ASTM E2060-06(2014)

(Guide)Standard Guide for Use of Coal Combustion Products for Solidification/Stabilization of Inorganic Wastes

Standard Guide for Use of Coal Combustion Products for Solidification/Stabilization of Inorganic Wastes

SIGNIFICANCE AND USE

4.1 General—CCPs can have chemical and mineralogical compositions that are conducive to use in the chemical stabilization of trace elements in wastes and wastewater. These elements include, but are not limited to, arsenic, barium, boron, cadmium, chromium, cobalt, lead, molybdenum, nickel, selenium, vanadium, and zinc. Chemical stabilization may be accompanied by solidification of the waste treated. Solidification is not a requirement for the stabilization of many trace elements, but does offer advantages in waste handling and in reduced permeability of the stabilized waste. This guide addresses the use of CCPs as a stabilizing agent without addition of other materials. S/S is considered the BDAT for the disposal of some wastes that contain metals since they cannot be destroyed by other means (2).

4.1.1 Advantages of Using CCPs—Advantages of using CCPs for waste stabilization include their ready availability in high volumes, generally good product consistency from one source, and easy handling. CCPs vary depending on the combustion or emission control process and the coal or sorbents used, or both, and CCPs contain trace elements, although usually at very low concentrations. CCPs are generally an environmentally suitable materials option for waste stabilization, but the compatibility of a specific CCP must be evaluated with individual wastes or wastewater through laboratory-scale tests followed by full-scale demonstration and field verification. CCPs suitable for this chemical stabilization have the ability to incorporate large amounts of free water into hydration products. CCPs that exhibit high pHs (>11.5) offer advantages in stabilizing trace elements that exist as oxyanions in nature (such as arsenic, boron, chromium, molybdenum, selenium, and vanadium) and trace elements that form oxyhydroxides or low-solubility precipitates at high pH (such as lead, cadmium, barium, and zinc). Additionally, CCPs that exhibit cementitious properties offer advantages in solid...

SCOPE

1.1 This guide covers methods for selection and application of coal combustion products (CCPs) for use in the chemical stabilization of trace elements in wastes and wastewater. These elements include, but are not limited to, arsenic, barium, boron, cadmium, chromium, cobalt, lead, molybdenum, nickel, selenium, vanadium, and zinc. Chemical stabilization may be accompanied by solidification of the waste treated. Solidification is not a requirement for the stabilization of many trace elements, but does offer advantages in waste handling and in reduced permeability of the stabilized waste.

1.1.1 Solidification is an important factor in treatment of wastes and especially wastewaters. Solidification/Stabilization (S/S) technology is often used to treat wastes containing free liquids. This guide addresses the use of CCPs as a stabilizing agent without the addition of other materials; however, stabilization or chemical fixation may also be achieved by using combinations of CCPs and other products such as lime, lime kiln dust, cement kiln dust, cement, and others. CCPs used alone or in combination with other reagents promote stabilization of many inorganic constituents through a variety of mechanisms. These mechanisms include precipitation as carbonates, silicates, sulfates, and so forth; microencapsulation of the waste particles through pozzolanic reactions; formation of metal precipitates; and formation of hydrated phases (1-4).2 Long-term performance of the stabilized waste is an issue that must be addressed in considering any S/S technology. In this guide, several tests are recommended to aid in evaluating the long-term performance of the stabilized wastes.

1.2 The CCPs that are suited to this application include fly ash, spent dry scrubber sorbents, and certain advanced sulfur control by-products from processes such as duct injection and fluidized-bed combustion (FBC).

1.3 The wastes or wastewater, or both, containi...

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2060 −06 (Reapproved 2014)

Standard Guide for

Use of Coal Combustion Products for Solidification/

Stabilization of Inorganic Wastes

This standard is issued under the fixed designation E2060; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.3 The wastes or wastewater, or both, containing the

problematic inorganic species will likely be highly variable, so

1.1 This guide covers methods for selection and application

the chemical characteristics of the waste or wastewater to be

of coal combustion products (CCPs) for use in the chemical

treated must be determined and considered in the selection and

stabilization of trace elements in wastes and wastewater. These

application of any stabilizing agent, including CCPs. In any

elementsinclude,butarenotlimitedto,arsenic,barium,boron,

waste stabilization process, laboratory-scale tests for compat-

cadmium, chromium, cobalt, lead, molybdenum, nickel,

ibility between the candidate waste or wastewater for stabili-

selenium, vanadium, and zinc. Chemical stabilization may be

zation with one or more selected CCPs and final waste stability

accompanied by solidification of the waste treated. Solidifica-

are recommended prior to full-scale application of the stabi-

tion is not a requirement for the stabilization of many trace

lizing agent.

elements, but does offer advantages in waste handling and in

reduced permeability of the stabilized waste.

1.4 This guide does not intend to recommend full-scale

1.1.1 Solidification is an important factor in treatment of

processes or procedures for waste stabilization. Full-scale

wastes and especially wastewaters. Solidification/Stabilization

processes should be designed and carried out by qualified

(S/S) technology is often used to treat wastes containing free

scientists, engineers, and environmental professionals. It is

liquids. This guide addresses the use of CCPs as a stabilizing

recommended that stabilized materials generated at the full-

agent without the addition of other materials; however, stabi-

scale stabilization site be subjected to testing to verify labora-

lization or chemical fixation may also be achieved by using

tory test results.

combinations of CCPs and other products such as lime, lime

1.5 The utilization of CCPs under this guide is a component

kiln dust, cement kiln dust, cement, and others. CCPs used

of a pollution prevention program; Guide E1609 describes

alone or in combination with other reagents promote stabiliza-

tion of many inorganic constituents through a variety of pollution prevention activities in more detail. Utilization of

CCPs in this manner conserves land, natural resources, and

mechanisms. These mechanisms include precipitation as

carbonates, silicates, sulfates, and so forth; microencapsulation energy.

of the waste particles through pozzolanic reactions; formation

1.6 This guide applies only to CCPs produced primarily

of metal precipitates; and formation of hydrated phases (1-4).

from the combustion of coal. It does not apply to ash or other

Long-term performance of the stabilized waste is an issue that

combustion products derived from the burning of waste;

must be addressed in considering any S/S technology. In this

municipal,industrial,orcommercialgarbage;sewagesludgeor

guide, several tests are recommended to aid in evaluating the

other refuse, or both; derived fuels; wood waste products; rice

long-term performance of the stabilized wastes.

hulls; agricultural waste; or other noncoal fuels.

1.2 The CCPs that are suited to this application include fly

1.7 Regulations governing the use of CCPs vary by state.

ash, spent dry scrubber sorbents, and certain advanced sulfur

The user of this guide has the responsibility to determine and

control by-products from processes such as duct injection and

comply with applicable regulations.

fluidized-bed combustion (FBC).

1.8 It is recommended that work performed under this guide

be designed and carried out by qualified scientists, engineers,

ThisguideisunderthejurisdictionofASTMCommitteeE50onEnvironmental and environmental professionals.

Assessment, Risk Management and Corrective Action and is the direct responsibil-

1.9 This standard does not purport to address all of the

ity of Subcommittee E50.03 on Beneficial Use.

Current edition approved Dec. 1, 2014. Published February 2015. Originally

safety concerns, if any, associated with its use. It is the

approved in 2000. Last previous edition approved in 2006 as F2060 – 06. DOI:

responsibility of the user of this standard to establish appro-

10.1520/E2060-06R14.

2 priate safety and health practices and determine the applica-

The boldface numbers in parentheses refer to the list of references at the end of

the text. bility of regulatory limitations prior to use.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2060−06 (2014)

2. Referenced Documents 3. Terminology

3.1 Definitions:

2.1 ASTM Standards:

3.1.1 Definitions are in accordance withTerminology D653.

C114 Test Methods for Chemical Analysis of Hydraulic

Cement

3.2 Definitions of Terms Specific to This Standard:

C311 Test Methods for Sampling and Testing Fly Ash or 3.2.1 advanced sulfur control (ASC) products—by-products

Natural Pozzolans for Use in Portland-Cement Concrete generated from advanced coal conversion technologies includ-

ing FBC and gasification and by-products from advanced

C400 Test Methods for Quicklime and Hydrated Lime for

environmental emissions cleanup technologies such as duct

Neutralization of Waste Acid

injection and lime injection multiphase burners (LIMB).

D75 Practice for Sampling Aggregates

D422 Test Method for Particle-Size Analysis of Soils

3.2.2 baghouse—a facility constructed at some coal-fired

D558 Test Methods for Moisture-Density (Unit Weight) power plants consisting of fabric filter bags that mechanically

Relations of Soil-Cement Mixtures trap particulates (fly ash) carried in the flue gases.

D653 Terminology Relating to Soil, Rock, and Contained

3.2.3 beneficial use—projects promoting public health and

Fluids

environmental protection, offering equivalent success relative

D1556 Test Method for Density and Unit Weight of Soil in

to other alternatives, and preserving natural resources.

Place by Sand-Cone Method

3.2.4 BDAT—best demonstrated available technology.

D1633 Test Methods for Compressive Strength of Molded

3.2.5 boiler slag—a molten ash collected at the base of slag

Soil-Cement Cylinders

tap and cyclone boilers that is quenched in a water-filled

D1635 Test Method for Flexural Strength of Soil-Cement

hopper and shatters into black, angular particles having a

Using Simple Beam with Third-Point Loading

smooth, glassy appearance.

D2166 Test Method for Unconfined Compressive Strength

3.2.6 bottom ash—agglomerated ash particles formed in

of Cohesive Soil

pulverized coal boilers that are too large to be carried in the

D2216 Test Methods for Laboratory Determination of Water

flue gases and impinge on the boiler walls or fall through open

(Moisture) Content of Soil and Rock by Mass

grates to an ash hopper at the bottom of the boiler. Bottom ash

D2922 Test Methods for Density of Soil and Soil-Aggregate

is typically grey-to-black in color, is quite angular, and has a

in Place by Nuclear Methods (Shallow Depth) (With-

porous surface texture.

drawn 2007)

3.2.7 coal combustion products—fly ash, bottom ash, boiler

D2937 Test Method for Density of Soil in Place by the

ash, or flue gas desulfurization (FGD) material resulting from

Drive-Cylinder Method

the combustion of coal.

D3441 Test Method for Mechanical Cone Penetration Tests

3.2.8 DSC—differential scanning calorimetry.

of Soil (Withdrawn 2014)

D3877 Test Methods for One-Dimensional Expansion, 3.2.9 DTA—differential thermal analysis.

Shrinkage, and Uplift Pressure of Soil-Lime Mixtures

3.2.10 DTG—differential thermal gravimetry.

D3987 Practice for Shake Extraction of Solid Waste with

3.2.11 electrostatic precipitator—a facility constructed at

Water

some coal-fired power plants to remove particulate matter (fly

D4318 Test Methods for Liquid Limit, Plastic Limit, and

ash) from the flue gas by producing an electric charge on the

Plasticity Index of Soils

particles to be collected and then propelling the charged

D4842 Test Method for Determining the Resistance of Solid

particles by electrostatic forces to collecting curtains.

Wastes to Freezing and Thawing (Withdrawn 2006)

3.2.12 encapsulation—complete coating or enclosure of a

D4843 Test Method for Wetting and Drying Test of Solid

toxic particle by an additive so as to sequester that particle

Wastes

from any environmental receptors that may otherwise have

D4972 Test Method for pH of Soils

been negatively impacted by that particle.

D5084 Test Methods for Measurement of Hydraulic Con-

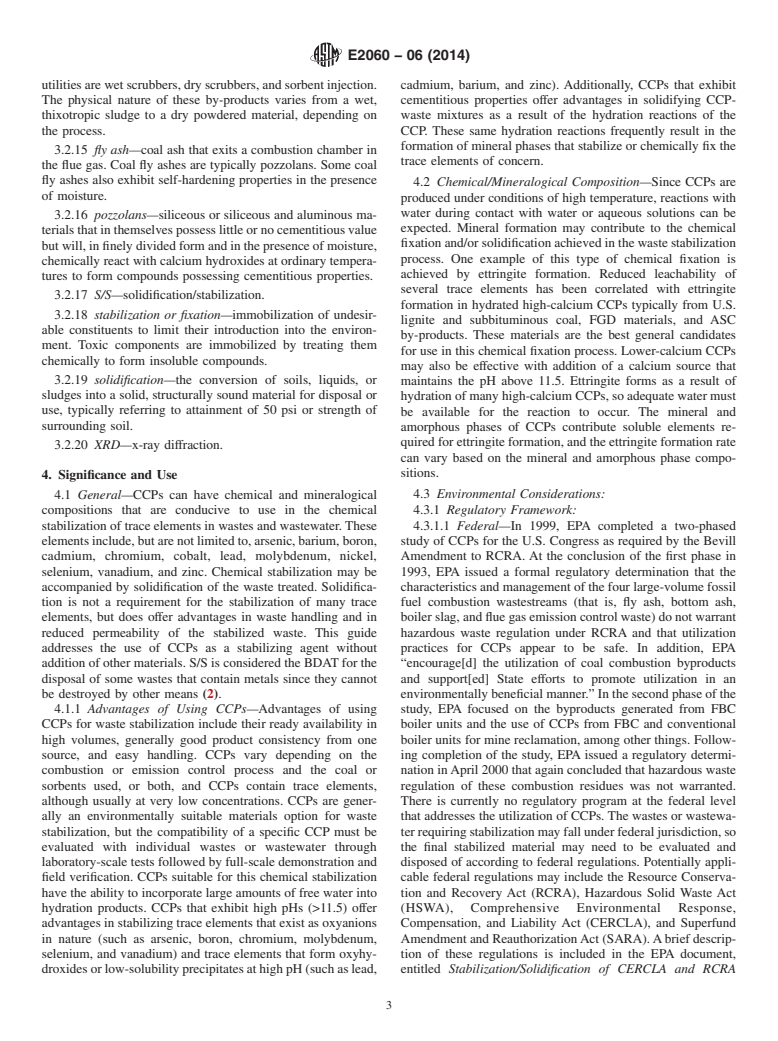

3.2.13 ettringite—a mineral with the nominal composition

ductivity of Saturated Porous Materials Using a Flexible

Ca Al (SO ) (OH) · 26H O. Ettringite is also the family

6 2 4 3 12 2

Wall Permeameter

name for a series of related compounds, known as a mineral

D5239 Practice for Characterizing Fly Ash for Use in Soil

group or family, which includes the following minerals (1):

Stabilization

Ettringite Ca Al (SO ) (OH) · 26H O

6 2 4 3 12 2

E1609 Guide for Development and Implementation of a

Charlesite Ca (Si,Al) (SO ) (B[OH] )(OH) · 26H O

6 2 4 2 4 12 2

Pollution Prevention Program (Withdrawn 2010) Sturmanite Ca Fe (SO ) (B[OH] )(OH) · 26H O

6 2 4 2 4 12 2

Thaumasite Ca Si (SO ) (CO ) (OH) · 24H O

6 2 4 2 3 2 12 2

Jouravskite Ca Mn (SO ) (CO ) (OH) · 24H O

6 2 4 2 3 2 12 2

Bentorite Ca (Cr,Al) (SO ) (OH) · 26H O

6 2 4 3 12 2

3.2.14 flue gas desulfurization material—a by-product of

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the removal of the sulfur gases from the flue gases, typically

Standards volume information, refer to the standard’s Document Summary page on

using a high-calcium sorbent such as lime or limestone.

the ASTM website.

Sodium-based sorbents are also used in some systems. The

The last approved version of this historical standard is referenced on

www.astm.org. three primary types of FGD processes commonly used by

E2060−06 (2014)

utilities are wet scrubbers, dry scrubbers, and sorbent injection. cadmium, barium, and zinc). Additionally, CCPs that exhibit

The physical nature of these by-products varies from a wet, cementitious properties offer advantages in solidifying CCP-

thixotropic sludge to a dry powdered material, depending on waste mixtures as a result of the hydration reactions of the

the process. CCP. These same hydration reactions frequently result in the

formation of mineral phases that stabilize or chemically fix the

3.2.15 fly ash—coal ash that exits a combustion chamber in

trace elements of concern.

the flue gas. Coal fly ashes are typically pozzolans. Some coal

fly ashes also exhibit self-hardening properties in the presence

4.2 Chemical/Mineralogical Composition—Since CCPs are

of moisture.

produced under conditions of high temperature, reactions with

water during contact with water or aqueous solutions can be

3.2.16 pozzolans—siliceous or siliceous and aluminous ma-

expected. Mineral formation may contribute to the chemical

terialsthatinthemselvespossesslittleornocementitiousvalue

fixation and/or solidification achieved in the waste stabilization

but will, in finely divided form and in the presence of moisture,

process. One example of this type of chemical fixation is

chemically react with calcium hydroxides at ordinary tempera-

achieved by ettringite formation. Reduced leachability of

tures to form compounds possessing cementitious properties.

several trace elements has been correlated with ettringite

3.2.17 S/S—solidification/stabilization.

formation in hydrated high-calcium CCPs typically from U.S.

3.2.18 stabilization or fixation—immobilization of undesir-

lignite and subbituminous coal, FGD materials, and ASC

able constituents to limit their introduction into the environ-

by-products. These materials are the best general candidates

ment. Toxic components are immobilized by treating them

for use in this chemical fixation process. Lower-calcium CCPs

chemically to form insoluble compounds.

may also be effective with addition of a calcium source that

3.2.19 solidification—the conversion of soils, liquids, or

maintains the pH above 11.5. Ettringite forms as a result of

sludges into a solid, structurally sound material for disposal or

hydration of many high-calcium CCPs, so adequate water must

use, typically referring to attainment of 50 psi or strength of

be available for the reaction to occur. The mineral and

surrounding soil.

amorphous phases of CCPs contribute soluble elements re-

quired for ettringite formation, and the ettringite formation rate

3.2.20 XRD—x-ray diffraction.

can vary based on the mineral and amorphous phase compo-

sitions.

4. Significance and Use

4.3 Environmental Considerations:

4.1 General—CCPs can have chemical and mineralogical

4.3.1 Regulatory Framework:

compositions that are conducive to use in the chemical

stabilization of trace elements in wastes and wastewater. These 4.3.1.1 Federal—In 1999, EPA completed a two-phased

elementsinclude,butarenotlimitedto,arsenic,barium,boron, study of CCPs for the U.S. Congress as required by the Bevill

cadmium, chromium, cobalt, lead, molybdenum, nickel, Amendment to RCRA. At the conclusion of the first phase in

selenium, vanadium, and zinc. Chemical stabilization may be 1993, EPA issued a formal regulatory determination that the

accompanied by solidification of the waste treated. Solidifica- characteristics and management of the four large-volume fossil

tion is not a requirement for the stabilization of many trace fuel combustion wastestreams (that is, fly ash, bottom ash,

elements, but does offer advantages in waste handling and in boiler slag, and flue gas emission control waste) do not warrant

reduced permeability of the stabilized waste. This guide hazardous waste regulation under RCRA and that utilization

addresses the use of CCPs as a stabilizing agent without practices for CCPs appear to be safe. In addition, EPA

addition of other materials. S/S is considered the BDAT for the “encourage[d] the utilization of coal combustion byproducts

disposal of some wastes that contain metals since they cannot and support[ed] State efforts to promote utilization in an

be destroyed by other means (2).

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2060 − 06 E2060 − 06 (Reapproved 2014)

Standard Guide for

Use of Coal Combustion Products for Solidification/

Stabilization of Inorganic Wastes

This standard is issued under the fixed designation E2060; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide covers methods for selection and application of coal combustion products (CCPs) for use in the chemical

stabilization of trace elements in wastes and wastewater. These elements include, but are not limited to, arsenic, barium, boron,

cadmium, chromium, cobalt, lead, molybdenum, nickel, selenium, vanadium, and zinc. Chemical stabilization may be

accompanied by solidification of the waste treated. Solidification is not a requirement for the stabilization of many trace elements,

but does offer advantages in waste handling and in reduced permeability of the stabilized waste.

1.1.1 Solidification is an important factor in treatment of wastes and especially wastewaters. Solidification/Stabilization (S/S)

technology is often used to treat wastes containing free liquids. This guide addresses the use of CCPs as a stabilizing agent without

the addition of other materials; however, stabilization or chemical fixation may also be achieved by using combinations of CCPs

and other products such as lime, lime kiln dust, cement kiln dust, cement, and others. CCPs used alone or in combination with other

reagents promote stabilization of many inorganic constituents through a variety of mechanisms. These mechanisms include

precipitation as carbonates, silicates, sulfates, and so forth; microencapsulation of the waste particles through pozzolanic reactions;

formation of metal precipitates; and formation of hydrated phases (1-4). Long-term performance of the stabilized waste is an issue

that must be addressed in considering any S/S technology. In this guide, several tests are recommended to aid in evaluating the

long-term performance of the stabilized wastes.

1.2 The CCPs that are suited to this application include fly ash, spent dry scrubber sorbents, and certain advanced sulfur control

by-products from processes such as duct injection and fluidized-bed combustion (FBC).

1.3 The wastes or wastewater, or both, containing the problematic inorganic species will likely be highly variable, so the

chemical characteristics of the waste or wastewater to be treated must be determined and considered in the selection and

application of any stabilizing agent, including CCPs. In any waste stabilization process, laboratory-scale tests for compatibility

between the candidate waste or wastewater for stabilization with one or more selected CCPs and final waste stability are

recommended prior to full-scale application of the stabilizing agent.

1.4 This guide does not intend to recommend full-scale processes or procedures for waste stabilization. Full-scale processes

should be designed and carried out by qualified scientists, engineers, and environmental professionals. It is recommended that

stabilized materials generated at the full-scale stabilization site be subjected to testing to verify laboratory test results.

1.5 The utilization of CCPs under this guide is a component of a pollution prevention program; Guide E1609 describes pollution

prevention activities in more detail. Utilization of CCPs in this manner conserves land, natural resources, and energy.

1.6 This guide applies only to CCPs produced primarily from the combustion of coal. It does not apply to ash or other

combustion products derived from the burning of waste; municipal, industrial, or commercial garbage; sewage sludge or other

refuse, or both; derived fuels; wood waste products; rice hulls; agricultural waste; or other noncoal fuels.

1.7 Regulations governing the use of CCPs vary by state. The user of this guide has the responsibility to determine and comply

with applicable regulations.

1.8 It is recommended that work performed under this guide be designed and carried out by qualified scientists, engineers, and

environmental professionals.

This guide is under the jurisdiction of ASTM Committee E50 on Environmental Assessment, Risk Management and Corrective Action and is the direct responsibility

of Subcommittee E50.03 on Pollution Prevention/Beneficial Beneficial Use.

Current edition approved Oct. 1, 2006Dec. 1, 2014. Published October 2006February 2015. Originally approved in 2000. Last previous edition approved in 20002006 as

F2060 – 00.F2060 – 06. DOI: 10.1520/E2060-06.10.1520/E2060-06R14.

The boldface numbers in parentheses refer to the list of references at the end of the text.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2060 − 06 (2014)

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C114 Test Methods for Chemical Analysis of Hydraulic Cement

C311 Test Methods for Sampling and Testing Fly Ash or Natural Pozzolans for Use in Portland-Cement Concrete

C400 Test Methods for Quicklime and Hydrated Lime for Neutralization of Waste Acid

D75 Practice for Sampling Aggregates

D422 Test Method for Particle-Size Analysis of Soils

D558 Test Methods for Moisture-Density (Unit Weight) Relations of Soil-Cement Mixtures

D653 Terminology Relating to Soil, Rock, and Contained Fluids

D1556 Test Method for Density and Unit Weight of Soil in Place by Sand-Cone Method

D1633 Test Methods for Compressive Strength of Molded Soil-Cement Cylinders

D1635 Test Method for Flexural Strength of Soil-Cement Using Simple Beam with Third-Point Loading

D2166 Test Method for Unconfined Compressive Strength of Cohesive Soil

D2216 Test Methods for Laboratory Determination of Water (Moisture) Content of Soil and Rock by Mass

D2922 Test Methods for Density of Soil and Soil-Aggregate in Place by Nuclear Methods (Shallow Depth) (Withdrawn 2007)

D2937 Test Method for Density of Soil in Place by the Drive-Cylinder Method

D3441 Test Method for Mechanical Cone Penetration Tests of Soil (Withdrawn 2014)

D3877 Test Methods for One-Dimensional Expansion, Shrinkage, and Uplift Pressure of Soil-Lime Mixtures

D3987 Practice for Shake Extraction of Solid Waste with Water

D4318 Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils

D4842 Test Method for Determining the Resistance of Solid Wastes to Freezing and Thawing (Withdrawn 2006)

D4843 Test Method for Wetting and Drying Test of Solid Wastes

D4972 Test Method for pH of Soils

D5084 Test Methods for Measurement of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall

Permeameter

D5239 Practice for Characterizing Fly Ash for Use in Soil Stabilization

E1609 Guide for Development and Implementation of a Pollution Prevention Program (Withdrawn 2010)

3. Terminology

3.1 Definitions:

3.1.1 Definitions are in accordance with Terminology D653.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 advanced sulfur control (ASC) products— by-products generated from advanced coal conversion technologies including

FBC and gasification and by-products from advanced environmental emissions cleanup technologies such as duct injection and

lime injection multiphase burners (LIMB).

3.2.2 baghouse—a facility constructed at some coal-fired power plants consisting of fabric filter bags that mechanically trap

particulates (fly ash) carried in the flue gases.

3.2.3 beneficial use—projects promoting public health and environmental protection, offering equivalent success relative to

other alternatives, and preserving natural resources.

3.2.4 BDAT—best demonstrated available technology.

3.2.5 boiler slag—a molten ash collected at the base of slag tap and cyclone boilers that is quenched in a water-filled hopper

and shatters into black, angular particles having a smooth, glassy appearance.

3.2.6 bottom ash—agglomerated ash particles formed in pulverized coal boilers that are too large to be carried in the flue gases

and impinge on the boiler walls or fall through open grates to an ash hopper at the bottom of the boiler. Bottom ash is typically

grey-to-black in color, is quite angular, and has a porous surface texture.

3.2.7 coal combustion products—fly ash, bottom ash, boiler ash, or flue gas desulfurization (FGD) material resulting from the

combustion of coal.

3.2.8 DSC—differential scanning calorimetry.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

E2060 − 06 (2014)

3.2.9 DTA—differential thermal analysis.

3.2.10 DTG—differential thermal gravimetry.

3.2.11 electrostatic precipitator—a facility constructed at some coal-fired power plants to remove particulate matter (fly ash)

from the flue gas by producing an electric charge on the particles to be collected and then propelling the charged particles by

electrostatic forces to collecting curtains.

3.2.12 encapsulation—complete coating or enclosure of a toxic particle by an additive so as to sequester that particle from any

environmental receptors that may otherwise have been negatively impacted by that particle.

3.2.13 ettringite—a mineral with the nominal composition Ca Al (SO ) (OH) · 26H O. Ettringite is also the family name for

6 2 4 3 12 2

a series of related compounds, known as a mineral group or family, which includes the following minerals (1):

Ettringite Ca Al (SO ) (OH) · 26H O

6 2 4 3 12 2

Charlesite Ca (Si,Al) (SO ) (B[OH] )(OH) · 26H O

6 2 4 2 4 12 2

Sturmanite Ca Fe (SO ) (B[OH] )(OH) · 26H O

6 2 4 2 4 12 2

Thaumasite Ca Si (SO ) (CO ) (OH) · 24H O

6 2 4 2 3 2 12 2

Jouravskite Ca Mn (SO ) (CO ) (OH) · 24H O

6 2 4 2 3 2 12 2

Bentorite Ca (Cr,Al) (SO ) (OH) · 26H O

6 2 4 3 12 2

3.2.14 flue gas desulfurization material—a by-product of the removal of the sulfur gases from the flue gases, typically using a

high-calcium sorbent such as lime or limestone. Sodium-based sorbents are also used in some systems. The three primary types

of FGD processes commonly used by utilities are wet scrubbers, dry scrubbers, and sorbent injection. The physical nature of these

by-products varies from a wet, thixotropic sludge to a dry powdered material, depending on the process.

3.2.15 fly ash—coal ash that exits a combustion chamber in the flue gas. Coal fly ashes are typically pozzolans. Some coal fly

ashes also exhibit self-hardening properties in the presence of moisture.

3.2.16 pozzolans—siliceous or siliceous and aluminous materials that in themselves possess little or no cementitious value but

will, in finely divided form and in the presence of moisture, chemically react with calcium hydroxides at ordinary temperatures

to form compounds possessing cementitious properties.

3.2.17 S/S—solidification/stabilization.

3.2.18 stabilization or fixation—immobilization of undesirable constituents to limit their introduction into the environment.

Toxic components are immobilized by treating them chemically to form insoluble compounds.

3.2.19 solidification—the conversion of soils, liquids, or sludges into a solid, structurally sound material for disposal or use,

typically referring to attainment of 50 psi or strength of surrounding soil.

3.2.20 XRD—x-ray diffraction.

4. Significance and Use

4.1 General—CCPs can have chemical and mineralogical compositions that are conducive to use in the chemical stabilization

of trace elements in wastes and wastewater. These elements include, but are not limited to, arsenic, barium, boron, cadmium,

chromium, cobalt, lead, molybdenum, nickel, selenium, vanadium, and zinc. Chemical stabilization may be accompanied by

solidification of the waste treated. Solidification is not a requirement for the stabilization of many trace elements, but does offer

advantages in waste handling and in reduced permeability of the stabilized waste. This guide addresses the use of CCPs as a

stabilizing agent without addition of other materials. S/S is considered the BDAT for the disposal of some wastes that contain

metals since they cannot be destroyed by other means (2).

4.1.1 Advantages of Using CCPs—Advantages of using CCPs for waste stabilization include their ready availability in high

volumes, generally good product consistency from one source, and easy handling. CCPs vary depending on the combustion or

emission control process and the coal or sorbents used, or both, and CCPs contain trace elements, although usually at very low

concentrations. CCPs are generally an environmentally suitable materials option for waste stabilization, but the compatibility of

a specific CCP must be evaluated with individual wastes or wastewater through laboratory-scale tests followed by full-scale

demonstration and field verification. CCPs suitable for this chemical stabilization have the ability to incorporate large amounts of

free water into hydration products. CCPs that exhibit high pHs (>11.5) offer advantages in stabilizing trace elements that exist as

oxyanions in nature (such as arsenic, boron, chromium, molybdenum, selenium, and vanadium) and trace elements that form

oxyhydroxides or low-solubility precipitates at high pH (such as lead, cadmium, barium, and zinc). Additionally, CCPs that exhibit

cementitious properties offer advantages in solidifying CCP-waste mixtures as a result of the hydration reactions of the CCP. These

same hydration reactions frequently result in the formation of mineral phases that stabilize or chemically fix the trace elements of

concern.

4.2 Chemical/Mineralogical Composition—Since CCPs are produced under conditions of high temperature, reactions with

water during contact with water or aqueous solutions can be expected. Mineral formation may contribute to the chemical fixation

and/or solidification achieved in the waste stabilization process. One example of this type of chemical fixation is achieved by

ettringite for

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.