ASTM E1054-02

(Test Method)Standard Test Methods for Evaluation of Inactivators of Antimicrobial Agents

Standard Test Methods for Evaluation of Inactivators of Antimicrobial Agents

SCOPE

1.1 These methods are used to determine the effectiveness of procedures and agents for inactivating (neutralizing, quenching) the microbiocidal properties of antimicrobial agents and to ensure that no components of the neutralizing procedures and agents, themselves, exert an inhibitory effect on microorganisms targeted for recovery.

Note 1—Knowledge of microbiological and statistical techniques is required for these procedures. These methods are not applicable to testing with viruses (see Test Method E 1482).

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1054–02

Standard Test Methods for

Evaluation of Inactivators of Antimicrobial Agents

This standard is issued under the fixed designation E 1054; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 antimicrobial effectiveness evaluation—a determina-

tion of microbiocidal properties of an antimicrobial agent by

1.1 These methods are used to determine the effectiveness

methods, such as Test Methods E 645 and E 1115.

of procedures and agents for inactivating (neutralizing,

3.1.3 CFU/mL—colony-forming units of a microorganism

quenching) the microbiocidal properties of antimicrobial

per millilitre of fluid.

agents and to ensure that no components of the neutralizing

3.1.4 neutralizer—a procedure or chemical agent used to

proceduresandagents,themselves,exertaninhibitoryeffecton

inactivate,neutralize,orquenchthemicrobiocidalpropertiesof

microorganisms targeted for recovery.

an antimicrobial agent.

NOTE 1—Knowledge of microbiological and statistical techniques is

3.1.5 neutralizer effectiveness—a neutralizer’s ability to

required for these procedures. These methods are not applicable to testing

inactivate,neutralize,orquenchthemicrobiocidalpropertiesof

with viruses (see Test Method E 1482).

an antimicrobial agent.

1.2 This standard does not purport to address all of the

3.1.6 neutralizer toxicity—any inhibitory effects a neutral-

safety concerns, if any, associated with its use. It is the

izer may have on the survival of a microbial population.

responsibility of the user of this standard to establish appro-

3.1.7 test material control—an evaluation of the activity of

priate safety and health practices and determine the applica-

an test material in reducing a known population of microor-

bility of regulatory limitations prior to use.

ganisms.

3.1.8 test organism viability—the population or viability of

2. Referenced Documents

a challenge microorganism used in a neutralization assay.

2.1 ASTM Standards:

E 645 Test Method for Effectiveness of Microbicides Used 4. Summary of Test Methods

in Cooling Systems

NOTE 2—The neutralization test method selected must be identical to

E 1115 Test Method for Evaluation of Surgical Hand Scrub

the method used in the antimicrobial effectiveness evaluation.

Formulations

4.1 Neutralization Assay with Recovery on Solid Medium—

E 1482 Test Method for Neutralization of Virucidal Agents

Neutralization assay for antimicrobial effectiveness tests that

in Virucidal Effectiveness Evaluations

recover and quantify microorganism populations on solid

(agar) media. This method is appropriate for antimicrobial

3. Terminology

agents that can be chemically inactivated or diluted to sub-

3.1 Definitions of Terms Specific to This Standard:

inhibitory levels.

3.1.1 antimicrobial agent—a test formulation, chemical

4.2 Neutralization Assay with Recovery in Liquid

compound, or product designed to prevent the growth of

Medium—Neutralization assay for antimicrobial effectiveness

microbes either by inhibiting growth or destroying the mi-

tests that recover surviving microorganism populations in

crobe.

liquid media for a growth/no growth determination. This

method is appropriate for antimicrobial agents that can be

chemically inactivated or diluted to sub-inhibitory levels.

These test methods are under the jurisdiction of ASTM Committee E35 on

4.3 Neutralization Assay with Recovery by Membrane

Pesticides and are the direct responsibility of Subcommittee E35.15 on Antimicro-

Filtration—Neutralization assay for antimicrobial effective-

bial Agents.

ness tests that recover and quantify microorganism populations

Current edition approved May 10, 2002. Published August 2002. Originally

published as E 1054 – 85. Last previous edition E 1054 – 91.

by using membrane filtration. This method is appropriate for

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

antimicrobial agents that cannot be chemically inactivated or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

diluted to sub-inhibitory levels. This method should not be

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. usedwhendifficultiesareincurredduringthefiltrationprocess.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1054–02

5. Significance and Use brane filter unit should be suitable for testing the antimicrobial

agent and recovery of the microorganisms.

5.1 The effectiveness of antimicrobial agents such as disin-

fectants, sanitizers and antiseptics are measured by their ability

7. Reagents and Materials

to kill microorganisms at or for a specified contact time.

7.1 Phosphate Buffered Saline Dilution Water—PBS (see

Accuratedeterminationofantimicrobialeffectivenesstherefore

Test Method E 645).

requires efficient and effective inactivation (neutralization) of

7.1.1 Phosphate Buffer Solution, Stock—Dissolve 34.0 g of

theantimicrobialagent.Inefficientorincompleteneutralization

potassium dihydrogen phosphate (KH PO ) in 500 mL of

2 4

will permit killing or inactivation of microorganisms to con-

water.Adjust pH to 7.2 6 0.2 with 0.1 N NaOH or 0.1 N HCl

tinue beyond the experimental exposure time, resulting in an

and bring to 1000 mL with deionized water.

over-estimation of antimicrobial activity.

7.1.2 Phosphate Buffer Saline Dilution Water—Add 1.25

5.2 The neutralization methods commonly used in antimi-

mL of stock phosphate buffer solution and 8.75 g of NaCl to a

crobial effectiveness evaluations are chemical inactivation,

volumetric flask, fill with deionized water to the 1000 mL

dilution and filtration. All critical parameters, for example,

mark, and mix. Final pH should be 7.2 6 0.2. Sterilize by

media, microorganism(s), equipment, and temperature of solu-

filtration or autoclave.

tions, of the antimicrobial effectiveness evaluation must be

7.2 Because the types of materials and reagents required for

mimicked when evaluating a neutralization procedure to be

various antimicrobial effectiveness evaluations are so diverse,

used in the antimicrobial effectiveness evaluation.

it is impractical to list them in this method. The specific

5.3 The evaluation must include at least three replications

materials and reagents to be used in the antimicrobial effec-

(five replications in Section 9) so that a statistical analysis can

tiveness evaluation, however, should be tested in the neutral-

be performed with the recovery data. The number of replicates

ization assay to confirm that the antimicrobial agent is being

used in the evaluation depends on the statistical significance

neutralized in a particular evaluation.

required for the expected results, the variability encountered in

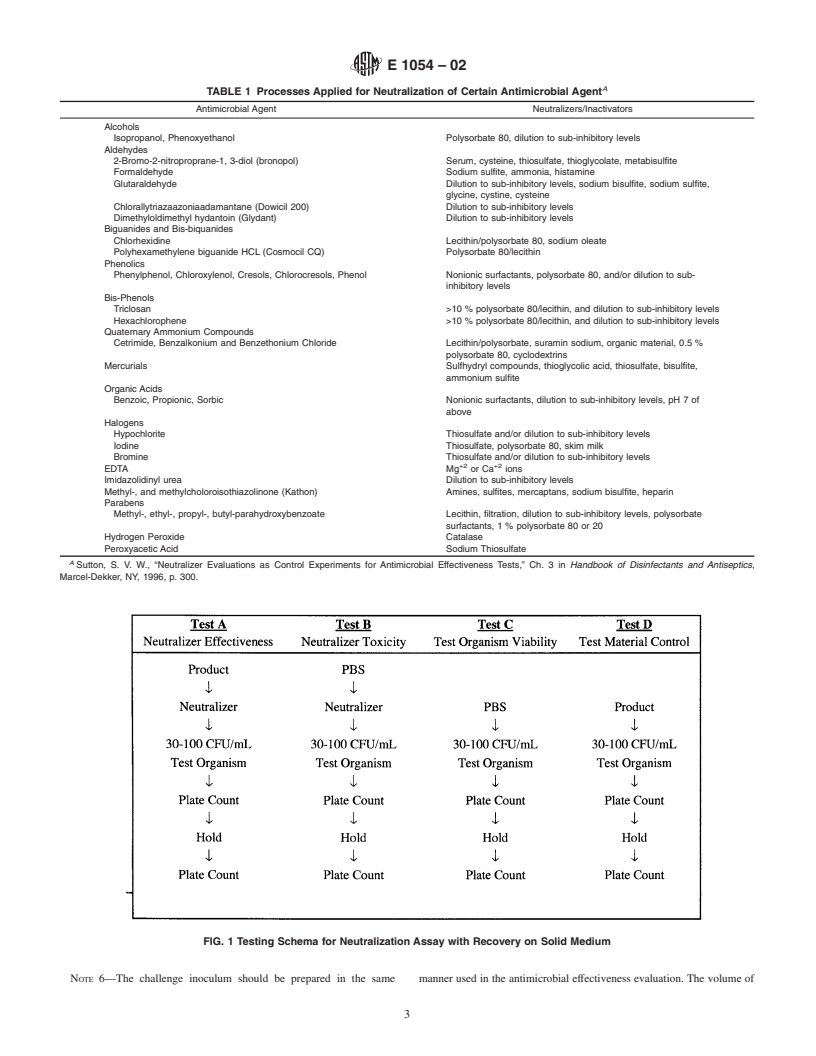

7.3 Table1providesapartiallistofmaterialsthathavebeen

the evaluation, and the relative efficacy of the neutralization

employed by researchers to inactivate the microbiocidal prop-

procedure.

erties of various antimicrobial agents. This list is provided as a

5.4 A limitation of these evaluation procedures is that they

guide for selecting neutralizers. A neutralization assay should

use microorganisms that have not been exposed to an antimi-

be performed to determine a selected neutralizer’s effective-

crobial. Under experimental conditions, cells exposed to neu-

ness.

tralization procedures are likely to be damaged to different

degrees by the antimicrobial agent. Sublethal injury may be a

8. Neutralization Assay with Recovery on Solid Medium

factor in recovery and the role of the neutralization procedure

(Fig. 1)

in recovery of injured organisms should be examined.

8.1 At least three replicates are required for these proce-

NOTE 3—Ideally, all microorganisms used in the antimicrobial effec-

dures.The number of replicates used in the evaluation depends

tiveness evaluation should be tested in the neutralization assay. However,

on the statistical significance required for the expected results,

“representative” organisms may be selected for testing, as judged appro-

the variability encountered in the evaluation, and the relative

priate by the investigator. The investigator is cautioned that failure to

efficacy of the neutralization procedure.

identify neutralizer efficacy and toxicity for all microorganisms could

8.2 All tests must be performed in a timely manner so that

result in exaggerated microbial reductions in an antimicrobial effective-

replication of the test organism does not occur.

ness evaluation. Also, for studies involving multiple antimicrobial prod-

ucts and a sample containing multiple species of microorganisms (for 8.3 Test A—Neutralizer Effectiveness:

example, skin flora), a single neutralizing procedure and/or combination

8.3.1 Add a volume of product, or solution containing

of agents suitable for the multiple products must be used for testing.

product, to neutralizer that will result in the same dilution ratio

to be used in the antimicrobial effectiveness evaluation. If the

6. Apparatus

antimicrobial effectiveness evaluation will employ the use of

6.1 Standard bacteriological devices and equipment should

carriers, use instead a carrier containing an amount of product

be used for performance of the neutralization assay. representative of that to be used in the test.

6.2 Colony Counter—Anyofseveraltypesmaybeused;for

NOTE 4—The dilution ratio of product to neutralizer can be manipu-

example, Quebec colony counters and similar devices, or

lated to determine the dilution at which adequate neutralization of the

automated, computerized plater/counter systems.

product will occur, particularly when testing products not readily neutral-

ized by chemical means.

6.3 Incubator—Any incubator capable of maintaining an

NOTE 5—The sequence of product-into-neutralizer, followed by the

appropriate temperature for growth of the microorganism may

challenge microorganism, allows the neutralizing action to take place. If

be used.

the microorganism is introduced into the neutralizing solution prior to

6.4 Sterilizer—Any steam sterilizer capable of producing

adding the product, there is possibility of the product acting on the

the conditions of sterilization.

microorganism there by reducing the population and disqualifying the

neutralizer.

6.5 Timer (stopwatch)—One that displays hours, minutes,

and seconds.

8.3.2 Within5sofexecutionof8.3.1,inoculatetheproduct/

6.6 Vortex Mixer or equivalent.

neutralizer mixture with a volume of the challenge microor-

6.7 Membrane Filter Units—Any sterilizable unit that per- ganism suspension so that the resulting suspension contains 30

mits filtration of microorganisms for enumeration. The mem- to 100 CFU/mL of the microorganism.

E1054–02

A

TABLE 1 Processes Applied for Neutralization of Certain Antimicrobial Agent

Antimicrobial Agent Neutralizers/Inactivators

Alcohols

Isopropanol, Phenoxyethanol Polysorbate 80, dilution to sub-inhibitory levels

Aldehydes

2-Bromo-2-nitroproprane-1, 3-diol (bronopol) Serum, cysteine, thiosulfate, thioglycolate, metabisulfite

Formaldehyde Sodium sulfite, ammonia, histamine

Glutaraldehyde Dilution to sub-inhibitory levels, sodium bisulfite, sodium sulfite,

glycine, cystine, cysteine

Chlorallytriazaazoniaadamantane (Dowicil 200) Dilution to sub-inhibitory levels

Dimethyloldimethyl hydantoin (Glydant) Dilution to sub-inhibitory levels

Biguanides and Bis-biquanides

Chlorhexidine Lecithin/polysorbate 80, sodium oleate

Polyhexamethylene biguanide HCL (Cosmocil CQ) Polysorbate 80/lecithin

Phenolics

Phenylphenol, Chloroxylenol, Cresols, Chlorocresols, Phenol Nonionic surfactants, polysorbate 80, and/or dilution to sub-

inhibitory levels

Bis-Phenols

Triclosan >10 % polysorbate 80/lecithin, and dilution to sub-inhibitory levels

Hexachlorophene >10 % polysorbate 80/lecithin, and dilution to sub-inhibitory levels

Quaternary Ammonium Compounds

Cetrimide, Benzalkonium and Benzethonium Chloride Lecithin/polysorbate, suramin sodium, organic material, 0.5 %

polysorbate 80, cyclodextrins

Mercurials Sulfhydryl compounds, thioglycolic acid, thiosulfate, bisulfite,

ammonium sulfite

Organic Acids

Benzoic, Propionic, Sorbic Nonionic surfactants, dilution to sub-inhibitory levels, pH 7 of

above

Halogens

Hypochlorite Thiosulfate and/or dilution to sub-inhibitory levels

Iodine Thiosulfate, polysorbate 80, skim milk

Bromine Thiosulfate and/or dilution to sub-inhibitory levels

+2 +2

EDTA Mg or Ca ions

Imidazolidinyl urea Dilution to sub-inhibitory levels

Methyl-, and methylcholoroisothiazolinone (Kathon) Amines, sulfites, mercaptans, sodium bisulfite, heparin

Parabens

Methyl-, ethyl-, propyl-, butyl-parahydroxybenzoate Lecithin, filtration, dilution to sub-inhibitory levels, polysorbate

surfactants, 1 % polysorbate 80 or 20

Hydrogen Peroxide Catalase

Peroxyacetic Acid Sodium Thiosulfate

A

Sutton, S. V. W., “Neutralizer Evaluations as Control Experiments for Antimicrobial Effectiveness Tests,” Ch. 3 in Handbook of Disinfectants and Antiseptics,

Marcel-Dekker, NY, 1996, p. 300.

FIG. 1 Testing Schema for Neutralization Assay with Recovery on Solid Medium

NOTE 6—The challenge inoculum should be prepared in the same manner used in the antimicrobial effectiveness evaluation. The volume of

E1054–02

the challenge inoculum should be kept to a minimum so it does not cause

8.5.2 Within 1 min of execution of 8.5.1, enumerate the

significant dilution of the product/neutralizer mixture.

PBS/microorganism suspension by quantitative pour or spread

plates, in duplicate, using an appropriate plating medium that

8.3.3 Within 1 min of execution of 8.3.2, enumerate the

does not contain neutralizers and is not a selective plating

product/neutralizer/microorganism suspension by quantitative

medium.

pour or spread plates, in duplicate, using appropriate plating

8.5.3 Allow the PBS/microorganism suspension to stand for

medium. If neutralizers are to be incorporated in the plating

the same exposure period used in Test A (see 8.3.4).

medium for the antimicrobial effectiveness evaluation, use this

8.5.4 After the hold-time, enumerate the PBS/

same medium for plating the suspension.

microorganism suspension by quantitative pour or spread

8.3.4 Allow the product/neutralizer/microorganism suspen-

plates, in duplicate, using an appropriate plating medium that

sion to stand for the longest exposure period representative of

does not contain neutralizers and is not a selective plating

that to be used in the antimicrobial effectiveness evaluation.

medium.

For

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.