ASTM A609/A609M-91(1997)

(Practice)Standard Practice for Castings, Carbon, Low-Alloy, and Martensitic Stainless Steel, Ultrasonic Examination Thereof

Standard Practice for Castings, Carbon, Low-Alloy, and Martensitic Stainless Steel, Ultrasonic Examination Thereof

SCOPE

1.1 This practice covers the standards and procedures for the pulse-echo ultrasonic examination of heat-treated carbon, low-alloy, and martensitic stainless steel castings by the longitudinal-beam technique.

1.2 This practice is to be used whenever the inquiry, contract, order, or specification states that castings are to be subjected to ultrasonic examination in accordance with Practice A 609/A 609M.

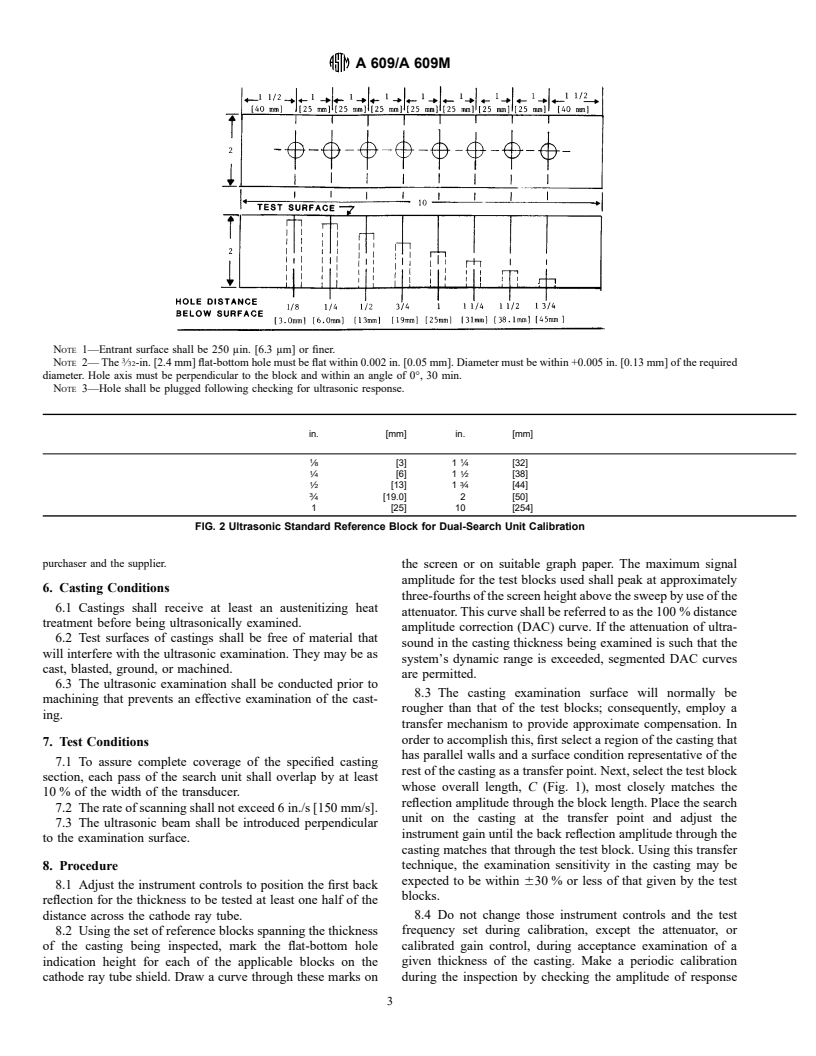

1.3 This practice contains two procedures for ultrasonic inspection of carbon, low-alloy, and martensitic stainless steel castings; that is, Procedure A and Procedure B. Procedure A is the original A 609/A 609M practice and requires calibration using a series of test blocks containing flat bottomed holes. It also provides supplementary requirements for angle beam testing. Procedure B requires calibration using a back wall reflection from a series of solid calibration blocks.

Note 1—Ultrasonic examination and radiography are not directly comparable. This examination technique is intended to complement Guide E 94 in the detection of discontinuities.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this practice.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: A 609/A 609M – 91 (Reapproved 1997) An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for

Castings, Carbon, Low-Alloy, and Martensitic Stainless

1

Steel, Ultrasonic Examination Thereof

This standard is issued under the fixed designation A 609/A 609M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

3

1. Scope able for High-Temperature Service

4

2

E 94 Guide for Radiographic Testing

1.1 This practice covers the standards and procedures for

E 317 Practice for Evaluating Performance Characteristics

the pulse-echo ultrasonic examination of heat-treated carbon,

of Ultrasonic Pulse-Echo Testing Systems Without the Use

low-alloy, and martensitic stainless steel castings by the

4

of Electronic Measurement Instruments

longitudinal-beam technique.

2.2 Other Document:

1.2 This practice is to be used whenever the inquiry,

SNT-TC-1A Recommended Practice for Non-Destructive

contract, order, or specification states that castings are to be

5

Testing Personnel Qualification and Certification

subjected to ultrasonic examination in accordance with Prac-

tice A 609/A 609M.

3. Ordering Information

1.3 This practice contains two procedures for ultrasonic

3.1 The inquiry and order should specify which procedure is

inspection of carbon, low-alloy, and martensitic stainless steel

to be used. If a procedure is not specified, Procedure A shall be

castings, that is, Procedure A and Procedure B. Procedure A is

used.

the original A 609/A 609M practice and requires calibration

3.2 Procedure A—Flat-Bottomed Hole Calibration Proce-

using a series of test blocks containing flat bottomed holes. It

dure:

also provides supplementary requirements for angle beam

3.2.1 When this practice is to be applied to an inquiry,

testing. Procedure B requires calibration using a back wall

contract, or order, the purchaser shall furnish the following

reflection from a series of solid calibration blocks.

information:

NOTE 1—Ultrasonic examination and radiography are not directly

3.2.1.1 Quality levels for the entire casting or portions

comparable. This examination technique is intended to complement Guide

thereof,

E 94 in the detection of discontinuities.

3.2.1.2 Sections of castings requiring longitudinal-beam

1.4 The values stated in either inch-pound units or SI units

examination,

are to be regarded separately as standard. Within the text, the

3.2.1.3 Sections of castings requiring dual element exami-

SI units are shown in brackets. The values stated in each

nation,

system are not exact equivalents; therefore, each system must

3.2.1.4 Sections of castings requiring supplementary exami-

be used independently of the other. Combining values from the

nation, using the angle-beam procedure described in Supple-

two systems may result in nonconformance with this practice.

mentary Requirement S1 in order to achieve more complete

1.5 This standard does not purport to address all of the

examination, and

safety concerns, if any, associated with its use. It is the

3.2.1.5 Any requirements additional to the provisions of this

responsibility of the user of this standard to establish appro-

practice.

priate safety and health practices and determine the applica-

3.3 Procedure B: Back-Wall Reflection Calibration

bility of regulatory limitations prior to use.

Procedure—When this procedure is to be applied to an inquiry,

contract, or order, the purchaser shall designate the quality

2. Referenced Documents

levels for the entire casting or applicable portions.

2.1 ASTM Standards:

A 217/A217M Specification for Steel Castings, Martensitic PROCEDURE A—FLAT-BOTTOMED HOLE

CALIBRATION PROCEDURE

Stainless and Alloy, for Pressure-Containing Parts, Suit-

4. Apparatus

1

This practice is under the jurisdiction of ASTM Committee A-1 on Steel,

4.1 Electronic Apparatus:

Stainless Steel, and Related Alloysand is the direct responsibility of Subcommittee

A01.18on Castings.

Current edition approved Dec. 15, 1991. Published July 1992. Originally

3

published as A 609 – 70. Last previous edition A 609/A 609M – 90.

Annual Book of ASTM Standards, Vol 01.02.

2

4

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

Annual Book of ASTM Standards, Vol 03.03.

5

cation SA-609 of Section II of that Code.

Available from American Society for Nondestructive Testing, 914 Chicago

Ave., Evanston, IL 60202.

1

---------------------- Page: 1 ----------------------

A 609/A 609M

4.1.1 An ultrasonic, pulsed, reflection type o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.