ASTM D4470-97

(Test Method)Standard Test Method for Static Electrification

Standard Test Method for Static Electrification

SCOPE

1.1 This test method covers the generation of electrostatic charge, the measurement of this charge and its associated electric field, and the test conditions which must be controlled in order to obtain reproducible results. This test method is applicable to both solids and liquids. This test method is not applicable to gases, since a transfer of a gas with no solid impurities in it does not generate an electrostatic charge. This test method also does not cover the beneficial uses of static electrification, its associated problems or hazards, or the elimination or reduction of unwanted electrostatic charge.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 4470 – 97

Standard Test Method for

Static Electrification

This standard is issued under the fixed designation D 4470; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 conducting material (conductor), n— a material

within which an electric current is produced by application of

1.1 This test method covers the generation of electrostatic

a voltage between points on or within the material.

charge, the measurement of this charge and its associated

3.1.1.1 Discussion—The term “conducting material” is usu-

electric field, and the test conditions which must be controlled

ally applied only to those materials in which a relatively small

in order to obtain reproducible results. This test method is

potential difference results in a relatively large current since all

applicable to both solids and liquids. This test method is not

materials appear to permit some conduction current. Metals

applicable to gases, since a transfer of a gas with no solid

and strong electrolytes are examples of conducting materials.

impurities in it does not generate an electrostatic charge. This

3.1.2 electric field strength, n—the magnitude of the vector

test method also does not cover the beneficial uses of static

force on a point charge of unit value and positive polarity.

electrification, its associated problems or hazards, or the

3.1.3 excess electrostatic charge, n—the algebraic sum of

elimination or reduction of unwanted electrostatic charge.

all positive and negative electric charges on the surface of, or

1.2 The values stated in SI units are to be regarded as the

in, a specific volume.

standard.

3.1.4 insulating material (insulator), n— a material in

1.3 This standard does not purport to address all of the

which a voltage applied between two points on or within the

safety concerns, if any, associated with its use. It is the

material produces a small and sometimes negligible current.

responsibility of the user of this standard to establish appro-

3.1.5 resistivity, surface—the surface resistance multiplied

priate safety and health practices and determine the applica-

by that ratio of specimen surface dimensions (width of elec-

bility of regulatory limitations prior to use.

trodes defining the current path divided by the distance

2. Referenced Documents between electrodes) which transforms the measured resistance

to that obtained if the electrodes formed the opposite sides of

2.1 ASTM Standards:

a square.

D 618 Practice for Conditioning Plastics for Testing

3.1.5.1 Discussion—Surface resistivity is expressed in

D 5032 Practice for Maintaining Constant Relative Humid-

ohms. It is popularly expressed also as ohms/square (the size of

ity by Means of Aqueous Glycerin Solutions

the square is immaterial). Surface resistivity is the reciprocal of

E 104 Practice for Maintaining Constant Relative Humidity

surface conductivity.

by Means of Aqueous Solutions

3.2 Definitions of Terms Specific to This Standard:

3. Terminology

3.2.1 apparent contact area, n—the area of contact between

two flat bodies.

3.1 Definitions:

3.2.1.1 Discussion—It is the area one would calculate by

measuring the length and width of the rectangular macroscopic

This test method is under the jurisdiction of ASTM Committee D-9 on

contact region.

Electrical and Electronic Insulating Materials and is the direct responsibility of

3.2.2 dissipative material, n—a material with a volume

Subcommittee D09.12 on Electrical Tests.

resistivity greater than 10 ohm-cm and less than 10 ohm-cm,

Current edition approved Sept. 10, 1997. Published February 1998. Originally

published as D 4470 – 85. Last previous edition D 4470 – 96. a resistivity range between conductive and insulating material

Vosteen, R. E., and Bartnikas, R., Chapter 5, “Electrostatic Charge Measure-

as defined in this test method.

ments,” Engineering Dielectrics, Vol. IIB, Electrical Properties of Solid Insulating

3.2.3 real contact area, n—the regions of contact between

Materials, Measurement Techniques , R. Bartnikas, Editor, ASTM STP 926, ASTM,

two bodies through which mechanical actions or reactions are

Philadelphia, 1987.

Annual Book of ASTM Standards, Vol 08.01.

transferred.

Annual Book of ASTM Standards, Vol 10.02.

Annual Book of ASTM Standards, Vol 11.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4470–97

3.2.3.1 Discussion—Since real bodies are never perfectly sliding down chutes, by vacuum platens, and by pinch rollers.

smooth, at least on a microscopic scale, the real contact area of Of these types of transport, pinch rollers and sliding down

apparently flat materials is always less than the apparent chutes generate the largest amount of charge. Generally, the

contact area. better the contact (larger real contact area), the greater will be

3.2.4 triboelectric charge generation—the formation, with the charge generated. Pinch rollers are usually a high pressure,

or without rubbing, of electrostatic charges by separation of small apparent area of contact, leading to a relatively large real

contacting materials. area of contact between the sheet and rollers. Sliding serves to

multiply the real area of contact over that which would be

4. Significance and Use

obtained with a contact without sliding.

4.1 Whenever two dissimilar materials are contacted and 5.2 Electrostatic Charge Measurements—Fig. 1 shows a

block diagram of the typical components necessary for this

separated, excess electrostatic charge (triboelectric charge) will

be found on these materials if at least one of the materials is a measurement while Fig. 2 shows a schematic diagram.

5.2.1 Faraday Cage—The Faraday cage consists of two

good insulator. This excess charge gives rise to electric fields

which can exert forces on other objects. If these fields exceed conducting enclosures, one enclosed and insulated from the

the breakdown strength of the surrounding gas, a disruptive other. The inner enclosure is electrically connected to the shunt

capacitors and the electrometer input. It is insulated from the

discharge (spark) may occur. The heat from this discharge may

ignite explosive atmospheres, the light may fog photosensi- outer enclosure by rigid, very high resistance, insulators which

have resistance practically independent of relative humidity (an

tized materials, and the current flowing in a static discharge

may cause catastrophic failure of solid state devices. Electric example is polytetrafluoroethylene (PFTE). The inner enclo-

sure should be of such construction that the test specimen can

forces may be used beneficially, as in electrostatic copying,

spray painting and beneficiation of ores. They may be detri- be substantially surrounded by it. The outer enclosure is

connected to ground and serves to shield the inner enclosure

mental as when they attract dirt to a surface or when they cause

sheets to stick together. Since most plastic materials in use from external fields which could affect the measurement.

5.2.2 Shunt Capacitors—Shunt capacitors may be neces-

today have very good insulating qualities, it is difficult to avoid

generation of static electricity. Since it depends on many sary to reduce the measured voltage to a range where it can be

read by the electrometer. Such shunt capacitors must have very

parameters, it is difficult to generate static electricity reliably

and reproducibly. low leakage insulation relatively unaffected by relative humid-

ity changes (for example, polystyrene). They should be kept

5. Apparatus

short-circuited when not in use and should be protected from

high relative humidity.

5.1 Charging Mechanisms—The charging mechanisms can

5.2.3 Electrometer—The electrometer voltmeter measures

be constructed in a variety of ways, and should preferably be

the voltage developed on the Faraday cage and shunt capaci-

made as analagous to the particular application as possible.

tors. The electrometer must have a high impedence (such as

Some examples of charging mechanisms are described in 5.1.1,

100 TV or higher) and a low drift rate concordant with the time

5.1.2, and 5.1.3.

of measurement. Electrometers are available with built-in

5.1.1 Powder or Liquids Transported Through Tubes or

shunt capacitors selected by a range switch. Electrometers are

Down Troughs—Contact between the specimen and wall of the

also available with negative feedback circuits which minimize

tube will charge the specimen or the tube, or both. Either the

the effect of input capacity. These circuits reduce the input

specimen or the tube must be insulating, or partially insulating.

voltage drop to nearly zero minimizing the effects of leakage of

When the specimen is separated from the tube, electrostatic

charge to ground and polarization of insulators.

charge will be generated. This charge may be measured by

5.2.4 Display Unit—The display unit indicates the voltage

catching a known amount of the specimen in a Faraday cage,

developed on the electrometer. If the input capacitance is

or the charge remaining on the tube may be measured. A trough

known and does not vary, or if negative feedback is used, the

may be substituted for the tube and gravity used to effect the

display unit may be calibrated to measure the charge on the

movement of the specimen along the trough.

Faraday cage directly. The unit may be a meter showing the

5.1.2 Webs Transported Over Rollers— Contact between

instantaneous value or it may be more complicated equipment,

the web and the roller surface will charge the web if it is an

such as a strip chart recorder giving a reading as a function of

insulator or partial insulator. If the rollers are insulators or

time. The electrometer and display unit may be combined in

partial insulators they will become charged thus lowering, or

one instrument.

eliminating, the charge transfer to the web after a period of

time. The electric field on the web may be measured with a

fieldmeter, or the charge on the web can be measured with a

cylindrical Faraday cage if the width of the web is not too

large.

5.1.3 Transport of Insulating or Partially Insulating Sheet

Material—Sheet materials may be transported on air layers, by

Shashoua, V. E., “Static Electricity in Polymers: Theory and Measurement,” FIG. 1 Block Diagram of Apparatus for Measurement of

Journal of Polymer Science, Vol XXXIII, 1958, pp 65–85. Electrostatic Charge

D4470–97

adequately shield the sensor and associated circuits from noise

generated by the motor driving the rotating vane.

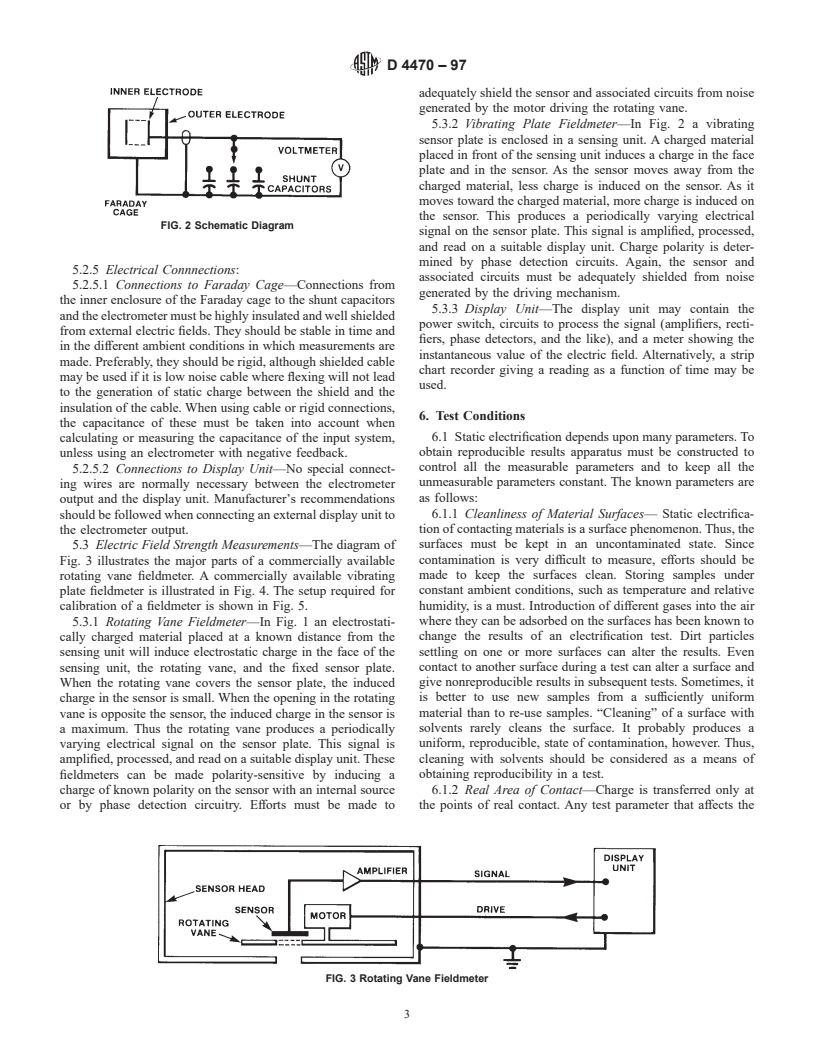

5.3.2 Vibrating Plate Fieldmeter—In Fig. 2 a vibrating

sensor plate is enclosed in a sensing unit. A charged material

placed in front of the sensing unit induces a charge in the face

plate and in the sensor. As the sensor moves away from the

charged material, less charge is induced on the sensor. As it

moves toward the charged material, more charge is induced on

the sensor. This produces a periodically varying electrical

FIG. 2 Schematic Diagram

signal on the sensor plate. This signal is amplified, processed,

and read on a suitable display unit. Charge polarity is deter-

mined by phase detection circuits. Again, the sensor and

5.2.5 Electrical Connnections:

associated circuits must be adequately shielded from noise

5.2.5.1 Connections to Faraday Cage—Connections from

generated by the driving mechanism.

the inner enclosure of the Faraday cage to the shunt capacitors

5.3.3 Display Unit—The display unit may contain the

and the electrometer must be highly insulated and well shielded

power switch, circuits to process the signal (amplifiers, recti-

from external electric fields. They should be stable in time and

fiers, phase detectors, and the like), and a meter showing the

in the different ambient conditions in which measurements are

instantaneous value of the electric field. Alternatively, a strip

made. Preferably, they should be rigid, although shielded cable

chart recorder giving a reading as a function of time may be

may be used if it is low noise cable where flexing will not lead

used.

to the generation of static charge between the shield and the

insulation of the cable. When using cable or rigid connections,

6. Test Conditions

the capacitance of these must be taken into account when

6.1 Static electrification depends upon many parameters. To

calculating or measuring the capacitance of the input system,

obtain reproducible results apparatus must be constructed to

unless using an electrometer with negative feedback.

control all the measurable parameters and to keep all the

5.2.5.2 Connections to Display Unit—No special connect-

unmeasurable parameters constant. The known parameters are

ing wires are normally necessary between the electrometer

as follows:

output and the display unit. Manufacturer’s recommendations

should be followed when connecting an external display unit to 6.1.1 Cleanliness of Material Surfaces— Static electrifica-

tion of contacting materials is a surface phenomenon. Thus, the

the electrometer output.

5.3 Electric Field Strength Measurements—The diagram of surfaces must be kept in an uncontaminated state. Since

contamination is very difficult to measure, efforts should be

Fig. 3 illustrates the major parts of a commercially available

rotating vane fieldmeter. A commercially available vibrating made to keep the surfaces clean. Storing samples under

constant ambient conditions, such as temperature and relative

plate fieldmeter is illustrated in Fig. 4. The setup required for

calibration of a fieldmeter is shown in Fig. 5. humidity, is a must. Introduction of different gases into the air

where they can be adsorbed on the surfaces has been known to

5.3.1 Rotating Vane Fieldmeter—In Fig. 1 an electrostati-

cally charged material placed at a known distance from the change the results of an electrification test. Dirt particles

settling on one or more surfaces can alter the results. Even

sensing unit will induce electrostatic charge in the face of the

sensing unit, the rotating vane, and the fixed sensor plate. contact to another surface during a test can alter a surface and

give nonreproducible results in subsequent tests. Sometimes, it

When the rotating vane covers the sensor plate, the induced

charge in the sensor is small. When the opening in the rotating is better to use new samples from a sufficiently uniform

material than to re-use samples. “Cleaning” of a surface with

vane is opposite the sensor, the induced charge in the sensor is

a maximum. Thus the rotating v

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.