ASTM F1092-14

(Specification)Standard Specification for Fiberglass (GRP) Pultruded Open-Weather Storm and Guard, Square Railing Systems

Standard Specification for Fiberglass (GRP) Pultruded Open-Weather Storm and Guard, Square Railing Systems

ABSTRACT

This specification provides the material requirements, construction, installation, and testing requirements for open-weather deck, storm-and-guard, fiberglass square railing systems. Components are to be manufactured by the pultrusion process. Handrails and stanchions shall be fiberglass pultruded square tube available in the following two types: Type 1F and Type 2F. Test at least one end stanchion and one other stanchion of each platform or deck by application of a load horizontally in accordance with the specification.

SCOPE

1.1 This specification provides the material requirements, construction, installation, and testing requirements for open-weather deck, storm-and-guard, fiberglass square railing systems. Components are to be manufactured by the pultrusion process.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazards caveat pertains only to the test methods portion, Section 9, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1092 −14 An American National Standard

Standard Specification for

Fiberglass (GRP) Pultruded Open-Weather Storm and

1

Guard, Square Railing Systems

This standard is issued under the fixed designation F1092; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D790Test Methods for Flexural Properties of Unreinforced

and Reinforced Plastics and Electrical Insulating Materi-

1.1 This specification provides the material requirements,

als

construction, installation, and testing requirements for open-

D792Test Methods for Density and Specific Gravity (Rela-

weather deck, storm-and-guard, fiberglass square railing sys-

tive Density) of Plastics by Displacement

tems. Components are to be manufactured by the pultrusion

D3846Test Method for In-Plane Shear Strength of Rein-

process.

forced Plastics

1.2 The values stated in inch-pound units are to be regarded

D3917Specification for Dimensional Tolerance of Thermo-

as standard. The values given in parentheses are mathematical

setting Glass-Reinforced Plastic Pultruded Shapes

conversions to SI units that are provided for information only

E84Test Method for Surface Burning Characteristics of

and are not considered standard.

Building Materials

1.3 The following safety hazards caveat pertains only to the

test methods portion, Section 9, of this specification: This

3. Terminology

standarddoesnotpurporttoaddressallofthesafetyconcerns,

3.1 pultrusion—process of pulling fiberglass rovings

ifany,associatedwithitsuse.Itistheresponsibilityoftheuser

(strands), mats, and other forms of reinforcements such as

of this standard to establish appropriate safety, health, and

woven fiberglass through baths of thermosetting liquid resin,

environmental practices and determine the applicability of

and then through a heated forming die (made of steel) to form

regulatory limitations prior to use.

a completed composite fiberglass structural shape.

1.4 This international standard was developed in accor-

3.1.1 Discussion—The heated die causes a chemical reac-

dance with internationally recognized principles on standard-

tion to be initiated in the resin.The liquid resin molecules will

ization established in the Decision on Principles for the

cross-linkanddevelopintoahardenedplasticthatisreinforced

Development of International Standards, Guides and Recom-

with the fiberglass.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

4. Classification

2. Referenced Documents 4.1 Handrails and stanchions shall be fiberglass pultruded

2 square tube available in the following two types:

2.1 ASTM Standards:

4.1.1 Type 1F—Three-course railing systems, for use along

D570Test Method for Water Absorption of Plastics

the exposed peripheries of freeboards, weather decks, and

D638Test Method for Tensile Properties of Plastics

superstructure decks.

D695Test Method for Compressive Properties of Rigid

4.1.2 Type 2F—Two-course railing systems, for use on

Plastics

bridges, platforms, walkways, and elsewhere as needed.

5. Ordering Information

5.1 Orders for materials under this specification shall in-

1

This specification is under the jurisdiction ofASTM Committee F25 on Ships

clude the following information:

and Marine Technology and is the direct responsibility of Subcommittee F25.03 on

5.1.1 Quantity (lineal feet (metres) of railing system).

Outfitting and Deck Machinery.

5.1.2 Name of material (fiberglass pultruded square railing

Current edition approved Nov. 1, 2014. Published November 2014. Originally

system).

approved in 1987. Last previous edition approved in 2010 as F1092–04 (2010).

DOI: 10.1520/F1092-14.

5.1.3 Type (see 4.1).

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

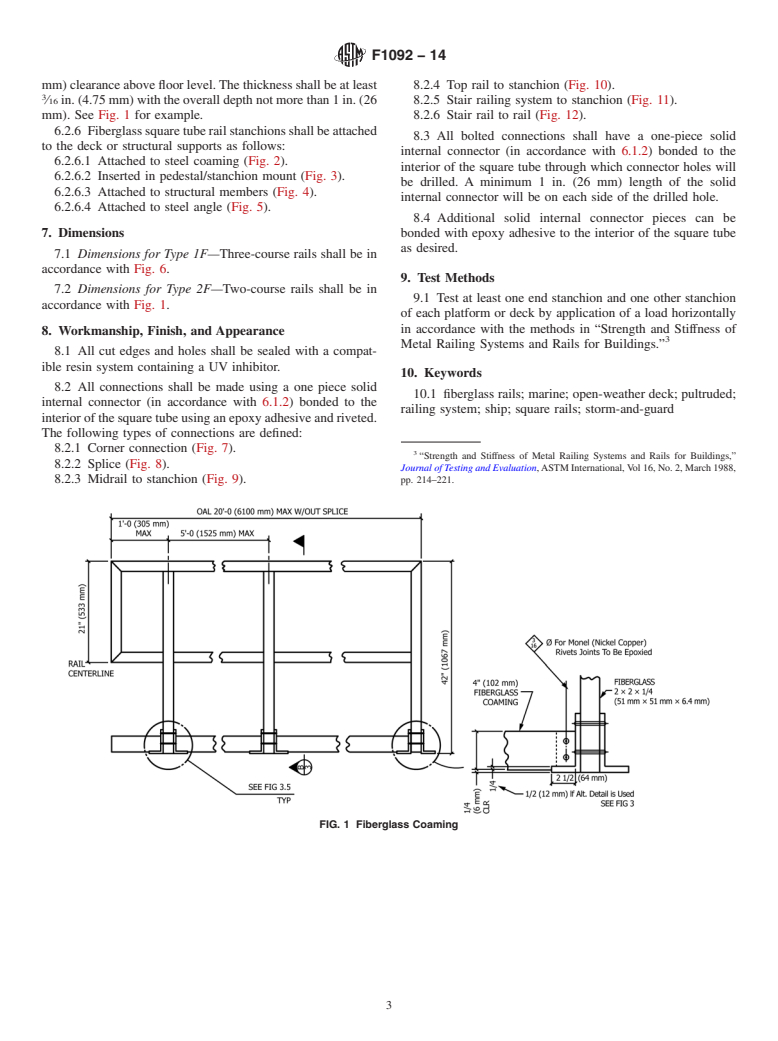

5.1.4 Fiberglass coaming, if specified (lineal feet (metres)).

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

(See 6.2.5.)

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 5.1.5 Attachment method for stanchions (see 6.2.6).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1092−14

5.1.6 ASTM designation and year of issue. fiberglass sheets that have been bonded together. Fiberglass

sheet used for angular connections shall meet the properties

6. Materials and Manufacture

1 1

specified in Table 1. Fiberglass solid bar, 1 ⁄2×1 ⁄2 in. (38.1 ×

6.1 Materials: 38.1 mm), shall be used for the straight connections and shall

meet the properties specified in Table 1.

6.1.1 The fibergla

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1092 − 04 (Reapproved 2010) F1092 − 14 An American National Standard

Standard Specification for

Fiberglass (GRP) Pultruded Open-Weather Storm and

1

Guard, Square Railing Systems

This standard is issued under the fixed designation F1092; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification provides the material requirements, construction, installation, and testing requirements for open-weather

deck, storm-and-guard, fiberglass square railing systems. Components are to be manufactured by the pultrusion process.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazards caveat pertains only to the test methods portion, Section 9, of this specification:This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D570 Test Method for Water Absorption of Plastics

D638 Test Method for Tensile Properties of Plastics

D695 Test Method for Compressive Properties of Rigid Plastics

D790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D3846 Test Method for In-Plane Shear Strength of Reinforced Plastics

D3917 Specification for Dimensional Tolerance of Thermosetting Glass-Reinforced Plastic Pultruded Shapes

E84 Test Method for Surface Burning Characteristics of Building Materials

3. Terminology

3.1 pultrusion—process of pulling fiberglass rovings (strands), mats, and other forms of reinforcements such as woven fiberglass

through baths of thermosetting liquid resin, and then through a heated forming die (made of steel) to form a completed composite

fiberglass structural shape.

1

This specification is under the jurisdiction of ASTM Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.03 on

Outfitting and Deck Machinery.

Current edition approved May 1, 2010Nov. 1, 2014. Published June 2010November 2014. Originally approved in 1987. Last previous edition approved in 20042010 as

F1092 – 04.F1092 – 04 (2010). DOI: 10.1520/F1092-04R10.10.1520/F1092-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.1.1 Discussion—

The heated die causes a chemical reaction to be initiated in the resin. The liquid resin molecules will cross-link and develop into

a hardened plastic that is reinforced with the fiberglass.

4. Classification

4.1 Handrails and stanchions shall be fiberglass pultruded square tube available in the following two types:

4.1.1 Type 1F—Three-course railing systems, for use along the exposed peripheries of freeboards, weather decks, and

superstructure decks.

4.1.2 Type 2F—Two-course railing systems, for use on bridges, platforms, walkways, and elsewhere as needed.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1092 − 14

5. Ordering Information

5.1 Orders for materials under this specification shall include the following information:

5.1.1 Quantity (lineal feet (metres) of railing system).

5.1.2 Name of material (fiberglass pultruded square railing system).

5.1.3 Type (See(see 4.1).

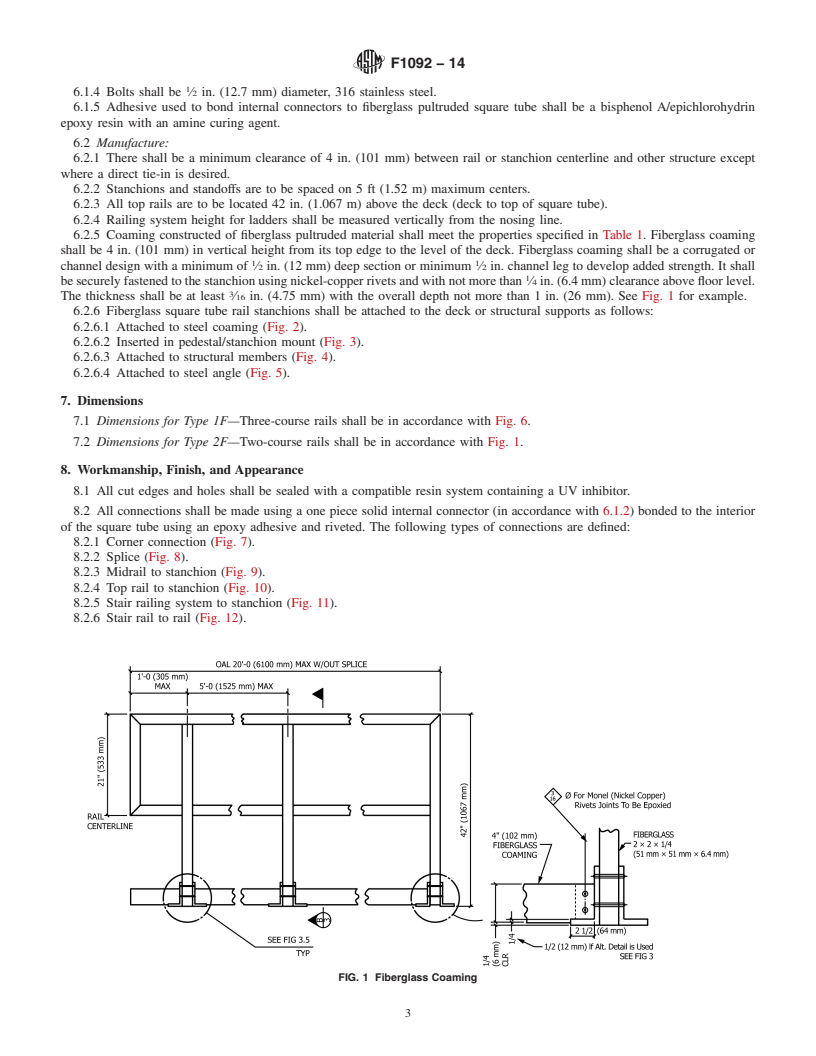

5.1.4 Fiberglass coaming, if specified (lineal feet (metres)). (See 6.2.5).)

5.1.5 Attachment method for stanchions (see 6.2.6).

5.1.6 ASTM designation and year of issue.

6. Materials and Manufacture

6.1 Materials:

1 5

6.1.1 The fiberglass (GRP) pultruded square tube shall be 2 × 2 × ⁄4 in. (50 × 50 × 6.4 mm) with the outside corner radius ⁄32

in. (4 mm). A synthetic surface veil shall be the outermost layer of reinforcement covering the entire exterior surface. T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.