ASTM C467-14(2023)

(Classification)Standard Classification of Mullite Refractories

Standard Classification of Mullite Refractories

SIGNIFICANCE AND USE

3.1 The mullite content of an alumina-silica refractory material has an important influence on volume stability, load-bearing properties, and its satisfactory use in refractory applications. This classification is considered useful for purchase specifications and quality control.

SCOPE

1.1 This classification covers refractory products consisting predominantly of mullite (3Al2O3·2SiO2) crystals that are formed by either converting any of the sillimanite group of minerals, or synthesizing from appropriate materials in a melt or sinter process.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C467 − 14 (Reapproved 2023)

Standard Classification of

Mullite Refractories

This standard is issued under the fixed designation C467; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope bearing properties, and its satisfactory use in refractory appli-

cations. This classification is considered useful for purchase

1.1 This classification covers refractory products consisting

specifications and quality control.

predominantly of mullite (3Al O ·2SiO ) crystals that are

2 3 2

formed by either converting any of the sillimanite group of

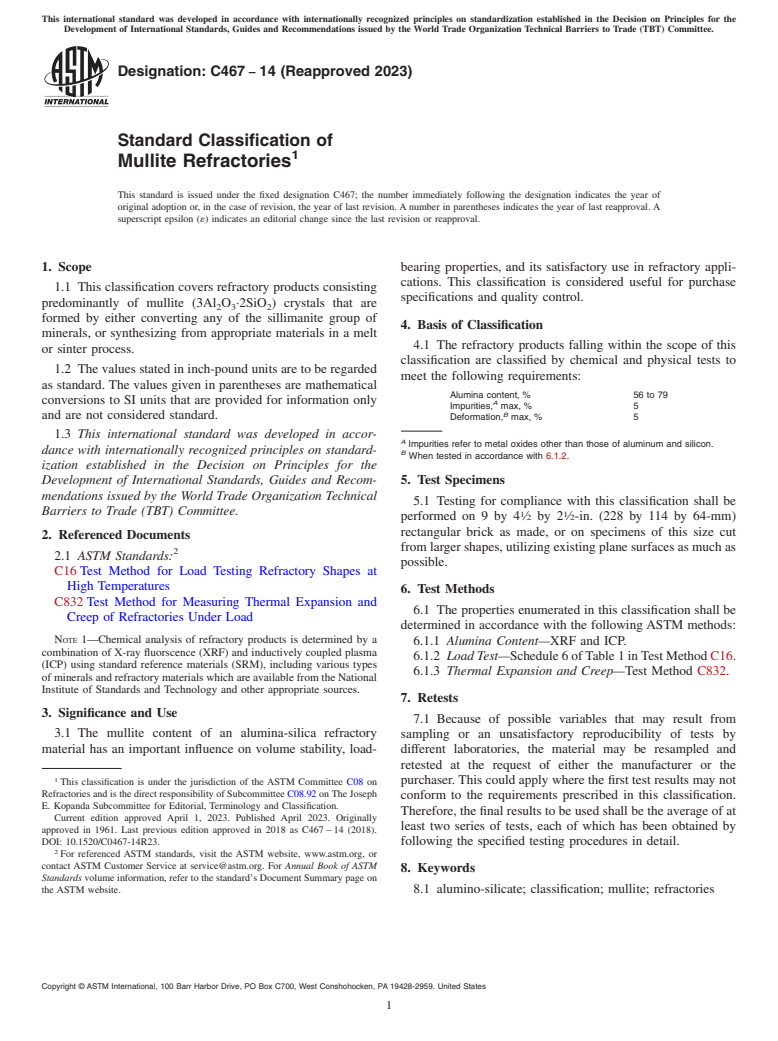

4. Basis of Classification

minerals, or synthesizing from appropriate materials in a melt

4.1 The refractory products falling within the scope of this

or sinter process.

classification are classified by chemical and physical tests to

1.2 The values stated in inch-pound units are to be regarded

meet the following requirements:

as standard. The values given in parentheses are mathematical

Alumina content, % 56 to 79

conversions to SI units that are provided for information only

A

Impurities, max, % 5

B

and are not considered standard.

Deformation, max, % 5

1.3 This international standard was developed in accor-

A

Impurities refer to metal oxides other than those of aluminum and silicon.

dance with internationally recognized principles on standard-

B

When tested in accordance with 6.1.2.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- 5. Test Specimens

mendations issued by the World Trade Organization Technical

5.1 Testing for compliance with this classification shall be

Barriers to Trade (TBT) Committee.

1 1

performed on 9 by 4 ⁄2 by 2 ⁄2-in. (228 by 114 by 64-mm)

rectangular brick as made, or on specimens of this size cut

2. Referenced Documents

from larger shapes, utilizing existing plane surfaces as much as

2.1 ASTM Standards:

possible.

C16 Test Method for Load Testing Refractory Shapes at

High Temperatures

6. Test Methods

C832 Test Method for Measuring Thermal Expansion and

6.1 The properties enumerated in this classification shall be

Creep of Refractories Under Load

determined in accordance with the following ASTM methods:

NOTE 1—Chemical analysis of refractory products is determined by a

6.1.1 Alumina Content—XRF and ICP.

combination of X-ray fluorscence (XRF) and inductively coupled plasma

6.1.2 Load Test—Schedule 6 of Table 1 in Test Method C16.

(ICP) using standard reference materials (SRM), including various types

6.1.3 Thermal Expansion and Creep—Test Method C832.

of minerals and refractory materials which are available from the National

Institute of Standards and Technology a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.