ASTM F1554-04

(Specification)Standard Specification for Anchor Bolts, Steel, 36, 55, and 105-ksi Yield Strength

Standard Specification for Anchor Bolts, Steel, 36, 55, and 105-ksi Yield Strength

SCOPE

1.1 This specification covers straight and bent, headed and headless, carbon, carbon boron, alloy, or high-strength low-alloy steel anchor bolts. The anchor bolts are furnished in three strength grades, two thread classes, and in the sizes specified in Section 4.

1.2 The anchor bolts are intended for anchoring structural supports to concrete foundations. Such structural supports include building columns, column supports for highway signs, street lighting and traffic signals, steel bearing plates, and similar applications.

1.3 Supplementary requirements are included to provide for Grade 55 weldable steel, permanent manufacturers and grade identification, and impact properties for Grades 55 and 105.

1.4 Zinc coating requirements are included in Section 7 for applications requiring corrosion protection.

1.5 The recommended grade and style of nut and washer are included in 6.6 and 6.7 for each grade.

1.6 This specification does not cover the requirements for mechanical expansion anchors, powder-activated nails or studs, or anchor bolts fabricated from deformed bar.

1.7 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: F 1554 – 04

Standard Specification for

1

Anchor Bolts, Steel, 36, 55, and 105-ksi Yield Strength

This standard is issued under the fixed designation F1554; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Section S1.5.1 was editorially corrected in March 2007.

1. Scope* Nuts for Bolts for High-Pressure or High-Temperature

Service, or Both

1.1 This specification covers straight and bent, headed and

A370 TestMethodsandDefinitionsforMechanicalTesting

headless, carbon, carbon boron, alloy, or high-strength low-

of Steel Products

alloy steel anchor bolts (also known as anchor rods). The

A563 Specification for Carbon and Alloy Steel Nuts

anchor bolts are furnished in three strength grades, two thread

A673/A673M Specification for Sampling Procedure for

classes, and in the sizes specified in Section 4.

Impact Testing of Structural Steel

1.2 The anchor bolts are intended for anchoring structural

A 751 Test Methods, Practices, and Terminology for

supports to concrete foundations. Such structural supports

Chemical Analysis of Steel Products

include building columns, column supports for highway signs,

B695 Specification for Coatings of Zinc Mechanically

street lighting and traffic signals, steel bearing plates, and

Deposited on Iron and Steel

similar applications.

D3951 Practice for Commercial Packaging

1.3 Supplementary requirements are included to provide for

F436 Specification for Hardened Steel Washers

Grade 55 weldable steel, permanent manufacturers and grade

F606 Test Methods for Determining the Mechanical Prop-

identification, and impact properties for Grades 55 and 105.

erties of Externally and Internally Threaded Fasteners,

1.4 Zinc coating requirements are included in Section 7 for

Washers, and Rivets

applications requiring corrosion protection.

2.2 Research Council on Structural Connections Stan-

1.5 Therecommendedgradeandstyleofnutandwasherare

3

dard:

included in 6.6 and 6.7 for each grade.

Specification for Structural Joints Using ASTM A325 or

1.6 This specification does not cover the requirements for

A490 Bolts

mechanical expansion anchors, powder-activated nails or

4

2.3 ANSI/ASME Standards:

studs, or anchor bolts fabricated from deformed bar.

B1.1 Unified Screw Threads

1.7 Thevaluesstatedininch-poundunitsaretoberegarded

B1.3 Screw Thread Gaging Systems for Dimensional Ac-

as the standard. The values given in parentheses are for

ceptability

information only.

B18.2.2 Square and Hex Nuts

2. Referenced Documents

B18.18.2M Inspection and Quality Assurance for High

2

Volume Machine Assembly Fasteners

2.1 ASTM Standards:

A153/A153M SpecificationforZincCoating(Hot-Dip)on

3. Terminology

Iron and Steel Hardware

3.1 Definitions of Terms Specific to This Standard:

A194/A194M Specification for Carbon and Alloy Steel

3.1.1 anchor bolt—steel rod or bar, one end of which is

intended to be cast in concrete, while the opposite end is

threaded and projects from the concrete, for anchoring other

1

This specification is under the jurisdiction of ASTM Committee F16 on

materialtotheconcrete.Theendcastinconcretemaybeeither

Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts,

straightorprovidedwithananchorsuchasabenthook,forged

Nuts, Rivets and Washers.

Current edition approved Aug. 1, 2004. Published August 2004. Originally

approved in 1994. Last previous edition approved in 1999 as F1554–99.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Research Council on Structural Connections, c/o Industrial

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Fasteners Institute, 1717 East 9th Street, Cleveland, OH 44114.

4

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

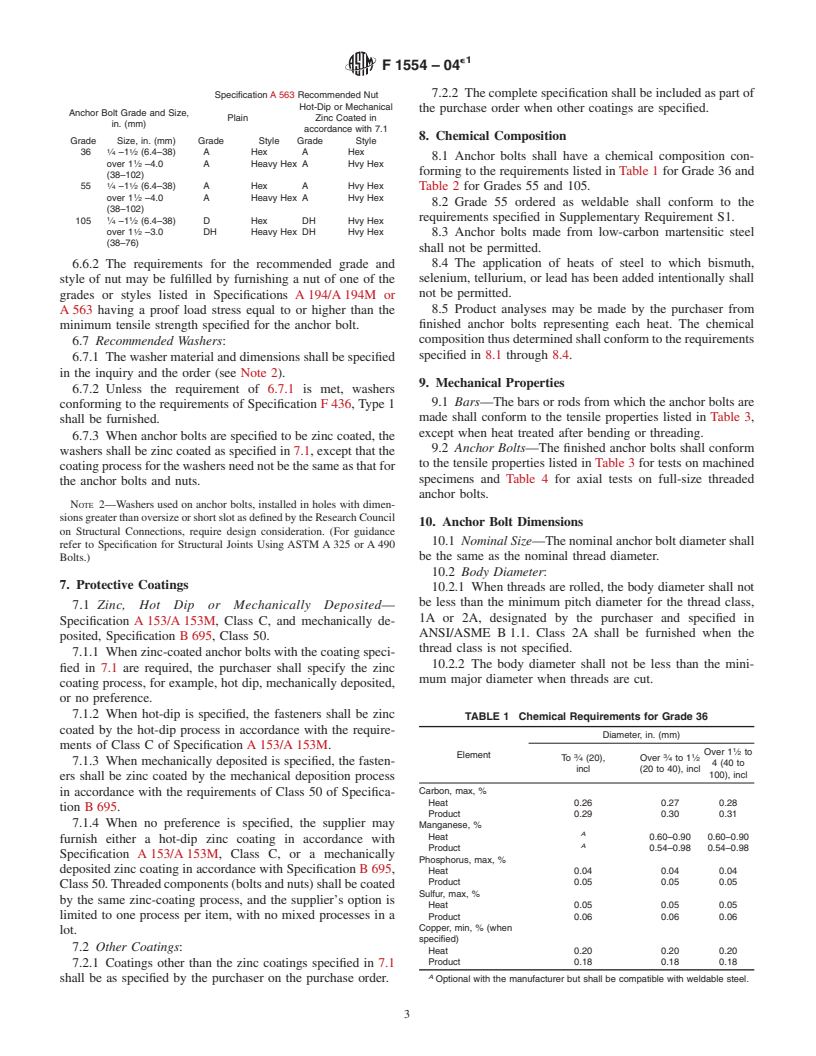

e1

F1554–04

head,oratappedorweldedattachmenttoresistforcesimposed 5.1.10 Number of washers, either the total number or

on the anchor bolt, as required. number per bolt, and dimensions if other than standard.

5.1.11 Inspection at place of manufacture, if required (see

3.1.2 manufacturer—manufacturer of the anchor bolt; the

party that performs the cutting, bending, and threading opera- 15.1).

5.1.12 Color coding, if different from the standard in 19.1.

tions.

5.1.13 Test rep

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.