ASTM C1223-09(2018)

(Test Method)Standard Test Method for Testing of Glass Exudation from AZS Fusion-Cast Refractories

Standard Test Method for Testing of Glass Exudation from AZS Fusion-Cast Refractories

SIGNIFICANCE AND USE

3.1 This test method was developed for use both by manufacturers as a process control tool for the production of AZS fusion-cast refractories, and by glass manufacturers in the selection of refractories and design of glass-melting furnaces.

3.2 The results may be considered as representative of the potential for an AZS refractory (specifically, in the tested region) to contribute to glass defect formation during the furnace production operation.

3.3 The procedures and results may be applied to other refractory types or applications (that is, reheat furnace skid rail brick) in which glass exudation is considered to be important.

SCOPE

1.1 This test method covers a procedure for causing the exudation of a glassy phase to the surface of fusion-cast specimens by subjecting them to temperatures corresponding to glass furnace operating temperatures.

1.2 This test method covers a procedure for measuring the exudate as the percent of volume increase of the specimen after cooling.

1.3 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3.1 Exception—The balance required for this test method uses only SI units (Section 6).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1223 − 09 (Reapproved 2018)

Standard Test Method for

Testing of Glass Exudation from AZS Fusion-Cast

1

Refractories

This standard is issued under the fixed designation C1223; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C20 Test Methods for Apparent Porosity, Water Absorption,

Apparent Specific Gravity, and Bulk Density of Burned

1.1 This test method covers a procedure for causing the

Refractory Brick and Shapes by Boiling Water

exudation of a glassy phase to the surface of fusion-cast

specimens by subjecting them to temperatures corresponding

3. Significance and Use

to glass furnace operating temperatures.

3.1 This test method was developed for use both by manu-

1.2 This test method covers a procedure for measuring the

facturers as a process control tool for the production of AZS

exudateasthepercentofvolumeincreaseofthespecimenafter

fusion-cast refractories, and by glass manufacturers in the

cooling.

selection of refractories and design of glass-melting furnaces.

1.3 Units—The values stated in inch-pound units are to be

3.2 The results may be considered as representative of the

regarded as standard. The values given in parentheses are

potential for an AZS refractory (specifically, in the tested

mathematical conversions to SI units that are provided for

region) to contribute to glass defect formation during the

information only and are not considered standard.

furnace production operation.

1.3.1 Exception—The balance required for this test method

3.3 The procedures and results may be applied to other

uses only SI units (Section 6).

refractory types or applications (that is, reheat furnace skid rail

1.4 This standard does not purport to address all of the

brick) in which glass exudation is considered to be important.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Apparatus and Materials

priate safety, health, and environmental practices and deter-

4.1 Scale—Alaboratory scale or balance rigged for suspen-

mine the applicability of regulatory limitations prior to use.

sion of specimens for dry/wet weight determinations to an

1.5 This international standard was developed in accor-

accuracy of 0.01 g.

dance with internationally recognized principles on standard-

4.2 Kiln—An electric kiln to accommodate several 4-in.

ization established in the Decision on Principles for the

(102-mm) specimen cores placed vertically on end, and for

Development of International Standards, Guides and Recom-

serviceat2750 °F(1510 °C),withavariationof<10 °F(6 °C).

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. 1

4.3 Foil—Cups formed from 2 ⁄4-in. (56-mm) squares of

platinum foil (Pt, 5 % Au alloy, 0.003 in. (0.076 mm) thick).

2. Referenced Documents

One cup required per specimen.

2

2.1 ASTM Standards:

4.4 AZS Casting—A virgin casting having no prior thermal

history except that of its own formation, and of a size and

1

This test method is under the jurisdiction of ASTM Committee C08 on casting process equivalent to the intended application (such as

Refractories and is the direct responsibility of Subcommittee C08.10 on Refracto-

an arch block) in which exudation potential is of interest.

ries for Glass.

Current edition approved Oct. 1, 2018. Published October 2018. Originally

5. Test Specimens and Sampling

approved in 1992. Last previous edition approved in 2014 as C1223 – 09 (2014).

DOI: 10.1520/C1223-09R18.

5.1 Specimens may be removed from the original casting

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

either as drilled cores or as sawed bars, depending on labora-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tory capability. Specimen cores or bars should be 4 in.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. (102 mm) long and either 1 in. (25.4 mm) in diameter or 1 by

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

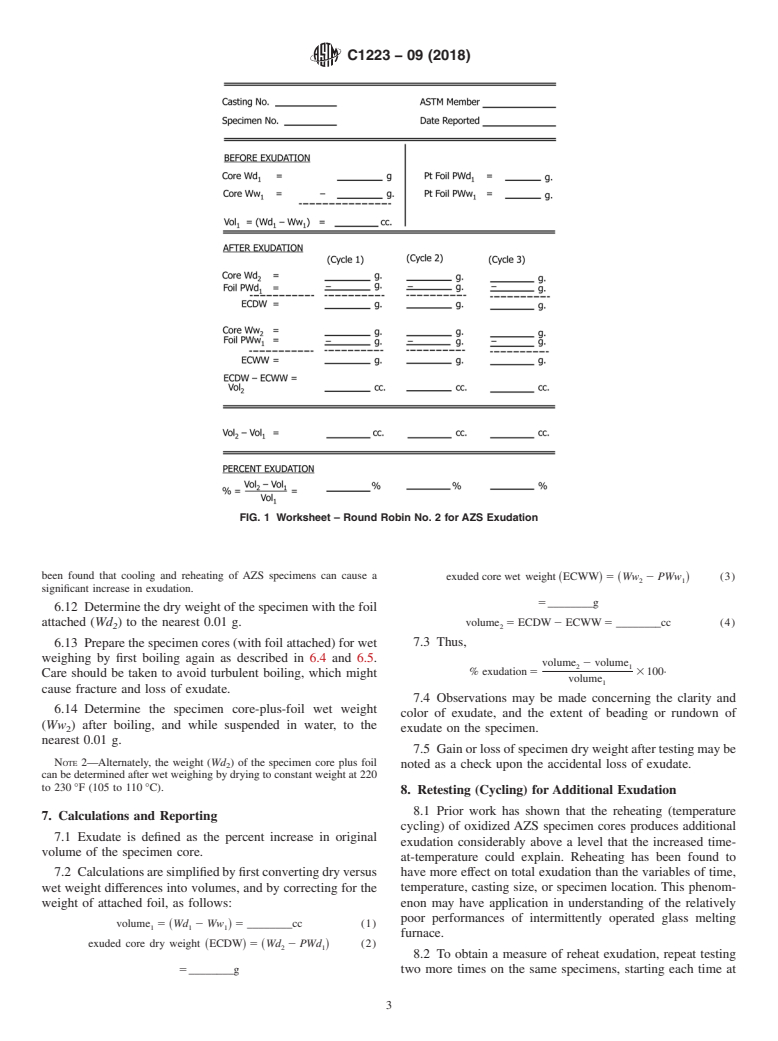

C1223 − 09 (2018)

1 in. (25.4 by 25.4 mm) in cross section. The length dimension surfaces, with the following restrictions: sampling should be at

of the specimen should be perpendicular to the surface of the least 4 in. (102 mm) from any edge, and the entire bottom

block from which it is removed. region should be avoided up to 8 in. (203 mm) from the bottom

(as cast). This lower region, which often becomes the top

5.2 The dimensi

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1223 − 09 (Reapproved 2014) C1223 − 09 (Reapproved 2018)

Standard Test Method for

Testing of Glass Exudation from AZS Fusion-Cast

1

Refractories

This standard is issued under the fixed designation C1223; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a procedure for causing the exudation of a glassy phase to the surface of fusion-cast specimens by

subjecting them to temperatures corresponding to glass furnace operating temperatures.

1.2 This test method covers a procedure for measuring the exudate as the percent of volume increase of the specimen after

cooling.

1.3 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are

mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3.1 Exception—The balance required for this test method uses only SI units (Section 6).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C20 Test Methods for Apparent Porosity, Water Absorption, Apparent Specific Gravity, and Bulk Density of Burned Refractory

Brick and Shapes by Boiling Water

3. Significance and Use

3.1 This test method was developed for use both by manufacturers as a process control tool for the production of AZS

fusion-cast refractories, and by glass manufacturers in the selection of refractories and design of glass-melting furnaces.

3.2 The results may be considered as representative of the potential for an AZS refractory (specifically, in the tested region) to

contribute to glass defect formation during the furnace production operation.

3.3 The procedures and results may be applied to other refractory types or applications (that is, reheat furnace skid rail brick)

in which glass exudation is considered to be important.

4. Apparatus and Materials

4.1 Scale—A laboratory scale or balance rigged for suspension of specimens for dry/wet weight determinations to an accuracy

of 0.01 g.

4.2 Kiln—An electric kiln to accommodate several 4-in. (102-mm) specimen cores placed vertically on end, and for service at

2750°F (1510°C),2750 °F (1510 °C), with a variation of <10°F (6°C).<10 °F (6 °C).

1

4.3 Foil—Cups formed from 2 ⁄4-in. (56-mm) squares of platinum foil (Pt, 5 % Au alloy, 0.003-in. (0.076-mm) 0.003 in. (0.076

mm) thick). One cup required per specimen.

1

This test method is under the jurisdiction of ASTM Committee C08 on Refractories and is the direct responsibility of Subcommittee C08.10 on Refractories for Glass.

Current edition approved Sept. 1, 2014Oct. 1, 2018. Published November 2014.October 2018. Originally approved in 1992. Last previous edition approved in 20092014

as C1223 – 09. 09 (2014). DOI: 10.1520/C1223-09R14.10.1520/C1223-09R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

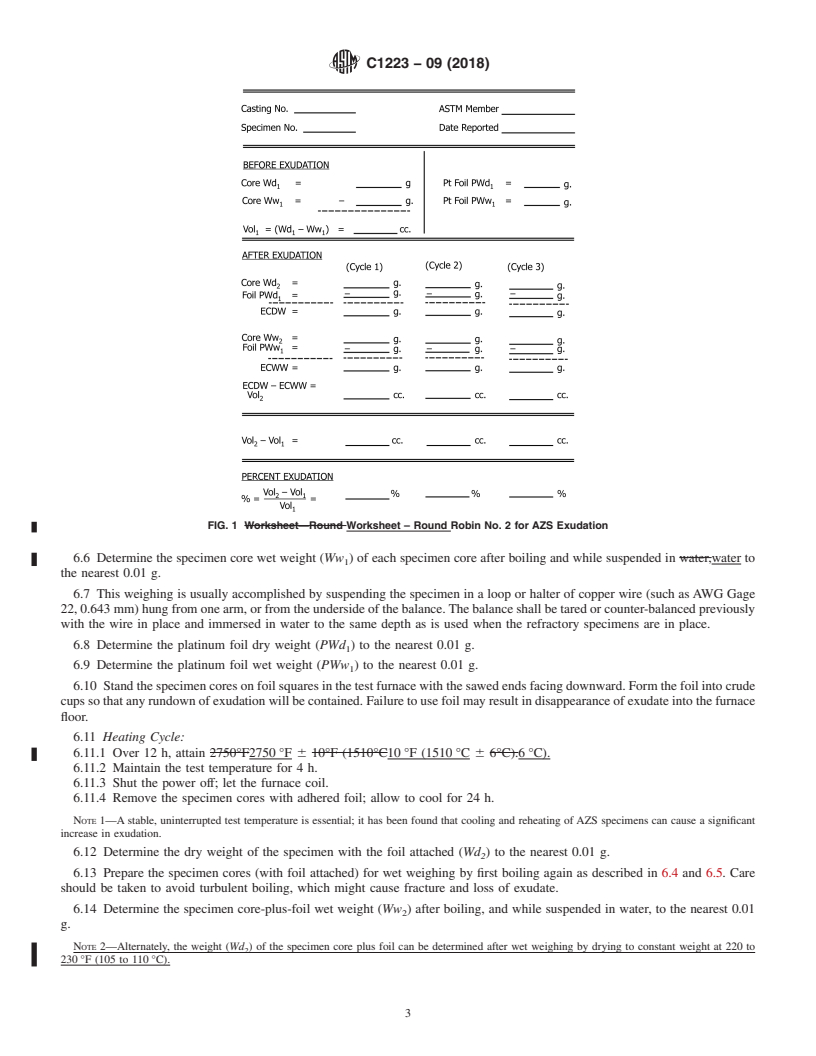

C1223 − 09 (2018)

4.4 AZS Casting—A virgin casting having no prior thermal history except that of its own formation, and of a size and casting

process equivalent to the intended application (such as an arch block) in which exudation potential is of interest.

5. Test Specimens and Sampling

5.1 Specimens may be removed from the original casting either as drilled cores or as sawed bars, depending on laboratory

capability. Specimen cores or bars should be 4-in. (102-mm) 4 in. (102 mm) long and either 1 in. (25

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.