—For convenience, the term “tube” or “tubular product” will

formed by passing the tube lengthwise through a coil energized

hereinafter be used to refer to both pipe and tubing.

with alternating current at one or more frequencies. See Fig. 1.

1.4 This standard does not purport to address all of the The electrical impedance of the coil is modified by the

safety concerns, if any, associated with its use. It is the

proximity of the tube, the tube dimensions, electrical conduc-

responsibility of the user of this standard to establish appro- tivity, saturating magnetic field, magnetic permeability, and

priate safety and health practices and determine the applica-

metallurgical or mechanical discontinuities in the tube. As the

bility of regulatory limitations prior to use. tube passes through the coil, the changes in electromagnetic

response caused by these variables in the tube change the coil

2. Referenced Documents

impedance, which activates an audible or visual signaling

2.1 ASTM Standards:

device or a mechanical marker.

E 309 Practice for Eddy-Current Examination of Steel Tu-

4.1.2 Probe Coil Technique—Probe coils are positioned in

bular Products Using Magnetic Saturation

close proximity to the outside diameter or to the inside

E 543 Practice for Agencies Performing Nondestructive

diameter, or to both diameter surfaces, of the tubular product

Testing

beingexaminedasshowninFig.1.Sincetheprobeisgenerally

E 1316 Terminology for Nondestructive Examinations

small and does not encircle the tube, it examines only a limited

2.2 Other Documents:

area in the vicinity of the probe. When required to examine the

SNT-TC-1A Recommended Practice for Personnel Qualifi-

entire volume of the tubular product, it is common practice to

cation and Certification in Nondestructive Testing

rotate either the tubular product or the probe around the tube.

ANSI/ASNT-CP-189 ASNT Standard for Qualification and

Frequently, in the case of welded tubular products, only the

weld is examined by scanning along the weld zone.

4.2 The magnetic permeability of magnetic materials se-

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

verely limits the depth of penetration of induced eddy currents.

structive Testing and is the direct responsibility of Subcommittee E07.07 on

Furthermore, the permeability variations inherent in magnetic

Electromagnetic Methods.

tubular products can cause spurious test results. A useful

Current edition approved July 10, 2003. Published September 2003. Originally

approved in 1976. Last previous edition approved in 1998 as E 571 - 98.

solution to this problem involves the application of a strong

For ASME Boiler and Pressure Vessel Code applications see related Practice

SE-571 in Section II of that Code.

Annual Book of ASTM Standards, Vol 03.03.

4 5

Available fromTheAmerican Society for NondestructiveTesting (ASNT), P.O. Available from Aerospace Industries Association of America, Inc., 1250 Eye

Box 28518, 1711 Arlingate Lane, Columbus, OH 43228-0518. Street, N.W., Washington, DC 20005.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

E 571 – 98 (2003)

decreases correspondingly. Phase changes are also associated

with changes in depth, allowing the use of phase analysis

techniques.

5.2 The response from natural discontinuities can be signifi-

cantly different than that from artificial discontinuities, such as

drilled holes or notches. For this reason, sufficient work should

be done to establish the sensitivity level and setup required to

detect natural discontinuities of consequence to the end use of

the product.

5.3 Some indications obtained by this method may not be

relevant to product quality; for example, an irrelevant indica-

tion may be caused by minute dents or tool chatter marks,

which are not detrimental to the end use of the product.

Irrelevant indications can mask unacceptable discontinuities.

Relevant indications are those which result from discontinui-

ties. Any indication that exceeds the rejection level shall be

treated as a relevant indication until it can be demonstrated that

it is irrelevant.

5.4 Generally, eddy-current examination systems are not

sensitive to discontinuities adjacent to the ends of the tube (end

effect).

5.5 Discontinuities such as scratches or seams that are

continuousanduniformoverthefulllengthofthetubemaynot

always be detected with differential encircling coils or probes

scanned along the tube length.

5.6 For material that is magnetic, a strong magnetic field

shall be placed in the region of the examining coil.Amagnetic

field may also be used to improve the signal-to-noise ratio in

tubing that exhibits slight residual magnetism.

FIG. 1 Encircling-Coil and Probe-Coil Techniques for

6. Basis of Application

Electromagnetic Examination of Tubular Products

6.1 The following criteria may be specified in the purchase

specification contractual agreement, or elsewhere, and may

external magnetic field in the region of the examining coil or

require agreement between the purchaser and the supplier.

probe. This technique, known as magnetic saturation, causes a

6.1.1 Acceptance criteria.

magnetic material to exhibit sufficiently small magnetic char-

6.1.2 Type, dimensions, and number of artificial disconti-

acteristics of permeability, hysteresis, etc., so that the material

nuities to be placed in the reference standard.

under examination is effectively rendered nonmagnetic. When

6.1.3 Extent of examination; that is, full circumference of

achieved, this condition allows an eddy-current system to

outside or inside diameter, or both, or weld only, if welded.

measure and detect electrical resistivity and geometrical varia-

6.1.4 Operator qualifications, if required (see 6.1.6 below).

tions (including defects) independent of concurrent variations

6.1.5 Standardization intervals.

in magnetic properties.

6.1.6 If specified in the contractual agreement, personnel

NOTE 2—Practice E 309 may be used for strongly magnetic materials.

performing examinations to this practice shall be qualified in

4.2.1 During the examination of slightly magnetic tubing

accordance with a nationally recognized NDT personnel quali-

the signals resulting from the variation of magnetic permeabil-

fication practice or standard such as ANSI/ASNT-CP-189,

ity can mask the signals resulting from small imperfections. A

SNT-TC-1A, NAS-410, ASNT-ACCP, or a similar document

magnetic saturation technique can be used to reduce this

and certified by the certifying agency as applicable. The

interference to an acceptable level.

practice or standard used and its applicable revision shall be

identified in the contractual agreement between the using

5. Significance and Use

parties.

5.1 Eddy-current examination is a nondestructive method of

NOTE 3—MIL-STD-410 is canceled and has been replaced with NAS-

locating discontinuities in metallic materials. Signals can be

410, however, it may be used with agreement between contracting parties.

produced by discontinuities originating on either the external

or internal surfaces of the tube or by discontinuities totally 6.1.7 If specified in the contractual agreement, NDT agen-

contained within the wall. Since the density of eddy currents cies shall be qualified and evaluated in accordance with

decreases nearly exponentially with increasing distance from Practice E 543. The applicable edition of Practice E 543 shall

the surface nearest the coil, the response to deep-seated defects be specified in the contractual agreement.

e1

E 571 – 98 (2003)

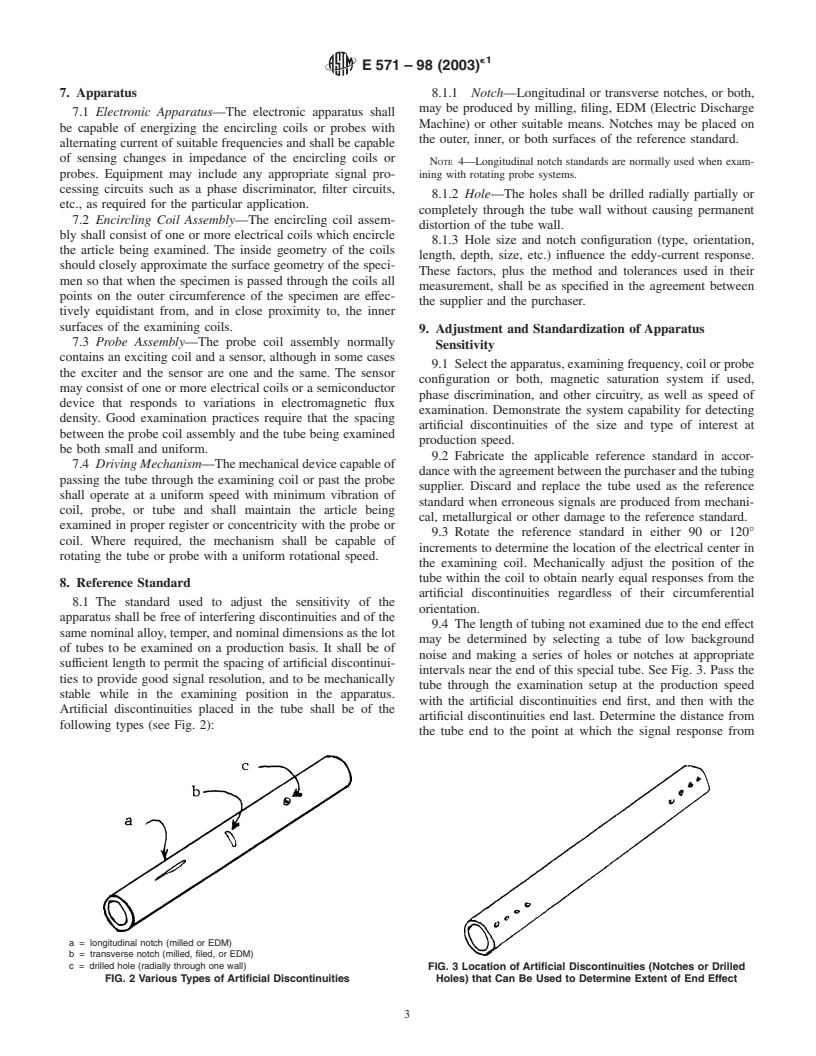

7. Apparatus 8.1.1 Notch—Longitudinal or transverse notches, or both,

may be produced by milling, filing, EDM (Electric Discharge

7.1 Electronic Apparatus—The electronic apparatus shall

Machine) or other suitable means. Notches may be placed on

be capable of energizing the encircling coils or probes with

the outer, inner, or both surfaces of the reference standard.

alternating current of suitable frequencies and shall be capable

of sensing changes in impedance of the encircling coils or

NOTE 4—Longitudinal notch standards are normally used when exam-

probes. Equipment may include any appropriate signal pro- ining with rotating probe systems.

cessing circuits such as a phase discriminator, filter circuits,

8.1.2 Hole—The holes shall be drilled radially partially or

etc., as req

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.