ASTM D1505-18

(Test Method)Standard Test Method for Density of Plastics by the Density-Gradient Technique

Standard Test Method for Density of Plastics by the Density-Gradient Technique

SIGNIFICANCE AND USE

4.1 The density of a solid is a conveniently measurable property which is frequently useful as a means of following physical changes in a sample, as an indication of uniformity among samples, and a means of identification.

4.2 This test method is designed to yield results accurate to better than 0.05 %.

Note 3: Where accuracy of 0.05 % or better is desired, the gradient tube shall be constructed so that vertical distances of 1 mm shall represent density differences no greater than 0.0001 g/cm.3 The sensitivity of the column is then 0.0001 g/cm3·mm. Where less accuracy is needed, the gradient tube shall be constructed to any required sensitivity.

SCOPE

1.1 This test method covers the determination of the density of solid plastics.

1.2 This test method is based on observing the level to which a test specimen sinks in a liquid column exhibiting a density gradient, in comparison with standards of known density.

Note 1: This test method is equivalent to ISO 1183-2.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1505 − 18

Standard Test Method for

1

Density of Plastics by the Density-Gradient Technique

This standard is issued under the fixed designation D1505; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* E2935 Practice for Conducting Equivalence Testing in

Laboratory Applications

1.1 This test method covers the determination of the density

2.2 ISO Standard:

of solid plastics.

ISO 1183-2 Methods for Determining the Density and

1.2 This test method is based on observing the level to

3

Relative Density of Noncellular Plastics

which a test specimen sinks in a liquid column exhibiting a

density gradient, in comparison with standards of known

3. Terminology

density.

3.1 Refer to Terminology D883 for definitions of other

NOTE 1—This test method is equivalent to ISO 1183-2.

terms relating to this test method.

1.3 The values stated in SI units are to be regarded as the

3.2 Definitions:

standard.

3.2.1 density of plastics—the weight per unit volume of

1.4 This standard does not purport to address all of the

material at 23°C, expressed as follows:

safety concerns, if any, associated with its use. It is the

23C 3

D , g/cm (1)

responsibility of the user of this standard to establish appro-

NOTE 2—Density is to be distinguished from specific gravity, which is

priate safety, health, and environmental practices and deter-

theratiooftheweightofagivenvolumeofthematerialtothatofanequal

mine the applicability of regulatory limitations prior to use. volume of water at a stated temperature.

1.5 This international standard was developed in accor-

4. Significance and Use

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

4.1 The density of a solid is a conveniently measurable

Development of International Standards, Guides and Recom-

property which is frequently useful as a means of following

mendations issued by the World Trade Organization Technical

physical changes in a sample, as an indication of uniformity

Barriers to Trade (TBT) Committee.

among samples, and a means of identification.

4.2 This test method is designed to yield results accurate to

2. Referenced Documents

better than 0.05 %.

2

2.1 ASTM Standards:

NOTE 3—Where accuracy of 0.05 % or better is desired, the gradient

D883 Terminology Relating to Plastics

tube shall be constructed so that vertical distances of 1 mm shall represent

D2839 Practice for Use of a Melt Index Strand for Deter-

3

density differences no greater than 0.0001 g/cm. The sensitivity of the

3

mining Density of Polyethylene

column is then 0.0001 g/cm ·mm. Where less accuracy is needed, the

D4703 Practice for Compression Molding Thermoplastic gradient tube shall be constructed to any required sensitivity.

Materials into Test Specimens, Plaques, or Sheets

5. Apparatus

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

5.1 Density-Gradient Tube—A suitable graduate with

4

ground-glass stopper.

5.2 Constant-Temperature Bath—A means of controlling

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

the temperature of the liquid in the tube at 23 6 0.1°C. A

and is the direct responsibility of Subcommittee D20.70 on Analytical Methods

thermostatted water jacket around the tube is a satisfactory and

(Section D20.70.01).

Current edition approved April 1, 2018. Published April 2018. Originally

convenient method of achieving this.

approved in 1957. Last previous edition approved in 2010 as D1505 - 10. DOI:

10.1520/D1505-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Standards volume information, refer to the standard’s Document Summary page on 4th Floor, New York, NY 10036, http://www.ansi.org.

4

the ASTM website. Tubes similar to those described in Refs (1) and (2) may also be used.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1505 − 18

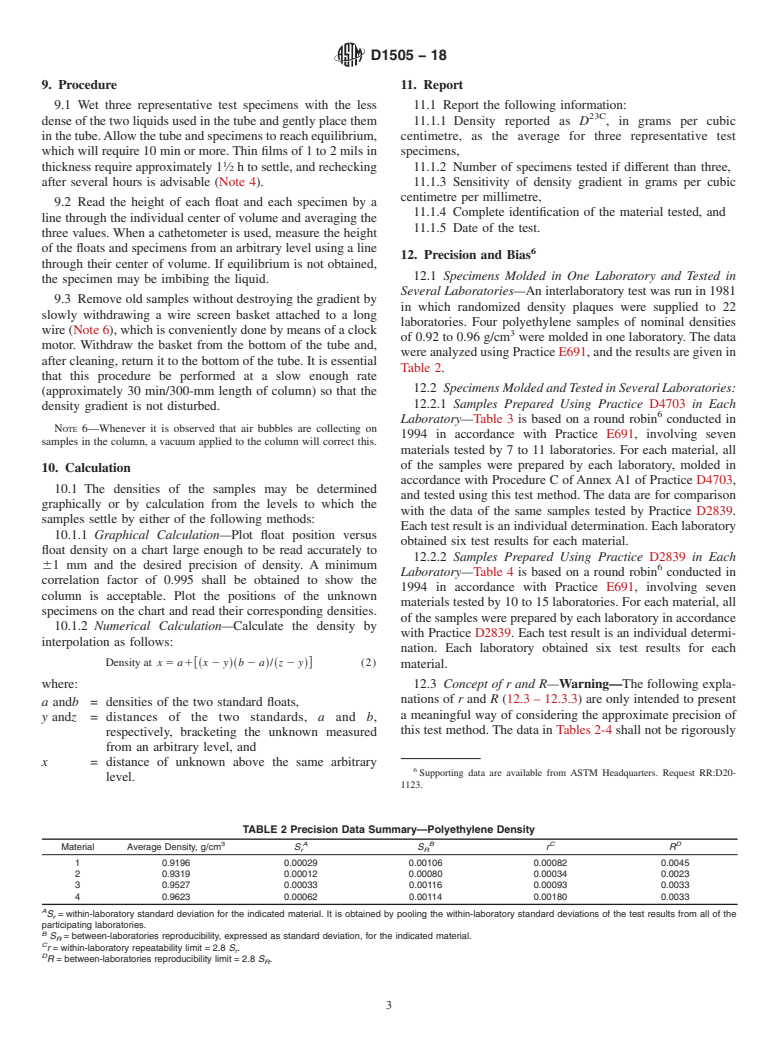

5.3 Glass Floats—A number of calibrated glass floats cov- 600 mL) of the liquids to be used in the gradie

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1505 − 10 D1505 − 18

Standard Test Method for

1

Density of Plastics by the Density-Gradient Technique

This standard is issued under the fixed designation D1505; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This test method covers the determination of the density of solid plastics.

1.2 This test method is based on observing the level to which a test specimen sinks in a liquid column exhibiting a density

gradient, in comparison with standards of known density.

NOTE 1—This test method is equivalent to ISO 1183-2.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

D2839 Practice for Use of a Melt Index Strand for Determining Density of Polyethylene

D4703 Practice for Compression Molding Thermoplastic Materials into Test Specimens, Plaques, or Sheets

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E2935 Practice for Conducting Equivalence Testing in Laboratory Applications

2.2 ISO Standard:

3

ISO 1183-2 Methods for Determining the Density and Relative Density of Noncellular Plastics

3. Terminology

3.1 Refer to Terminology D883 for definitions of other terms relating to this test method.

3.2 Definitions:

3.2.1 density of plastics—the weight per unit volume of material at 23°C, expressed as follows:

23C 3

D , g/cm (1)

NOTE 2—Density is to be distinguished from specific gravity, which is the ratio of the weight of a given volume of the material to that of an equal

volume of water at a stated temperature.

4. Significance and Use

4.1 The density of a solid is a conveniently measurable property which is frequently useful as a means of following physical

changes in a sample, as an indication of uniformity among samples, and a means of identification.

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.70 on Analytical Methods (Section

D20.70.01).

Current edition approved July 1, 2010April 1, 2018. Published September 2010April 2018. Originally approved in 1957. Last previous edition approved in 20032010 as

D1505 - 03.D1505 - 10. DOI: 10.1520/D1505-10.10.1520/D1505-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1505 − 18

4.2 This test method is designed to yield results accurate to better than 0.05 %.

NOTE 3—Where accuracy of 0.05 % or better is desired, the gradient tube shall be constructed so that vertical distances of 1 mm shall represent density

3 3

differences no greater than 0.0001 g/cm. The sensitivity of the column is then 0.0001 g/cm ·mm. Where less accuracy is needed, the gradient tube shall

be constructed to any required sensitivity.

5. Apparatus

4

5.1 Density-Gradient Tube—A suitable graduate with ground-glass stopper.

5.2 Constant-Temperature Bath—A means of controlling the temperature of the liquid in the tube at 23 6 0.1°C. A thermostatted

water jacket around the tube is a satisfactory and c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.