ASTM D3087-91(1998)

(Test Method)Standard Test Method for Operating Performance of Anion-Exchange Materials for Strong Acid Removal

Standard Test Method for Operating Performance of Anion-Exchange Materials for Strong Acid Removal

SCOPE

1.1 This test method covers the determination of the operating capacity of anion-exchange materials when used for the removal of hydrochloric and sulfuric acid from water. It is designed to simulate operating conditions for strong acid removal and is intended for use in testing both new and used materials.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Note 1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 3087 – 91 (Reapproved 1998)

Standard Test Method for

Operating Performance of Anion-Exchange Materials for

Strong Acid Removal

This standard is issued under the fixed designation D 3087; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Significance and Use

1.1 This test method covers the determination of the oper- 5.1 This test method can be used for evaluating performance

ating capacity of anion-exchange materials when used for the of commercially available anion-exchange materials regardless

removal of hydrochloric and sulfuric acid from water. It is of the basic strength of the ion exchange groups. When

designed to simulate operating conditions for strong acid previous operating history is known, a good interpretation of

removal and is intended for use in testing both new and used resin fouling or malfunction can be obtained by comparison

materials. against a reference sample of unused ion-exchange material

1.2 The values stated in SI units are to be regarded as the evaluated in the same way.

standard. The inch-pound units given in parentheses are for 5.2 While resistivity has been chosen as the preferred

information only. analytical method for defining the exhaustion end point, with

1.3 This standard does not purport to address all of the titration as the alternative, it is understood that observation of

safety concerns, if any, associated with its use. It is the pH during rinse and the service run can yield useful informa-

responsibility of the user of this standard to establish appro- tion. The variations in pH observed with an ion exchange

priate safety and health practices and determine the applica- material suspected of having degraded, can be helpful in

bility of regulatory limitations prior to use. Specific precau- interpretation of performance when compared with similar data

tionary statements are given in Note 1. for a reference sample of unused material exhausted in the

same way.

2. Referenced Documents

6. Apparatus

2.1 ASTM Standards:

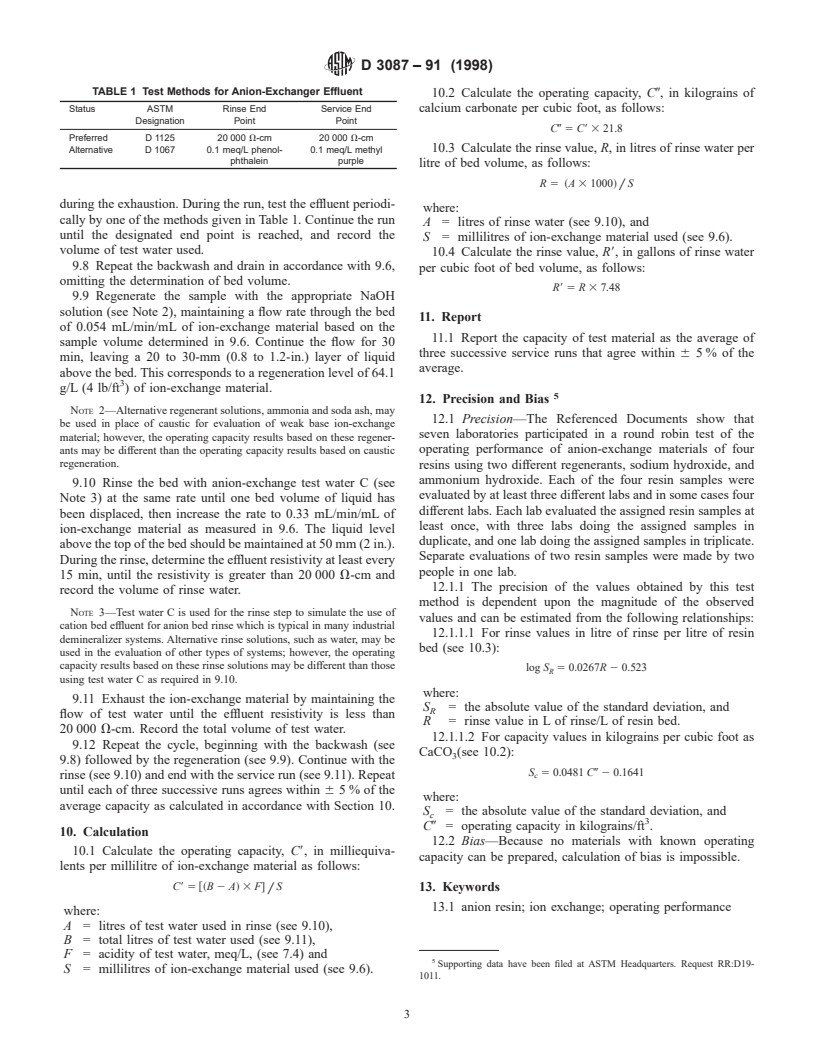

D 1067 Test Methods for Acidity or Alkalinity of Water 6.1 Test Assembly (see Fig. 1), consisting of the following:

D 1125 Test Methods for Electrical Conductivity and Re- 6.1.1 Column, transparent, vertically supported, 25.4 6

sistivity of Water 2.5-mm (1.0 6 0.1-in.) inside diameter and approximately 1.5

D 1129 Terminology Relating to Water m (60 in.) long. The bottom of the column shall be closed and

D 1193 Specification for Reagent Water provided with an outlet of approximately 6-mm ( ⁄4-in.) inside

D 2687 Practices for Sampling Particulate Ion-Exchange diameter. Connections shall be provided at the top and bottom

Materials for the admission and removal of the solutions described in

Section 7. Adequate means for measuring and regulating the

3. Terminology

flow shall also be provided. The column shall be calibrated in

3.1 Definitions—For definitions of terms used in this test

such a manner that the volume readings required by the method

method, refer to Terminology D 1129. can be made (see Section 9). All measurements shall be made

at 25 6 5°C.

4. Summary of Test Method

6.1.2 Support the sample at least 50 mm (2 in.) above the

4.1 The test method consists of repeated cycles of back-

bottom of the column outlet using quartz, gravel, glass beads or

1 1

wash, base regeneration, rinse, and exhaustion of the sample in

other material from 1.5 to 3.5 mm ( ⁄16 to ⁄8 in.) in diameter,

the form of a bed in a transparent column. The exhaustion

insoluble in the reagents used, and retained on a corrosion-

medium used is an ion-exchange test water.

resistant screen. However, other supports may be used at the

discretion of the interested parties.

This test method is under the jurisdiction of ASTM Committee D-19 on Water,

7. Reagents

and is the direct responsibility of Subcommittee D19.08 on Membranes and Ion

Exchange Materials. 7.1 Purity of Reagents—Reagent grade chemicals shall be

Current edition approved June 15, 1991. Published February 1992. Originally

used in all tests. Unless otherwise indicated, it is intended that

e1

published as D 3087 – 78. Last previous edition D 3087 – 78 (1986) .

all reagents shall conform to the specifications of the Commit-

Annual Book of ASTM Standards, Vol 11.01.

tee on Analytical Reagents of the American Chemical Society,

Annual Book of ASTM Standards, Vol 11.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 3087 – 91 (1998)

7.5.2 For Weak, Intermediate, and Strong Base Ion-

Exchange Materials:

7.5.2.1 Sodium Hydroxide Solution (40 g/L)—Dissolve 40 g

of sodium hydroxide (NaOH) in 800 mL of water and dilute to

1 L. The solution should be freshly prepared to avoid absorp-

tion of carbon dioxide (CO ) from the air.

8. Sampling

8.1 For sampling procedures refer to Practices D 2687.

9. Procedure

9.1 Adjust temperature of the water and all solutions to be

used in this procedure to 25 6 5°C and maintain this

temperature throughout the test.

9.2 Fill the column approximately half full of water and add

sufficient sample to give a bed height of 750 6 75 mm (30 6

3 in.) above the top of the support. To avoid drying out of the

ion-exchange material, maintain a layer of liquid at least 20 to

30 mm (0.8 to 1.2 in.) deep above the top of the bed at all times

during the procedure.

9.3 Backwash with water for 10 min using a flow rate that

will maintain a 50 % expansion of the bed. If the supernatant

liquid is clear at this point, proceed to 9.4. If the supernatant

liquid is cloudy (indicating the presence of light, insoluble,

extraneous material), adjust the backwash outlet tube to a

height above the bed equal to 75 % of the bed height. Continue

backwashing at the same rate until the effluent is clear.

FIG. 1 Typical Arrangement of Apparatus for Performance Testing

of Ion-Exchange Materials 9.4 Allow the bed to settle and then drain at a rate of

approximately 100 mL/min until the water level is 20 to 30 mm

(0.8 to 1.2 in.) above the top of the bed. Record the volume, in

where such specifications are available. Other grades may be

millilitres, of ion-exchange material for use in the following

used, provided it is first ascertained that the reagent is of

pretreatment. Regenerate the sample with the appropriate

sufficiently high puritity to permit its use without lessening the

dilute sodium hydroxide solution (see Note 2) for 90 min at a

accuracy of the determination.

flow rate of 0.11 mL/min for each millilitre of ion exchanger in

7.2 Purity of Water— Unless otherwise indicated, refer-

the column. This corresponds to a regeneration level of 400 g/L

ences to water shall be understood to mean reagent water

(25 lb/ft ) of ion exchange material.

conforming to Specification D 1193, Type III.

9.5 When only a 20 to 30-mm (0.8 to 1.2-in.) layer of liquid

7.3 Acidity Test Reagents—For reagents used in determin-

remains above the bed, rinse with water using the same flow

ing acidity, refer to Test Methods D 1067.

rate, until a volume equal to the volume of resin has been

7.4 Anion Exchange Test Water C (10 meq/L)—Carefully

displaced (one bed volume). Increase the rinse rate to approxi-

add 18.1 mL of sulfuric acid (H SO , sp gr 1.84) and 27.5 mL

mately 100 mL/min and continue the rinse until a total of ten

2 4

of hydrochloric acid (HCl, sp gr 1.19) to 500 mL of water and

bed volumes liquid have been used.

dilute to 1 L. Prepare the test water by adding 1 volume of the

9.6 Backwash with water for 10 min using a flow rate that

mixed acid solution to 99 volumes of water. Determine the

will maintain a 50 % expansion of the bed. Allow the bed to

aci

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.