ASTM E1510-95(2013)e1

(Practice)Standard Practice for Installing Fused Silica Open Tubular Capillary Columns in Gas Chromatographs

Standard Practice for Installing Fused Silica Open Tubular Capillary Columns in Gas Chromatographs

SIGNIFICANCE AND USE

5.1 This practice is intended to be used by all analysts using fused silica capillary chromatography. It contains the recommended steps for installation, preparation, proper installation, and continued column maintenance.

SCOPE

1.1 This practice covers the installation and maintenance of fused silica capillary columns in gas chromatographs that are already retrofitted for their use. This practice excludes information on:

1.1.1 Injection techniques.

1.1.2 Column selection.

1.1.3 Data acquisition.

1.1.4 System troubleshooting and maintenance.

1.2 For additional information on gas chromatography, please refer to Practice E260. For specific precautions, see 7.2.2.2(1), 7.2.2.2(2), 7.2.7, and 7.2.7.2.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific safety information, see Section 6, 7.2.2.2(1), 7.2.2.2(2), 7.2.7, and 7.2.7.2.2TABLE 1 Typical Splitter Vent Flow Rates (50 to 1 split ratio) (at optimum linear velocity)

Carrier gas

0.25-mm ID,

cm3 /min

0.32-mm ID,

cm3 /min

0.53-mm ID,

cm3 /min

helium

hydrogen

35

70

80

160

125

250

Note 1—The curves were generated by plotting the height equivalent to a theoretical plate (length of column divided by the total number of theoretical plates, H.E.T.P.) against the column's average linear velocity. The lowest point on the curve indicates the carrier gas velocity in which the highest column efficiency is reached.Note 2—Gases information available from Compressed Gas Association (CGA), 4221 Walney Rd., 5th Floor, Chantilly, VA 20151-2923, http://www.cganet.com.FIG. 1 Van Deemter Profile for Hydrogen, Helium, and Nitrogen Carrier Gases

Carrier gas: Hydrogen

Carrier gas: Helium

Linear velocity: 40 cm/s

Linear velocity: 20 cm/s

Note 1—Fig. 2 shows that the resolution is similar but the analysis time is reduced by 50 % when comparing hydrogen to helium in an isothermal analysis using optimum flow velocities.Note 2—Hydrogen provides similar resolution in one-half the analysis time of helium for an isothermal analysis.Note 3—

1. Tetrachloro-m-

8. Heptachlor epoxide

15. Endosulfan II

xylene

9. γ-chlordane

16. DDD

2. α-BHC

10. Endosulfan I

17. Endrin aldehyde

3. β-BHC

11. α-chlordane

18. Endosulfan sulfate

4. γ-BHC

12. Dieldrin

19. DDT

5. δ-BHC

13. DDE

20. Endrin ketone

6. Heptachlor

14. Endrin

21. Methyoxychlor

7. Aldrin

Note 4—30 m, 0.25-mm ID, 0.25 μm 5 % diphenyl − 95 % dimethyl polysiloxane 0.1-μL split injection of chlorinated pesticides.

Oven temperature: 210°C isothermal

Injector and detector temperature: 250°C/300°C

ECD sensitivity: 512 × 10 −11

Split vent: 100 cm 3 /min

FIG. 2 Hydrogen Versus Helium (Isothermal Analysis)

FIG. 3 Capping Silanol Groups with Dimethyl Dichlorosilane (DMDCS)

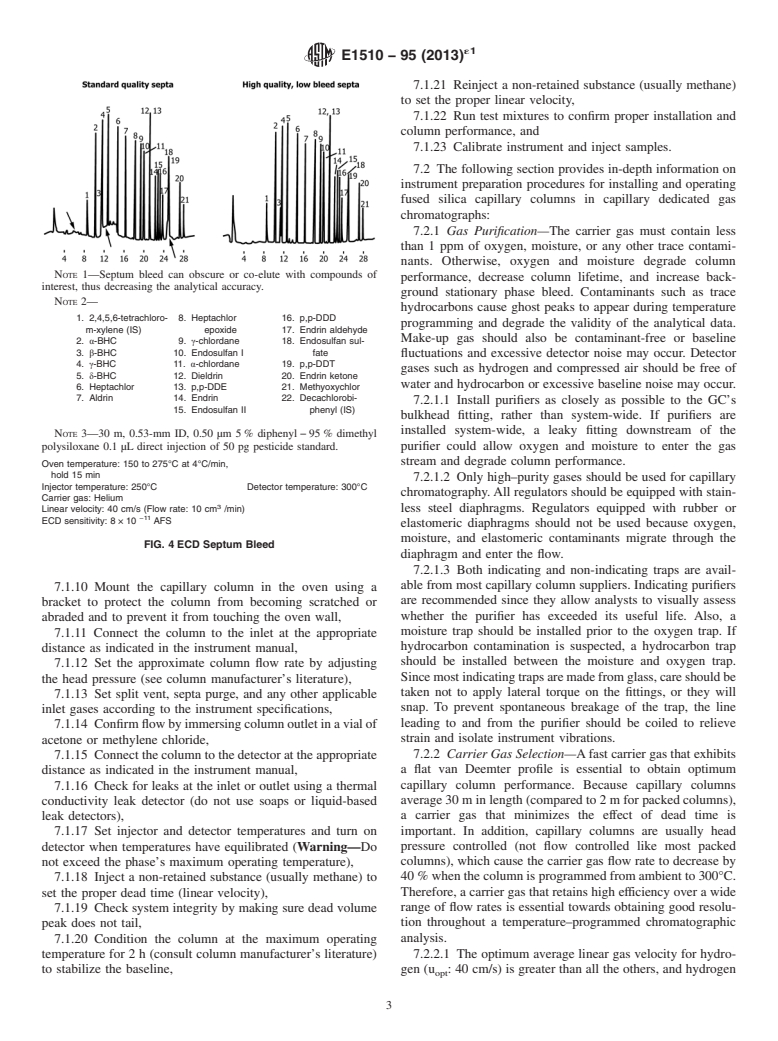

Note 1—Septum bleed can obscure or co-elute with compounds of interest, thus decreasing the analytical accuracy.Note 2—

1. 2,4,5,6-tetrachloro-

8. Heptachlor

16. p,p-DDD

m-xylene (IS)

epoxide

17. Endrin aldehyde

2. α-BHC

9. γ-chlordane

18. Endosulfan sul-

3. β-BHC

10. Endosulfan I

fate

4. γ-BHC

11. α-chlordane

19. p,p-DDT

5. δ-BHC

12. Dieldrin

20. Endrin ketone

6. Heptachlor

13. p,p-DDE

21. Methyoxychlor

7. Aldrin

14. Endrin

22. Decachlorobi-

15. Endosulfan II

phenyl (IS)

Note 3—30 m, 0.5...

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:E1510 −95 (Reapproved 2013)

Standard Practice for

Installing Fused Silica Open Tubular Capillary Columns in

Gas Chromatographs

This standard is issued under the fixed designation E1510; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Warning statements were editorially corrected in January 2013.

1. Scope 2.2 CGA Publications:

CGAP-1SafeHandlingofCompressedGasesinContainers

1.1 This practice covers the installation and maintenance of

CGA G-5.4Standard for Hydrogen Piping Systems at Con-

fused silica capillary columns in gas chromatographs that are

sumer Locations

already retrofitted for their use. This practice excludes infor-

CGA P-9The Inert Gases: Argon, Nitrogen and Helium

mation on:

CGA V-7Standard Method of Determining Cylinder Valve

1.1.1 Injection techniques.

Outlet Connections for Industrial Gas Mixtures

1.1.2 Column selection.

CGA P-12Safe Handling of Cryogenic Liquids

1.1.3 Data acquisition.

HB-3Handbook of Compressed Gases

1.1.4 System troubleshooting and maintenance.

3. Terminology

1.2 For additional information on gas chromatography,

please refer to Practice E260. For specific precautions, see

3.1 Terms and relations are defined in Practice E355.

7.2.2.2(1), 7.2.2.2(2), 7.2.7, and 7.2.7.2.

3.2 Nomenclature for open tubular or capillary columns

1.3 The values stated in SI units are to be regarded as

with a bore of 0.75 mm or less:

standard. No other units of measurement are included in this

3.3 porous layer open tubular (PLOT)—refers to columns

standard.

with particles attached on the inside wall consisting of copo-

1.4 This standard does not purport to address all of the

lymers such as styrene/divinylbenzene, molecular sieves, or

safety concerns, if any, associated with its use. It is the

adsorbents such as Al O in film thicknesses of 5 to 50 µm.

2 2

responsibility of the user of this standard to establish appro-

3.4 support coated open tubular (SCOT)—refers to fine

priate safety and health practices and determine the applica-

particles (silica or fine diatomite) coated with liquid stationary

bility of regulatory limitations prior to use. For specific safety

phase, which is then deposited on the inside column wall to

information, see Section 6, 7.2.2.2(1), 7.2.2.2(2), 7.2.7, and

improve stationary phase stability and sample capacity.

7.2.7.2.

3.5 wall coated open tubular (WCOT)—refers to columns

coated on the inside wall with a liquid stationary phase in film

2. Referenced Documents

thicknesses of 0.1 to 10.0 µm. Also referred to as FSOT or

2.1 ASTM Standards:

fused silica open tubular.

E260Practice for Packed Column Gas Chromatography

E355PracticeforGasChromatographyTermsandRelation-

4. Summary of Practice

ships

4.1 The packed gas chromatography system is described in

Practice E260 and is essentially the same as a capillary gas

chromatographysystemexceptformodificationstotheinjector

This practice is under the jurisdiction ofASTM Committee E13 on Molecular

and detector to accommodate the low flow rates and sample

Spectroscopy and Separation Science and is the direct responsibility of Subcom-

capacity associated with capillary columns. Refer to the gas

mittee E13.19 on Separation Science.

Current edition approved Jan. 1, 2013. Published January 2013. Originally

chromatography(GC)instrumentmanualforspecificdetailson

approved in 1993. Last previous edition approved in 2005 as E1510–95 (2005).

injector or detector pneumatics for capillary columns.

DOI: 10.1520/E1510-95R13.

Reprinted by permission of Restek Corp., 110 Benner Circle, Bellefonte, PA

4.2 Prior to performing a capillary GC analysis, the capil-

16823-8812.

lary column configuration must be determined. The stationary

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Compressed Gas Association (CGA), 4221 Walney Rd., 5th

the ASTM website. Floor, Chantilly, VA 20151-2923, http://www.cganet.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E1510−95 (2013)

TABLE 1 Typical Splitter Vent Flow Rates (50 to 1 split ratio)

(at optimum linear velocity)

0.25-mm ID, 0.32-mm ID, 0.53-mm ID,

Carrier gas

3 3 3

cm /min cm /min cm /min

helium 35 80 125

hydrogen 70 160 250

Carrier gas: Hydrogen Carrier gas: Helium

Linear velocity: 40 cm/s Linear velocity: 20 cm/s

NOTE1—Fig.2showsthattheresolutionissimilarbuttheanalysistime

is reduced by 50% when comparing hydrogen to helium in an isothermal

analysis using optimum flow velocities.

NOTE 2—Hydrogen provides similar resolution in one-half the analysis

time of helium for an isothermal analysis.

NOTE1—Thecurvesweregeneratedbyplottingtheheightequivalentto

NOTE 3—

a theoretical plate (length of column divided by the total number of

1. Tetrachloro-m- 8. Heptachlor epoxide 15. Endosulfan II

theoretical plates, H.E.T.P.) against the column’s average linear velocity.

xylene 9. γ-chlordane 16. DDD

The lowest point on the curve indicates the carrier gas velocity in which

2. α-BHC 10. Endosulfan I 17. Endrin aldehyde

the highest column efficiency is reached.

3. β-BHC 11. α-chlordane 18. Endosulfan sulfate

NOTE 2—Gases information available from Compressed Gas Associa- 4. γ-BHC 12. Dieldrin 19. DDT

5. δ-BHC 13. DDE 20. Endrin ketone

tion (CGA), 4221 Walney Rd., 5th Floor, Chantilly, VA 20151-2923,

6. Heptachlor 14. Endrin 21. Methyoxychlor

http://www.cganet.com.

7. Aldrin

FIG. 1Van Deemter Profile for Hydrogen, Helium, and Nitrogen

Carrier Gases

NOTE 4—30 m, 0.25-mm ID, 0.25 µm 5% diphenyl−95% dimethyl

polysiloxane 0.1-µL split injection of chlorinated pesticides.

Oven temperature: 210°C isothermal

phase type, stationary phase film thickness, column inside

Injector and detector temperature: 250°C/300°C

−11

ECD sensitivity: 512 × 10

diameter, and column length must be selected. It is beyond the

Split vent: 100 cm /min

scope of this practice to provide these details. Consult a

column or instrument supplier for details on selecting the

FIG. 2Hydrogen Versus Helium (Isothermal Analysis)

appropriate capillary column configuration.

4.3 Apply caution during handling or installation to avoid

scratching or abrading the protective outer coating of the

column. Scratches or abrasions cause the fused silica capillary

column to spontaneously break or fail during usage.

5. Significance and Use

5.1 Thispracticeisintendedtobeusedbyallanalystsusing FIG. 3 Capping Silanol Groups with Dimethyl Dichlorosilane

(DMDCS)

fused silica capillary chromatography. It contains the recom-

mended steps for installation, preparation, proper installation,

and continued column maintenance.

6. Hazards

7.1.1 Cool all heated zones and replace spent oxygen and

moisture scrubbers,

6.1 Gas Handling Safety—The safe handling of compressed

7.1.2 Clean or deactivate, or both, injector and detector

gases and cryogenic liquids for use in chromatography is the

responsibility of every laboratory. The Compressed Gas sleeves (if necessary),

7.1.3 Replace critical injector and detector seals,

Association, a member group of specialty and bulk gas

suppliers, publishes the following guidelines to assist the 7.1.4 Replace septum,

laboratory chemist to establish a safe work environment: CGA 7.1.5 Set make-up and detector gas flow rates,

P-1, CGA G-5.4, CGA P-9, CGA V-7, CGA P-12, and HB-3.

7.1.6 Carefully inspect the column for damage or breakage,

7.1.7 Cutapproximately10cmfromeachendofthecolumn

7. Installation Procedure for Fused Silica Capillary

using a ceramic scoring wafer or sapphire scribe,

Columns

7.1.8 Install nut and appropriately sized ferrule on both

7.1 Abriefoutlineofthestepsnecessaryforinstallingfused column ends,

silica capillary columns in capillary dedicated gas chromato- 7.1.9 Cut an additional 10 cm from each end of the column

graphs is as follows: to remove ferrule shards,

´1

E1510−95 (2013)

7.1.21 Reinject a non-retained substance (usually methane)

to set the proper linear velocity,

7.1.22 Run test mixtures to confirm proper installation and

column performance, and

7.1.23 Calibrate instrument and inject samples.

7.2 The following section provides in-depth information on

instrument preparation procedures for installing and operating

fused silica capillary columns in capillary dedicated gas

chromatographs:

7.2.1 Gas Purification—The carrier gas must contain less

than 1 ppm of oxygen, moisture, or any other trace contami-

nants. Otherwise, oxygen and moisture degrade column

NOTE 1—Septum bleed can obscure or co-elute with compounds of

performance, decrease column lifetime, and increase back-

interest, thus decreasing the analytical accuracy.

ground stationary phase bleed. Contaminants such as trace

NOTE 2—

hydrocarbons cause ghost peaks to appear during temperature

1. 2,4,5,6-tetrachloro- 8. Heptachlor 16. p,p-DDD

programming and degrade the validity of the analytical data.

m-xylene (IS) epoxide 17. Endrin aldehyde

Make-up gas should also be contaminant-free or baseline

2. α-BHC 9. γ-chlordane 18. Endosulfan sul-

3. β-BHC 10. Endosulfan I fate

fluctuations and excessive detector noise may occur. Detector

4. γ-BHC 11. α-chlordane 19. p,p-DDT

gases such as hydrogen and compressed air should be free of

5. δ-BHC 12. Dieldrin 20. Endrin ketone

water and hydrocarbon or excessive baseline noise may occur.

6. Heptachlor 13. p,p-DDE 21. Methyoxychlor

7. Aldrin 14. Endrin 22. Decachlorobi-

7.2.1.1 Install purifiers as closely as possible to the GC’s

15. Endosulfan II phenyl (IS)

bulkhead fitting, rather than system-wide. If purifiers are

installed system-wide, a leaky fitting downstream of the

NOTE 3—30 m, 0.53-mm ID, 0.50 µm 5% diphenyl−95% dimethyl

polysiloxane 0.1 µL direct injection of 50 pg pesticide standard. purifier could allow oxygen and moisture to enter the gas

stream and degrade column performance.

Oven temperature: 150 to 275°C at 4°C/min,

hold15min

7.2.1.2 Only high–purity gases should be used for capillary

Injector temperature: 250°C Detector temperature: 300°C

chromatography.All regulators should be equipped with stain-

Carrier gas: Helium

Linear velocity: 40 cm/s (Flow rate: 10 cm /min) less steel diaphragms. Regulators equipped with rubber or

−11

ECD sensitivity: 8 × 10 AFS

elastomeric diaphragms should not be used because oxygen,

moisture, and elastomeric contaminants migrate through the

FIG. 4ECD Septum Bleed

diaphragm and enter the flow.

7.2.1.3 Both indicating and non-indicating traps are avail-

able from most capillary column suppliers. Indicating purifiers

7.1.10 Mount the capillary column in the oven using a

are recommended since they allow analysts to visually assess

bracket to protect the column from becoming scratched or

whether the purifier has exceeded its useful life. Also, a

abraded and to prevent it from touching the oven wall,

moisture trap should be installed prior to the oxygen trap. If

7.1.11 Connect the column to the inlet at the appropriate

hydrocarbon contamination is suspected, a hydrocarbon trap

distance as indicated in the instrument manual,

should be installed between the moisture and oxygen trap.

7.1.12 Set the approximate column flow rate by adjusting

Sincemostindicatingtrapsaremadefromglass,careshouldbe

the head pressure (see column manufacturer’s literature),

taken not to apply lateral torque on the fittings, or they will

7.1.13 Set split vent, septa purge, and any other applicable

snap. To prevent spontaneous breakage of the trap, the line

inlet gases according to the instrument specifications,

leading to and from the purifier should be coiled to relieve

7.1.14 Confirmflowbyimmersingcolumnoutletinavialof

strain and isolate instrument vibrations.

acetone or methylene chloride,

7.1.15 Connectthecolumntothedetectorattheappropriate 7.2.2 Carrier Gas Selection—Afastcarriergasthatexhibits

a flat van Deemter profile is essential to obtain optimum

distance as indicated in the instrument manual,

7.1.16 Check for leaks at the inlet or outlet using a thermal capillary column performance. Because capillary columns

average30minlength(comparedto2mforpackedcolumns),

conductivity leak detector (do not use soaps or liquid-based

leak detectors), a carrier gas that minimizes the effect of dead time is

important. In addition, capillary columns are usually head

7.1.17 Set injector and detector temperatures and turn on

detector when temperatures have equilibrated (Warning—Do pressure controlled (not flow controlled like most packed

columns), which cause the carrier gas flow rate to decrease by

not exceed the phase’s maximum operating temperature),

7.1.18 Inject a non-retained substance (usually methane) to 40%whenthecolumnisprogrammedfromambientto300°C.

Therefore, a carrier gas that retains high efficiency over a wide

set the proper dead time (linear velocity),

range of flow rates is essential towards obtaining good resolu-

7.1.19 Check system integrity by making sure dead volume

tion throughout a temperature–programmed chromatographic

peak does not tail,

analysis.

7.1.20 Condition the column at the maximum operating

temperature for 2 h (consult column manufacturer’s literature) 7.2.2.1 The optimum average linear gas velocity for hydro-

to stabilize the baseline, gen (u : 40 cm/s) is greater than all the others, and hydrogen

opt

´1

E1510−95 (2013)

exhibits the flattest van Deemter profile. Helium is the next Proper safety precautions should be utilized to prevent an

best choice (u : 20 cm/s). Note that head pressures at explosion in the oven chamber. Some gas chromatographs are

opt

optimum flow rates are similar for hydrogen and helium designed with spring–loaded doors, perforated or corrugated

because hydrogen has half the viscosity but double the linear metal oven chambers, and back pressure/flow controlled

velocityashelium.Becauseofthelowoptimumlinearvelocity pneumatics,whichminimizethehazardswhenusinghydrogen

(u : 10 cm/s) and steep van Deemter profile, nitrogen gives carrier gas. Additional precautions used by analysts include:

opt

inferior performance with capillary columns and is usually not (a)Frequently check for carrier gas leaks using a sensi-

recommended. tive electronic leak detector,

7.2.2.2 Temperature programming usually provides similar (b)Use electronic sensors that shut down the carrier gas

analysis times between hydrogen and helium since the elution flow should an explosive atmosphere be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.