ASTM E953-88(2004)

(Test Method)Standard Test Method for Fusibility of Refuse-Derived Fuel (RDF) Ash

Standard Test Method for Fusibility of Refuse-Derived Fuel (RDF) Ash

SIGNIFICANCE AND USE

The standard is available to producers and users of RDF to use in determining the fusibility of ash produced from RDF.

Limitations of Ash Fusibility Data—Ash fusibility data are too often over-interpreted. In practice, types of burning equipment, rate of burning, temperature and thickness of fire bed or ball, distribution of ash forming mineral matter in the RDF, and viscosity of the molten ash may influence ash behavior more than the ash fusibility characteristics determined by the laboratory test. Furthermore, conditions existing during applied combustion of RDF are so complex that they are impossible to duplicate completely in a small-scale laboratory test. Therefore, the test should be considered an empirical one and the data, at best, only qualitative.

SCOPE

1.1 This test method covers the observation of the temperatures at which triangular pyramids (cones) prepared from RDF ash attain and pass through certain stages of fusing and flow when heated at a specific rate in controlled, mildly-reducing, and oxidizing atmospheres.

1.2 The test method is empirical, and strict observance of the requirements and conditions is necessary to obtain reproducible temperatures and enable different laboratories to obtain concordant results.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Section for additional hazard information.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E953–88(Reapproved 2004)

Standard Test Method for

Fusibility of Refuse-Derived Fuel (RDF) Ash

This standard is issued under the fixed designation E 953; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

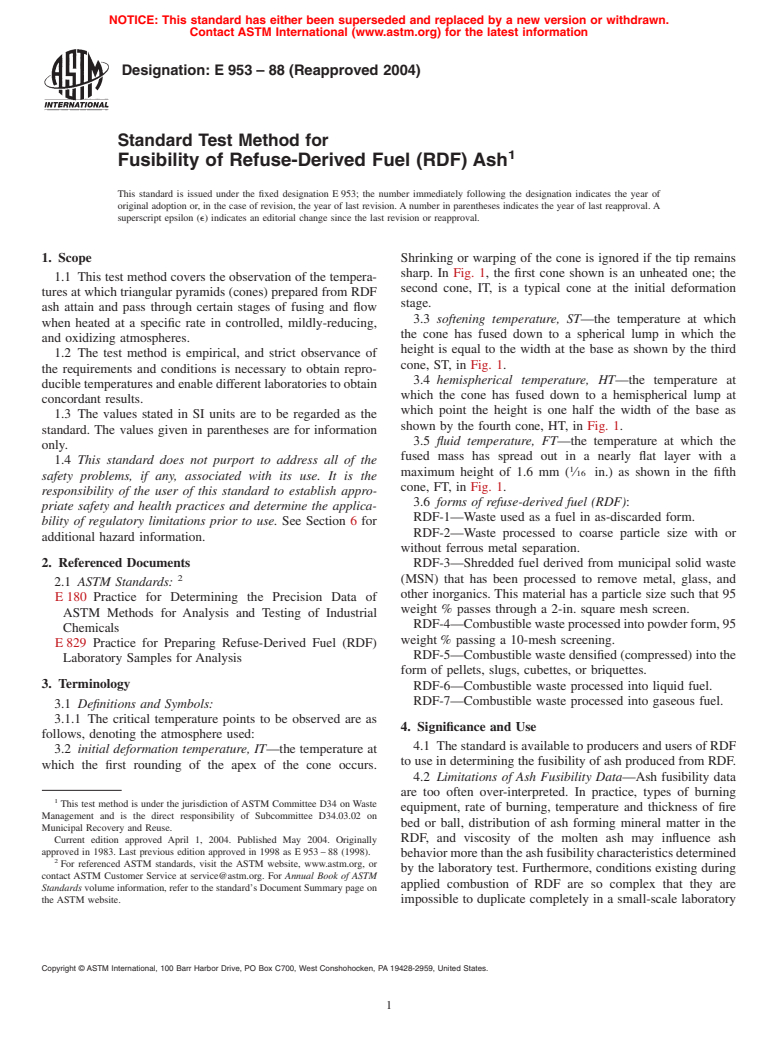

1. Scope Shrinking or warping of the cone is ignored if the tip remains

sharp. In Fig. 1, the first cone shown is an unheated one; the

1.1 This test method covers the observation of the tempera-

second cone, IT, is a typical cone at the initial deformation

tures at which triangular pyramids (cones) prepared from RDF

stage.

ash attain and pass through certain stages of fusing and flow

3.3 softening temperature, ST—the temperature at which

when heated at a specific rate in controlled, mildly-reducing,

the cone has fused down to a spherical lump in which the

and oxidizing atmospheres.

height is equal to the width at the base as shown by the third

1.2 The test method is empirical, and strict observance of

cone, ST, in Fig. 1.

the requirements and conditions is necessary to obtain repro-

3.4 hemispherical temperature, HT—the temperature at

ducible temperatures and enable different laboratories to obtain

which the cone has fused down to a hemispherical lump at

concordant results.

which point the height is one half the width of the base as

1.3 The values stated in SI units are to be regarded as the

shown by the fourth cone, HT, in Fig. 1.

standard. The values given in parentheses are for information

3.5 fluid temperature, FT—the temperature at which the

only.

fused mass has spread out in a nearly flat layer with a

1.4 This standard does not purport to address all of the

maximum height of 1.6 mm ( ⁄16 in.) as shown in the fifth

safety problems, if any, associated with its use. It is the

cone, FT, in Fig. 1.

responsibility of the user of this standard to establish appro-

3.6 forms of refuse-derived fuel (RDF):

priate safety and health practices and determine the applica-

RDF-1—Waste used as a fuel in as-discarded form.

bility of regulatory limitations prior to use. See Section 6 for

RDF-2—Waste processed to coarse particle size with or

additional hazard information.

without ferrous metal separation.

2. Referenced Documents

RDF-3—Shredded fuel derived from municipal solid waste

(MSN) that has been processed to remove metal, glass, and

2.1 ASTM Standards:

other inorganics. This material has a particle size such that 95

E 180 Practice for Determining the Precision Data of

weight % passes through a 2-in. square mesh screen.

ASTM Methods for Analysis and Testing of Industrial

RDF-4—Combustiblewasteprocessedintopowderform,95

Chemicals

weight % passing a 10-mesh screening.

E 829 Practice for Preparing Refuse-Derived Fuel (RDF)

RDF-5—Combustible waste densified (compressed) into the

Laboratory Samples for Analysis

form of pellets, slugs, cubettes, or briquettes.

3. Terminology

RDF-6—Combustible waste processed into liquid fuel.

RDF-7—Combustible waste processed into gaseous fuel.

3.1 Definitions and Symbols:

3.1.1 The critical temperature points to be observed are as

4. Significance and Use

follows, denoting the atmosphere used:

4.1 The standard is available to producers and users of RDF

3.2 initial deformation temperature, IT—the temperature at

to use in determining the fusibility of ash produced from RDF.

which the first rounding of the apex of the cone occurs.

4.2 Limitations of Ash Fusibility Data—Ash fusibility data

are too often over-interpreted. In practice, types of burning

This test method is under the jurisdiction of ASTM Committee D34 on Waste

equipment, rate of burning, temperature and thickness of fire

Management and is the direct responsibility of Subcommittee D34.03.02 on

bed or ball, distribution of ash forming mineral matter in the

Municipal Recovery and Reuse.

RDF, and viscosity of the molten ash may influence ash

Current edition approved April 1, 2004. Published May 2004. Originally

approved in 1983. Last previous edition approved in 1998 as E 953 – 88 (1998).

behaviormorethantheashfusibilitycharacteristicsdetermined

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

by the laboratory test. Furthermore, conditions existing during

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

applied combustion of RDF are so complex that they are

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. impossible to duplicate completely in a small-scale laboratory

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E953–88 (2004)

FIG. 1 Critical Temperature Points

test. Therefore, the test should be considered an empirical one

and the data, at best, only qualitative.

5. Apparatus

5.1 Furnace—Any gas-fired or electric furnace conforming

to the following requirements may be used.

5.1.1 The furnace shall be capable of maintaining a uniform

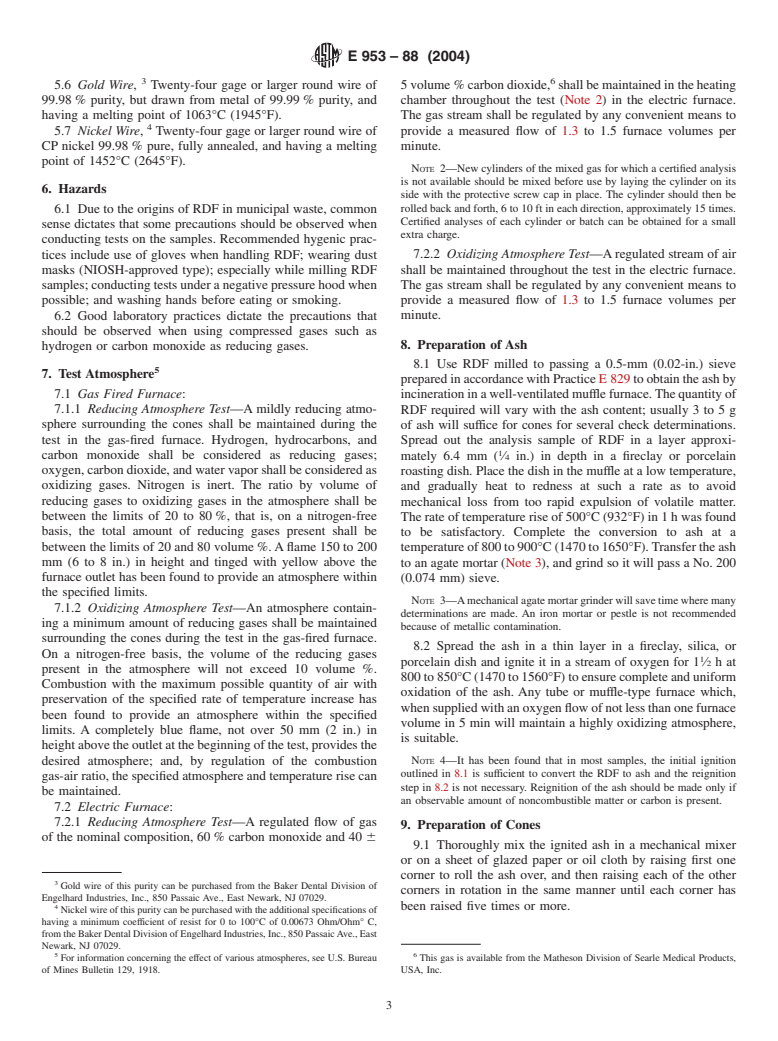

U.S. Customary Units. SI Units,

temperature zone in which to heat the ash cones. This zone

in. mm

shall be such that the difference in the melting point of 12.7

⁄4 6.4

mm ( ⁄2 in.) pieces of pure gold wire when mounted in place of

⁄4 19.1

the ash cones on the cone support shall be not greater than 1 ⁄2 38.1

2 50.2

11°C (20°F) in a reducing atmosphere test run.

3 76.2

5.1.2 The furnace shall be capable of maintaining the

FIG. 2 Brass Cone Mold

desired atmosphere surrounding the cones during heating. The

composition of the atmosphere, reducing or oxidizing, shall be

maintained within the limits specified in Section 7.The desired

National Bureau of Standards, or checked periodically against equipment

atmosphere in the gas-fired furnace surrounding the cones shall

certified by the National Bureau of Standards.

be obtained by regulation of the ratio of gas to air in the

combustion mixture. The desired atmosphere in the electric

5.3.2 Thermocouple—A thermocouple of platinum and

furnaceshallbeobtainedbymeansofgasesintroducedintothe

platinum-rhodium, protected from the furnace gases by a

heatingchamber.Themuffleshallbegas-impervious,freefrom

glazed porcelain sheath, shall be used with a high-resistance

cracks, and the closure-plug tight fitting. Since state-of-the-art

millivoltmeterorpotentiometeraccurateandreadabletowithin

furnaces vary somewhat in design, the gas supply inlet tube

5.5°C (10°F). The sheath shall be sealed to the furnace wall by

shall be installed per instructions of furnace manufacturer.

alundum cement. The hot junction of the thermocouple shall

5.1.3 The furnace shall be capable of regulation so that the

touch the end of the sheath and shall be located in the center of

rate of temperature rise shall be 8 6 3°C (15 6 5°F) per

the muffle and immediately to the rear of the cones. The

minute.

thermocouple protective sheath shall be checked periodically

5.1.4 The furnace shall provide a means of observing the

for cracks. The thermocouple and its meter shall meet the

ash cones during the heating. Observation shall be on the same

requirements of Section 10. The potentiometer or millivoltme-

horizontal plane as the cone-support surface.

ter shall be located or shielded adequately as to prevent radiant

5.2 Cone Mold—A commercially available cone mold as

or convection heating of the cold junction. The room tempera-

shown in Fig. 2 shall be used.The cone shall be 19 mm ( ⁄4 in.)

ture compensator shall be adjusted to the existing temperature.

in height and 6.4 mm ( ⁄4 in.) in width at each side of the base

5.4 Ash-Cone Refractory Support—The ash cone shall be

which is an equilateral triangle.

mounted on a refractory base composed of a mixture of equal

5.2.1 Asteel spatula with a pointed tip, ground off to fit the

parts by weight of kaolin and alumina conforming to the

cone depression in the mold, is suitable for removal of the ash

following requirements:

cone.

5.4.1 Kaolin—NF-Grade powder passing a No. 200 (0.074

5.3 Optical Pyrometer or Thermocouple, for temperature

mm) sieve.

measurements, conforming to the following requirements:

5.4.2 Aluminum Oxide—Reagent grade powder passing a

5.3.1 Optical Pyrometer—An optical pyrometer of the dis-

No. 100 (0.149 mm) sieve.

appearing filament type shall be used. The instrument shall

5.5 Refractory Support Mold—A mold with flat top and

have been calibrated to be accurate within 11°C (20°F) up to

bottom surfaces to provide a refractory support of suitable

1400°C(2550°F)andwithin16°C(30°F)from1400to1600°C

thickness to minimize warping shall be used. A side mold not

(2550°F to 2900°F) (Note 1). The pyrometer filament shall be

over ⁄4 in. (6.4 mm) high of any convenient shape, placed on

sighted on the cones until the softening point temperature (Fig.

an iron plate so that the top surface of the refractory mix can

1) has been passed, and then sighted on the cone support. The

be struck off flat and parallel to the base by means of a

pyrometer shall have readable graduations not larger than

straightedge, is satisfactory. For electric furnace use, legs not

5.5°C (10°F). 1

over3mm( ⁄8 in.) long may be provided on the corners of the

cone support by suitable holes bored in the iron base plate of

NOTE 1—The pyrometer equipment shall be standardized periodically

by a suitably equipped standardizing laboratory such as that of the the mold.

E953–88 (2004)

3 6

5.6 Gold Wire, Twenty-four gage or larger round wire of 5volume %carbondioxide, shallbemaintainedintheheating

99.98 % purity, but drawn from metal of 99.99 % purity, and chamber throughout the test (Note 2) in the electric furnace.

having a melting point of 1063°C (1945°F). The gas stream shall be regulated by any convenient means to

5.7 Nickel Wire, Twenty-four gage or larger round wire of provide a measured flow of 1.3 to 1.5 furnace volumes per

CP nickel 99.98 % pure, fully annealed, and having a melting minute.

point of 1452°C (2645°F).

NOTE 2—New cylinders of the mixed gas for which a certified analysis

is not available should be mixed before use by laying the cylinder on its

6. Hazards

side with the protective screw cap in place. The cylinder should then be

6.1 Due to the origins of RDF in municipal waste, common rolled back and forth, 6 to 10 ft in each direction, approximately 15 times.

Certified analyses of each cylinder or batch can be obtained for a small

sense dictates that some precautions should be observed when

extra charge.

conducting tests on the samples. Recommended hygenic prac-

tices include use of gloves when handling RDF; wearing dust 7.2.2 Oxidizing Atmosphere Test—Aregulated stream of air

masks (NIOSH-approved type); especially while milling RDF shall be maintained throughout the test in the electric furnace.

samples; conducting tests under a negative pressure hood when The gas stream shall be regulated by any convenient means to

possible; and washing hands before eating or smoking. provide a measured flow of 1.3 to 1.5 furnace volumes per

minute.

6.2 Good laboratory practices dictate the precautions that

should be observed when using compressed gases such as

8. Preparation of Ash

hydrogen or carbon monoxide as reducing gases.

8.1 Use RDF milled to passing a 0.5-mm (0.02-in.) sieve

7. Test Atmosphere

preparedinaccordancewithPracticeE 829toobtaintheashby

7.1 Gas Fired Furnace:

incinerationinawell-ventilatedmufflefurnace.Thequantityof

7.1.1 Reducing Atmosphere Test—A mildly reducing atmo- RDF required will vary with the ash content; usually 3 to 5 g

sphere surrounding the cones shall be maintained during the

of ash will suffice for cones for several check determinations.

test in the gas-fired furnace. Hydrogen, hydrocarbons, and Spread out the analysis sample of RDF in a layer approxi-

carbon monoxide shall be considered as reducing gases;

mately 6.4 mm ( ⁄4 in.) in depth in a fireclay or porcelain

oxygen,carbondioxide,andwatervaporshallbeconsideredas roasting dish. Place the dish in the muffle at a low temperature,

oxidizing gases. Nitrogen is inert. The ratio by volume of

and gradually heat to redness at such a rate as to avoid

reducing gases to oxidizing gases in the atmosphere shall be mechanical loss from too rapid expulsion of volatile matter.

between the limits of 20 to 80 %, that is, on a nitrogen-free

The rate of temperature rise of 500°C (932°F) in 1 h was found

basis, the total amount of reducing gases present shall be

to be satisfactory. Complete the conversion to ash at a

between the limits of 20 and 80 volume %.Aflame 150 to 200

temperatureof800to900°C(1470to1650°F).Transfertheash

mm (6 to 8 in.) in height and tinged with yellow above the

to an agate mortar (Note 3), and grind so it will pass a No. 200

furnace outlet has been found to provide an atmosphere within

(0.074 mm) sieve.

the specified limits.

NOTE 3—Amechanicalagatemortargrinderwillsavetimewheremany

7.1.2 Oxidizing Atmosphere Test—An atmosphere contain-

determinations are made. An iron mortar or pestle is not recommended

ing a minimum amount of reducing gases shall be maintained

because of metallic contamination.

surrounding the cones during the test in the gas-fired furnace.

8.2 Spread the ash in a thin layer in a fireclay, silica, or

On a nitrogen-free basis, the volume of the reducing gases

porcelain dish and ignite it in a stream of oxygen for 1 ⁄2hat

present in the atmosphere will not exceed 10 volume %.

800to850°C(1470to1560°F)toensurecompleteanduniform

Combustion with the maximum possible quantity of air with

oxidation of the ash. Any tube or muffle-type furnace which,

preservation of the specified rate of temperature increase has

whensuppliedwithanoxygenflowofnotlessthanonefurnace

been found to provide an atmosphere within the specified

volume in 5 min will maintain a highly oxidizing atmosphere,

limits. A completely blue flame, not over 50 mm (2 in.) in

is suitable.

heightabovetheoutletatthebeginningofthetest,providesthe

NOTE 4—It has been found that in most samples, the initial ignition

desired atmosphere; and, by regulation of the combustion

outlined in 8.1 is sufficient to convert the RDF to ash and the reignition

gas-air ratio, the specified atmosphere and temperature rise can

step in 8.2 is not necessary. Reignition of the ash should be made only if

be maintained.

an observable amount of noncombustible matter or carbon is present.

7.2 Electric Furnace:

7.2.1 Reducing Atmosphere Test—A regulated flow of gas

9. Preparation of Cones

of the nominal composition, 60 % carbon monoxide and 40 6

9.1 Thoroughly mix the ignited ash in a mechanical mixer

or on a sheet of glazed paper or oil cloth by raising first one

corner to roll the a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.