ASTM D3279-12

(Test Method)Standard Test Method for n-Heptane Insolubles

Standard Test Method for <emph type="ital">n</emph>-Heptane Insolubles

SIGNIFICANCE AND USE

4.1 This test method is useful in quantifying the asphaltene content of petroleum asphalts, gas oils, heavy fuel oils, and crude petroleum. Asphaltene content is defined as those components not soluble in n-heptane.

SCOPE

1.1 This test method covers determination of the mass percent of asphaltenes as defined by insolubility in normal-heptane solvent. It is applicable to all solid and semi-solid petroleum asphalts containing little or no mineral matter, to gas oils, to heavy fuel oils, and to crude petroleum that has been topped to a cut-point of 343°C or higher.

1.2 The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Section 7 for a specific hazard statement.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3279 − 12

StandardTest Method for

1

n-Heptane Insolubles

This standard is issued under the fixed designation D3279; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Apparatus and Materials

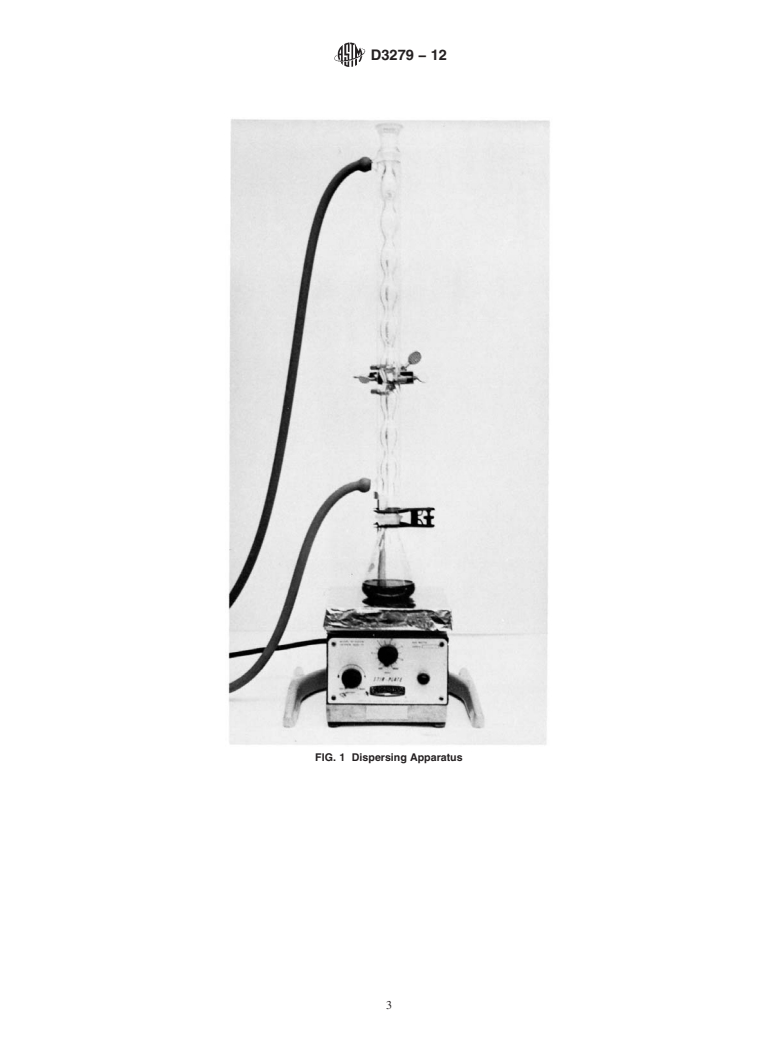

1.1 This test method covers determination of the mass 5.1 Theassemblyofthedispersingapparatusisillustratedin

percent of asphaltenes as defined by insolubility in normal- Fig. 1 with details of the component parts as follows:

heptane solvent. It is applicable to all solid and semi-solid 5.1.1 Erlenmeyer Flask, of 250-mL capacity adapted to an

petroleumasphaltscontaininglittleornomineralmatter,togas Allihn-type reflux condenser.

oils, to heavy fuel oils, and to crude petroleum that has been 5.1.2 Magnetic Stirrer and Magnetic-Stirrer Hot Plate

topped to a cut-point of 343°C or higher. 5.1.3 Bitumen Crucible or Gooch Crucible, glazed inside

and outside with the exception of the outside bottom surface.

1.2 The values stated in SI units are to be regarded as the

The approximate dimensions shall be a diameter of 44 mm at

standard. No other units of measurement are included in this

the top tapering to 36 mm at the bottom and a depth of

standard.

20–30mm.

1.3 This standard does not purport to address all of the

5.1.4 Glass Microfiber Filter Pad, 32–34 mm in diameter

safety concerns, if any, associated with its use. It is the

fine porosity, fast flow rate, 1.5υm particle retention.

responsibility of the user of this standard to establish appro-

5.1.5 Filter Flask, heavy-wall with side tube, 500-mL

priate safety and health practices and determine the applica-

capacity.

bility of regulatory limitations prior to use. See Section 7 for a

5.1.6 Filter Tube, 40 to 42 mm in inside diameter.

specific hazard statement.

5.1.7 Rubber Tubing, or adapter for holding Gooch crucible

on the filter tube.

2. Referenced Documents

NOTE 1—Other suitable assemblies permitting vacuum filtration with a

2

2.1 ASTM Standards:

crucible may be used.

C670Practice for Preparing Precision and Bias Statements

5.1.8 Oven, capable of maintaining a temperature of 110 6

for Test Methods for Construction Materials

5ºC.

3. Summary of Test Method

6. Reagent

3.1 The sample is dispersed in n-heptane and filtered

6.1 n-Heptane, 99.0 minimum mol% (Pure Grade).

through a glass-fiber pad. The insoluble material is washed,

7. Hazards

dried, and weighed.

7.1 n-Heptane has a boiling point of 98°C and a flash point

of −1°C, which means that it should be handled with care. It is

4. Significance and Use

recommended that both the reflux dispersion and filtration

4.1 This test method is useful in quantifying the asphaltene

steps be conducted in a ventilated hood and away from flames

content of petroleum asphalts, gas oils, heavy fuel oils, and

or other sources of heat.

crude petroleum. Asphaltene content is defined as those com-

ponents not soluble in n-heptane.

8. Preparation of Crucible

8.1 PlacetheGoochcrucibleplusonethicknessfilterpadin

an oven at about 110 6 5ºC for 30 min, allow to cool in a

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

desiccator for 30 6 5 , and then determine the mass to the

and Paving Materials and is the direct responsibility of Subcommittee D04.47 on

nearest 0.1 mg. Designate this mass asA. Store in a desiccator

Miscellaneous Asphalt Tests.

until ready for use.

Current edition approved Dec. 1, 2012. Published December 2012. Originally

approved in 1973. Last previous edition approved in 2007 as D3279–07. DOI:

9. Sample Preparation

10.1520/D3279-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

9.1 If the sample is not fluid, heat to any convenient

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

temperature, but in any case not more than 100ºC above the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. softening point.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3279 − 12

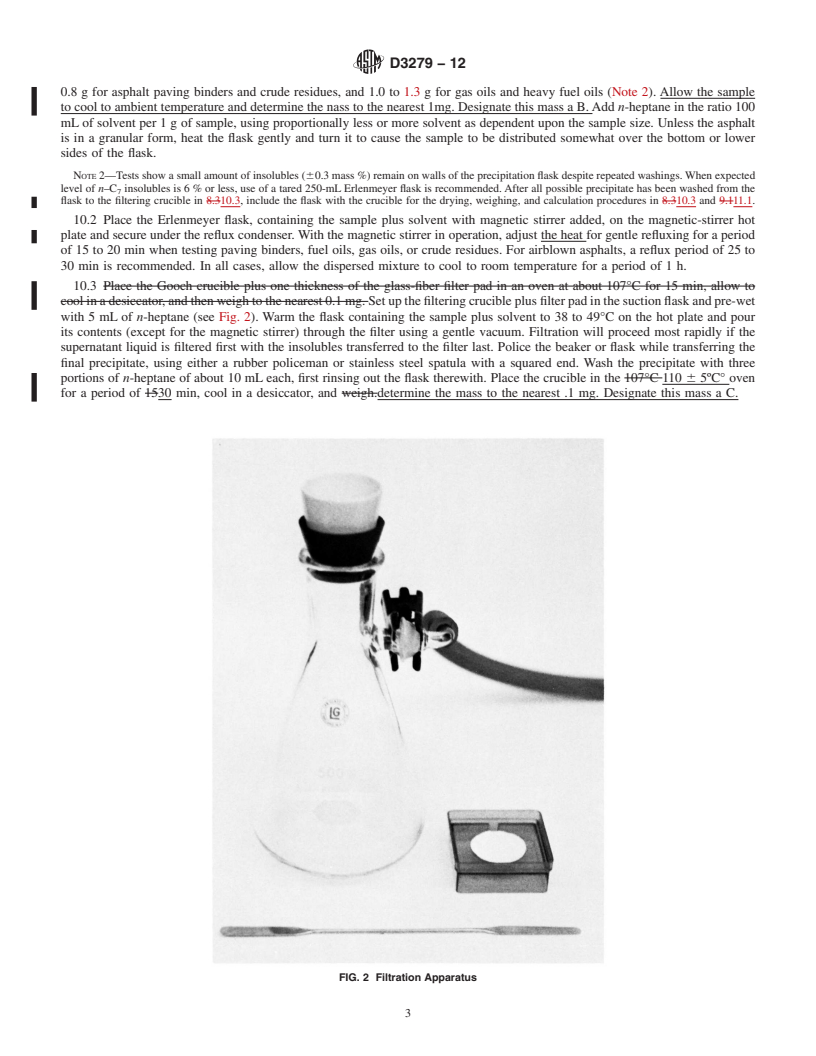

10. Procedure with the insolubles transferred to the filter last. Police the

beaker or flask while transferring the final precipitate, using

10.1 Note Safety precautions in 7. Transfer into the tared

either a rubber policeman or stainless steel spatula with a

250-mL Erlenmeyer flask, the approximate amount of sample

squared end. Wash the precipitate with three portions of

to be tested. Use 0.5 to 0.6 g for airblown asphalts, 0.7 to 0.8

n-heptane of about 10 mL each, first rinsing out the flask

g for asphalt paving binders

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3279 − 07 D3279 − 12

Standard Test Method for

1

n-Heptane Insolubles

This standard is issued under the fixed designation D3279; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers determination of the mass percent of asphaltenes as defined by insolubility in normal-heptane

solvent. It is applicable to all solid and semi-solid petroleum asphalts containing little or no mineral matter, to gas oils, to heavy

fuel oils, and to crude petroleum that has been topped to a cut-point of 343°C or higher.

1.2 The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. See Section 7 for a specific hazard statement.

2. Referenced Documents

2

2.1 ASTM Standards:

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

3. Summary of Test Method

3.1 The sample is dispersed in n -heptane and filtered through a glass-fiber pad. The insoluble material is washed, dried, and

weighed.

4. Significance and Use

4.1 This test method is useful in quantifying the asphaltene content of petroleum asphalts, gas oils, heavy fuel oils, and crude

petroleum. Asphaltene content is defined as those components not soluble in n-heptane.

5. Apparatus and Materials

5.1 The assembly of the dispersing apparatus is illustrated in Fig. 1 with details of the component parts as follows:

5.1.1 Erlenmeyer Flask, of 250-mL capacity adapted to an Allihn-type reflux condenser, each with a 35/25 ball joint.condenser.

5.1.2 Magnetic Stirrer and Magnetic-Stirrer Hot Plate,Plate equipped with a voltage regulator.

5.1.3 Bitumen Crucible or Gooch Crucible, glazed inside and outside with the exception of the outside bottom surface. The

approximate dimensions shall be a diameter of 44 mm at the top tapering to 36 mm at the bottom and a depth of 20–30mm.

5.1.4 Glass Microfiber Filter Pad, glass-fiber 32 32–34 mm in diameter.diameter fine porosity, fast flow rate, 1.5υm particle

retention.

5.1.5 Filter Flask, heavy-wall with side tube, 500-mL capacity.

5.1.6 Filter Tube, 40 to 42 mm in inside diameter.

5.1.7 Rubber Tubing, or adapter for holding Gooch crucible on the filter tube.

NOTE 1—Other suitable assemblies permitting vacuum filtration with a Gooch crucible may be used.

5.1.8 Oven, capable of maintaining a temperature of 110 6 5ºC.

6. SolventReagent

6.1 n-Heptane, 99.0 minimum mol % (Pure Grade).

1

This test method is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.47 on

Miscellaneous Asphalt Tests.

Current edition approved Aug. 1, 2007Dec. 1, 2012. Published August 2007December 2012. Originally approved in 1973. Last previous edition approved in 20012007

as D3279 – 97 (2001).D3279 – 07. DOI: 10.1520/D3279-07.10.1520/D3279-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3279 − 12

FIG. 1 Dispersing Apparatus

7. Hazards

7.1 n-Heptane has a boiling point of 98°C and a flash point of −1°C, which means that it should be handled with care. It is

recommended that both the reflux dispersion and filtration steps be conducted in a ventilated hood and away from flames or other

sources of heat.

8. Preparation of Crucible

8.1 Place the Gooch crucible plus one thickness filter pad in an oven at about 110 6 5ºC for 30 min, allow to cool in a desiccator

for 30 6 5 , and then determine the mass to the nearest 0.1 mg. Designate this mass as A. Store in a desicator until ready for use.

9. Sample Preparation

9.1 If the sample is not fluid, heat to any convenient temperature, but in any case not more than 100ºC above the softening poin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.