ASTM B873-17

(Test Method)Standard Test Method for Measuring Volume of Apparent Density Cup Used in Test Methods B212, B329, and B417

Standard Test Method for Measuring Volume of Apparent Density Cup Used in Test Methods B212, B329, and B417

SIGNIFICANCE AND USE

5.1 This test method enables the measurement of the volume of the apparent density cup to ensure that it complies with the specified volume of 25.00 ± 0.03 cm3 (cylindrical cup), or 16.39 ± 0.05 cm3 (square cup). Use of an out-of-specification cup will give erroneous apparent density values using the formulae in Test Methods B212, B329, and B417.

SCOPE

1.1 This test method covers a procedure for measuring the volume of the apparent density cups used in Test Methods B212, B329, and B417.

1.2 The apparent density cup, particularly its rim, may become worn during use, and it is recommended that the volume of the cup be checked periodically (at least every 6 months) in order to ensure that it complies with the specified volume.

1.3 With the exception of the values for density and the mass used to determine density, for which the use of the gram per cubic centimetre (g/cm3) and gram (g) units is the long standing industry practice, the values in SI units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B873 − 17

Standard Test Method for

Measuring Volume of Apparent Density Cup Used in Test

1

Methods B212, B329, and B417

This standard is issued under the fixed designation B873; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* B329 Test Method for Apparent Density of Metal Powders

and Compounds Using the Scott Volumeter

1.1 This test method covers a procedure for measuring the

B417 Test Method for Apparent Density of Non-Free-

volume of the apparent density cups used in Test Methods

Flowing Metal Powders Using the Carney Funnel

B212, B329, and B417.

E691 Practice for Conducting an Interlaboratory Study to

1.2 The apparent density cup, particularly its rim, may

Determine the Precision of a Test Method

become worn during use, and it is recommended that the

volume of the cup be checked periodically (at least every 6 3. Terminology

months) in order to ensure that it complies with the specified

3.1 Definitions—Definitions of powder metallurgy terms

volume.

can be found in Terminology B243. Additional descriptive

1.3 With the exception of the values for density and the information is available in the Related Materials section of Vol

mass used to determine density, for which the use of the gram 02.05 of the Annual Book of ASTM Standards.

3

per cubic centimetre (g/cm ) and gram (g) units is the long

4. Summary of Test Method

standing industry practice, the values in SI units are to be

regarded as standard.

4.1 The apparent density cup is filled with water and

weighed to obtain the mass of water contained, which is then

1.4 This standard does not purport to address all of the

converted to a volume.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

5.1 This test method enables the measurement of the vol-

bility of regulatory limitations prior to use.

ume of the apparent density cup to ensure that it complies with

1.5 This international standard was developed in accor-

3

the specified volume of 25.00 6 0.03 cm (cylindrical cup), or

dance with internationally recognized principles on standard-

3

16.39 6 0.05 cm (square cup). Use of an out-of-specification

ization established in the Decision on Principles for the

cup will give erroneous apparent density values using the

Development of International Standards, Guides and Recom-

formulae in Test Methods B212, B329, and B417.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

6. Apparatus

6.1 Density Cup—Acylindrical cup (see Fig. 1) designed to

2. Referenced Documents

3

haveacapacityof25.00 60.03cm (asinTestMethodsB212,

2

2.1 ASTM Standards:

B329, and B417) or a square cup designed to have a capacity

B212 Test Method for Apparent Density of Free-Flowing

3

of 16.39 6 0.05 cm (as in Test Method B329).

Metal Powders Using the Hall Flowmeter Funnel

6.2 Balance, readable to 0.0001 g with a minimum capacity

B243 Terminology of Powder Metallurgy

of 200 g to be used for determining mass to the nearest

0.001 g.

1

This test method is under the jurisdiction of ASTM Committee B09 on Metal 6.3 Microscope Slide—A transparent microscope slide at

Powders and Metal Powder Products and is the direct responsibility of Subcom-

least as wide as the outer diameter of the apparent density cup.

mittee B09.02 on Base Metal Powders.

Current edition approved April 1, 2017. Published November 2012. Originally 6.4 Water—Distilled or deionized water boiled to remove

approved in 1996. Last previous edition approved in 2012 as B873 – 12. DOI:

dissolved air.

10.1520/B0873-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6.5 Alcohol—Low residue ethyl alcohol.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.6 Wire—Awire not exceeding 2.5 mm in diameter by 150

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. mm long.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B873 − 17

A

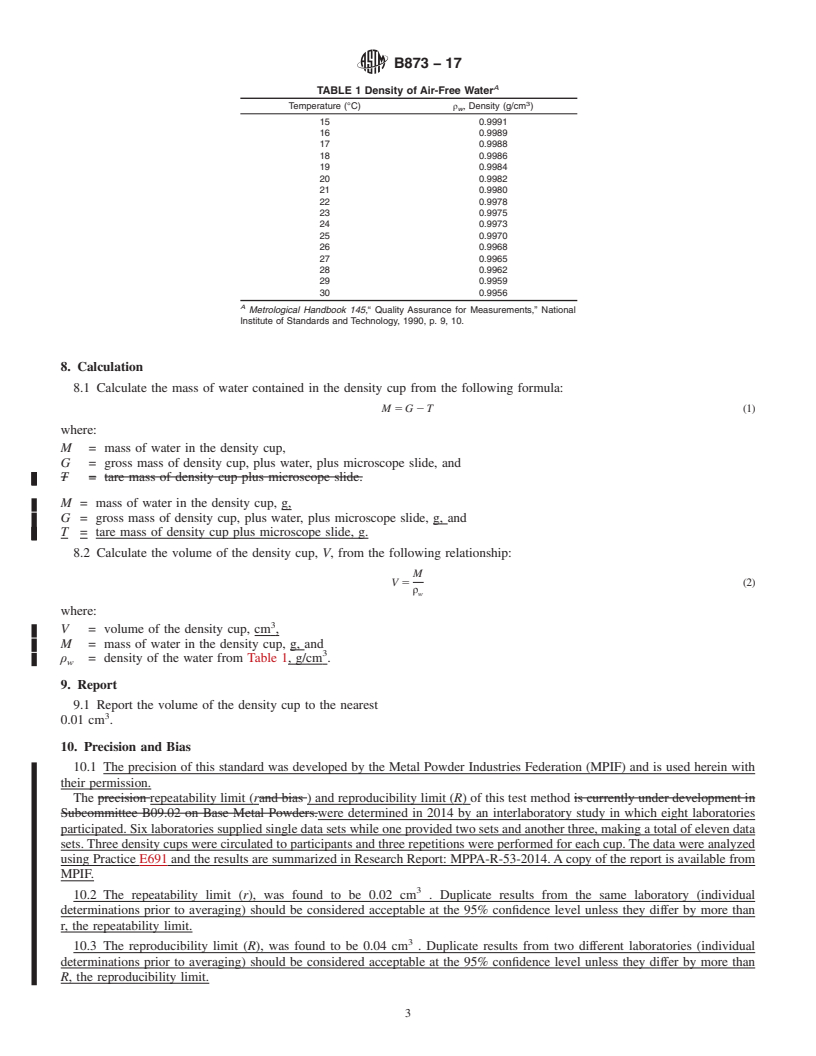

TABLE 1 Density of Air-Free Water

3

Temperature (°C) ρ , Density (g/cm )

w

15 0.9991

16 0.9989

17 0.9988

18 0.9986

19 0.9984

20 0.9982

21 0.9980

22 0.9978

23 0.9975

24 0.9973

25 0.9970

26 0.9968

27 0.9965

28 0.9962

29 0.9959

30 0.9956

A

Metrological Handbook 145,“ Quality Assurance for Measurements,” National

Institut

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B873 − 12 B873 − 17

Standard Test Method for

Measuring Volume of Apparent Density Cup Used in Test

1

Methods B 212, B 329,B212, B329, and B 417B417

This standard is issued under the fixed designation B873; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers a procedure for measuring the volume of the apparent density cups used in Test Methods B212,

B329, and B417.

1.2 The apparent density cup, particularly its rim, may become worn during use, and it is recommended that the volume of the

cup be checked periodically (at least every 6 months) in order to ensure that it complies with the specified volume.

1.3 With the exception of the values for density and the mass used to determine density, for which the use of the gram per cubic

3

centimetre (g/cm ) and gram (g) units is the long standing industry practice, the values in SI units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B212 Test Method for Apparent Density of Free-Flowing Metal Powders Using the Hall Flowmeter Funnel

B243 Terminology of Powder Metallurgy

B329 Test Method for Apparent Density of Metal Powders and Compounds Using the Scott Volumeter

B417 Test Method for Apparent Density of Non-Free-Flowing Metal Powders Using the Carney Funnel

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions—Definitions of powder metallurgy terms can be found in Terminology B243. Additional descriptive information

is available in the Related Materials section of Vol 02.05 of the Annual Book of ASTM Standards.

4. Summary of Test Method

4.1 The apparent density cup is filled with water and weighed to obtain the mass of water contained, which is then converted

to a volume.

5. Significance and Use

5.1 This test method enables the measurement of the volume of the apparent density cup to ensure that it complies with the

3 3

specified volume of 25.00 6 0.03 cm (cylindrical cup), or 16.39 6 0.05 cm (square cup). Use of an out-of-specification cup will

give erroneous apparent density values using the formulae in Test Methods B212, B329, and B417.

1

This test method is under the jurisdiction of ASTM Committee B09 on Metal Powders and Metal Powder Products and is the direct responsibility of Subcommittee B09.02

on Base Metal Powders.

Current edition approved Nov. 1, 2012April 1, 2017. Published November 2012. Originally approved in 1996. Last previous edition approved in 20072012 as

B873 – 01B873 – 12.(2007). DOI: 10.1520/B0873-12.10.1520/B0873-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B873 − 17

6. Apparatus

3

6.1 Density Cup—A cylindrical cup (see Fig. 1) designed to have a capacity of 25.00 6 0.03 cm (as in Test Methods B212,

3

B329, and B417) or a square cup designed to have a capacity of 16.39 6 0.05 cm (as in Test Method B329).

6.2 Balance, readable to 0.0001 g with a minimum capacity of 200 g to be used for determining mass to the nearest

0.001 g.

6.3 Microscope Slide—A transparent microscope slide at least as wide as the outer diameter of the apparent density cup.

6.4 Water—Distilled or deionized water boiled to remove dissolved air.

6.5 Alcohol—Low residue ethyl alcohol.

6.6 Wire—A wire not exceeding 2.5

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.