ASTM F1801-97(2009)e1

(Test Method)Standard Practice for Corrosion Fatigue Testing of Metallic Implant Materials

Standard Practice for Corrosion Fatigue Testing of Metallic Implant Materials

SIGNIFICANCE AND USE

Implants, particularly orthopedic devices, are usually exposed to dynamic forces. Thus, implant materials must have high fatigue resistance in the physiological environment.

This practice provides a procedure for fatigue testing in a simulated physiological environment. Axial tension-tension fatigue tests in an environmental test chamber are recommended as a standard procedure. The axial fatigue loading shall comply with Practice E466 and Practice E467.

Bending and rotating bending beam fatigue tests or torsion tests may be performed in a similar environmental cell.

This practice is intended to assess the fatigue and corrosion fatigue properties of materials that are employed or projected to be employed for implants. This practice is suitable for studying the effects of different material treatments and surface conditions on the fatigue behavior of implant materials. The loading mode of the actual implants may be different from that of this practice. Determining the fatigue behavior of implants and implant components may require separate tests that consider the specific design and loading mode.

As a substitute for body fluid, 0.9 % saline solution is recommended as a standard environment. One of the various Ringer's solutions or another substitute for body fluid may also be suitable for particular tests. However, these various solutions may not give equal fatigue endurance results. The chloride ions are the most critical constituent in these solutions for initiating corrosion fatigue.

Because implants are manufactured from highly corrosion-resistant materials, no visible corrosion may be detectable by optical or electron-optical (SEM) means. Only a decrease of fatigue strength in the high cyclic life range may be noticeable. Therefore, S-N curves covering a broad fatigue loading range should be generated in 0.9 % saline solution (Ringer's solutions) and air. Comparison of fatigue curves generated in air and saline solution may be the only way to assess the...

SCOPE

1.1 This practice covers the procedure for performing corrosion fatigue tests to obtain S-N fatigue curves or statistically derived fatigue strength values, or both, for metallic implant materials. This practice describes the testing of axially loaded fatigue specimens subjected to a constant amplitude, periodic forcing function in saline solution at 37°C and in air at room temperature. The environmental test method for implant materials may be adapted to other modes of fatigue loading such as bending or torsion. While this practice is not intended to apply to fatigue tests on implantable components or devices, it does provide guidelines for fatigue tests with standard specimens in an environment related to physiological conditions.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F1801 − 97(Reapproved 2009)

Standard Practice for

Corrosion Fatigue Testing of Metallic Implant Materials

This standard is issued under the fixed designation F1801; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Units information was editorially corrected in January 2010.

1. Scope E468Practice for Presentation of Constant Amplitude Fa-

tigue Test Results for Metallic Materials

1.1 This practice covers the procedure for performing cor-

E739PracticeforStatisticalAnalysisofLinearorLinearized

rosion fatigue tests to obtain S-N fatigue curves or statistically

Stress-Life (S-N) and Strain-Life (´-N) Fatigue Data

derived fatigue strength values, or both, for metallic implant

E1012Practice for Verification of Testing Frame and Speci-

materials. This practice describes the testing of axially loaded

men Alignment Under Tensile and Compressive Axial

fatigue specimens subjected to a constant amplitude, periodic

Force Application

forcing function in saline solution at 37°C and in air at room

E1150Definitions of Terms Relating to Fatigue (Withdrawn

temperature. The environmental test method for implant mate-

1996)

rials may be adapted to other modes of fatigue loading such as

F86Practice for Surface Preparation and Marking of Metal-

bending or torsion.While this practice is not intended to apply

lic Surgical Implants

to fatigue tests on implantable components or devices, it does

F601Practice for Fluorescent Penetrant Inspection of Me-

provide guidelines for fatigue tests with standard specimens in

tallic Surgical Implants

an environment related to physiological conditions.

G15Terminology Relating to Corrosion and CorrosionTest-

1.2 The values stated in either SI units or inch-pound units

ing (Withdrawn 2010)

are to be regarded separately as standard. The values stated in

2.2 ANSI Standard:

each system may not be exact equivalents; therefore, each

ANSI B46.1Surface Texture

system shall be used independently of the other. Combining

values from the two systems may result in non-conformance

3. Terminology

with the standard.

3.1 Definitions:

1.3 This standard does not purport to address all of the

3.1.1 Theterminologyusedinconjunctionwiththispractice

safety concerns, if any, associated with its use. It is the

complies to Terminology E1150 and Terminology G15.

responsibility of the user of this standard to establish appro-

3.2 Definitions of Terms Specific to This Standard:

priate safety and health practices and determine the applica-

3.2.1 S-N curves—S-N curves (also known as Wöhler-

bility of regulatory limitations prior to use.

curves)showthecorrelationbetweentheappliedstress(S)and

the counted number (N) of cycles to failure.

2. Referenced Documents

2.1 ASTM Standards:

4. Significance and Use

E4Practices for Force Verification of Testing Machines

E466Practice for Conducting Force Controlled Constant 4.1 Implants, particularly orthopedic devices, are usually

exposed to dynamic forces. Thus, implant materials must have

Amplitude Axial Fatigue Tests of Metallic Materials

high fatigue resistance in the physiological environment.

E467Practice for Verification of Constant Amplitude Dy-

4.1.1 This practice provides a procedure for fatigue testing

namic Forces in an Axial Fatigue Testing System

in a simulated physiological environment. Axial tension-

tension fatigue tests in an environmental test chamber are

ThispracticeisunderthejurisdictionofASTMCommitteeF04onMedicaland

recommended as a standard procedure. The axial fatigue

Surgical Materials and Devices and is the direct responsibility of Subcommittee

loading shall comply with Practice E466 and Practice E467.

F04.15 on Material Test Methods.

Current edition approved Dec. 1, 2009. Published January 2010. Originally

approved in 1997. Last previous edition approved in 2004 as F1801–97(2004).

DOI: 10.1520/F1801-97R09E01.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F1801 − 97 (2009)

4.1.1.1 Bending and rotating bending beam fatigue tests or measured dynamically as described in Practice E467, shall be

torsion tests may be performed in a similar environmental cell. maintained within an accuracy of less than or equal to 2% of

4.1.2 This practice is intended to assess the fatigue and the extreme loads applied during testing.

corrosion fatigue properties of materials that are employed or

5.3 Non Axial Fatigue Testing—Corrosion fatigue tests un-

projectedtobeemployedforimplants.Thispracticeissuitable

derloadingconditionsdifferentfromaxialtension-tensionmay

for studying the effects of different material treatments and

be requested. In such cases established experimental arrange-

surfaceconditionsonthefatiguebehaviorofimplantmaterials.

ments for bending, rotating bending beam, or torsional testing

Theloadingmodeoftheactualimplantsmaybedifferentfrom

may replace the axial tension-tension mode.An environmental

that of this practice. Determining the fatigue behavior of

test chamber is attached to the equipment and the environmen-

implants and implant components may require separate tests

tal tests are carried out under conditions as described in this

that consider the specific design and loading mode.

standard. Except for the mechanical testing arrangements the

4.1.3 As a substitute for body fluid, 0.9% saline solution is

conditions of this standard practice apply where possible.

recommended as a standard environment. One of the various

Reporting should follow Section 9 and should include all

Ringer’ssolutionsoranothersubstituteforbodyfluidmayalso

details where the testing deviates from the standard procedure.

be suitable for particular tests. However, these various solu-

5.4 Environmental Chamber:

tions may not give equal fatigue endurance results. The

5.4.1 For corrosion fatigue testing, the machine shall be

chlorideionsarethemostcriticalconstituentinthesesolutions

fittedwithanenvironmentaltestcellsurroundingthespecimen

for initiating corrosion fatigue.

gauge section as shown in Fig. 1. A heated solution reservoir,

4.1.4 Because implants are manufactured from highly

a solution pump, and connecting lines for circulating the test

corrosion-resistant materials, no visible corrosion may be

solution to the specimen surface are required. The solution

detectable by optical or electron-optical (SEM) means. Only a

should be pumped from the reservoir through the system at a

decreaseoffatiguestrengthinthehighcyclicliferangemaybe

rate that will maintain the temperature at 37 6 1°C in the test

noticeable. Therefore, S-N curves covering a broad fatigue

cell, but with flow rates low enough to avoid flow-dependent

loading range should be generated in 0.9% saline solution

phenomenalikeerosion-corrosion.Thereservoirshouldhavea

(Ringer’s solutions) and air. Comparison of fatigue curves

minimum capacity of 1000 mL per square centimeter of

generated in air and saline solution may be the only way to

specimensurfaceexposedtotheelectrolyte.Thereservoirshall

assess the effect of the saline environment.

be vented to the atmosphere. If the solution volume decreases,

4.1.5 Where the fatigue behavior of a material system is

the reservoir shall be replenished with distilled water to

already established, it may suffice to test modifications of the

maintain the saline concentration, or the solution should be

materialpropertiesorsurfaceconditioninonlyaselectedstress

exchanged. During long testing periods exchange of the

range.

solution is recommended.Atypical environmental test cell for

4.1.6 The recommended loading frequency of one hertz

axial fatigue testing is shown in Fig. 1.

corresponds to the frequency of weight-bearing during walk-

5.4.2 The test equipment should be manufactured of mate-

ing. For screening tests, higher test frequencies may be used;

rials or should be protected in such a manner that corrosion is

but it must be realized that higher frequencies may affect the

avoided. In particular galvanic corrosion in conjunction with

results.

the test specimen and loosening of the specimen grips due to

4.1.7 Summary of Standard Conditions—For inter-

corrosion must be avoided.

laboratory comparisons the following conditions are consid-

ered as the standard test. Axial tension-tension tests with

6. Test Solution

cylindrical specimens in 37°C 0.9% saline solution and air

6.1 To prepare the saline solution, dissolve9gof reagent-

under a loading frequency of 1 Hz.

grade sodium chloride in distilled water and make up to 1000

mL. If other typical Ringer’s solutions are used, note the

5. Testing Equipment

solution in the report.

5.1 The mechanics of the testing machine should be ana-

lyzed to ensure that the machine is capable of maintaining the

7. Test Specimen

desired form and magnitude of loading for the duration of the

7.1 Specimen Design:

test (see Practices E4).

7.1.1 Axial Fatigue Testing:

5.2 Axial Fatigue Testing: 7.1.1.1 The design of the axial load fatigue test specimens

5.2.1 Tension-tensionfatiguetestsmaybeperformedonone

should comply to Practice E466 (see Fig. 2, Fig. 3, Fig. 4 and

of the following types of axial fatigue testing machines: Fig.5).Forthedimensionalproportionsofflatspecimensrefer

5.2.1.1 Mechanical,

to the drawing in Practice E468. The ratio of the test section

5.2.1.2 Electromechanical or magnetically driven, and area to end section area will depend on the specimen geometry

5.2.1.3 Hydraulic or electrohydraulic. and should comply to those standards. The test specimens

5.2.2 The machine shall have a load-monitoring system, specified in Practice E466 and Practice E468 are designed so

such as a transducer mounted in series with the specimen. The that fatigue failure should occur in the section with reduced

test loads shall be monitored continuously in the early stage of diameter and not at the grip section.

the test and periodically thereafter, to ensure that the desired 7.1.1.2 For bending tests one may refer to the specimen

load is maintained. The magnitude of the varying loads, configuration suggested in Practice E466.

´1

F1801 − 97 (2009)

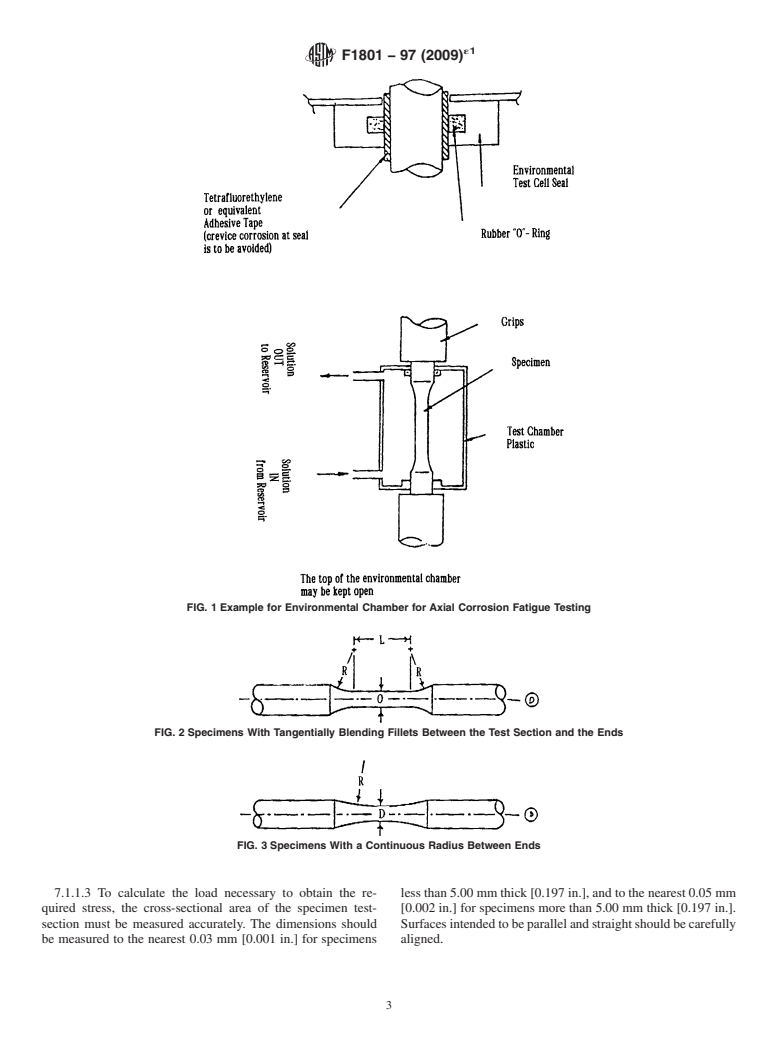

FIG. 1 Example for Environmental Chamber for Axial Corrosion Fatigue Testing

FIG. 2 Specimens With Tangentially Blending Fillets Between the Test Section and the Ends

FIG. 3 Specimens With a Continuous Radius Between Ends

7.1.1.3 To calculate the load necessary to obtain the re- lessthan5.00mmthick[0.197in.],andtothenearest0.05mm

quired stress, the cross-sectional area of the specimen test- [0.002 in.] for specimens more than 5.00 mm thick [0.197 in.].

section must be measured accurately. The dimensions should Surfacesintendedtobeparallelandstraightshouldbecarefully

be measured to the nearest 0.03 mm [0.001 in.] for specimens aligned.

´1

F1801 − 97 (2009)

FIG. 4 Specimens With Tangentially Blending Fillets Between the Uniform Test Section and the Ends

FIG. 5 Specimens With Continuous Radius Between Ends

7.2 Specimen Dimensions—Consult Practice E466 and in an inert medium or exsiccator, to prevent surface change

PracticeE468forthedimensionsoffatiguespecimensforaxial until the beginning of the test.

tension-tension loading (Fig. 2, Fig. 3, Fig. 4, and Fig. 5). If 7.3.5 Visualinspectionsatamagnificationofapproximately

bending specimens corresponding to the example of Practice 20× shall be performed on all specimens. When such inspec-

F466 are used, observe the suggested dimensions. tions reveal potential defects, nondestructive dye penetrant,

ultrasonic methods, or other suitable tests may be employed.

7.3 Specimen Preparation:

Dimensional inspection should be conducted without altering

7.3.1 The method of surface preparation and the resulting

or damaging the specimen’s surface. Specimens with surface

surface condition of the test specimens are of great importance

defects should not be used for testing. Inspection should take

because they influence the test results strongly. Standard

place prior to final surface cleaning.

preparation shall consist of machining, grinding, or polishing,

7.3.6 Immediately prior to testing, the specimens may be

or all of these.Afinal mechanical polish is suggested to give a

steamsterilizedatatemperatureof120 610°Candapressure

finish of 16 Min RA or less in accordance with ANSI B46.1.

of 0.10 MPa [14.5 psi] to simulate the actual implant surface

Alternatively, a finish with 600 grit paper in the longitudinal

conditions. Specimens shall be allowed to cool to room

direction may be used. However, specimens that are to be

temperature prior to testing. This sterilizing procedure is not

compared should be prepared the same way. Mechanically

mandatory. If it is used, it should be employed consistently in

finished specimens shall then be degreased in acetone, flushed

test series that are related and should be reported in the test

first with ethyl alcohol, then with distilled water, and finally

protocol.

blown dry with warm air.

7.3.7 In the liquid environmental testing, the time elapsed

7.3.1.1 Surface passivation may be carried out where ap-

between surface preparation and testing can influence the

propriate (compare Practice F86).

results due to the growth of a passive film. The elapsed time

7.3.1.2 The surface preparation may be also exactly as used

should thus be reported.

or intended to be used for surgical implants.Afull account of

the surface preparation should be given in the test protocol.

8. Procedure

7.3.2 Allspecimensusedinanygivenseriesofexperiments,

8.1 Test Set-Up:

includingcomparisonbetweentheairandliquidenvironments,

8.1.1 Specimen grips shall be designed so that alignment is

should be prepared with the same geometry and by the same

consistently good from one specimen to the next. Every effort

methodtoensurecomparableandreproducibleresults.Regard-

shouldbemadetopreventmisalignment,dueeithertotwisting

less of the machining, grinding or polishing method used, the

(rotation of the grips) or to displacement in their axes of

final mechanical working direction should be approximately

symmetry.

parallel to the long axis o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.