ASTM D4470-18

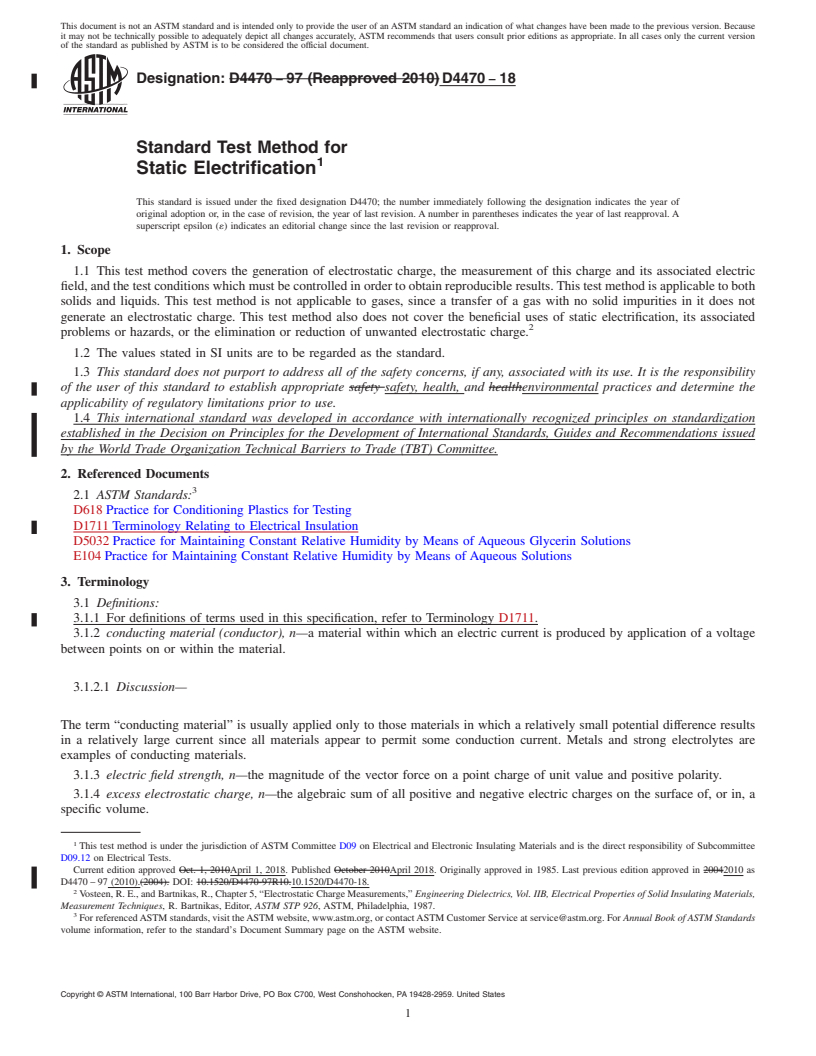

(Test Method)Standard Test Method for Static Electrification

Standard Test Method for Static Electrification

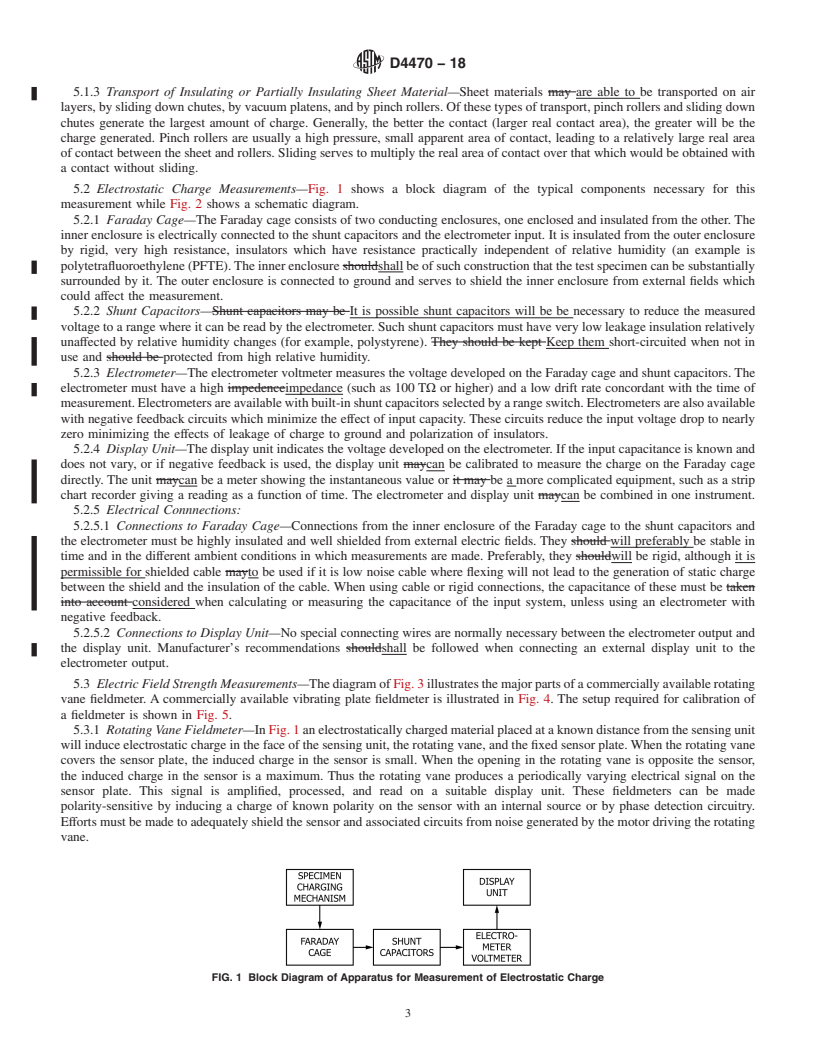

SIGNIFICANCE AND USE

4.1 Whenever two dissimilar materials are contacted and separated, excess electrostatic charge (triboelectric charge) will be found on these materials if at least one of the materials is a good insulator. This excess charge gives rise to electric fields which can exert forces on other objects. If these fields exceed the breakdown strength of the surrounding gas, a disruptive discharge (spark) can occur. The heat from this discharge can ignite explosive atmospheres, the light can fog photosensitized materials, and the current flowing in a static discharge can cause catastrophic failure of solid state devices. Electric forces can be used beneficially, as in electrostatic copying, spray painting and beneficiation of ores. They can be detrimental as when they attract dirt to a surface or when they cause sheets to stick together. Since most plastic materials in use today have very good insulating qualities, it is difficult to avoid generation of static electricity. Since it depends on many parameters, it is difficult to generate static electricity reliably and reproducibly.

SCOPE

1.1 This test method covers the generation of electrostatic charge, the measurement of this charge and its associated electric field, and the test conditions which must be controlled in order to obtain reproducible results. This test method is applicable to both solids and liquids. This test method is not applicable to gases, since a transfer of a gas with no solid impurities in it does not generate an electrostatic charge. This test method also does not cover the beneficial uses of static electrification, its associated problems or hazards, or the elimination or reduction of unwanted electrostatic charge.2

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D4470 −18

Standard Test Method for

1

Static Electrification

This standard is issued under the fixed designation D4470; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope by Means of Aqueous Glycerin Solutions

E104Practice for Maintaining Constant Relative Humidity

1.1 This test method covers the generation of electrostatic

by Means of Aqueous Solutions

charge, the measurement of this charge and its associated

electric field, and the test conditions which must be controlled

3. Terminology

in order to obtain reproducible results. This test method is

applicable to both solids and liquids. This test method is not

3.1 Definitions:

applicable to gases, since a transfer of a gas with no solid

3.1.1 Fordefinitionsoftermsusedinthisspecification,refer

impurities in it does not generate an electrostatic charge. This

to Terminology D1711.

test method also does not cover the beneficial uses of static

3.1.2 conductingmaterial(conductor),n—amaterialwithin

electrification, its associated problems or hazards, or the

which an electric current is produced by application of a

2

elimination or reduction of unwanted electrostatic charge.

voltage between points on or within the material.

3.1.2.1 Discussion—The term “conducting material” is usu-

1.2 The values stated in SI units are to be regarded as the

ally applied only to those materials in which a relatively small

standard.

potentialdifferenceresultsinarelativelylargecurrentsinceall

1.3 This standard does not purport to address all of the

materials appear to permit some conduction current. Metals

safety concerns, if any, associated with its use. It is the

and strong electrolytes are examples of conducting materials.

responsibility of the user of this standard to establish appro-

3.1.3 electric field strength, n—the magnitude of the vector

priate safety, health, and environmental practices and deter-

force on a point charge of unit value and positive polarity.

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor- 3.1.4 excess electrostatic charge, n—the algebraic sum of

dance with internationally recognized principles on standard-

all positive and negative electric charges on the surface of, or

ization established in the Decision on Principles for the in, a specific volume.

Development of International Standards, Guides and Recom-

3.1.5 insulatingmaterial(insulator),n—amaterialinwhich

mendations issued by the World Trade Organization Technical

a voltage applied between two points on or within the material

Barriers to Trade (TBT) Committee.

produces a small and sometimes negligible current.

3.1.6 resistivity, surface, n—the surface resistance multi-

2. Referenced Documents

plied by that ratio of specimen surface dimensions (width of

3

2.1 ASTM Standards:

electrodes defining the current path divided by the distance

D618Practice for Conditioning Plastics for Testing

between electrodes) which transforms the measured resistance

D1711Terminology Relating to Electrical Insulation

to that obtained if the electrodes formed the opposite sides of

D5032PracticeforMaintainingConstantRelativeHumidity

a square.

3.1.6.1 Discussion—Surface resistivity is expressed in

ohms.Itispopularlyexpressedalsoasohms/square(thesizeof

1

This test method is under the jurisdiction of ASTM Committee D09 on

thesquareisimmaterial).Surfaceresistivityisthereciprocalof

Electrical and Electronic Insulating Materials and is the direct responsibility of

surface conductivity.

Subcommittee D09.12 on Electrical Tests.

Current edition approved April 1, 2018. Published April 2018. Originally

3.2 Definitions of Terms Specific to This Standard:

approved in 1985. Last previous edition approved in 2010 as D4470–97(2010).

DOI: 10.1520/D4470-18. 3.2.1 apparent contact area, n—the area of contact between

2

Vosteen, R. E., and Bartnikas, R., Chapter 5, “Electrostatic Charge

two flat bodies.

Measurements,” Engineering Dielectrics, Vol. IIB, Electrical Properties of Solid

3.2.1.1 Discussion—It is the area one would calculate by

Insulating Materials, Measurement Techniques, R. Bartnikas, Editor, ASTM STP

measuringthelengthandwidthoftherectangularmacroscopic

926, ASTM, Philadelphia, 1987.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact region.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2.2 dissipative material, n—a material with a volume

St

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4470 − 97 (Reapproved 2010) D4470 − 18

Standard Test Method for

1

Static Electrification

This standard is issued under the fixed designation D4470; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the generation of electrostatic charge, the measurement of this charge and its associated electric

field, and the test conditions which must be controlled in order to obtain reproducible results. This test method is applicable to both

solids and liquids. This test method is not applicable to gases, since a transfer of a gas with no solid impurities in it does not

generate an electrostatic charge. This test method also does not cover the beneficial uses of static electrification, its associated

2

problems or hazards, or the elimination or reduction of unwanted electrostatic charge.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D1711 Terminology Relating to Electrical Insulation

D5032 Practice for Maintaining Constant Relative Humidity by Means of Aqueous Glycerin Solutions

E104 Practice for Maintaining Constant Relative Humidity by Means of Aqueous Solutions

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this specification, refer to Terminology D1711.

3.1.2 conducting material (conductor), n—a material within which an electric current is produced by application of a voltage

between points on or within the material.

3.1.2.1 Discussion—

The term “conducting material” is usually applied only to those materials in which a relatively small potential difference results

in a relatively large current since all materials appear to permit some conduction current. Metals and strong electrolytes are

examples of conducting materials.

3.1.3 electric field strength, n—the magnitude of the vector force on a point charge of unit value and positive polarity.

3.1.4 excess electrostatic charge, n—the algebraic sum of all positive and negative electric charges on the surface of, or in, a

specific volume.

1

This test method is under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and is the direct responsibility of Subcommittee

D09.12 on Electrical Tests.

Current edition approved Oct. 1, 2010April 1, 2018. Published October 2010April 2018. Originally approved in 1985. Last previous edition approved in 20042010 as

D4470 – 97 (2010).(2004). DOI: 10.1520/D4470-97R10.10.1520/D4470-18.

2

Vosteen, R. E., and Bartnikas, R., Chapter 5, “Electrostatic Charge Measurements,” Engineering Dielectrics, Vol. IIB, Electrical Properties of Solid Insulating Materials,

Measurement Techniques, R. Bartnikas, Editor, ASTM STP 926, ASTM, Philadelphia, 1987.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4470 − 18

3.1.5 insulating material (insulator), n—a material in which a voltage applied between two points on or within the material

produces a small and sometimes negligible current.

3.1.6 resistivity, surface—surface, n—the surface resistance multiplied by that ratio of specimen surface dimensions (width of

electrodes defining the current path divided by the distance between electrodes) which transforms the measured resistance to that

obtained if the electro

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.