ASTM F51-00(2007)

(Test Method)Standard Test Method for Sizing and Counting Particulate Contaminant In and On Clean Room Garments

Standard Test Method for Sizing and Counting Particulate Contaminant In and On Clean Room Garments

SIGNIFICANCE AND USE

The test method for particulate sizing and numbers on garments is nondestructive and may be used to evaluate the contamination levels of fibers and particles on and in clean room garments. The test may be used for evaluating the cleanliness levels of new or newly cleaned garments. It also may be used to evaluate the extent of fiber and particulate contamination on garments that have been worn, if necessary. For this application, it is necessary to sample representative areas of the garment fabric.

SCOPE

1.1 This test method covers the determination of detachable particulate contaminant 5 m or larger, in and on the fabric of clean room garments.

1.2 This test method does not apply to nonporous fabrics such as Tyvek or Gortex. It only applies to fabrics that are porous such as cotton or polyester.

1.3 The values stated in SI units are to be regarded as the standard. The inch-pound values given in parentheses are for information only.

1.4 This test method provides not only the traditional optical microscopic analysis but also a size distribution and surface obscuration analysis for particles on a fine-textured membrane filter or in a tape lift sample. It utilizes transmitted illumination to render all particles darker than the background for gray level detection. Particles collected on opaque plates must be transferred to a suitable membrane filter.

This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F51 − 00(Reapproved 2007)

Standard Test Method for

Sizing and Counting Particulate Contaminant In and On

1

Clean Room Garments

ThisstandardisissuedunderthefixeddesignationF51;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Institute of Environmental Sciences and Technology

3

(IEST) Document:

1.1 Thistestmethodcoversthedeterminationofdetachable

IEST-RP-CC003.2, Garment System Considerations for

particulate contaminant 5 µm or larger, in and on the fabric of

Cleanrooms and Other Controlled Environments

clean room garments.

1.2 This test method does not apply to nonporous fabrics

3. Terminology

such as Tyvek® or Gortex®. It only applies to fabrics that are

3.1 Definitions:

porous such as cotton or polyester.

3.1.1 fiber, n—particle longer than 100 µm and with a

1.3 The values stated in SI units are to be regarded as the

length-to-width ratio exceeding 10:1.

standard. The inch-pound values given in parentheses are for -6

3.1.2 micrometre (µm), n—SIunitoflengthwhichis10 of

information only.

a metre or approximately 0.00004 in.

1.4 Thistestmethodprovidesnotonlythetraditionaloptical

3.1.3 particle size (L) (µm)—majorprojecteddimensionofa

microscopic analysis but also a size distribution and surface

particle.

obscuration analysis for particles on a fine-textured membrane

filterorinatapeliftsample.Itutilizestransmittedillumination

4. Summary of Test Method

torenderallparticlesdarkerthanthebackgroundforgraylevel

2

4.1 Filtered air is drawn through five designated 0.01-m

detection. Particles collected on opaque plates must be trans-

2 2

(1.5-in. or approximately 0.01-ft ) areas of a single thickness

ferred to a suitable membrane filter.

of the garment fabric at a rate of 14 L/min (0.5 cfm) for a

1.5 This standard may involve hazardous materials,

period of 1 min for each area.

operations, and equipment. This standard does not purport to

4.2 The air drawn through the garment subsequently passes

address all of the safety concerns, if any, associated with its

through a membrane filter disk, impinging the entrained

use. It is the responsibility of the user of this standard to

particles upon the filter surface.

establish appropriate safety and health practices and deter-

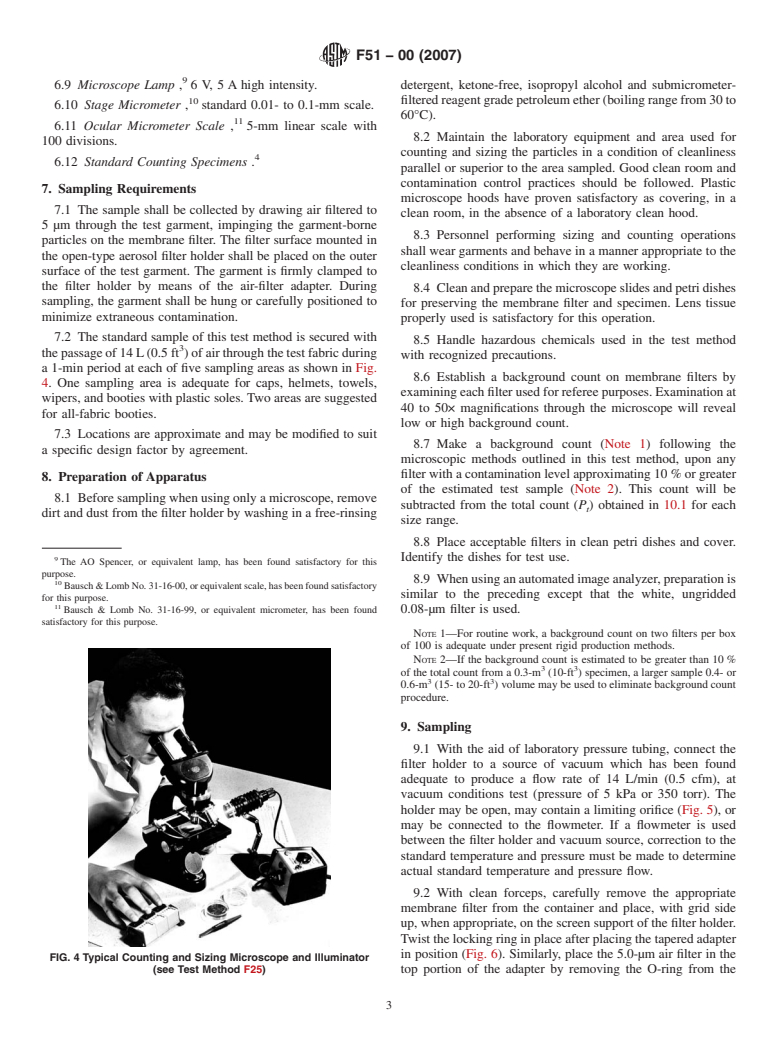

4.3 The filter disk is then examined microscopically for

mine the applicability of regulatory limitations prior to use.

particles removed from the garment.

2. Referenced Documents

4.4 For particles larger than 5 µm, use optical analysis. For

2

2.1 ASTM Standards: particles smaller than 5 µm, use automated image analysis.

E1216Practice for Sampling for Particulate Contamination

4.5 Cleaning and counting techniques are in accordance

by Tape Lift

with those established in Section 10.

F25Test Method for Sizing and CountingAirborne Particu-

late Contamination in Cleanrooms and Other Dust-

5. Significance and Use

Controlled Areas

5.1 The test method for particulate sizing and numbers on

garments is nondestructive and may be used to evaluate the

contamination levels of fibers and particles on and in clean

1

This test method is under the jurisdiction ofASTM Committee E21 on Space

room garments. The test may be used for evaluating the

SimulationandApplicationsofSpaceTechnologyandisthedirectresponsibilityof

Subcommittee E21.05 on Contamination. cleanliness levels of new or newly cleaned garments. It also

Current edition approved April 1, 2007. Published April 2007. Originally

may be used to evaluate the extent of fiber and particulate

´1

approvedin1965.Lastpreviouseditionapprovedin2002asF51-00(2002) .DOI:

contamination on garments that have been worn, if necessary.

10.1520/F0051-00R07.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standardsvolume information,referto thestandard’sDocumentSummary page on Available from IEST, 940 E. Northwest Highway, Mount Prospect, IL 60056.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F51 − 00 (2007)

For this application, it is necessary to sample representative

areas of the garment fabric.

6. Apparatus

4

6.1 Filter Assembly and Adapter , see Fig. 1and Fig. 2.

6.1.1 Filter Holder, aerosol open type having an effective

2

filter area of 960 6 25 mm .

6.2 Vacuum Pump or Aspirator, capable of operating at a

pressure of 7 kPa (500 torr) with a flow rate of 14 L/min (0.5

cfm).

4

6.3 Flowmeter or Orifice, calibratedandhavingacapacity

inexcessof14L/min(0.5cfm),oralimitingorificecalibrated

withthepump,filter

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.