ASTM F1182-90(2001)

(Specification)Standard Specification for Anodes, Sacrificial Zinc Alloy

Standard Specification for Anodes, Sacrificial Zinc Alloy

SCOPE

1.1 This specification covers the requirements for zinc anodes in the form of slabs, plates, discs, and rods for corrosion protection (cathodic protection) of metals and alloys.

1.2 The anodes are primarily intended to reduce corrosion of surface ship and submarine hulls, steel and aluminum equipment and structures, sea chests, sonar domes, and the seawater side of condensers and other heat exchangers.

1.3 The values stated in inch-pound units are to be regarded as standard. The metric (SI) units, given in parentheses, are for information purposes only and may be approximate.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 1182 – 90 (Reapproved 2001)

Standard Specification for

Anodes, Sacrificial Zinc Alloy

This standard is issued under the fixed designation F 1182; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope MIL-STD-105 Sampling Procedures and Tables for Inspec-

tion by Attributes

1.1 This specification covers the requirements for zinc

MIL-STD-129 Marking for Shipment and Storage

anodesintheformofslabs,plates,discs,androdsforcorrosion

MIL-STD-1186 Cushioning,Anchoring,Bracing,Blocking,

protection (cathodic protection) of metals and alloys.

and Waterproofing; With Appropriate Test Methods

1.2 The anodes are primarily intended to reduce corrosion

2.4 Military Specification:

of surface ship and submarine hulls, steel and aluminum

MIL-P-15011 Pallets Material Handling, Wood Post Con-

equipment and structures, sea chests, sonar domes, and the

struction, 4-Way Entry

seawater side of condensers and other heat exchangers.

2.5 Federal Specifications:

1.3 The values stated in inch-pound units are to be regarded

PPP-B-601 Boxes, Wood, Cleated Plywood

asstandard.Themetric(SI)units,giveninparentheses,arefor

PPP-B-621 Boxes, Wood, Nailed and Lock-Corner

information purposes only and may be approximate.

PPP-B-636 Boxes, Shipping, Fiberboard

1.4 This standard does not purport to address the safety

2.6 American National Standards Institute Standard:

concerns associated with its use. It is the responsibility of the

ANSI/ASME B1.20.1—Pipe Threads, General Purpose

user of this standard to establish appropriate safety and health

(Inch)

practices and determine the applicability of regulatory limita-

tions prior to use.

3. Classification

2. Referenced Documents 3.1 The anodes shall be of the following classes and types,

as specified (see 4.1.2):

2.1 Order of Precedence—Intheeventofaconflictbetween

3.1.1 Class 1—Cast-in cores:

thetextofthisspecificationandthereferencescitedherein,the

3.1.1.1 Type ZHS—Zinc,hullslab,steelstraps,23and42-lb

text of this specification shall take precedence.

(10 and 19-kg) sizes.

2.2 ASTM Standards

3.1.1.2 Type ZHB—Zinc, hull slab, brass straps, 23-lb

A36/A36M Specification for Carbon Structural Steel

3 (10-kg) size.

B21 Specification for Naval Brass Rod, Bar, and Shapes

3.1.1.3 Type ZHC—Zinc, hull slab, core strap, 23 and 42-lb

B103 SpecificationforPhosphorBronzePlate,Sheet,Strip,

3 (10 and 19-kg) sizes.

and Rolled Bar

3.1.1.4 Type ZSS—Zinc, submarine slab, steel strap, 12 and

D3951 Practice for Commercial Packaging

24-lb (5 and 11-kg) sizes.

E290 TestMethodforSemi-GuidedBendTestforDuctility

3.1.1.5 Type ZTS—Zinc, teardrop shape, steel strap, 5-lb

of Metallic Materials

(2-kg) size.

E536 Test Method for ChemicalAnalysis of Zinc and Zinc

3.1.1.6 Type ZEP—Zinc, heat exchanger or fair water disc,

Alloys

7 (pipe core or pipe bushing core):

2.3 Military Standards:

Style A square slab, 9-lb (4-kg) size

Style B circular slab, various sizes

This specification is under the jurisdiction ofASTM Committee F25 on Ships

Style C semicircular slab, 23-lb (10-kg) size

and Marine Technology and is the direct responsibility of Subcommittee F25.07 on

3.1.1.7 Type ZBP—Zinc, bar, pipe core, 8-lb (4-kg) size.

General Requirements.

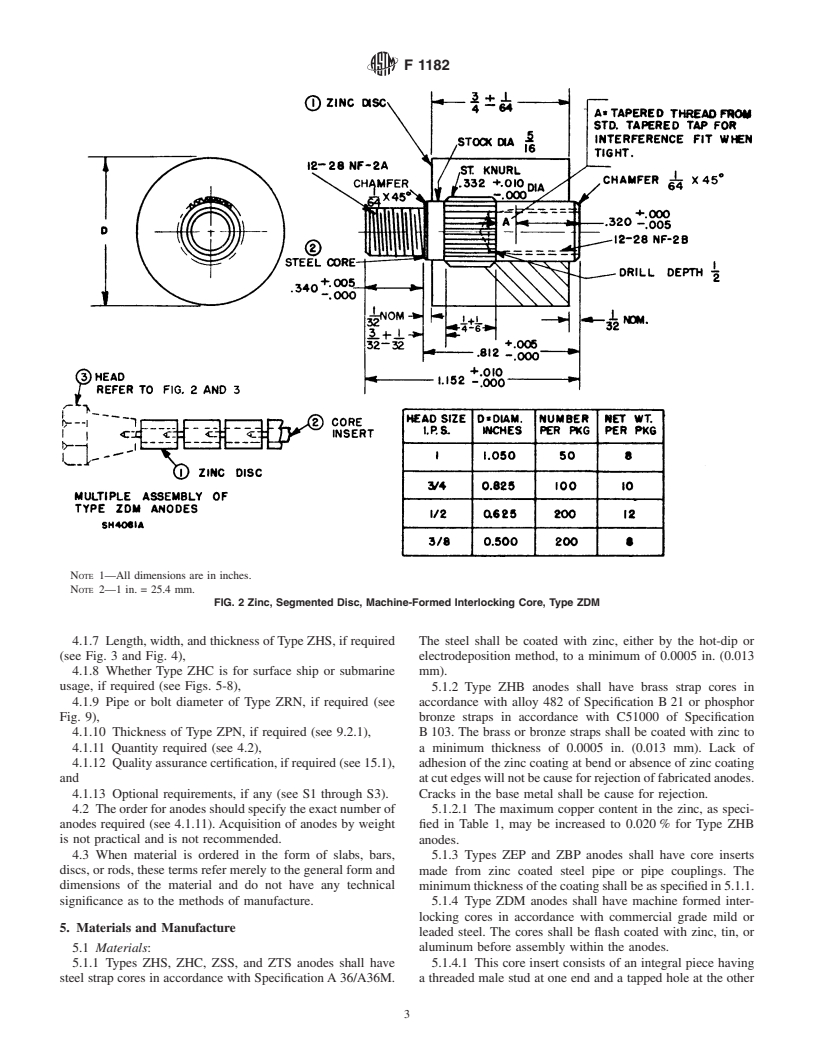

3.1.1.8 Type ZDM—Zinc, segmented disc, machine formed

Current edition approved June 29, 1990. Published August 1990. Originally

interlocking core, various sizes.

published as F1182-88. Last previous edition F1182-88.

Annual Book of ASTM Standards, Vol 01.04.

3.1.2 Class 2—Plain, no cores;

Annual Book of ASTM Standards, Vol 02.01.

Annual Book of ASTM Standards, Vol 15.09.

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 03.05.

7 8

AvailablefromStandardizationDocuments,OrderDesk,Building4,SectionD, Available from American National Standards Institute, 25 W. 43rd St., 4th

700 Robbins Ave., Philadelphia, PA 19111–5094, Attn: NPODS. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1182

3.1.2.1 Type ZRN—Zinc, rod, no core, extruded, drawn or

B brass straps

S steel straps

rolled.

C core strap

3.1.2.2 Type ZPN—Zinc, plate, no core, rolled.

P pipe core

M machine formed interlocking core

3.2 The letter designations of types of anodes have the

N no core

following meanings:

3.2.1 The first letter designates anode metal:

4. Ordering Information

Z zinc

4.1 Ordersformaterialunderthisspecificationshallinclude

the following information:

3.2.2 The second letter designates the shape or general use:

4.1.1 ASTM designation and year of issue,

H hull slab

S submarine slab 4.1.2 Class and type (see 3.1),

T teardrop shape

4.1.3 StyleofTypeZEP,ifrequired(see3.1.1.6andFig.1),

E heat exchanger slab

4.1.4 Diameter of Type ZEP, Style B, if required (see Fig.

R rod, cylindrical

P plate 1),

B bar, square

4.1.5 For Type ZDM, whether straight or tapered thread

D disc, segmented

support plug head is required (see section 5.1.4.2,)

3.2.3 The third letter designates the core: 4.1.6 Diameter of Type ZDM, if required (see Fig. 2),

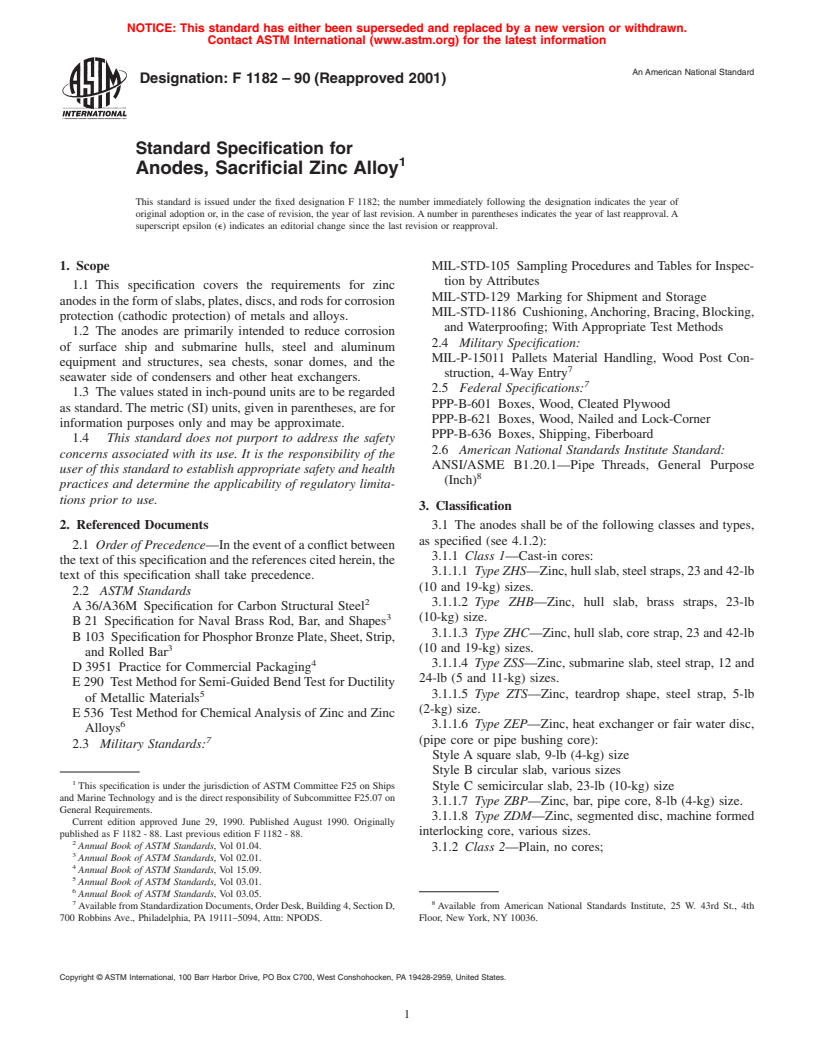

FIG. 1 ZEP Heat Exchanger Slab

F 1182

NOTE 1—All dimensions are in inches.

NOTE 2—1 in. = 25.4 mm.

FIG. 2 Zinc, Segmented Disc, Machine-Formed Interlocking Core, Type ZDM

4.1.7 Length, width, and thickness ofType ZHS, if required The steel shall be coated with zinc, either by the hot-dip or

(see Fig. 3 and Fig. 4), electrodeposition method, to a minimum of 0.0005 in. (0.013

4.1.8 Whether Type ZHC is for surface ship or submarine mm).

usage, if required (see Figs. 5-8), 5.1.2 Type ZHB anodes shall have brass strap cores in

4.1.9 Pipe or bolt diameter of Type ZRN, if required (see accordance with alloy 482 of Specification B21 or phosphor

Fig. 9), bronze straps in accordance with C51000 of Specification

4.1.10 Thickness of Type ZPN, if required (see 9.2.1), B103. The brass or bronze straps shall be coated with zinc to

4.1.11 Quantity required (see 4.2), a minimum thickness of 0.0005 in. (0.013 mm). Lack of

4.1.12 Qualityassurancecertification,ifrequired(see15.1), adhesion of the zinc coating at bend or absence of zinc coating

and atcutedgeswillnotbecauseforrejectionoffabricatedanodes.

4.1.13 Optional requirements, if any (see S1 through S3). Cracks in the base metal shall be cause for rejection.

4.2 Theorderforanodesshouldspecifytheexactnumberof 5.1.2.1 The maximum copper content in the zinc, as speci-

anodes required (see 4.1.11).Acquisition of anodes by weight fied in Table 1, may be increased to 0.020% for Type ZHB

is not practical and is not recommended. anodes.

4.3 When material is ordered in the form of slabs, bars, 5.1.3 Types ZEP and ZBP anodes shall have core inserts

discs, or rods, these terms refer merely to the general form and made from zinc coated steel pipe or pipe couplings. The

dimensions of the material and do not have any technical

minimumthicknessofthecoatingshallbeasspecifiedin5.1.1.

significance as to the methods of manufacture.

5.1.4 Type ZDM anodes shall have machine formed inter-

locking cores in accordance with commercial grade mild or

5. Materials and Manufacture

leaded steel. The cores shall be flash coated with zinc, tin, or

5.1 Materials: aluminum before assembly within the anodes.

5.1.1 Types ZHS, ZHC, ZSS, and ZTS anodes shall have 5.1.4.1 This core insert consists of an integral piece having

steel strap cores in accordance with SpecificationA36/A36M. a threaded male stud at one end and a tapped hole at the other

F 1182

NOTE 1—Anode may be cast with strap in the up or down position.All

NOTE 1—Anode may be cast with strap in the up or down position.All dimensions (inches) refer to the wider and longer edges of the anode.

dimensions (inches) refer to the wider and longer edges of the anodes. NOTE 2—Tolerance 6 ⁄8in.

NOTE 2—Tolerance 6 ⁄8in. NOTE 3—1 in. = 25.4 mm.

NOTE 3—1 in. = 25.4 mm. NOTE 4—Minimum weight 41 lb (18.6 kg).

NOTE 4—Minimum weight 21.5 lb (9.7 kg). FIG. 4 Zinc Hull Slab (Steel Straps), Type ZHS-42

FIG. 3 Zinc Hull Slab (Steel Straps), Type ZHS-23; Zinc Hull Slab

(Brass Straps), Type ZHB

washer fits snugly between the hull and anode core to prevent

anode movement or vibration.

5.2.2.2 Type ZSS, ZHS, ZHB, and ZTS anodes may be

end. Provision has been made to achieve self-locking charac-

mounted by welding or by fasteners. Those intended to be

teristics to interlocking threaded assemblies of multiple seg-

attached by fasteners shall indicate the requirements for

mented anode discs by interference fit of bottom male threads

mounting holes in the strap. The mounting hole shall be

into a taper tapped hole.

counterbored on the structure side of the strap.

5.2 Manufacture:

5.2.3 The pipe core inserts for Type ZEP anodes shall

5.2.1 All anodes covered under this specification shall be

conform to 5.1.3. The position of the pipe core insert shall not

manufacturedbyanyprocesssuitabletothecontractingagency

vary more than 6 ⁄8in. (3 mm) from the center as shown on

provided they meet the mechanical properties and other re-

Fig. 1.

quirements of this specification. 5.2.4 The position of the pipe core insert for Type ZBP

5.2.2 For Types ZHS, ZHB, ZHC, ZSS, and ZTS anodes,

anodes specified in 5.1.3 shall not vary more than 6 ⁄4in. (6

open or closed molds may be used. Cores and straps shall be mm) from the center as shown on Fig. 12.

1 1 1

positioned so that they are embedded ⁄4,+ ⁄8,or− ⁄16in. (6,

5.2.5 Metallic bonding or an interference fit of the core into

+3, or −2 mm) as shown on Figs. 3-5, Fig. 7, and Fig. 10 and Type ZDM anode (see Fig. 2) shall be required so that an axial

Fig. 11, which may be measured from either surface of the

force applied from the stud end to remove the core insert is a

anode as applicable, except Fig. 11 (bottom), which shall be minimum of 750 lb (340 kg) (see 13.1.3).

3 1 1

embedded ⁄8,+ ⁄8,or− ⁄16in. (10, +3, or −2 mm).

5.2.6 The machine formed core insert specified in 5.1.4

5.2.2.1 TypeZHCanodesdesignatedasshownonFig.6and shall be manufactured in accordance with details and toler-

Fig. 8 and are intended for use with rubber washers for ances shown for Piece 2 on Fig. 1 and ANSI/ASME B1.20.1.

submarine application. The countersink for the rubber washer 5.2.6.1 ThepiecesshownonFig.1shallscrewtogethervery

may be cast or machined. The anode shall be manufactured so snugly by hand tightening or by using simple hand tools such

thatthecountersinkiscenteredonthecoreholeandtherubber as pliers or pipe wrenches.

F 1182

NOTE 1—Anode may be cast with exposed face in the up or down

position. All dimensions are in inches.

NOTE 2—Tolerance 6 ⁄8in.

NOTE 3—1 in. = 25.4 mm.

NOTE 4—Minimum weight 21.5 lb (9.7 kg).

FIG. 5 Zinc Hull Slab (Core Strap), Type ZHC-23

6. Chemical Composition

NOTE 1—Anode may be cast with exposed face in the up or down

6.1 The anodes shall conform to the composition specified

position. All dimensions are in inches.

in Table 1. Total of elemental constituents not specified in

NOTE 2—Tolerance 6 ⁄8in.

Table 1 shall not exceed 0.10%. Metallic elements not

NOTE 3—1 in. = 25.4 mm.

specified in Table 1 are considered contaminants. NOTE 4—Minimum weight 21.5 lb (9.7 kg).

FIG. 6 Zinc Hull Slab (Core Strap), Type ZHC-23, Submarine

7. Mechanical Properties

Application

7.1 When tested in accordance with 13.2, Types ZRN rods

and ZPN plates shall not fracture or show signs of cracking.

7.2 When tested in accordance with 13.2.1, ZRN anodes

9.2 Type ZPN anode shall be 48 in. (1220 mm) in length by

shall have a minimum torsional shear strength of 12000 psi

24 in. (610 cm) in width.

(83 MPa). 1

9.2.1 Thethicknessshallbeeither

⁄2or1in.(13or25mm)

as specified (see 4.1.10).

8. Other Requirements

9.3 TypesZSS-12,ZSS-24,ZHC-23,ZHC-42,ZHS-23,and

8.1 When tested in accordance with 13.1.1 or 13.1.2, Types

ZHS-42 shall have the following minimum weight require-

ZHS,ZHB,ZHC,ZSS,ZTS,ZEP,andZBPanodesshallobtain

ments:

a sound metallurgical bond between the zinc and core for at

Anode Weight, min, lb (kg)

least30%ofthetotalsurfaceareaofeachcoreincontactwith

the anode.

ZSS-12 11.0 (5)

ZSS-24, ZHC-23, ZHS-23 21.5 (10)

8.2 During the manufacturing process, certain toxic com-

ZHC-42 39.0 (18)

pounds (such as zinc phosphide) may become by-products.

ZHS-42 41.0 (19)

Caution should be taken in disposal of process wastewater to

9.3.1 The total weight of the specified type of anode

ensurethatthecompositionofthewatermeetswithlocal,state,

received divided by the total number of anodes of that type

and federal regulations.

shall be equal to or greater than the minimum weight (11.0,

9. Dimensions, Mass, and Permissible Variations

21.5, 39.0, 41.0 lb (5, 10, 18, 19 kg)) of the anode type

9.1 Types ZHS, ZHB, ZHC, ZTS, ZSS, ZEP, ZBP, ZDM, specified.Iftheweightislessthantheminimumweightforthe

type of anode specified, it shall be cause for rejection of the

and ZRN anodes shall be in accordance with the dimensions

shown in Figs. 1-11, inclusive. entire lot.

F 1182

NOTE 1—Anode may be cast with exposed face in the up or down position. All dimensions are in inches.

NOTE 2—Tolerance 6 ⁄8in.

NOTE 3—1 in. = 25.4 mm.

NOTE 4—Minimum weight 39 lb (17.7 kg).

FIG. 7 Zinc Hull Slab (Core Strap), Type ZHC-42

9.4 The length and width of Types ZHS, ZHB, ZHC, ZTS, 10. Workmanship, Finish, and Appearance

ZPN,ZSS,andZBPanodesshallnotvarymorethan 6 ⁄8in.(3

10.1 The zinc anodes shall be free of flash burrs, cracks,

mm), measured at the widest surface of the tapered (for mold

blow holes, pipes, and surface slag consistent with good

release) anode.

commercial practice.

9.5 The length of Type ZRN anodes will be permitted to

10.1.1 For anodes less than 2 in. (50 mm) thick, when

have a variation of 61 in. (25 mm) based on nominal lengths

measured with a straightedge placed diagonally across the

of 3 and 6 ft (914 and 1829 mm).

opposite edges of the cast anode, the anode shall be free of

9.6 The diameter or width, whichever is the larger, of Type

shrinkage cavities exceeding ⁄4in. (6 mm) in depth.Anodes 2

ZEP anodes shall not vary from the specified dimension by

in. (50 mm) thick or more shall be free of shrinkage cavities

more than 6 ⁄8in. (3 mm). 3

exceeding ⁄8in. (10 mm) in depth.

9.7 The diameter of Type ZDM anodes shall not vary more

10.1.1.1 For Type ZPN anodes, shrinkage cavities shall be

than +0.025 in. (1 mm) or −0.005 in. (0.13 mm) from the

mea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.