ASTM F330-89(2004)

(Test Method)Standard Test Method for Bird Impact Testing of Aerospace Transparent Enclosures

Standard Test Method for Bird Impact Testing of Aerospace Transparent Enclosures

SIGNIFICANCE AND USE

This test method may be used for: bird impact testing of aircraft crew compartment transparencies and supporting structure to verify the design; compilation of test data for use in verification of future transparency and supporting structure design and analytical methods; and comparative evaluation of materials.

SCOPE

1.1 This test method covers conducting bird impact tests under a standard set of conditions by firing a packaged bird at a stationary transparency mounted in a support structure.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:F330–89(Reapproved2004)

Standard Test Method for

1

Bird Impact Testing of Aerospace Transparent Enclosures

ThisstandardisissuedunderthefixeddesignationF330;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.2.2 Bird velocity, and

3.2.3 Instrumentation.

1.1 This test method covers conducting bird impact tests

under a standard set of conditions by firing a packaged bird at

4. Significance and Use

a stationary transparency mounted in a support structure.

4.1 Thistestmethodmaybeusedfor:birdimpacttestingof

1.2 The values stated in inch-pound units are to be regarded

aircraftcrewcompartmenttransparenciesandsupportingstruc-

as the standard. The values given in parentheses are for

ture to verify the design; compilation of test data for use in

information only.

verification of future transparency and supporting structure

1.3 This standard does not purport to address all of the

design and analytical methods; and comparative evaluation of

safety concerns, if any, associated with its use. It is the

materials.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Apparatus

bility of regulatory limitations prior to use. For specific hazard

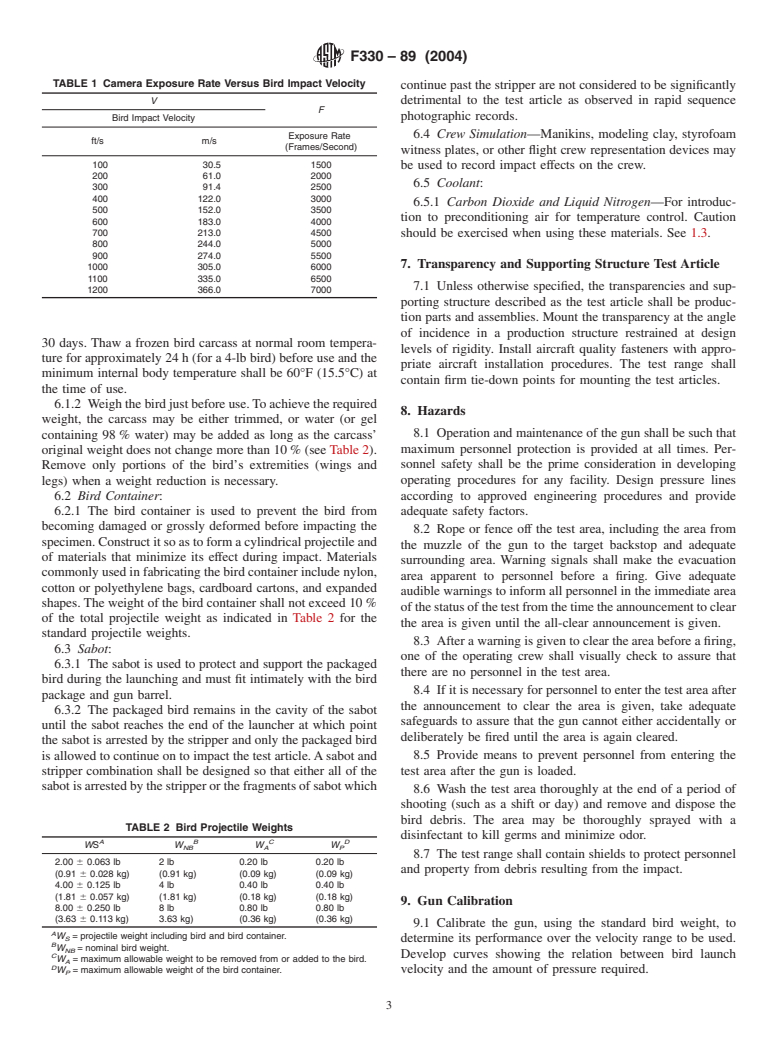

5.1 Gun, compressed gas, conforming in principle to Fig. 1,

statements, see Section 8.

comprising:

2. Terminology 5.1.1 Pressure Tank, of capacity and working pressure as

discussed in Note 1.

2.1 Definitions:

2.1.1 bird—thecarcassthatisusedtoimpactthetestarticle.

NOTE 1—Agun capable of propelling a 4-lb (1.81-kg) bird in excess of

2.1.2 bird package—the bird and container that encases the 650 knots (334 m/s) has a barrel 60 ft (18.3 m) long, bore of 6 in. (153

3 3

mm), and a pressure tank volume of 30 ft (0.849 m ) with an allowable

bird to prevent disintegration enroute to target.

6

working pressure of 250 psi (1.725 310 Pa).

2.1.3 gun—the device that propels the bird toward the

target. 5.1.2 Release Mechanism, comprised of a firing solenoid,

2.1.4 sabot—the container that is used to adapt the bird

diaphragm, and a cutter. Upon initiation of the firing sequence,

package to the gun barrel. the release mechanism allows the compressed gas stored in the

2.1.5 stripper—the device that stops the sabot at the end of

pressure tank to flow rapidly into the gun barrel and propel the

the gun barrel so that only the bird and package exits from the projectile.

barrel.

NOTE 2—The most common designs normally use either one or two

2.1.6 test article—the transparency and supporting struc-

diaphragms in the release mechanism. In the single diaphragm design, the

ture.

diaphragm is mechanically ruptured upon firing (see Fig. 1). In the dual

diaphragm system, pressurized gas between the two pressurized gas

3. Summary of Test Method

diaphragms is bled to initiate firing by allowing the stored gas to burst

each diaphragm in rapid succession.

3.1 This test method employs a smooth-bore bird gun that

fires a chicken carcass so that it impacts a stationary aerospace

5.1.3 Barrel (Launch Tube), a smooth bore tube that guides

transparency mounted in a supporting structure.

thepackagedbird(andsabotifused)duringitsaccelerationby

3.2 The specific parameters described by this test method

the expanding air from the pressure tank. The bore and length

are:

of the barrel is chosen both to accommodate the largest of the

3.2.1 Bird weight and condition,

projectiles to be used and for the overall performance require-

ments of the gun.

5.1.4 Sabot Stripper may be mounted at the end of the

1

This test method is under the jurisdiction of ASTM Committee F07 on

launcher tube. The purpose of the sabot stripper is to arrest or

Aerospace andAircraft and is the direct responsibility of Subcommittee F07.08 on

Transparent Enclosures and Materials. deflectthesabot,allowingonlythepackagedbirdtoimpactthe

Current edition approved Oct. 1, 2004. Published October 2004. Originally

test article.

approved in 1979. Last previous edition approved in 1999 as F330–89 (1999).

DOI: 10.1520/F0330-89R04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F330–89 (2004)

FIG. 1 Representative Air Gun

5.2 Velocity Measurement System: 5.4 Test Instrumentation:

5.2.1 The essential features of the velocity measurement

5.4.1 Weight Measurement—The weight scale shall have an

system are that it be accurate and repeatable, not be triggered

accuracy of at least 0.063 oz (1.8 g).

bysmallstrayobjectst

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.