ASTM D500-95(2009)

(Test Method)Standard Test Methods of Chemical Analysis of Sulfonated and Sulfated Oils

Standard Test Methods of Chemical Analysis of Sulfonated and Sulfated Oils

ABSTRACT

These test methods cover the chemical analysis of sulfonated and sulfated oils. Water by distillation with volatile solvent and moisture and volatile matter by hot-plate shall be tested to meet the requirements prescribed. Titration test, extraction-titration test, and ash-gravimetric test shall be performed to meet the requirements specified. Total desulfated fatty matter, total active ingredients, unsaponifiable non-volatile matter, inorganic salts, total alkalinity, and total ammonia shall be tested to meet the requirements prescribed. In the absence of ammonium or triethanolamine soaps test method, brine test method, and in the presence of ammonium or triethanolamine soaps test method shall be performed to meet the requirements prescribed. Water-immiscible organic solvents volatile with steam shall be tested to meet the requirements prescribed.

SCOPE

1.1 These test methods cover the chemical analysis of sulfonated and sulfated oils. The analytical procedures appear in the following order:

Section Moisture: Test Method A. Water by Distillation with Volatile Solvent4-9 Test Method B. Moisture and Volatile Matter by Hot-Plate Method10-14 Organically Combined Sulfuric Anhydride: Test Method A. Titration Test15-19 Test Method B. Extraction-Titration Test20-24 Test Method C. Ash-Gravimetric Test (in the Presence of True

Sulfonates)25-28 Total Desulfated Fatty Matter29-32 Total Active Ingredients33-36 Unsaponifiable Nonvolatile Matter37-41 Inorganic Salts42-46 Total Alkalinity47-49 Total Ammonia50-52 Acidity as Free Fatty Acids or Acid Number: Test Method A. In the Absence of Ammonium or Triethanolamine Soaps53-56 Test Method B. In the Presence of Dark Colored Oils but in the

Absence of Ammonium or Triethanolamine Soaps (Brine Test)57-60 Test Method C. In the Presence of Ammonium or Triethanolamine Soaps61-63 Water-Immiscible Organic Solvents Volatile with Steam64-70

1.2 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units may be approximate.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Material Safety Data Sheets are available for reagents and materials. Review them for hazards prior to usage.

4.1 This test method covers the determination of water existing in a sample of sulfonated or sulfated oil, or both, by distilling the sample with a volatile solvent. The method is applicable only to sulfonated and sulfated oils that do not contain the following: mineral acids, free sulfonic acids, or free sulfuric acid esters; or alkali hydroxides, carbonates or acetates; or alcohol, glycerin, diethylene glycol, acetone, or other water-miscible volatile compounds.

10.1 This test method covers the determination of the percentage of water and other compounds volatile at about 100°C existing in a sample of sulfonated or sulfated oil, or both, by rapid evaporation. The test method is applicable only to sulfonated and sulfated oils that do not contain the following: mineral acids, free sulfonic acids or free sulfuric acid esters, ammonia, acetic acid or similar volatile acids, alkali hydroxides, carbonates, acetates or similar salts that may react with oleic acid at elevated temperatures liberating volatile acids, or glycerin, diethylene glycol, xylene, or other compounds of similar volatility.

15.1 This test method covers the determination of the organically combined sulfuric anhydride existing in a sample of sulfated oil by boiling the sample with sulfuric acid and determining the acidity of the reaction mixture. This method is applicable only to oils that split off their combined SO3 upon boiling with mineral acids and that do not contain compounds that cannot be accurately titrated in wat...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D500 − 95(Reapproved 2009)

Standard Test Methods of

Chemical Analysis of Sulfonated and Sulfated Oils

This standard is issued under the fixed designation D500; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 These test methods cover the chemical analysis of 2.1 ASTM Standards:

sulfonated and sulfated oils. The analytical procedures appear D1193Specification for Reagent Water

in the following order:

3. Purity of Reagents

Section

3.1 Purity of Reagents—Reagent grade chemicals shall be

Moisture:

used in all tests. Unless otherwise indicated, it is intended that

Test Method A. Water by Distillation with Volatile Solvent 4–9

all reagents shall conform to the specifications of the Commit-

Test Method B. Moisture and Volatile Matter by Hot-Plate Method 10–14

Organically Combined Sulfuric Anhydride:

tee onAnalytical Reagents of theAmerican Chemical Society,

Test Method A. Titration Test 15–19

where such specifications are available. Other grades may be

Test Method B. Extraction-Titration Test 20–24

Test Method C. Ash-Gravimetric Test (in the Presence of True 25–28 used, provided it is first ascertained that the reagent is of

Sulfonates)

sufficiently high purity to permit its use without lessening the

Total Desulfated Fatty Matter 29–32

accuracy of the determination.

Total Active Ingredients 33–36

Unsaponifiable Nonvolatile Matter 37–41

3.2 Purity of Water—Unless otherwise indicated, references

Inorganic Salts 42–46

towatershallbeunderstoodtomeanreagentwaterconforming

Total Alkalinity 47–49

Total Ammonia 50–52

to Specification D1193.

Acidity as Free Fatty Acids or Acid Number:

Test Method A. In the Absence of Ammonium or Triethanolamine 53–56

MOISTURE

Soaps

Test Method B. In the Presence of Dark Colored Oils but in the 57–60

Method A. Water by Distillation with Volatile Solvent

Absence of Ammonium or Triethanolamine Soaps (Brine Test)

Test Method C. In the Presence of Ammonium or Triethanolamine 61–63

Soaps 4. Scope

Water-Immiscible Organic Solvents Volatile with Steam 64–70

4.1 This test method covers the determination of water

1.2 The values stated in inch-pound units are to be regarded

existing in a sample of sulfonated or sulfated oil, or both, by

as the standard. The metric equivalents of inch-pound units

distilling the sample with a volatile solvent. The method is

may be approximate.

applicable only to sulfonated and sulfated oils that do not

1.3 This standard does not purport to address all of the

containthefollowing:mineralacids,freesulfonicacids,orfree

safety concerns, if any, associated with its use. It is the

sulfuric acid esters; or alkali hydroxides, carbonates or ac-

responsibility of the user of this standard to establish appro-

etates;oralcohol,glycerin,diethyleneglycol,acetone,orother

priate safety and health practices and determine the applica-

water-miscible volatile compounds.

bility of regulatory limitations prior to use. Material Safety

Data Sheets are available for reagents and materials. Review

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

them for hazards prior to usage.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

These test methods are under the jurisdiction of ASTM Committee D12 on the ASTM website.

SoapsandOtherDetergentsandisthedirectresponsibilityofSubcommitteeD12.12 Reagent Chemicals, American Chemical Society Specifications, American

on Analysis and Specifications of Soaps, Synthetics, Detergents and their Compo- Chemical Society, Washington, DC. For suggestions on the testing of reagents not

nents. listed by the American Chemical Society, see Analar Standards for Laboratory

Current edition approved Oct. 1, 2009. Published December 2009. Originally Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

approved in 1937. Last previous edition approved in 2003 as D500–95(2003). and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

DOI: 10.1520/D0500-95R09. MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D500 − 95 (2009)

5. Apparatus each 1-mL line numbered (5 mL at top). The error in any

indicated capacity may not be greater than 0.05 mL.

5.1 The apparatus required consists of a glass flask heated

by suitable means and provided with a reflux condenser

6. Reagents

discharging into a trap and connected to the flask. The

6.1 Oleic Acid, heated previous to use for 5 to 10 min over

connections between the trap and the condenser and flask shall

a free flame at a temperature of 130 to 135°C.

beinterchangeablegroundjoints.Thetrapservestocollectand

6.2 Xylene.

measure the condensed water and to return the solvent to the

flask.Asuitable assembly of the apparatus is illustrated in Fig.

7. Calibration

1.

7.1 To calibrate the apparatus add approximately1gof

5.1.1 Flask,500-mL,ofeithertheshort-neck,round-bottom

water to a mixture of 80 g of xylene and 10 g of oleic acid.

type or the Erlenmeyer type.

Conduct the distillation as described in 8.2 – 8.4.When all the

5.1.2 Heat Source—The source of heat may be either an oil

water has distilled, cool the apparatus, add another g of water,

bath (stearic acid, paraffin wax, etc.), or an electric heater

and repeat the distillation. Continue the calibration up to the

providedwithaslidingrheostatorothermeansofheatcontrol.

capacity of the receiving tube.

5.1.3 Condenser—A water-cooled glass reflux condenser

(Fig. 1), having a jacket approximately 400 mm (15 ⁄4 in.) in

8. Procedure

3 1

length with an inner tube 9.5 to 12.7 mm ( ⁄8 to ⁄2 in.) in

8.1 Clean the condenser and the receiving tube thoroughly

outsidediameter.Theendofthecondensertobeinsertedinthe

with soap and warm water before using. Rinse well, then treat

trapshallbegroundoffatanangleof30°fromtheverticalaxis

with hot cleaning solution (a mixture of 10 mL of saturated

of the condenser. When inserted into the trap, the tip of the

potassium dichromate (K Cr O ) and 990 mL of sulfuric acid

2 2 7

condensershallbeabout7mm( ⁄4in.)abovethesurfaceofthe

(H SO , sp gr 1.84)), and finally thoroughly wash and dry.

2 4

liquid in the trap after the distillation conditions have been

8.2 Take enough of the sample to be tested for analysis to

established. Fig. 1 shows a conventional sealed-in type of

condenser, but any other condenser fulfilling the detailed yield about 4 mLof water. Introduce the approximate quantity

into a weighing bottle and make the weighings from the bottle

requirements above may be used.

5.1.4 Trap—Atrapmadeofwell-annealedglassconstructed into the flask, taking care that after removal of the sample no

drops of oil are left on the outside of the weighing bottle.Add

in accordance with Fig. 1 and graduated as shown to contain 5

mLat 20°C. It shall be subdivided into 0.1-mLdivisions, with 80 g of xylene and oleic acid equivalent to about two and

one-half times the weight of the bone-dry sample to prevent

foaming and jellying of the contents of the flask. Introduce

glass beads to prevent bumping and mix the contents of the

flask thoroughly by swirling, taking care to avoid any loss of

material.Fillthetrapwithxyleneandimmediatelyconnectthe

flask with the distillation apparatus. Insert a loose cotton plug

in the top of the condenser tube to prevent condensation of

atmospheric moisture in the condenser tube.

8.3 Heat the flask and regulate the heating so that the

condenser tube immediately below the water jacket is just

barely hot. In this way a minimum of water will condense

farther up the condenser where it may be difficult to volatilize

any moisture condensed on the walls.

8.4 Continue the distillation at the specified rate until

practically no water is visible on any part of the apparatus

except within the graduations of the trap. This operation

usuallyrequireslessthan1h.Increasetherateofdistillationin

order to remove all traces of condensed water in the condenser

tube, and continue the distillation until the water level in the

trap remains unchanged after a 10-min interval. Dislodge any

droplets adhering to the side of the receiver with a thin copper

wire twisted into a loop. Immerse the receiving tube in warm

A=45to55mm water at about 40°C for 15 min or until the xylene layer

B = 22 to 24 mm in inside diameter

becomes clear, then read and record the temperature and the

C = 9 to 11 mm in inside diameter

exact volume of the water in the trap.

D = 235 to 240 mm

E = 146 to 156 mm

9. Calibration

F and G are interchangeable joints, standard taper 24/40.

9.1 The volume of condensed water measured in the trap

maybeconvertedintoitsequivalentweightingramsbymeans

FIG. 1 Apparatus for Water Determination by Distillation with

Volatile Solvent, Method A of Table 1. Calculate the percentage of water as follows:

D500 − 95 (2009)

A

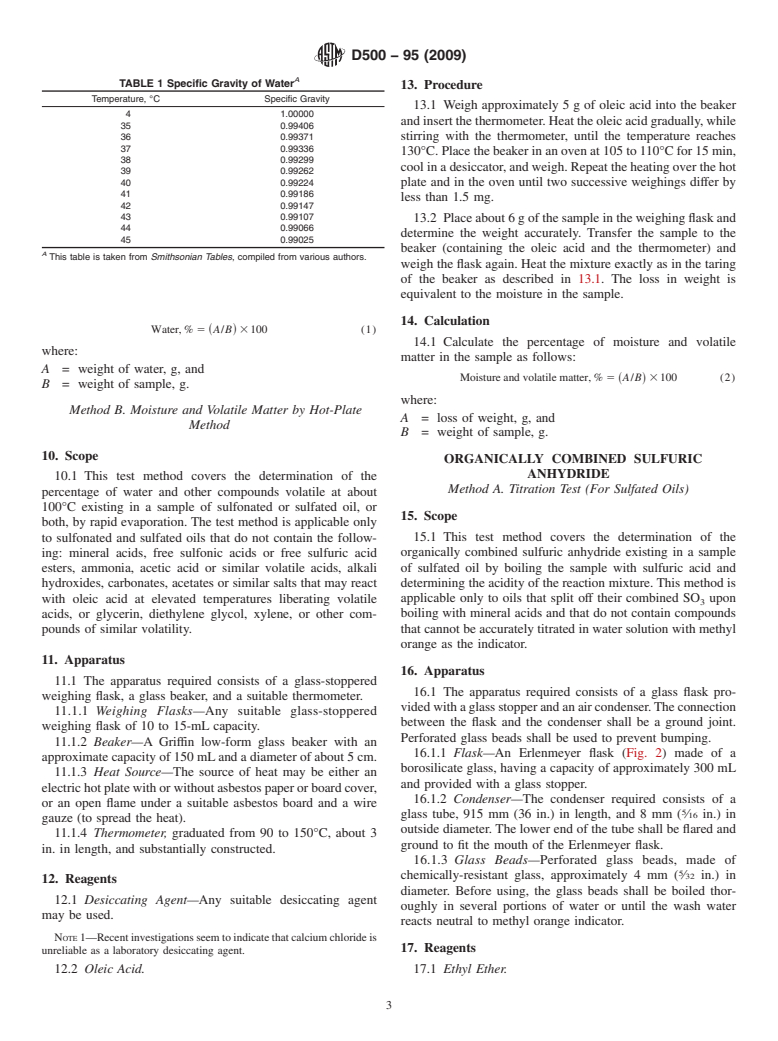

TABLE 1 Specific Gravity of Water

13. Procedure

Temperature, °C Specific Gravity

13.1 Weigh approximately5gof oleic acid into the beaker

4 1.00000

andinsertthethermometer.Heattheoleicacidgradually,while

35 0.99406

36 0.99371 stirring with the thermometer, until the temperature reaches

37 0.99336

130°C.Placethebeakerinanovenat105to110°Cfor15min,

38 0.99299

coolinadesiccator,andweigh.Repeattheheatingoverthehot

39 0.99262

40 0.99224 plate and in the oven until two successive weighings differ by

41 0.99186

less than 1.5 mg.

42 0.99147

43 0.99107

13.2 Placeabout6gofthesampleintheweighingflaskand

44 0.99066

determine the weight accurately. Transfer the sample to the

45 0.99025

beaker (containing the oleic acid and the thermometer) and

A

This table is taken from Smithsonian Tables, compiled from various authors.

weigh the flask again. Heat the mixture exactly as in the taring

of the beaker as described in 13.1. The loss in weight is

equivalent to the moisture in the sample.

14. Calculation

Water,% 5 A/B 3100 (1)

~ !

14.1 Calculate the percentage of moisture and volatile

where:

matter in the sample as follows:

A = weight of water, g, and

Moistureandvolatilematter,% 5 A/B 3100 (2)

~ !

B = weight of sample, g.

where:

Method B. Moisture and Volatile Matter by Hot-Plate

A = loss of weight, g, and

Method

B = weight of sample, g.

10. Scope

ORGANICALLY COMBINED SULFURIC

ANHYDRIDE

10.1 This test method covers the determination of the

Method A. Titration Test (For Sulfated Oils)

percentage of water and other compounds volatile at about

100°C existing in a sample of sulfonated or sulfated oil, or

15. Scope

both, by rapid evaporation. The test method is applicable only

to sulfonated and sulfated oils that do not contain the follow- 15.1 This test method covers the determination of the

organically combined sulfuric anhydride existing in a sample

ing: mineral acids, free sulfonic acids or free sulfuric acid

esters, ammonia, acetic acid or similar volatile acids, alkali of sulfated oil by boiling the sample with sulfuric acid and

determining the acidity of the reaction mixture.This method is

hydroxides, carbonates, acetates or similar salts that may react

with oleic acid at elevated temperatures liberating volatile applicable only to oils that split off their combined SO upon

boiling with mineral acids and that do not contain compounds

acids, or glycerin, diethylene glycol, xylene, or other com-

pounds of similar volatility. that cannot be accurately titrated in water solution with methyl

orange as the indicator.

11. Apparatus

16. Apparatus

11.1 The apparatus required consists of a glass-stoppered

16.1 The apparatus required consists of a glass flask pro-

weighing flask, a glass beaker, and a suitable thermometer.

videdwithaglassstopperandanaircondenser.Theconnection

11.1.1 Weighing Flasks—Any suitable glass-stoppered

between the flask and the condenser shall be a ground joint.

weighing flask of 10 to 15-mL capacity.

Perforated glass beads shall be used to prevent bumping.

11.1.2 Beaker—A Griffin low-form glass beaker with an

16.1.1 Flask—An Erlenmeyer flask (Fig. 2) made of a

approximatecapacityof150mLandadiameterofabout5cm.

borosilicate glass, having a capacity of approximately 300 mL

11.1.3 Heat Source—The source of heat may be either an

and provided with a glass stopper.

electrichotplatewithorwithoutasbestospaperorboardcover,

16.1.2 Condenser—The condenser required consists of a

or an open flame under a suitable asbestos board and a wire

glass tube, 915 mm (36 in.) in length, and 8 mm ( ⁄16 in.) in

gauze (to spread the heat).

outside diameter.The lower end of the tube shall be flared and

11.1.4 Thermometer, graduated from 90 to 150°C, about 3

ground to fit the mouth of the Erlenmeyer flask.

in. in length, and substantially constructed.

16.1.3 Glass Beads—Perforated glass beads, made of

chemically-resistant glass, approximately 4 mm ( ⁄32 in.) in

12. Reagents

diameter. Before using, the glass beads shall be boiled thor-

12.1 Desiccating Agent—Any suitable desiccating agent

oughly in several portions of water or until the wash water

may be used.

reacts neutral to methyl orange indicator.

NOTE1—Recentinvestigationsseemtoindicatethatcalciumchlorideis

17. Reagents

unreliable as a laboratory desiccating agent.

12.2 Oleic Acid. 17.1 Ethyl Ether.

D500 − 95 (2009)

after each addition of reagent. Drain burets for 3 min before

taking readings. Calculate the alkalinity, A, as follows:

A 5 @ B 3 D 2 C 3 E #/W (3)

~ ! ~ !

where:

A = total alkalinity, mg of KOH/g,

B = millilitresofH SO requiredfortitrationofthesample,

2 4

C = millilitresofNaOHsolutionrequiredfortitrationofthe

sample,

D = strength of H SO , mg of KOH/mL,

2 4

E = strength of NaOH solution, mg of KOH/mL, and

W = weight of sample, g.

18.1.2 Increase in Acidity upon Boiling, F—Weigh 10 g of

the sample into the Erlenmeyer flask and boil under the air

condenserwithH SO (1+19)for1 ⁄2horuntilboththeoiland

2 4

water layers are perfectly clear, using glass beads to prevent

bumping. The volume of H SO added shall be sufficient to

2 4

neutralize the total alkalinity, A, of the sample plus 25 mL in

FIG. 2 Apparatus for Determination of Organically Combined

excess. Regulate the heating so that the solution boils rather

Sulfuric Anhydride, Method A

vigorously but with very little evaporation taking place.At the

end of the heating period allow the contents to cool, wash the

17.2 Methyl Orange Indicator Solution (1 g/L)—Dissolve condenser with a spray of water from a wash bottle, and

0.1 g of methyl orange i

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D500 – 95 (Reapproved 2003)

Standard Test Methods of

Chemical Analysis of Sulfonated and Sulfated Oils

This standard is issued under the fixed designation D500; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods cover the chemical analysis of sulfonated and sulfated oils. The analytical procedures appear in the

following order:

Section

Moisture:

Test Method A. Water by Distillation with Volatile Solvent 4-9

Test Method B. Moisture and Volatile Matter by Hot-Plate Method 10-14

Organically Combined Sulfuric Anhydride:

Test Method A. Titration Test 15-19

Test Method B. Extraction-Titration Test 20-24

Test Method C. Ash-Gravimetric Test (in the Presence of True 25-28

Sulfonates)

Total Desulfated Fatty Matter 29-32

Total Active Ingredients 33-36

Unsaponifiable Nonvolatile Matter 37-41

Inorganic Salts 42-46

Total Alkalinity 47-49

Total Ammonia 50-52

Acidity as Free Fatty Acids or Acid Number:

Test Method A. In the Absence of Ammonium or Triethanolamine 53-56

Soaps

Test Method B. In the Presence of Dark Colored Oils but in the 57-60

Absence of Ammonium or Triethanolamine Soaps (Brine Test)

Test Method C. In the Presence of Ammonium or Triethanolamine 61-63

Soaps

Water-Immiscible Organic Solvents Volatile with Steam 64-70

1.2 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units may

be approximate.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Material Safety Data Sheets are available for reagents and materials. Review them for hazards prior to

usage.

2. Referenced Documents

2.1 ASTM Standards:

D1193 Specification for Reagent Water

3. Purity of Reagents

3.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

These test methods are under the jurisdiction of ASTM Committee D12 on Soaps and Other Detergents and is the direct responsibility of Subcommittee D12.12 on

Analysis of Soaps and Synthetic Detergents.

Current edition approved April 15, 1995. Published June 1995. Originally published as D500–37. Last previous edition D500–89. DOI: 10.1520/D0500-95R039.

Annual Book of ASTM Standards, Vol 11.01.

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For suggestions on the testing of reagents not listed by

the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville, MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D500 – 95 (2003)

3.2 Purity of Water—Unless otherwise indicated, references to water shall be understood to mean reagent water conforming to

Specification D1193.

MOISTURE

Method A. Water by Distillation with Volatile Solvent

4. Scope

4.1 This test method covers the determination of water existing in a sample of sulfonated or sulfated oil, or both, by distilling

the sample with a volatile solvent.The method is applicable only to sulfonated and sulfated oils that do not contain the following:

mineral acids, free sulfonic acids, or free sulfuric acid esters; or alkali hydroxides, carbonates or acetates; or alcohol, glycerin,

diethylene glycol, acetone, or other water-miscible volatile compounds.

5. Apparatus

5.1 The apparatus required consists of a glass flask heated by suitable means and provided with a reflux condenser discharging

into a trap and connected to the flask. The connections between the trap and the condenser and flask shall be interchangeable

groundjoints.Thetrapservestocollectandmeasurethecondensedwaterandtoreturnthesolventtotheflask.Asuitableassembly

of the apparatus is illustrated in Fig. 1.

5.1.1 Flask, 500-mL, of either the short-neck, round-bottom type or the Erlenmeyer type.

5.1.2 Heat Source—The source of heat may be either an oil bath (stearic acid, paraffin wax, etc.), or an electric heater provided

with a sliding rheostat or other means of heat control.

5.1.3 Condenser—Awater-cooled glass reflux condenser (Fig. 1), having a jacket approximately 400 mm (15 ⁄4 in.) in length

3 1

with an inner tube 9.5 to 12.7 mm ( ⁄8 to ⁄2 in.) in outside diameter. The end of the condenser to be inserted in the trap shall be

ground off at an angle of 30° from the vertical axis of the condenser. When inserted into the trap, the tip of the condenser shall

beabout7mm( ⁄4in.)abovethesurfaceoftheliquidinthetrapafterthedistillationconditionshavebeenestablished.Fig.1shows

a conventional sealed-in type of condenser, but any other condenser fulfilling the detailed requirements above may be used.

5.1.4 Trap—Atrapmadeofwell-annealedglassconstructedinaccordancewithFig.1andgraduatedasshowntocontain5mL

at 20°C. It shall be subdivided into 0.1-mL divisions, with each 1-mL line numbered (5 mL at top). The error in any indicated

capacity may not be greater than 0.05 mL.

6. Reagents

6.1 Oleic Acid, heated previous to use for 5 to 10 min over a free flame at a temperature of 130 to 135°C.

A=45to55mm

B = 22 to 24 mm in inside diameter

C = 9 to 11 mm in inside diameter

D = 235 to 240 mm

E = 146 to 156 mm

F and G are interchangeable joints, standard taper 24/40.

FIG. 1 Apparatus for Water Determination by Distillation with

Volatile Solvent, Method A

D500 – 95 (2003)

6.2 Xylene.

7. Calibration

7.1 To calibrate the apparatus add approximately1gof water to a mixture of 80 g of xylene and 10 g of oleic acid. Conduct

the distillation as described in 8.2-8.4. When all the water has distilled, cool the apparatus, add another g of water, and repeat the

distillation. Continue the calibration up to the capacity of the receiving tube.

8. Procedure

8.1 Clean the condenser and the receiving tube thoroughly with soap and warm water before using. Rinse well, then treat with

hot cleaning solution (a mixture of 10 mL of saturated potassium dichromate (K Cr O ) and 990 mL of sulfuric acid (H SO,sp

2 2 7 2 4

gr 1.84)), and finally thoroughly wash and dry.

8.2 Take enough of the sample to be tested for analysis to yield about 4 mL of water. Introduce the approximate quantity into

a weighing bottle and make the weighings from the bottle into the flask, taking care that after removal of the sample no drops of

oil are left on the outside of the weighing bottle. Add 80 g of xylene and oleic acid equivalent to about two and one-half times

the weight of the bone-dry sample to prevent foaming and jellying of the contents of the flask. Introduce glass beads to prevent

bumpingandmixthecontentsoftheflaskthoroughlybyswirling,takingcaretoavoidanylossofmaterial.Fillthetrapwithxylene

and immediately connect the flask with the distillation apparatus. Insert a loose cotton plug in the top of the condenser tube to

prevent condensation of atmospheric moisture in the condenser tube.

8.3 Heat the flask and regulate the heating so that the condenser tube immediately below the water jacket is just barely hot. In

thiswayaminimumofwaterwillcondensefartherupthecondenserwhereitmaybedifficulttovolatilizeanymoisturecondensed

on the walls.

8.4 Continue the distillation at the specified rate until practically no water is visible on any part of the apparatus except within

thegraduationsofthetrap.Thisoperationusuallyrequireslessthan1h.Increasetherateofdistillationinordertoremovealltraces

of condensed water in the condenser tube, and continue the distillation until the water level in the trap remains unchanged after

a 10-min interval. Dislodge any droplets adhering to the side of the receiver with a thin copper wire twisted into a loop. Immerse

the receiving tube in warm water at about 40°C for 15 min or until the xylene layer becomes clear, then read and record the

temperature and the exact volume of the water in the trap.

9. Calibration

9.1 The volume of condensed water measured in the trap may be converted into its equivalent weight in grams by means of

Table 1. Calculate the percentage of water as follows:

Water,% 5 ~A/B! 3100 (1)

where:

A = weight of water, g, and

B = weight of sample, g.

Method B. Moisture and Volatile Matter by Hot-Plate Method

10. Scope

10.1 Thistestmethodcoversthedeterminationofthepercentageofwaterandothercompoundsvolatileatabout100°Cexisting

inasampleofsulfonatedorsulfatedoil,orboth,byrapidevaporation.Thetestmethodisapplicableonlytosulfonatedandsulfated

oilsthatdonotcontainthefollowing:mineralacids,freesulfonicacidsorfreesulfuricacidesters,ammonia,aceticacidorsimilar

volatile acids, alkali hydroxides, carbonates, acetates or similar salts that may react with oleic acid at elevated temperatures

liberating volatile acids, or glycerin, diethylene glycol, xylene, or other compounds of similar volatility.

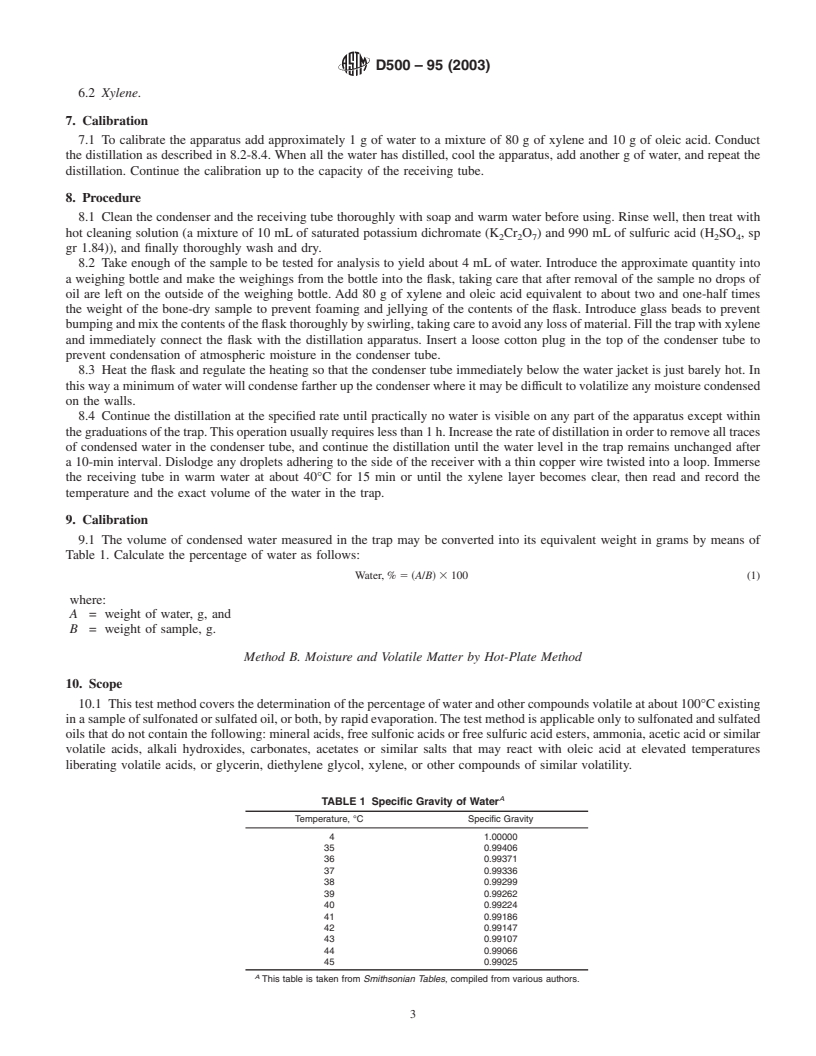

A

TABLE 1 Specific Gravity of Water

Temperature, °C Specific Gravity

4 1.00000

35 0.99406

36 0.99371

37 0.99336

38 0.99299

39 0.99262

40 0.99224

41 0.99186

42 0.99147

43 0.99107

44 0.99066

45 0.99025

A

This table is taken from Smithsonian Tables, compiled from various authors.

D500 – 95 (2003)

11. Apparatus

11.1 The apparatus required consists of a glass-stoppered weighing flask, a glass beaker, and a suitable thermometer.

11.1.1 Weighing Flasks—Any suitable glass-stoppered weighing flask of 10 to 15-mL capacity.

11.1.2 Beaker—A Griffin low-form glass beaker with an approximate capacity of 150 mL and a diameter of about 5 cm.

11.1.3 Heat Source—The source of heat may be either an electric hot plate with or without asbestos paper or board cover, or

an open flame under a suitable asbestos board and a wire gauze (to spread the heat).

11.1.4 Thermometer, graduated from 90 to 150°C, about 3 in. in length, and substantially constructed.

12. Reagents

12.1 Desiccating Agent—Any suitable desiccating agent may be used.

NOTE 1—Recent investigations seem to indicate that calcium chloride is unreliable as a laboratory desiccating agent.

12.2 Oleic Acid.

13. Procedure

13.1 Weigh approximately5gof oleic acid into the beaker and insert the thermometer. Heat the oleic acid gradually, while

stirring with the thermometer, until the temperature reaches 130°C. Place the beaker in an oven at 105 to 110°C for 15 min, cool

in a desiccator, and weigh. Repeat the heating over the hot plate and in the oven until two successive weighings differ by less than

1.5 mg.

13.2 Place about6gofthe sample in the weighing flask and determine the weight accurately.Transfer the sample to the beaker

(containing the oleic acid and the thermometer) and weigh the flask again. Heat the mixture exactly as in the taring of the beaker

as described in 13.1. The loss in weight is equivalent to the moisture in the sample.

14. Calculation

14.1 Calculate the percentage of moisture and volatile matter in the sample as follows:

Moistureandvolatilematter,% 5 ~A/B! 3100 (2)

where:

A = loss of weight, g, and

B = weight of sample, g.

ORGANICALLY COMBINED SULFURIC ANHYDRIDE

Method A. Titration Test (For Sulfated Oils)

15. Scope

15.1 This test method covers the determination of the organically combined sulfuric anhydride existing in a sample of sulfated

oil by boiling the sample with sulfuric acid and determining the acidity of the reaction mixture. This method is applicable only

to oils that split off their combined SO upon boiling with mineral acids and that do not contain compounds that cannot be

accurately titrated in water solution with methyl orange as the indicator.

16. Apparatus

16.1 Theapparatusrequiredconsistsofaglassflaskprovidedwithaglassstopperandanaircondenser.Theconnectionbetween

the flask and the condenser shall be a ground joint. Perforated glass beads shall be used to prevent bumping.

16.1.1 Flask—An Erlenmeyer flask (Fig. 2) made of a borosilicate glass, having a capacity of approximately 300 mL and

provided with a glass stopper.

16.1.2 Condenser—The condenser required consists of a glass tube, 915 mm (36 in.) in length, and 8 mm ( ⁄16 in.) in outside

diameter. The lower end of the tube shall be flared and ground to fit the mouth of the Erlenmeyer flask.

16.1.3 Glass Beads—Perforated glass beads, made of chemically-resistant glass, approximately 4 mm ( ⁄32 in.) in diameter.

Beforeusing,theglassbeadsshallbeboiledthoroughlyinseveralportionsofwateroruntilthewashwaterreactsneutraltomethyl

orange indicator.

17. Reagents

17.1 Ethyl Ether.

17.2 Methyl Orange Indicator Solution (1 g/L)—Dissolve 0.1 g of methyl orange in 100 mL of water.

17.3 Sodium Chloride (NaCl), solid.

17.4 Sodium Hydroxide, Standard Solution (1 N)—Accurately prepare and standardize a 1 N sodium hydroxide (NaOH)

solution. Express the strength or concentration of the solution as milligrams of KOH per millilitre; 1 mL of 1 N NaOH solution

is equivalent to 56.1 mg of KOH.

D500 – 95 (2003)

FIG. 2 Apparatus for Determination of Organically Combined

Sulfuric Anhydride, Method A

17.5 Sodium Hydroxide, Standard Solution (0.5 N)—Accurately prepare and standardize a 0.5 N NaOH solution. Express the

strength of the solution as milligrams of KOH per millilitre; 1 mL of 0.5 N NaOH solution is equivalent to 28.05 mg of KOH.

17.6 Sulfuric Acid, Standard (0.5 N)—Accurately prepare and standardize a 0.5 N sulfuric acid (H SO ) solution. Express the

2 4

strength of the solution as milligrams of KOH per millilitre; 1 mL of 0.5 N H SO is equivalent to 28.05 mg of KOH.

2 4

17.7 SulfuricAcid(1 + 19)—Carefullymix1volumeofconcentratedsulfuricacid(H SO ,spgr1.84)into19volumesofwater

2 4

while stirring.

18. Procedure

18.1 Theprocedureconsistsoft

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.