ASTM D1015-99

(Test Method)Standard Test Method for Freezing Points of High-Purity Hydrocarbons

Standard Test Method for Freezing Points of High-Purity Hydrocarbons

SCOPE

1.1 This test method describes a procedure for the precise measurement of the freezing points of high-purity hydrocarbons.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Notes 2, 3, and 4. Note 1-For the calculation of the molal purity of essentially pure compounds from measured freezing points and for procedures to be used for the sampling and determination of purity of certain specific compounds, see Test Method D1016.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 1015 – 99

Standard Test Method for

Freezing Points of High-Purity Hydrocarbons

This standard is issued under the fixed designation D 1015; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This test method describes a procedure for the precise 4.1 The freezing point measured by this test method, when

measurement of the freezing points of high-purity hydrocar- used in conjunction with the physical constants for the hydro-

bons. carbons listed in Test Method D 1016, allows the determination

1.2 The values stated in SI units are to be regarded as the of the purity of the material under test. A knowledge of the

standard. The values in parentheses are for information only. purity of these hydrocarbons is often needed to help control

1.3 This standard does not purport to address all of the their manufacture and to determine their suitability for use as

safety concerns, if any, associated with its use. It is the reagent chemicals or for conversion to other chemical inter-

responsibility of the user of this standard to establish appro- mediates or finished products.

priate safety and health practices and determine the applica-

5. Apparatus

bility of regulatory limitations prior to use. For specific hazard

statements, see 5.1, 6.1 and 6.2. 5.1 Freezing-Point Apparatus, as shown in Fig. 1, Fig. 2,

and Fig. 3, comprising a freezing tube, a metal sheath for the

NOTE 1—For the calculation of the molal purity of essentially pure

freezing tube, a Dewar flask for the cooling bath, a Dewar flask

compounds from measured freezing points and for procedures to be used

for the warming bath, a stirring mechanism, suitable clamps

for the sampling and determination of purity of certain specific com-

and holders for the parts, and the absorption tubes. The outer

pounds, see Test Method D 1016.

walls of all Dewar flasks can be covered with adhesive tape to

2. Referenced Documents

minimize danger from glass in case of breakage. (Warning:

2.1 ASTM Standards: When using liquid nitrogen as a refrigerant, provide a means to

D 1016 Test Method for Purity of Hydrocarbons from prevent condensation of oxygen in the space between the

Freezing Points freezing tube and the metal sheath and subsequent sealing of

D 1265 Practice for Sampling Liquefied Petroleum (LP) the space by ice forming on the asbestos collar. Provide the

Gases (Manual Method) metal sheath with suitable openings in the sides and bottom.

D 4057 Practice for Manual Sampling of Petroleum and Failure to do this may result in breakage of the freezing tube

Petroleum Products when the liquefied oxygen evaporates within the sealed space.)

5.2 Resistance Bridge, Mueller type, reading from 0.0001

3. Summary of Test Method

to 50 V, in steps of 0.001 V.

3.1 The precise experimental measurement of the freezing

point is made from interpretation of time-temperature freezing

A suitable apparatus is available from Reliance Glass Works, Inc., Bensenville,

or melting curves.

IL, Cat. No. R6878–100.

Apparatus described in 5.2, 5.3, 5.4 and 5.5 was manufactured by the Leeds and

Northrup Co., Philadelphia, PA, under the following catalog numbers: resistance

This test method is under the jurisdiction of ASTM Committee D-2 on bridge, No. 8069 B; platinum resistance thermometer, No. 8163 B; galvanometer,

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee highest precision, No. 2284 D; galvanometer, routine precision, No. 2430 A; lamp

D02.04.OD on Physical Methods. and scale, No. 2100. The galvanometer, routine precision, No. 2430-A, and the lamp

Current edition approved Nov. 10, 1999. Published December 1999. Originally and scale, No. 2100, are still available from Leeds and Northrup. The platinum

published as D 1015 – 49 T. Last previous edition D 1015 – 94. resistance thermometer, No. 8163-B, is no longer available from Leeds and

Annual Book of ASTM Standards, Vol 05.01. Northrup, but is available with the same part number from Yellows Springs

Annual Book of ASTM Standards, Vol 05.02. Instrument Co., Yellow Springs, OH. The resistance bridge No. 8069-B, and the

For details not given here, see Glasgow, A. R., Jr., Rossini, F. D., and Streiff, galvanometer, highest precision, No. 2284-D, are no longer available; however, they

A. J., “Determination of the Purity of Hydrocarbons by Measurement of Freezing may be obtainable from instrument exchanges or used equipment suppliers. If other

Points,” Journal of Research, JNBAA, National Institute of Standards and Tech- available instrumentation is substituted for the original, the precision statement of

nology, Vol 35, No. 6, 1945, p. 355. Section 13 will not apply.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1015–99

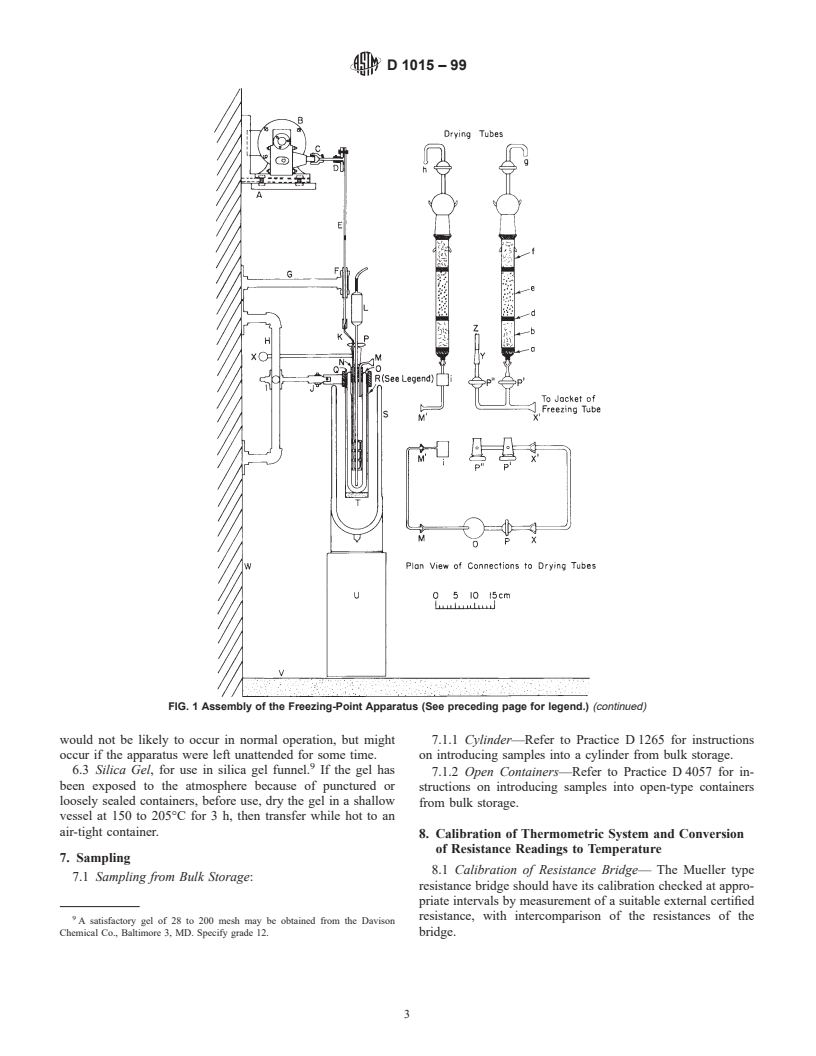

Legend for Fig. 1 (see following page):

A—Bracket for motor, with rubber pad.

B—Motor, with reduction gears, to give 120 r/min.

C—Coupling. (See Fig. 3).

D—Wheel. (See Fig. 3).

E—Steel rod. (See Fig. 3).

F—Bearing. (See Fig. 3).

G—Support for bearing. (See Fig. 3).

H—Support for freezing tube.

I—Adjustable clamp holder.

J—Clamp for freezing tube.

K—Stirrer. (See Fig. 3).

L—Thermometer.

M—Tube for inlet of dry air, with 12/5 spherical joint.

M8—12/5 spherical joint connection to rotameter.

N—Cork stopper, with holes as shown, plus a small hole for the “seed” wire.

O—Freezing tube, with silvered jacket. (See Fig. 2.)

P—Stopcock on freezing tube.

P8—Stopcock (high vacuum) to drying tube.

P9—Stopcock (high vacuum) to vacuum line.

Q—Asbestos collar.

1 1

R—Brass cylinder, 317.5 mm (12 ⁄2 in.) in length and 54 mm (2 ⁄8 in.) in inside diameter, with bakelite collar; when liquid nitrogen is used, the metal shield

must be provided with suitable openings in sides and bottom (see 5.1). If liquid air is used, the metal shield should be constructed so as to keep hydrocar-

bon from contact with liquid air (see 6.2).

S—Dewar flask, for cooling or warming bath; approximate inside diameter, 101 mm (4 in.); approximate inside depth, 330 mm (13 in.).

T—Asbestos pad at bottom of cylinder R.

U—Wood block support.

V—Table top.

W—Wall.

X,X8—Spherical joint, 18/7.

Y—Standard metal (copper or brass) to glass taper connections soldered.

Z—Connection to vacuum pump.

a—Anhydrous calcium sulfate, with indicator.

b—Anhydrous magnesium perchlorate, granular.

d—Separating layer of glass wool.

e—Ascarite.

f—Anhydrous calcium sulfate.

g—To air.

h—To source of compressed air.

i—Flow meter, for rates of 10 to 20 mL/min.

5.3 Platinum Resistance Thermometer, precision grade, 6. Materials

with a resistance near 25.5 V at 0°C, calibrated by the National

6.1 Carbon Dioxide Refrigerant—Solid carbon dioxide in a

Institute of Standards and Technology for the range from −190

suitable liquid. ( Warning: Extremely cold (−78.5°C). Liber-

to 500°C.

ates heavy gas which can cause suffocation. Contact with skin

5.4 Null Point Indicator, may be either a galvanometer or a

causes burns or freezing, or both. Vapors can react violently

microvolt ammeter.

with hot magnesium or aluminum alloys.) Acetone is recom-

5.4.1 Galvanometer, having a sensitivity of 0.1 mV/m at 1

mended. (Warning—Extremely flammable. Harmful if in-

m for highest precision or a sensitivity of 0.5 mV/m at1mfor

haled. High concentrations can cause unconsciousness or

routine precision.

death. Contact can cause skin irritation and dermatitis. Use

5.4.2 Microvolt Ammeter.

refrigerant bath only with adequate ventilation.)

5.5 Lamp and Scale, any suitable type.

6.2 Liquid Nitrogen or Liquid Air—(Warning: Extremely

5.6 Stopwatch or Clock, preferably having graduations in

cold. Liberates gas which can cause suffocation. Contact with

minutes and hundredths of minutes.

skin causes burns or freezing, or both. Vapors can react

5.7 High-Vacuum Oil Pump, capable of evacuating the

violently with hot magnesium or aluminum alloys.) For use as

jacket of the freezing tube to a pressure of 0.133 Pa in 10 min

a refrigerant. If obtainable, liquid nitrogen is preferable be-

or less.

cause of its safety.

5.8 Seeding Apparatus, as shown in Fig. 4, for inducing

6.2.1 Use liquid nitrogen refrigerant only with adequate

crystallization.

ventilation. If liquid air is used as a refrigerant, it is imperative

5.9 Silica Gel Funnel, as shown in Fig. 5, for filtering

that any glass vessel containing hydrocarbon or other combus-

compounds through silica gel to remove water. To be used only

tible compound and immersed in liquid air be protected with a

when specified in Test Method D 1016.

suitable metal shield. The mixing of a hydrocarbon or other

combustible compound with liquid air due to the breaking of a

glass container would almost certainly result in a violent

Model No. 155, manufactured by Keithley Instruments, Inc., 28775 Aurora Rd.,

explosion. If liquid nitrogen is used as a refrigerant, no

Cleveland, OH, or equivalent, has been found satisfactory for this purpose.

hydrocarbon sample should ever be permitted to cool below the

A suitable pump is available from Boekel Industries, Inc. Philadelphia, PA, Cat.

No. 91105. condensation temperature of oxygen (−183°C at 1 atm). This

D1015–99

FIG. 1 Assembly of the Freezing-Point Apparatus (See preceding page for legend.) (continued)

would not be likely to occur in normal operation, but might 7.1.1 Cylinder—Refer to Practice D 1265 for instructions

occur if the apparatus were left unattended for some time. on introducing samples into a cylinder from bulk storage.

6.3 Silica Gel, for use in silica gel funnel. If the gel has

7.1.2 Open Containers—Refer to Practice D 4057 for in-

been exposed to the atmosphere because of punctured or

structions on introducing samples into open-type containers

loosely sealed containers, before use, dry the gel in a shallow

from bulk storage.

vessel at 150 to 205°C for 3 h, then transfer while hot to an

air-tight container.

8. Calibration of Thermometric System and Conversion

of Resistance Readings to Temperature

7. Sampling

8.1 Calibration of Resistance Bridge— The Mueller type

7.1 Sampling from Bulk Storage:

resistance bridge should have its calibration checked at appro-

priate intervals by measurement of a suitable external certified

resistance, with intercomparison of the resistances of the

A satisfactory gel of 28 to 200 mesh may be obtained from the Davison

Chemical Co., Baltimore 3, MD. Specify grade 12. bridge.

D1015–99

and the freezing point of the pure material tf , should be on the same

o

temperature scale. The values of tf given in Test Method D 1016 are on

o

the 1968 IPTS. Therefore, values of t determined using thermometers

f

calibrated on the 1948 scale should be converted to their 1968 IPTS

equivalent. This conversion can be made by applying the appropriate

correction from Table 1.

8.3 Checking of the Ice Point—Frequent measurements (at

least once every month) should be made of the resistance of the

given platinum thermometer at the ice point, 0°C, as measured

on the given resistance bridge. This value should differ only

slightly from the certified value of R . If the difference

becomes appreciable (approaching 0.001 V), the calibration of

the bridge should be checked. If the bridge has not changed, the

change has occurred in the thermometer, and a recalibration of

it is recommended.

8.4 Conversion of Resistance Readings to Temperature—

When determinations are made on a number of substances

having freezing points at different temperatures, time will be

saved by making up a table giving values of the resistance, R,

for each unit degree of temperature in the given range. Values

of resistance for unit degrees, for the ranges from −190 to

+50°C and +50 to 290°C, with differences between successive

unit degrees tabulated for linear interpolation (which is per-

missible), may be easily placed on a single 300 by 400-mm (14

by 16-in.) sheet for each range. Calculate values for the

resistance, R, from unit values of temperature, t, by means of

one of the following equations:

For temperatures below 0°C:

–4 –3 2

R 5 R 1 1 Ct 1 1 0.01 d! 2 10 dt 2 10 b t 2 100!t (1)

$ @~ ~ #%

For temperatures above 0° C:

–4

R 5 R 1 1 Ct@~1 1 0.01 d! 2 10 dt# (2)

$ %

where:

A—High-vacuum stopcock, hollow plug, oblique 3 ⁄2-mm bore.

t = given temperature, °C, on the International Tempera-

B—Inside opening of freezing tube, which must have no bulge at this point.

ture Scale (see Note 2),

C—Slanted connection to jacket of freezing tube.

D—Internal walls of jacket of freezing tube, silvered. R = resistance of the thermometer in ohms at the tempera-

E—Spherical joint, 18/7.

ture t,

FIG. 2 Details of the Freezing Tube R = resistance of the thermometer in ohms at 0°C, and

C, d, and b = constants certified for the given platinum

thermometer by the National Institute of Standards and Tech-

8.2 Calibration of Resistance Thermometer—The platinum-

nology.

resistance thermometer is provided with four calibration con-

stants certified by the National Institute of Standards and

9. General Procedure for Determining a Freezing Curve

Technology for use in converting the resistance of the ther-

9.1 Assemble the apparatus, with no refrigerant and no

mometer into temperature according to the International Tem-

sample yet in place, but with a stream of air, freed of carbon

perature Scale, for use in the range from −190 to 500°C,

dioxide and water, flowing at a rate of 10 to 20 mL/min. Fill the

namely, R , C, d, and b. If the thermometer has been properly

jacket of the freezing tube with air freed of carbon dioxide and

constructed and annealed, the certified constants C, d, and b

water.

will not change significantly with time, but the value of R may

9.2 As required, the operator must be prepared to induce

change slightly.

crystallization in the sample as soon as possible after the

NOTE 2—International Practical Temperature Scale—In 1968 a new

temperature has passed below the freezing point of the sample

IPTS was adopted, replacing the previous scale in use since 1948. The

1948 IPTS was based on the boiling point of oxygen, the sulfur point, ice

point, and steam point. The 1968 IPTS is based on the triple point of

water, tin point, zinc point, and boiling point of oxygen. The differences

The ice point may be measured according to the procedure described by J.

in the two temperature scales T –T vary. Above 100°C the differ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.