ASTM E794-06

(Test Method)Standard Test Method for Melting And Crystallization Temperatures By Thermal Analysis

Standard Test Method for Melting And Crystallization Temperatures By Thermal Analysis

SIGNIFICANCE AND USE

Differential scanning calorimetry and differential thermal analysis provide a rapid method for determining the fusion and crystallization temperatures of crystalline materials.

This test is useful for quality control, specification acceptance, and research.

SCOPE

1.1 This test method describes the determination of melting (and crystallization) temperatures of pure materials by differential scanning calorimetry (DSC) and differential thermal analysis (DTA).

1.2 This test method is generally applicable to thermally stable materials with well-defined melting temperatures.

1.3 The normal operating range is from 120 to 600 C for DSC and 25 to 1500 C for DTA. The temperature range can be extended depending upon the instrumentation used.

1.4 Computer or electronic based instruments, techniques, or data treatment equivalent to those in this test method may be used.

1.5 SI units are the standard.

This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E794 − 06

StandardTest Method for

Melting And Crystallization Temperatures By Thermal

1

Analysis

This standard is issued under the fixed designation E794; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

3.1 Definitions—Specialized terms used in this test method

1.1 This test method describes the determination of melting

(and crystallization) temperatures of pure materials by differ- are defined in Terminologies E473 and E1142.

ential scanning calorimetry (DSC) and differential thermal

4. Summary of Test Method

analysis (DTA).

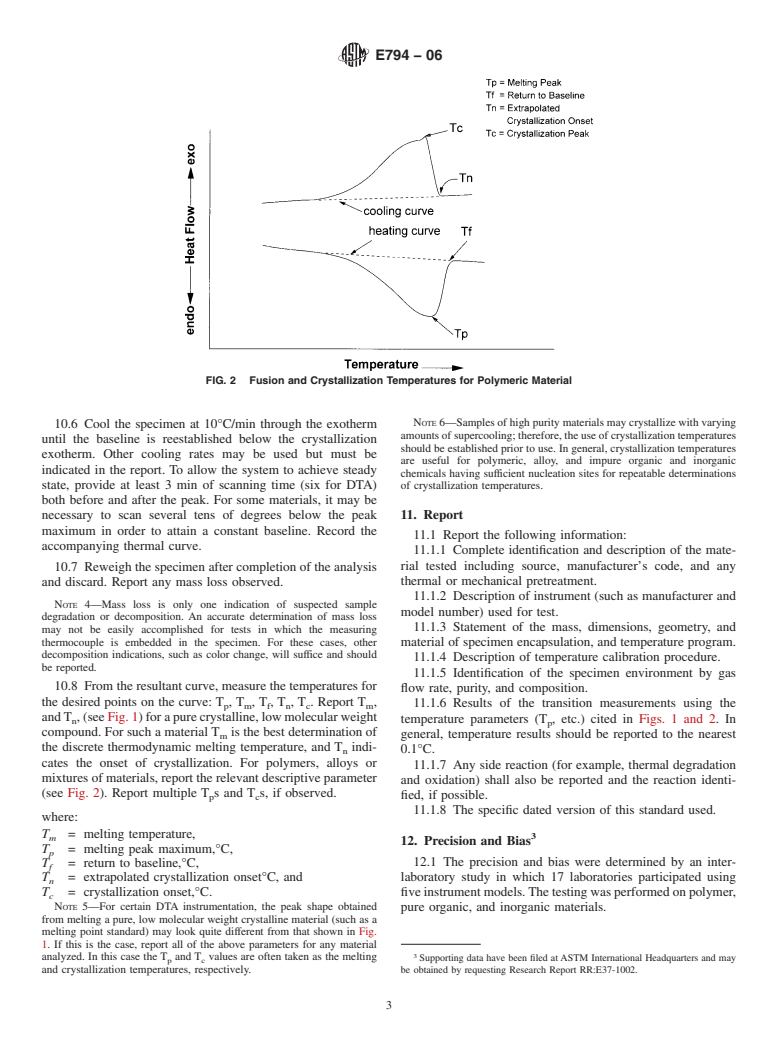

4.1 The test method involves heating (or cooling) a test

1.2 This test method is generally applicable to thermally

specimen at a controlled rate in a controlled environment

stable materials with well-defined melting temperatures.

throughtheregionoffusion(orcrystallization).Thedifference

1.3 The normal operating range is from −120 to 600°C for

in heat flow (for DSC) or temperature (for DTA) between the

DSCand25to1500°CforDTA.Thetemperaturerangecanbe

test material and a reference material due to energy changes is

extended depending upon the instrumentation used.

continuously monitored and recorded. A transition is marked

by absorption (or release) of energy by the specimen resulting

1.4 Computer or electronic based instruments, techniques,

in a corresponding endothermic (or exothermic) peak in the

ordatatreatmentequivalenttothoseinthistestmethodmaybe

heating (or cooling) curve.

used.

NOTE 1—Enthalpies of fusion and crystallization are sometimes deter-

1.5 SI units are the standard.

minedinconjunctionwithmeltingorcrystallizationtemperaturemeasure-

1.6 This standard does not purport to address all of the

ments. These enthalpy values may be obtained by Test Method E793.

safety problems, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5.1 Differential scanning calorimetry and differential ther-

bility of regulatory limitations prior to use.

malanalysisprovidearapidmethodfordeterminingthefusion

and crystallization temperatures of crystalline materials.

2. Referenced Documents

5.2 This test is useful for quality control, specification

2

2.1 ASTM Standards:

acceptance, and research.

E473Terminology Relating to Thermal Analysis and Rhe-

6. Interferences

ology

E793Test Method for Enthalpies of Fusion and Crystalliza-

6.1 Test specimens need to be homogeneous, since milli-

tion by Differential Scanning Calorimetry

gram quantities are used.

E967Test Method for Temperature Calibration of Differen-

6.2 Toxic or corrosive effluents, or both, may be released

tial Scanning Calorimeters and Differential ThermalAna-

when heating the material and could be harmful to personnel

lyzers

and to apparatus.

E1142Terminology Relating to Thermophysical Properties

7. Apparatus

7.1 Apparatus shall be of either type listed below:

1

ThistestmethodisunderthejurisdictionofASTMCommitteeE37onThermal

7.1.1 Differential Scanning Calorimeter (DSC) or Differen-

Measurements and is the direct responsibility of Subcommittee E37.01 on Calo-

tial Thermal Analyzer (DTA)—The essential instrumentation

rimetry and Mass Loss.

required to provide the minimum differential scanning calori-

Current edition approved March 1, 2006. Published April 2006. Originally

metric or differential thermal analyzer capability for this

approved in 1981. Last previous edition approved in 2001 as E794–01. DOI:

10.1520/E0794-06.

method includes:

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

7.1.1.1 Test Chamber composed of:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

(1)A furnace or furnaces to provide uniform controlled

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. heating (cooling) of a specimen and reference to a constant

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E794 − 06

temperatureorataconstantratewithintheapplicabletempera- 9. Calibration

ture range of this method.

9.1 Using the same heating rate, purge gas, and flow rate as

(2)A temperature sensor to provide an indication of the

that to be used for analyzing the specimen, calibrate the

specimen or furnace temperature to within 6 0.01°C.

temperature axis of the instrument using the procedure in

(3)Differential sensors to detect a heat flow difference

Practice E967.

(DSC) or temperatur

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.