ASTM D5423-23

(Specification)Standard Specification for Forced-Convection Laboratory Ovens for Evaluation of Electrical Insulation

Standard Specification for Forced-Convection Laboratory Ovens for Evaluation of Electrical Insulation

ABSTRACT

This specification covers forced-convection ventilated electrically-heated ovens and used for thermal endurance evaluation of electrical insulating materials. The ovens shall be classified according to ventilations: Type I and Type II. Rate of ventilation, set temperature, temperature variation, and thermal log time properties shall be determined using specified test methods.

SCOPE

1.1 This specification covers forced-convection ventilated electrically-heated ovens, operating over all or part of the temperature range from 20 °C above the ambient temperature to 500 °C, and used for thermal endurance evaluation of electrical insulating materials.

1.2 The specification requirements for Type I ovens are based on IEC Publication 60216-4-1, and are technically identical to it. The requirements for Type II ovens are essentially identical to the requirements of Specification D2436. This specification and an associated test method, D5374, have replaced Specification D2436.

1.3 While the ovens covered by this specification are intended primarily for thermal endurance evaluation, their characteristics make them suitable for other applications as applicable.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5423 − 23

Standard Specification for

Forced-Convection Laboratory Ovens for Evaluation of

1

Electrical Insulation

This standard is issued under the fixed designation D5423; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This specification covers forced-convection ventilated

D1711 Terminology Relating to Electrical Insulation

electrically-heated ovens, operating over all or part of the

D2436 Specification for Forced-Convection Laboratory Ov-

temperature range from 20 °C above the ambient temperature

3

ens for Electrical Insulation (Withdrawn 1994)

to 500 °C, and used for thermal endurance evaluation of

D5374 Test Methods for Forced-Convection Laboratory Ov-

electrical insulating materials.

ens for Evaluation of Electrical Insulation

1.2 The specification requirements for Type I ovens are

2.2 Other Document:

based on IEC Publication 60216-4-1, and are technically

IEC Publication 60216-4-1 Electrical Insulating Materials—

identical to it. The requirements for Type II ovens are essen-

Thermal Endurance Properties—Part 4-1: Ageing

tially identical to the requirements of Specification D2436.

4

Ovens—Single-Chamber Ovens

This specification and an associated test method, D5374, have

replaced Specification D2436.

3. Terminology

1.3 While the ovens covered by this specification are

3.1 For terms related to electrical and electronic insulating

intended primarily for thermal endurance evaluation, their

materials issues refer to Terminology D1711.

characteristics make them suitable for other applications as

3.2 Definitions of Terms Specific to This Standard:

applicable.

3.2.1 rate of ventilation, n—the number of air changes per

1.4 The values stated in SI units are to be regarded as

hour in the oven chamber.

standard. No other units of measurement are included in this

3.2.2 set temperature, n—the average of all of the measured

standard.

temperatures within the oven, averaged over the period of any

1.5 This standard does not purport to address all of the

cyclic temperature variation that occurs.

safety concerns, if any, associated with its use. It is the

3.2.2.1 Discussion—This is the actual operating temperature

responsibility of the user of this standard to establish appro-

of the oven. In IEC 60216-4-1, this term is called the exposure

priate safety, health, and environmental practices and deter-

temperature.

mine the applicability of regulatory limitations prior to use.

3.2.3 temperature fluctuation, n—maximum change in tem-

1.6 This international standard was developed in accor-

perature at one point in the oven over a period of time.

dance with internationally recognized principles on standard-

3.2.3.1 Discussion—This property depends upon the sensi-

ization established in the Decision on Principles for the

tivity and type (on/off or proportional) of control used and the

Development of International Standards, Guides and Recom-

heater mass in relation to surface area.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This specification is under the jurisdiction of ASTM Committee D09 on Standards volume information, refer to the standard’s Document Summary page on

Electrical and Electronic Insulating Materials and is the direct responsibility of the ASTM website.

3

Subcommittee D09.17 on Fire and Thermal Properties. The last approved version of this historical standard is referenced on www.ast-

Current edition approved Feb. 1, 2023. Published February 2023. Originally m.org.

4

approved in 1993. Last previous edition approved in 2022 as D5423 – 22. DOI: Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/D5423-23. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5423 − 23

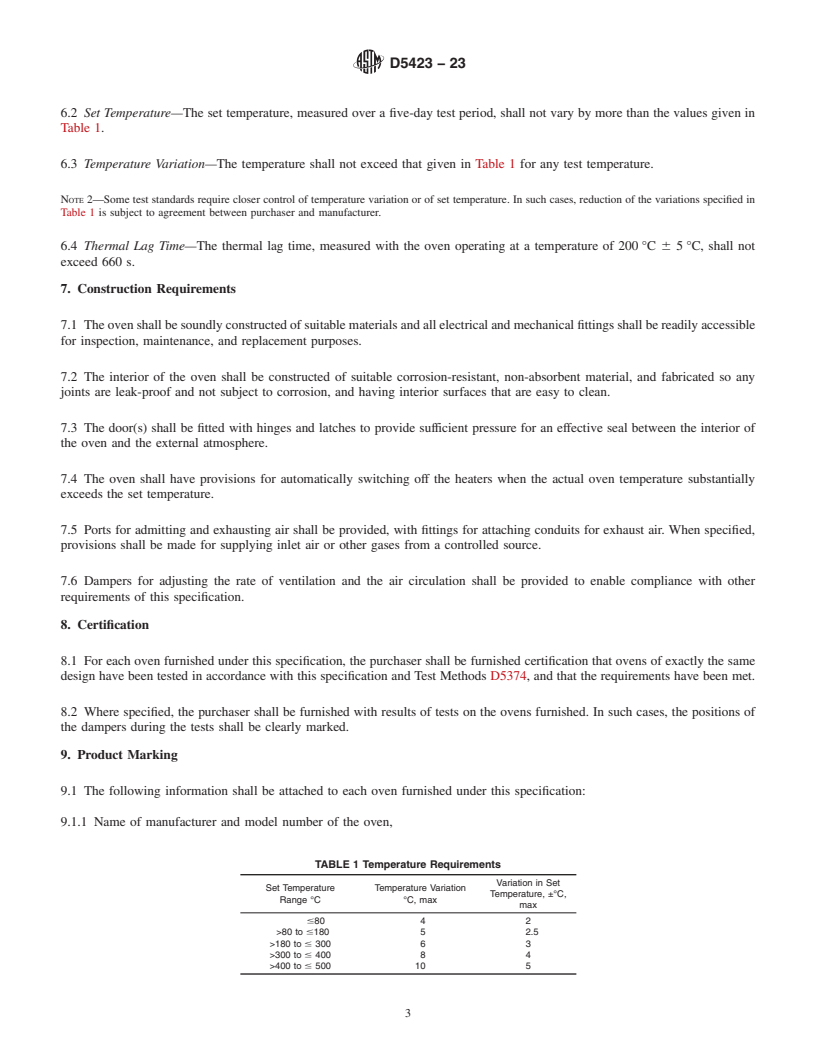

3.2.4 temperature gradient, n—the maximum temperature 6.4 Thermal Lag Time—The thermal lag time, measured

difference at one time between any two points in the oven with the oven operating at a temperature of 200 °C 6 5 °C,

chamber. shall not exceed 660 s.

3.2.4.1 Discussion—This property depends on such factors

as uniformity of heater temperatur

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5423 − 22 D5423 − 23

Standard Specification for

Forced-Convection Laboratory Ovens for Evaluation of

1

Electrical Insulation

This standard is issued under the fixed designation D5423; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers forced-convection ventilated electrically-heated ovens, operating over all or part of the temperature

range from 20 °C above the ambient temperature to 500 °C, and used for thermal endurance evaluation of electrical insulating

materials.

1.2 The specification requirements for Type I ovens are based on IEC Publication 60216-4-1, and are technically identical to it.

The requirements for Type II ovens are essentially identical to the requirements of Specification D2436. This specification and an

associated test method, D5374, have replaced Specification D2436.

1.3 While the ovens covered by this specification are intended primarily for thermal endurance evaluation, their characteristics

make them suitable for other applications as applicable.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D1711 Terminology Relating to Electrical Insulation

3

D2436 Specification for Forced-Convection Laboratory Ovens for Electrical Insulation (Withdrawn 1994)

D5374 Test Methods for Forced-Convection Laboratory Ovens for Evaluation of Electrical Insulation

1

This specification is under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and is the direct responsibility of Subcommittee

D09.17 on Fire and Thermal Properties.

Current edition approved May 1, 2022Feb. 1, 2023. Published May 2022February 2023. Originally approved in 1993. Last previous edition approved in 20142022 as

D5423 – 14.D5423 – 22. DOI: 10.1520/D5423-22.10.1520/D5423-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5423 − 23

2.2 Other Document:

IEC Publication 60216-4-1 Electrical Insulating Materials—Thermal Endurance Properties—Part 4-1: Ageing Ovens—Single-

4

Chamber Ovens

3. Terminology

3.1 For terms related to electrical and electronic insulating materials issues refer to Terminology D1711.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 rate of ventilation, n—the number of air changes per hour in the oven chamber.

3.2.2 set temperature, n—the average of all of the measured temperatures within the oven, averaged over the period of any cyclic

temperature variation that occurs.

3.2.2.1 Discussion—

This is the actual operating temperature of the oven. In IEC 60216-4-1, this term is called the exposure temperature.

3.2.3 temperature fluctuation, n—maximum change in temperature at one point in the oven over a period of time.

3.2.3.1 Discussion—

This property depends upon the sensitivity and type (on/off or proportional) of control used and the heater mass in relation to

surface area.

3.2.4 temperature gradient, n—the maximum temperature difference at one time between any two points in the oven chamber.

3.2.4.1 Discussion—

This property depends on such factors as uniformity of heater temperature, heater distribution about the oven, and air flow patterns

within the oven. In

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.