ASTM D613-95

(Test Method)Standard Test Method for Cetane Number of Diesel Fuel Oil

Standard Test Method for Cetane Number of Diesel Fuel Oil

SCOPE

1.1 This test method determines the rating of diesel fuel oil in terms of an arbitrary scale of cetane numbers using a standard single cylinder, four-stroke cycle, variable compression ratio, indirect injected diesel engine.

1.2 The cetane number scale covers the range from zero (0) to 100 but typical testing is in the range of 30 to 65 cetane number.

1.3 The values for operating conditions are stated in SI units and are considered standard. The values in parentheses are the historical inch-pounds units. In addition, the engine measurements continue to be in inch-pounds units because of the extensive and expensive tooling that has been created for these units.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For more specific hazard statements, see .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 613 – 95 An American National Standard

Designation: 41/99

Standard Test Method for

Cetane Number of Diesel Fuel Oil

This standard is issued under the fixed designation D 613; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 542 Practice for Calibration of Laboratory Volumetric

Apparatus

1.1 This test method determines the rating of diesel fuel oil

E 832 Specification for Laboratory Filter Papers

in terms of an arbitrary scale of cetane numbers using a

standard single cylinder, four-stroke cycle, variable compres-

3. Terminology

sion ratio, indirect injected diesel engine.

3.1 Definitions:

1.2 The cetane number scale covers the range from zero (0)

3.1.1 cetane number, n—a measure of the ignition perfor-

to 100 but typical testing is in the range of 30 to 65 cetane

mance of a diesel fuel oil obtained by comparing it to reference

number.

fuels in a standardized engine test. D 4175

1.3 The values for operating conditions are stated in SI units

3.1.1.1 Discussion—In the context of this method, ignition

and are considered standard. The values in parentheses are the

performance is understood to mean the ignition delay of the

historical inch-pounds units. In addition, the engine measure-

fuel as determined in a standard test engine under controlled

ments continue to be in inch-pounds units because of the

conditions of fuel flow rate, injection timing and compression

extensive and expensive tooling that has been created for these

ratio.

units.

3.1.2 compression ratio, n—the ratio of the volume of the

1.4 This standard does not purport to address all of the

combustion chamber including the precombustion chamber

safety concerns, if any, associated with its use. It is the

with the piston at bottom dead center to the comparable volume

responsibility of the user of this standard to establish appro-

with the piston at top dead center.

priate safety and health practices and determine the applica-

3.1.3 ignition delay, n—that period of time, expressed in

bility of regulatory limitations prior to use. For more specific

degrees of crank angle rotation, between the start of fuel

hazard statements, see Note 1, Note 2, Note 4, Note 5, Note 6,

injection and the start of combustion.

Note 7, Note 8, Note 9, and Annex A1.

3.1.4 injection timing (injection advance), n—that time in

2. Referenced Documents the combustion cycle, measured in degrees of crank angle, at

which fuel injection into the combustion chamber is initiated.

2.1 ASTM Standards:

3.2 Definitions of Terms Specific to This Standard:

D 975 Specification for Diesel Fuel Oils

3.2.1 handwheel reading, n—an arbitrary numerical value,

D 1193 Specification for Reagent Water

related to compression ratio, obtained from a micrometer scale

D 2500 Test Method for Cloud Point of Petroleum Oils

that indicates the position of the variable compression plug in

D 4057 Practice for Manual Sampling of Petroleum and

the precombustion chamber of the engine.

Petroleum Products

3.2.2 cetane meter (ignition delay meter), n—the electronic

D 4175 Terminology Relating to Petroleum, Petroleum

instrument which displays injection advance and ignition delay

Products, and Lubricants

5 derived from input pulses of multiple transducers (pickups).

E 1 Specification for ASTM Thermometers

3.2.3 injector opening pressure, n—the fuel pressure that

overcomes the resistance of the spring which normally holds

the nozzle pintle closed, and thus forces the pintle to lift and

This test method is under the jurisdiction of ASTM Committee D-2 on release an injection spray from the nozzle.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

3.2.4 reference pickups, n—transducer(s) mounted over the

D02.01 on Combustion Characteristics.

flywheel of the engine, triggered by a flywheel indicator, used

Current edition approved Sept. 10, 1995. Published November 1995. Originally

to establish a top-dead-center (tdc) reference and a time base

published as D 613 – 41. Last previous edition D 613 – 93.

Annual Book of ASTM Standards, Vol 05.01.

for calibration of the ignition delay meter.

Annual Book of ASTM Standards, Vol 11.01.

Annual Book of ASTM Standards, Vol 05.02.

Annual Book of ASTM Standards, Vol 14.03.

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 613

3.2.5 injector pickup, n—transducer to detect motion of the 5.3 Cetane number is determined at constant speed in a

injector pintle, thereby indicating the beginning of injection. precombustion chamber type compression ignition test engine.

3.2.6 combustion pickup, n—pressure transducer exposed to The relationship of test engine performance to full scale,

cylinder pressure to indicate the start of combustion. variable speed, variable load engines is not completely under-

3.2.7 primary reference fuels, n— n-cetane, heptamethyl stood.

nonane (HMN) and volumetrically proportioned mixtures of 5.4 This test may be used for unconventional fuels such as

these materials which now define the cetane number scale by synthetics, vegetable oils, and the like. However, the relation-

the relationship: ship to the performance of such materials in full scale engines

is not completely understood.

Cetane Number 5 % n2cetane 1 0.15 ~% HMN! (1)

3.2.7.1 Discussion—1—In the context of this method, the 6. Interferences

arbitrary cetane number scale was originally defined as the

6.1 Certain gases and fumes present in the area where the

volume percent of n-cetane in a blend with alpha-

cetane test engine is located may have a measurable effect on

methylnaphthalene (AMN) where n-cetane had an assigned

the cetane number test result.

value of 100 and AMN an assigned value of zero (0). A change

6.2 This test method is not suitable for rating diesel fuel oils

from alpha-methylnaphthalene to heptamethylnonane as the

with fluid properties that interfere with unimpeded gravity flow

low cetane ingredient was made in 1962 to utilize a material of

of fuel to the fuel pump or delivery through the injector nozzle.

better storage stability and availability. Heptamethylnonane

was determined to have a cetane number of 15 based on engine 7. Apparatus

calibration by the ASTM Diesel National Exchange Group,

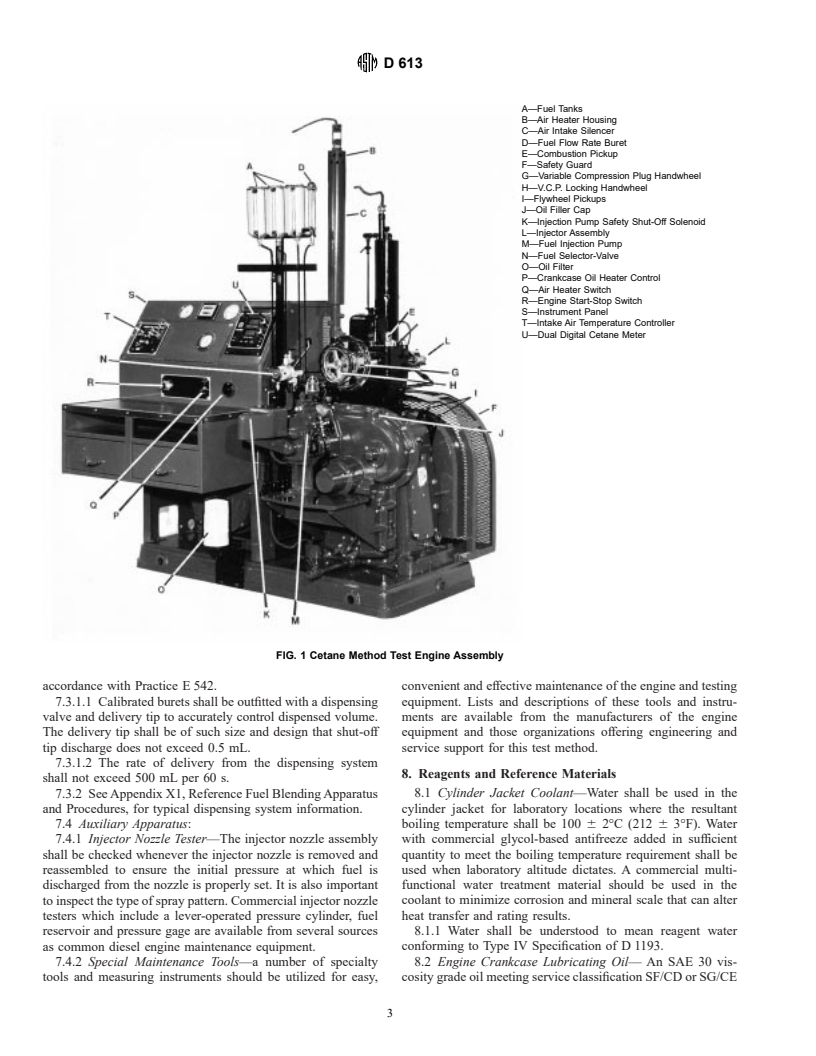

7.1 Engine Equipment —This test method uses a single

using blends of n-cetane and AMN as primary reference fuels.

cylinder engine which consists of a standard crankcase with

3.2.7.2 Discussion—2—In the context of this method, the

fuel pump assembly, a cylinder with separate head assembly of

Diesel National Exchange Group of Subcommittee D02.01 is

the precombustion type, thermal syphon recirculating jacket

composed of petroleum industry, governmental, and indepen-

coolant system, multiple fuel tank system with selector valv-

dent laboratories. It conducts regular monthly exchange sample

ing, injector assembly with specific injector nozzle, electrical

analyses to generate precision data for this engine test standard

controls, and a suitable exhaust pipe. The engine is belt

and calibrates reference materials used by all laboratories.

connected to a special electric power-absorption motor which

3.2.8 secondary reference fuels, n—volumetrically propor-

acts as a motor driver to start the engine and as a means to

tioned blends of two selected hydrocarbon mixtures designated

absorb power at constant speed when combustion is occurring

T Fuel (high cetane) and U Fuel (low cetane) where each

(engine firing). See Fig. 1.

numbered, paired set of T Fuel and U Fuel is calibrated by the

7.1.1 See Annex A2, Engine Equipment Description and

ASTM Diesel National Exchange Group in various combina-

Specifications, for detail and description of all critical, non-

tions by comparison to primary reference fuel blends.

critical and equivalent engine equipment.

3.2.9 check fuels, n—diesel fuel oils calibrated by the 8

7.2 Instrumentation —This test method uses an electronic

ASTM Diesel National Exchange Group which provide a guide

instrument to measure injection and ignition delay timing as

for an individual laboratory to check the cetane rating perfor-

well as conventional thermometry, gages and general purpose

mance of a specific engine unit.

meters.

7.2.1 A Cetane Meter (Ignition Delay Meter) is critical and

4. Summary of Test Method

shall be used for this test method.

4.1 The cetane number of a diesel fuel oil is determined by

7.2.2 See Annex A3, Instrumentation Description and

comparing its combustion characteristics in a test engine with

Specifications, for detail and description of all critical, non-

those for blends of reference fuels of known cetane number

critical and equivalent instrumentation.

under standard operating conditions. This is accomplished

7.3 Reference Fuel Dispensing Equipment—This test

using the bracketing handwheel procedure which varies the

method requires repeated volumetric blending of two second-

compression ratio (handwheel reading) for the sample and each

ary reference fuel materials on an as-needed basis. Measure-

of two bracketing reference fuels to obtain a specific ignition

ment shall be performed accurately because rating error is

delay permitting interpolation of cetane number in terms of

proportional to blending error. A set of two burets or accurate

handwheel reading.

volumetric ware shall be used and the desired batch quantity

5. Significance and Use

shall be collected in a glass, metal or selected plastic container

and thoroughly mixed before being introduced to the engine

5.1 The cetane number provides a measure of the ignition

fuel system.

characteristics of diesel fuel oil in compression ignition en-

7.3.1 Calibrated burets or volumetric ware having a capac-

gines.

ity of 400 or 500 mL and a maximum volumetric tolerance of

5.2 This test is used by engine manufacturers, petroleum

6 0.2 % shall be used. Calibration shall be verified in

refiners and marketers, and in commerce as a primary specifi-

cation measurement related to matching of fuels and engines.

Engine equipment and instrumentation are available from the single source

Bylaws governing ASTM Subcommittee D02.01 on Combustion Characteris- manufacturer, Waukesha Engine Division, Dresser Industries, Inc., 1000 West St.

tics are available from the Subcommittee D02.01 on Combustion Characteristics Paul Avenue, Waukesha, WI 53188, FAX 414-549-2960 Waukesha Engine Division

Chairman or by contacting ASTM Headquarters for address reference. also has authorized sales and service organizations in selected geographical areas.

D 613

A—Fuel Tanks

B—Air Heater Housing

C—Air Intake Silencer

D—Fuel Flow Rate Buret

E—Combustion Pickup

F—Safety Guard

G—Variable Compression Plug Handwheel

H—V.C.P. Locking Handwheel

I—Flywheel Pickups

J—Oil Filler Cap

K—Injection Pump Safety Shut-Off Solenoid

L—Injector Assembly

M—Fuel Injection Pump

N—Fuel Selector-Valve

O—Oil Filter

P—Crankcase Oil Heater Control

Q—Air Heater Switch

R—Engine Start-Stop Switch

S—Instrument Panel

T—Intake Air Temperature Controller

U—Dual Digital Cetane Meter

FIG. 1 Cetane Method Test Engine Assembly

accordance with Practice E 542. convenient and effective maintenance of the engine and testing

7.3.1.1 Calibrated burets shall be outfitted with a dispensing equipment. Lists and descriptions of these tools and instru-

valve and delivery tip to accurately control dispensed volume. ments are available from the manufacturers of the engine

The delivery tip shall be of such size and design that shut-off equipment and those organizations offering engineering and

tip discharge does not exceed 0.5 mL. service support for this test method.

7.3.1.2 The rate of delivery from the dispensing system

8. Reagents and Reference Materials

shall not exceed 500 mL per 60 s.

7.3.2 See Appendix X1, Reference Fuel Blending Apparatus 8.1 Cylinder Jacket Coolant—Water shall be used in the

and Procedures, for typical dispensing system information. cylinder jacket for laboratory locations where the resultant

boiling temperature shall be 100 6 2°C (212 6 3°F). Water

7.4 Auxiliary Apparatus:

7.4.1 Injector Nozzle Tester—The injector nozzle assembly with commercial glycol-based antifreeze added in sufficient

quantity to meet the boiling temperature requirement shall be

shall be checked whenever the injector nozzle is removed and

reassembled to ensure the initial pressure at which fuel is used when laboratory altitude dictates. A commercial multi-

discharged from the nozzle is properly set. It is also important functional water treatment material should be used in the

to inspect the type of spray pattern. Commercial injector nozzle coolant to minimize corrosion and mineral scale that can alter

testers which include a lever-operated pressure cylinder, fuel heat transfer and rating results.

reservoir and pressure gage are available from several sources 8.1.1 Water shall be understood to mean reagent water

as common diesel engine maintenance equipment. conforming to Type IV Specification of D 1193.

7.4.2 Special Maintenance Tools—a number of specialty 8.2 Engine Crankcase Lubricating Oil— An SAE 30 vis-

tools and measuring instruments should be utilized for easy, cosity grade oil meeting service classification SF/CD or SG/CE

D 613

shall be used. It shall contain a detergent additive and have a 9.3 Filtration—Samples may be filtered through a Type I,

kinematic viscosity of 9.3 to 12.5 cSt (mm per s) at 100°C Class A filter paper at room temperature and pressure before

(212°F) and a viscosity index of not less than 85. Oils engine testing. See Specification E 832.

containing viscosity index improvers shall not be used. Multi-

10. Basic Engine and Instrument Settings and Standard

graded oils shall not be used.

Operating Conditions

8.3 Primary Reference Fuels:

10.1 Installation of Engine Equipment and Instrumentation:

NOTE 1—Warning: Primary Reference Fuel—Combustible. Vapor

Installation of the engine and instrumentation requires place-

Harmful. See Annex A1.

ment of the engine on a suitable foundation and hook-up of all

8.3.1 n-Cetane (n-hexadecane) with a minimum purity of

utilities. Engineering and technical support for this function is

99.0 % as determined by chromatographic analysis shall be

required, and the user shall be responsible to comply with all

used as the designated 100 cetane number component.

local and national codes and installation requirements.

8.3.2 Heptamethylnonane—(2,2,4,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.