ASTM D1043-02

(Test Method)Standard Test Method for Stiffness Properties of Plastics as a Function of Temperature by Means of a Torsion Test

Standard Test Method for Stiffness Properties of Plastics as a Function of Temperature by Means of a Torsion Test

SIGNIFICANCE AND USE

The property measured by this test is the apparent modulus of rigidity, G, sometimes called the apparent shear modulus of elasticity. It is important to note that this property is not the same as the modulus of elasticity, E, measured in tension, flexure, or compression. The relationship between these properties is shown in Annex A1.

The measured modulus of rigidity is termed “apparent” since it is the value obtained by measuring the angular deflection occurring when the specimen is subjected to an applied torque. Since the specimen may be deflected beyond its elastic limit, the calculated value may not represent the true modulus of rigidity within the elastic limit of the material. In addition, the value obtained by this test method will also be affected by the creep characteristics of the material, since the load application time is arbitrarily fixed. For many materials, there may be a specification that requires the use of this test method, but with some procedural modifications that take precedence when adhering to the specification. Therefore, it is advisable to refer to that material specification before using this test method. Table 1 in Classification D 4000 lists the current ASTM materials standards.

This test method is useful for determining the relative changes in stiffness over a wide range of temperatures.

SCOPE

1.1 This test method covers the determination of the stiffness characteristics of plastics over a wide temperature range by direct measurement of the apparent modulus of rigidity.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—This test method is not equivalent to ISO 458/1:1985 or ISO 458/2:1985 and results cannot be directly compared between the two methods.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 1043 – 02

Standard Test Method for

Stiffness Properties of Plastics as a Function of

1

Temperature by Means of a Torsion Test

This standard is issued under the fixed designation D1043; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

5

1. Scope* D4805 Terminology for Plastics Standards

1.1 This test method covers the determination of the stiff-

3. Terminology

ness characteristics of plastics over a wide temperature range

3.1 Definitions—For definitions of the technical terms per-

by direct measurement of the apparent modulus of rigidity.

taining to plastics used in this test method, see Terminology

1.2 The values stated in SI units are to be regarded as the

D883 or Terminology D4805.

standard. The values given in parentheses are for information

only.

4. Significance and Use

1.3 This standard does not purport to address all of the

4.1 The property measured by this test is the apparent

safety concerns, if any, associated with its use. It is the

modulus of rigidity, G, sometimes called the apparent shear

responsibility of the user of this standard to establish appro-

modulus of elasticity. It is important to note that this property

priate safety and health practices and determine the applica-

is not the same as the modulus of elasticity, E, measured in

bility of regulatory limitations prior to use.

tension, flexure, or compression. The relationship between

NOTE 1—This test method is not equivalent to ISO 458/1:1985 or ISO

these properties is shown in Annex A1.

458/2:1985 and results cannot be directly compared between the two

4.2 The measured modulus of rigidity is termed “apparent”

methods.

since it is the value obtained by measuring the angular

deflection occurring when the specimen is subjected to an

2. Referenced Documents

appliedtorque.Sincethespecimenmaybedeflectedbeyondits

2.1 ASTM Standards:

elastic limit, the calculated value may not represent the true

2

D618 Practice for Conditioning Plastics for Testing

modulus of rigidity within the elastic limit of the material. In

2

D638 Test Method for Tensile Properties of Plastics

addition, the value obtained by this test method will also be

D747 Test Method for Apparent Bending Modulus of

affected by the creep characteristics of the material, since the

2

Plastics by Means of a Cantilever Beam

load application time is arbitrarily fixed. For many materials,

2

D883 Terminology Relating to Plastics

there may be a specification that requires the use of this test

D1053 Test Method for Rubber Property—Stiffening at

method, but with some procedural modifications that take

Low Temperatures: Flexible Polymers and Coated Fab-

precedence when adhering to the specification. Therefore, it is

3

rics

advisabletorefertothatmaterialspecificationbeforeusingthis

D4000 Classification System for Specifying Plastic Mate-

test method. Table 1 in Classification D4000 lists the current

4

rials

ASTM materials standards.

D4066 Classification System for Nylon Injection and Ex-

4.3 This test method is useful for determining the relative

4

trusion Materials

changes in stiffness over a wide range of temperatures.

1 5. Apparatus

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

5.1 Testing Machine—A machine capable of exerting a

Current edition approved April 10, 2002. Published June 2002. Originally

torque sufficient to deflect a test specimen in the range of 5 to

published as D1043–49. Last previous edition D1043–99.

2

Annual Book of ASTM Standards, Vol 08.01.

3

Annual Book of ASTM Standards, Vol 09.01.

4 5

Annual Book of ASTM Standards, Vol 08.02. Annual Book of ASTM Standards, Vol 08.03.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1043–02

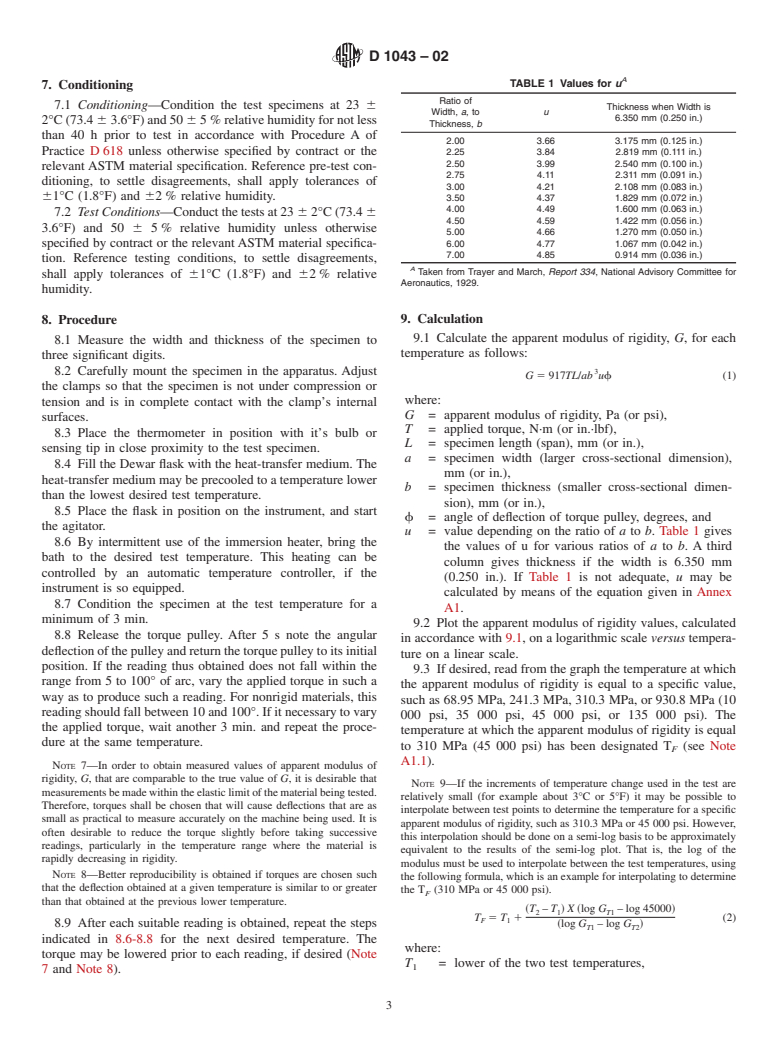

FIG. 2 Test Specimen

has been shown that the liquid does not soften or otherwise

affect the test specimen.

NOTE 5—Amongtheliquidsfoundusefulareacetone,ethanol,butanol,

methanol, normal hexane, silicone oil, and a mixture of methyl phosphate

and water in the ratio of 87 to 13 by volume. For temperatures to−70°C

(−94°F), a mixture of 50 parts ethanol, 30 parts ethylene glycol, and 20

parts water may be found useful.

5.2.5 Refrigeration—Means shall be provided for cooling

the heat-transfer medium. This cooling can be by means of a

refrigeration cooling coil built into

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.