ASTM D4354-12(2020)

(Practice)Standard Practice for Sampling of Geosynthetics and Rolled Erosion Control Products (RECPs) for Testing

Standard Practice for Sampling of Geosynthetics and Rolled Erosion Control Products (RECPs) for Testing

SIGNIFICANCE AND USE

5.1 This practice provides a means by which samples of geosynthetics may be selected to provide a statistically valid sample for the selection of test specimens without previous knowledge of the variability that may exist between production units.

5.2 The principles stated in Practice D4271, and the illustrative text in that practice, can be used by test method authors in preparing sampling statements.

5.3 This practice gives three procedures for sampling: one for manufacturer's quality control (MQC), one for manufacturer's quality assurance (MQA) testing, and a third for purchaser's specification conformance testing. For this reason, test methods containing a section on sampling that requires the use of this practice should contain a statement in the section on reporting similar to the following: “Report which procedure from Practice D4354 was used for sampling: Procedure A for Manufacturer's Quality Control (MQC), Procedure B for Manufacturer's Quality Assurance (MQA) Testing, or Procedure C for Purchaser's Specification Conformance Testing.

5.4 Manufacturer's quality assurance is done internally to assure the manufacturer of the MQC program. When it is required to provide certification to a purchaser as to quality assurance, the MQA testing is to be done by an external MQA testing facility.

SCOPE

1.1 This practice covers three procedures for the sampling of geosynthetics and rolled erosion control products (RECPs) for testing. This practice requires that instructions on taking laboratory samples and test specimens be part of every test method for geosynthetics.

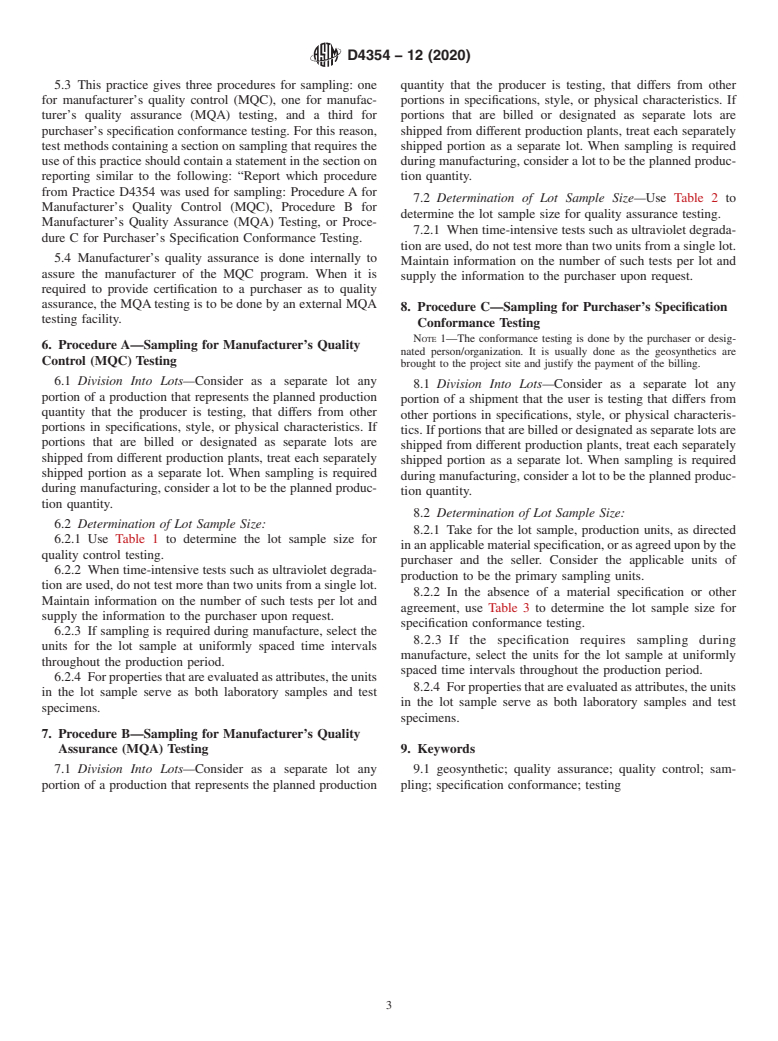

1.1.1 The first procedure describes the sampling of production units for the purpose of manufacturer's quality control (MQC) (Table 1).

1.1.2 The second procedure describes the sampling of production units for the purpose of manufacturer's quality assurance (MQA) testing during the manufacturing process. This requires that backup statistical process control records be maintained during the manufacturing process (Table 2).

1.1.3 The third procedure describes the division of shipments of geosynthetics and rolled erosion control products into lots and the determination of lot sample size for purchaser's specification conformance testing (Table 3).

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4354 − 12 (Reapproved 2020)

Standard Practice for

Sampling of Geosynthetics and Rolled Erosion Control

Products (RECPs) for Testing

This standard is issued under the fixed designation D4354; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4271 Practice for Writing Statements on Sampling in Test

Methods for Textiles (Withdrawn 2009)

1.1 This practice covers three procedures for the sampling

D4439 Terminology for Geosynthetics

of geosynthetics and rolled erosion control products (RECPs)

for testing. This practice requires that instructions on taking

3. Terminology

laboratory samples and test specimens be part of every test

3.1 Definitions:

method for geosynthetics.

3.1.1 geosynthetic, n—a planar product manufactured from

1.1.1 The first procedure describes the sampling of produc-

polymeric material used with soil, rock, earth, or other geo-

tion units for the purpose of manufacturer’s quality control

technical engineering related material as an integral part of a

(MQC) (Table 1).

man-made project, structure, or system.

1.1.2 The second procedure describes the sampling of

3.1.2 lot, n—a unit of production, or a group of other units

production units for the purpose of manufacturer’s quality

assurance (MQA) testing during the manufacturing process. or packages, taken for sampling or statistical examination,

having one or more common properties and being readily

This requires that backup statistical process control records be

separable from other similar units.

maintained during the manufacturing process (Table 2).

1.1.3 The third procedure describes the division of ship-

3.1.3 quality assurance, n—all those planned or systematic

ments of geosynthetics and rolled erosion control products into

actions necessary to provide adequate confidence that a

lots and the determination of lot sample size for purchaser’s

material, product, system, or service will satisfy given needs.

specification conformance testing (Table 3).

3.1.4 quality control, n—the operational techniques and the

1.2 This standard does not purport to address all of the

activities which sustain a quality of material, product, system,

safety concerns, if any, associated with its use. It is the

or service that will satisfy given needs; also the use of such

responsibility of the user of this standard to establish appro-

techniques and activities.

priate safety, health, and environmental practices and deter-

3.1.5 sample, n—(1) a portion of material which is taken for

mine the applicability of regulatory limitations prior to use.

testing or for record purposes. (See also sample, lot; sample,

1.3 This international standard was developed in accor-

laboratory;and specimen.)(2)agroupofspecimensused,orof

dance with internationally recognized principles on standard-

observationsmade,whichprovideinformationthatcanbeused

ization established in the Decision on Principles for the

for making statistical inferences about the population(s) from

Development of International Standards, Guides and Recom-

which the specimens are drawn.

mendations issued by the World Trade Organization Technical

3.1.6 sample, laboratory, n—a portion of material taken to

Barriers to Trade (TBT) Committee.

represent the lot sample, or the original material, and used in

2. Referenced Documents

the laboratory as a source of test specimens.

2.1 ASTM Standards: 3.1.7 sample, lot, n—one or more shipping units taken at

D123 Terminology Relating to Textiles random to represent an acceptance sampling lot and used as a

source of laboratory samples.

This practice is under the jurisdiction of ASTM Committee D35 on Geosyn- 3.1.8 sampling unit, n—an identifiable, discrete unit or

thetics and is the direct responsibility of Subcommittee D35.01 on Mechanical

subunit of material that could be taken as part of a sample.

Properties.

3.1.8.1 Discussion—Fig. 1 is included to show the differ-

Current edition approved May 1, 2020. Published May 2020. Originally

ence between lot sample, laboratory sample, and test speci-

approved in 1984. Last previous edition approved in 2012 as D4354 – 12. DOI:

10.1520/D4354-12R20.

men.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4354 − 12 (2020)

TABLE 1 Number of Units to be Selected as Lot Sample—

acceptance testing requires taking into account not only the

Manufacturer’s Quality Control

variability between primary sampling units but also the vari-

Number of Units in Lot Number of Units Selected

ability between subunits within primary sampling units and

1to2 1

between specimens from a single subunit in a primary sam-

3to8 2

pling unit.

9to27 3

28 to 64 4

3.1.10 specimen, n—a specific portion of a material or

65 to 125 5

laboratory sample upon which a test is performed or which is

126 to 216 6

217 to 343 7

taken for that purpose. (Syn. test specimen.)

344 to 512 8

513 to 729 9 3.1.11 test result, n—a value obtained by applying a given

730 to 1000 10

test method, expressed either as a single observation or a

1001 or more 11

specified combination of a number of observations.

3.1.11.1 Discussion—Atest result is the value reported for a

single subunit of the laboratory sample. For different test

TABLE 2 Number of Units to be Selected as Lot Sample—

Manufacturer’s Quality Assurance methods a test result might be (1) the value of a single

observation (such as a measurement of a property, a count of

Number of Units in Lot Number of Units Selected

defects, or a grading or rating) on a single specimen from a

1to200 1

201 to 500 2

single subunit of the laboratory sample; (2) the average or

501 to 1000 3

some other function of the values for single observations on

1001 or more 4

each of n specimens from a single subunit of the laboratory

sample; or (3) a ratio of successes to total observations for n

specimens from a single subunit of the laboratory sample.

TABLE 3 Number of Units to be Selected as Lot Sample—

Purchaser’s Specification Conformance

3.1.12 For definitions of other textile terms used in this

Number of Units in Lot Number of Units Selected

practice, refer to Terminology D123.

1to200 1

3.1.13 For definitions of other geosynthetic terms used in

201 to 500 2

501 to 1000 3 this practice, refer to Terminology D4439.

1001 or more 4

3.2 Definitions of Terms Specific to This Standard:

3.2.1 production unit—as referred to in this practice,isa

quantity of geosynthetic agreed upon by the purchaser and

seller for the purpose of sampling.

3.2.1.1 Discussion—In the absence of an agreed-upon

2 2

quantity, 1000 m (1200 yd ) is recommended. For example, a

production run may be 6000 m . For the purpose of sampling,

if 1000 m criteria is used, this would be six production units.

3.2.1.2 Discussion—For the purpose of this practice, the

purchaserisconsideredto

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.