ASTM E338-91(1997)

(Test Method)Standard Test Method of Sharp-Notch Tension Testing of High-Strength Sheet Materials

Standard Test Method of Sharp-Notch Tension Testing of High-Strength Sheet Materials

SCOPE

1.1 This test method covers the determination of a comparative measure of the resistance of sheet materials to unstable fracture originating from a very sharp stress-concentrator or crack. It relates specifically to fracture under continuously increasing load and excludes conditions of loading that produce creep or fatigue. The quantity determined is the sharp-notch strength of a specimen of particular dimensions, and this value depends upon these dimensions as well as the characteristics of the material. The sharp-notch strength:yield strength ratio is also determined.

1.2 This test method is restricted to one specimen width which is generally suitable for evaluation of high-strength materials (yield strength-to-density ratio above ? 700 000 psi/lb[dot]in. or (18 kgf/mm )/(g/cm )). The test will discriminate differences in resistance to unstable fracture when the sharp-notch strength is less than the tensile yield strength. The discrimination increases as the ratio of the notch strength to the yield strength decreases.

1.3 This test method is restricted to sheet materials not less than 0.64 mm (0.025 in.) and not exceeding 6 mm (0.25 in.) in thickness. Since the notch strength may depend on the sheet thickness, comparison of various material conditions must be based on tests of specimens having the same nominal thickness.

1.4 The sharp-notch strength may depend strongly upon temperature within a certain range depending upon the characteristics of the material. The test method is suitable for tests at any appropriate temperature. However, comparisons of various material conditions must be based on tests conducted at the same temperature. Note 1-Further information on background and need for this type of test is given in the first report by the ASTM Committee on Fracture Testing of High-Strength Sheet Materials. Note 2-The values stated in SI (metric) units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 338 – 91 (Reapproved 1997)

Standard Test Method of

Sharp-Notch Tension Testing of High-Strength Sheet

Materials

This standard is issued under the fixed designation E 338; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the determination of a compara-

responsibility of the user of this standard to establish appro-

tive measure of the resistance of sheet materials to unstable

priate safety and health practices and determine the applica-

fracture originating from a very sharp stress-concentrator or

bility of regulatory limitations prior to use.

crack. It relates specifically to fracture under continuously

increasing load and excludes conditions of loading that pro-

2. Referenced Documents

duce creep or fatigue. The quantity determined is the sharp-

2.1 ASTM Standards:

notch strength of a specimen of particular dimensions, and this

E 4 Practices for Force Verification of Testing Machines

value depends upon these dimensions as well as the character-

E 8 Test Methods for Tension Test of Metallic Materials

istics of the material. The sharp-notch strength:yield strength

E 602 Test Method for Sharp-Notch Tension Testing with

ratio is also determined.

Cylindrical Specimens

1.2 This test method is restricted to one specimen width

E 616 Terminology Relating to Fracture Testing

which is generally suitable for evaluation of high-strength

materials (yield strength-to-density ratio above 700 000 psi/

3. Terminology

−3 2 3

lb·in. or (18 kgf/mm )/(g/cm )). The test will discriminate

3.1 Definitions:

differences in resistance to unstable fracture when the sharp-

−2

3.1.1 crack strength, s [FL ]—the maximum value of the

c

notch strength is less than the tensile yield strength. The

nominal (net-section) stress that a cracked specimen is capable

discrimination increases as the ratio of the notch strength to the

of sustaining.

yield strength decreases.

3.1.1.1 Discussion—See definition of nominal (net-

1.3 This test method is restricted to sheet materials not less

section) stress in Terminology E 616.

than 0.64 mm (0.025 in.) and not exceeding 6 mm (0.25 in.) in

3.1.1.2 Discussion—Crack strength is calculated on the

thickness. Since the notch strength may depend on the sheet

basis of the maximum load and the original minimum cross-

thickness, comparison of various material conditions must be

sectional area (net cross section or ligament). Thus, it takes into

based on tests of specimens having the same nominal thick-

account the original size of the crack, but ignores any crack

ness.

extension that may occur during the test.

1.4 The sharp-notch strength may depend strongly upon

3.1.1.3 Discussion—Crack strength is analogous to the

temperature within a certain range depending upon the char-

ultimate tensile strength, as it is based on the ratio of the

acteristics of the material. The test method is suitable for tests

maximum load to the minimum cross-sectional area of the

at any appropriate temperature. However, comparisons of

specimen at the start of the test.

various material conditions must be based on tests conducted at

−2

3.1.2 sharp-notch strength, s [FL ]—the maximum nomi-

s

the same temperature.

nal (net-section) stress that a sharply notched specimen is

NOTE 1—Further information on background and need for this type of

capable of sustaining.

test is given in the first report by the ASTM Committee on Fracture

3.1.2.1 Discussion—See definition of nominal (net-

Testing of High-Strength Sheet Materials.

section) stress in Terminology E 616.

NOTE 2—The values stated in SI (metric) units are to be regarded as the

3.1.2.2 Discussion—Values of sharp-notch strength may

standard.

depend on notch and specimen configuration as these affect the

net cross section and the elastic stress concentration.

This method is under the jurisdiction of ASTM Committee E-8 on Fatigue and

3.1.2.3 Discussion—The tension specimens used in Test

Fracture and is the direct responsibility of Subcommittee E08.02 on Standards and

Method E 602 and this test method have notch root radii that

Terminology.

Current edition approved Aug. 15, 1991. Published October 1991. Originally

e1

published as E 338 – 67. Last previous edition E 338 – 81(86) .

“Fracture Testing of High-Strength Sheet Materials,” ASTM Bulletin, ASTBA,

No. 243, 1960, pp. 29–40; ibid., No. 244, 1960, pp. 18–28. Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 338

approach the limit of machining capability. For these speci- 5. Apparatus

mens, the radius is believed to be small enough that any

5.1 The test shall be conducted with a tension testing

smaller radius that is obtainable by standard machining meth-

machine that conforms to the requirements of Practices E 4.

ods would not produce changes, in notch strength, that are

5.2 The devices for transmitting load to the specimen shall

significant from an engineering viewpoint.

be such that the major axis of the specimen coincides with the

3.1.2.4 Discussion—In these test methods, the notch root

load axis. A satisfactory arrangement incorporates clevises

radii are very small (approaching the limit for machining

carrying hardened pins which pass through holes in the ends of

capability), and values of sharp-notch strength may depend on the specimen, the diameter of the pins being only slightly

notch root radius. See definition of notch tensile strength in

smaller than that of the holes. Spacing washers of the necessary

Terminology E 616. thickness shall be used to center the specimen in the clevises.

A typical arrangement is shown in Fig. 1.

4. Significance and Use

4.1 The test method provides a comparative measure of the

resistance of sheet materials to unstable fracture originating

from the presence of cracks or crack-like stress concentrators.

It is not intended to provide an absolute measure of resistance

to crack propagation which might be used in calculations of the

strength of structures. However, it can serve the following

purposes:

4.1.1 In research and development of materials, to study the

effects of the variables of composition, processing, heat-

treatment, etc.;

4.1.2 In service evaluation, to compare the relative crack-

propagation resistance of a number of materials which are

otherwise equally suitable for an application, or to eliminate

materials when an arbitrary minimum acceptable sharp-notch

strength can be established on the basis of service performance

correlation, or some other adequate basis;

4.1.3 For specifications of acceptance and manufacturing

quality control when there is a sound basis for establishing a

FIG. 1 Specimen Loading Clevis with Hardened Pin

minimum acceptable sharp-notch strength. Detailed discussion

of the basis for setting a minimum in a particular case is

5.3 Temperature Control—For the tests at other than room

beyond the scope of this method.

temperature, any suitable means may be used to heat or cool

4.2 The sharp-notch strength may decrease rapidly through

the specimen and to maintain a uniform temperature over the

a narrow range of decreasing temperature. This temperature

region that includes the notch or crack. The ability of the

range and the rate of decrease depend on the material and its

equipment to provide a region of uniform temperature shall be

thickness. The temperature of the specimen during each test

established by measurements of the temperature at positions on

shall therefore be controlled and recorded. Tests shall be

both faces of a specimen as shown in Fig. 2. The temperature

conducted throughout the range of expected service tempera-

surveys shall be conducted either at each temperature level at

tures to ascertain the relation between notch strength and

which tests are to be made, or at a series of temperature levels

temperature. Care shall be taken that the lowest and highest

at intervals of 30°C (50°F) over the range of test temperatures.

anticipated service temperatures are included.

1 1

The test temperature shall be held within 61 ⁄2°C (62 ⁄2 °F)

4.3 Limited results suggest that the sharp-notch strengths of

during the course of the test. At the test temperature the

stable high-strength steels are not appreciably sensitive to rate

difference between the indicated temperatures at any two of the

of loading within the range of loading rates normally used in

four thermocouple positions shall not exceed 3°C (5°F).

conventional tension tests. Where very low or high rates of

loading are expected in service, the effect of loading rate NOTE 3—A convenient means of heating or cooling flat specimens

consists of a pair of flat copper or brass plates which contact the surfaces

should be investigated using special procedures that are beyond

of the specimen. The plates are fitted with heating or cooling devices

the scope of this method.

designed to maintain uniformity of temperature of the contact surfaces.

4.4 The precision of sharp-notch strength measurement

Thermocouples may be permanently incorporated with their junctions at

should be equivalent to that of the ordinary tensile strength of

the contact surfaces. Such devices have been found convenient and

a sheet specimen since both depend upon measurements of

reliable for temperatures from that of liquid nitrogen to at least 330°C

(600°F). The use of liquid baths for heating specimens shall be avoided

load and of dimensions of comparable magnitude. However,

unless it can be established that the liquid has no effect on the sharp-notch

the sharp-notch strength is more sensitive to local flaws than

strength of the material.

the tensile strength and normally shows more scatter. The

influence of this scatter should be reduced by testing duplicate

specimens and averaging the results. Srawley, J. E., and Beachem, C. D., NRL Report 5127, NRLRA, April 9, 1958.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 338

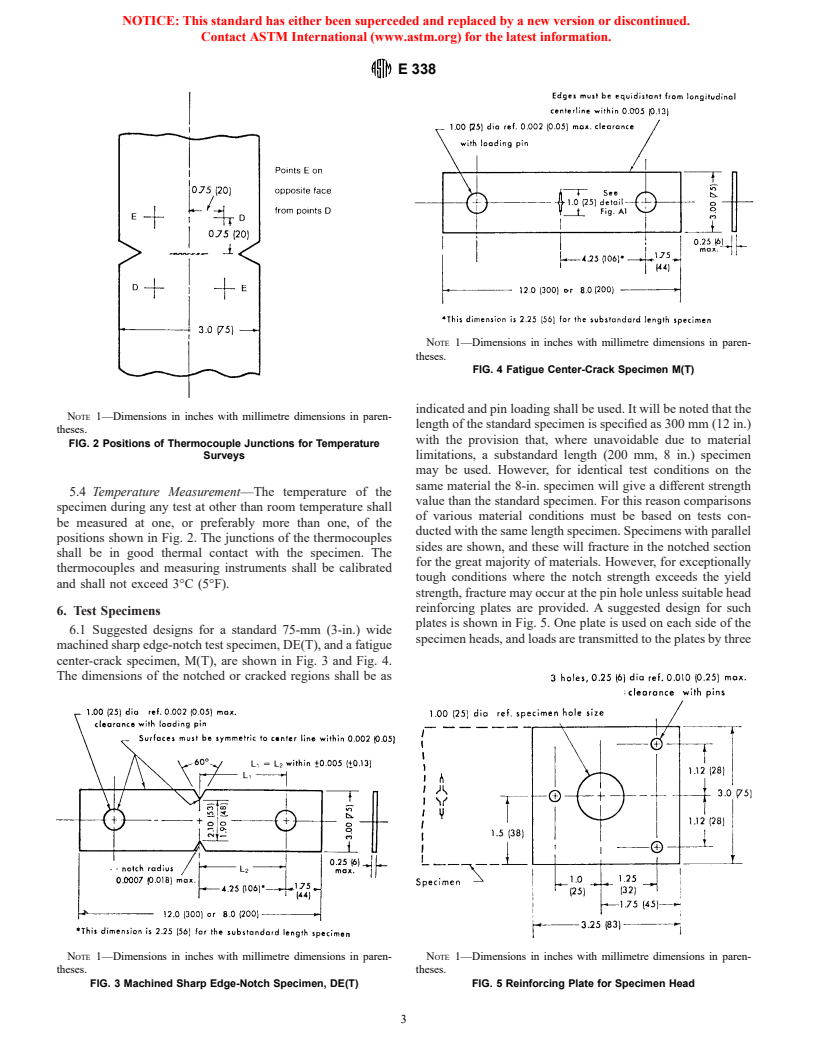

NOTE 1—Dimensions in inches with millimetre dimensions in paren-

theses.

FIG. 4 Fatigue Center-Crack Specimen M(T)

indicated and pin loading shall be used. It will be noted that the

NOTE 1—Dimensions in inches with millimetre dimensions in paren-

length of the standard specimen is specified as 300 mm (12 in.)

theses.

with the provision that, where unavoidable due to material

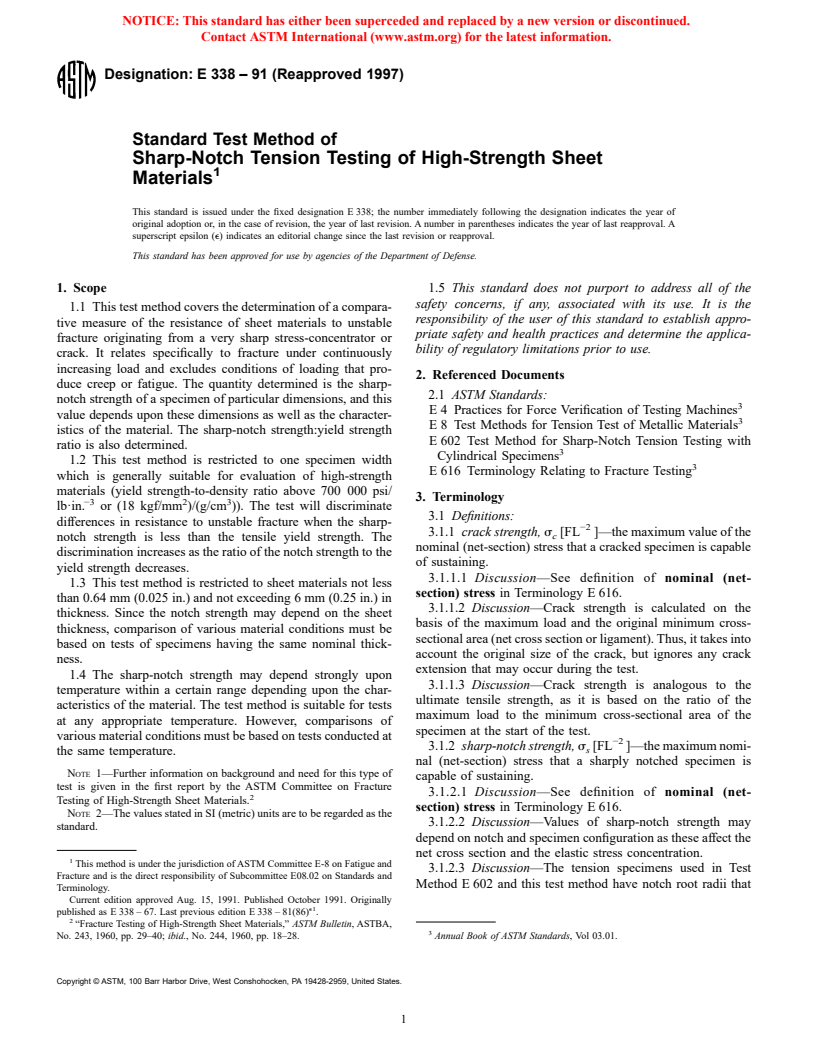

FIG. 2 Positions of Thermocouple Junctions for Temperature

Surveys limitations, a substandard length (200 mm, 8 in.) specimen

may be used. However, for identical test conditions on the

same material the 8-in. specimen will give a different strength

5.4 Temperature Measurement—The temperature of the

value than the standard specimen. For this reason comparisons

specimen during any test at other than room temperature shall

of various material conditions must be based on tests con-

be measured at one, or preferably more than one, of the

ducted with the same length specimen. Specimens with parallel

positions shown in Fig. 2. The junctions of the thermocouples

sides are shown, and these will fracture in the notched section

shall be in good thermal contact with the specimen. The

for the great majority of materials. However, for exceptionally

thermocouples and measuring instruments shall be calibrated

tough conditions where the notch strength exceeds the yield

and shall not exceed 3°C (5°F).

strength, fracture may occur at the pin hole unless suitable head

reinforcing plates are provided. A suggested design for such

6. Test Specimens

plates is shown in Fig. 5. One plate is used on each side of the

6.1 Suggested designs for a standard 75-mm (3-in.) wide

specimen heads, and loads are transmitted to the plates by three

machined sharp edge-notch test specimen, DE(T), and a fatigue

center-crack specimen, M(T), are shown in Fig. 3 and Fig. 4.

The dimensions of the notched or cracked regions shall be as

NOTE 1—Dimensions in inches with millimetre dimensions in paren- NOTE 1—Dimensions in inches with millimetre dimensions in paren-

theses. theses.

FIG. 3 Machined Sharp Edge-Notch Specimen, DE(T) FIG. 5 Reinforcing Plate for Specimen Head

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 338

hardened 6-mm ( ⁄4-in.) diameter pins having a length that will 7.4 Fracture Appearance—The appearance of the fracture

permit them to enter the slot in the loading clevises (see Fig. 1). is valuable subsidiary information and shall be briefly noted for

If the plates are 3 mm ( ⁄8 in.) thick and made of a material each specimen. One common type of fracture is shown in Fig.

having a 1380-MPa (200 000-psi) minimum yield strength, 6(a). This consists of a central flat band, transverse to the

they may be used in any test covered by this method. specimen axis, and bordered by relatively narrow oblique

6.2 The sharpness of the machined notches is a critical bands. If the oblique bands are fairly uniform, measure the

feature of the sharp edge-notched specimen, DE(T), of Fig. 3 average width, b, of the transverse band and record the ratio

and special care is required to prepare them. Finish machining (B − b)/B as the proportion of oblique fracture per unit

of the notch may be completed either before or after final heat thickness, or oblique fraction. In the case of test specimen

treatment. For each specimen the notch root radii and notch DE(T), the measurement b shall be at a point within the middle

location with respect to the pin-hole centers shall be measured third of the specimen width. For specimen M(T), make

prior to testing, and specimens that do not meet the require- measurements on each side of the center slot at points not

ments of Fig. 3 shall be discarded or reworked. closer than one plate thickness to the edge nor farther than 8

6.3 Center-cracked specimens having high notch acuity mm ( ⁄16in.) from the edge. Average these measurements to

have been prepared by machining with sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.