ASTM D7394-18(2023)

(Practice)Standard Practice for Rheological Characterization of Architectural Coatings using Three Rotational Bench Viscometers

Standard Practice for Rheological Characterization of Architectural Coatings using Three Rotational Bench Viscometers

SIGNIFICANCE AND USE

5.1 A significant feature of this practice is the ability to survey coating rheology over a broad range of shear rates with the same bench viscometers and test protocol that paint formulators and paint quality control (QC) analysts routinely use. By using this procedure, measurement of the shear rheology of a coating is possible without using an expensive laboratory rheometer, and performance predictions can be made based on those measurements.

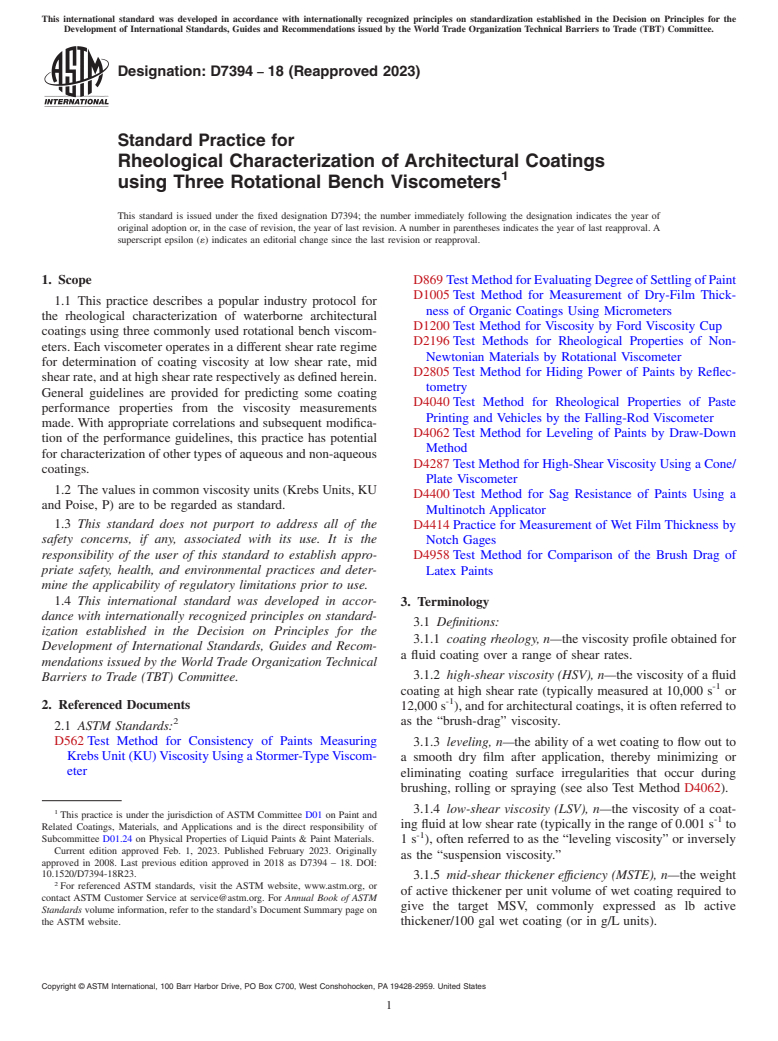

5.2 Low-Shear Viscosity (LSV)—The determination of low-shear viscosity in this practice can be used to predict the relative “in-can” performance of coatings for their ability to suspend pigment or prevent syneresis, or both. The LSV can also predict relative performance for leveling and sag resistance after application by roll, brush or spray. Fig. 1 shows the predictive low-shear viscosity relationships for several coatings properties.

FIG. 1 Low Shear Viscosity (LSV)

5.3 Mid-Shear Viscosity (MSV)—The determination of MSV (coating consistency) in this practice is often the first viscosity obtained. This viscosity reflects the coatings resistance to flow on mixing, pouring, pumping, or hand stirring. Architectural coatings nearly always have a target specification for mid-shear viscosity, which is usually obtained by adjusting the level of thickener in the coating. Consequently, mid-shear viscosity is ideally a constant for a given series of coatings being tested to provide meaningful comparisons of low-shear and high-shear viscosity. With viscosities at the same KU value, MSV can also be used to obtain the relative Mid-Shear Thickener Efficiency (MSTE) of different thickeners in the same coating expressed as lb thickener/100 gal wet coating or g thickener/L wet coating.

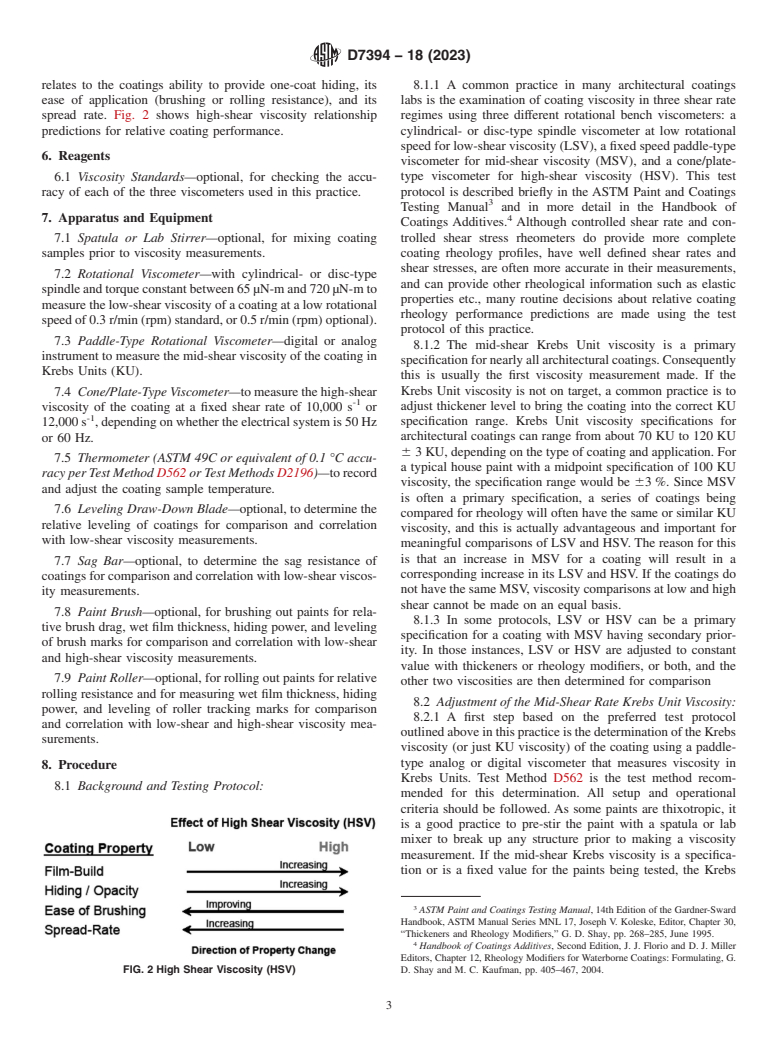

5.4 High-Shear Viscosity (HSV)—High-shear viscosity in this practice is a measure of the coatings resistance to flow on application by brush or roller, which is often referred to as brush-drag or rolling resistance respectively. This viscosity rela...

SCOPE

1.1 This practice describes a popular industry protocol for the rheological characterization of waterborne architectural coatings using three commonly used rotational bench viscometers. Each viscometer operates in a different shear rate regime for determination of coating viscosity at low shear rate, mid shear rate, and at high shear rate respectively as defined herein. General guidelines are provided for predicting some coating performance properties from the viscosity measurements made. With appropriate correlations and subsequent modification of the performance guidelines, this practice has potential for characterization of other types of aqueous and non-aqueous coatings.

1.2 The values in common viscosity units (Krebs Units, KU and Poise, P) are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7394 − 18 (Reapproved 2023)

Standard Practice for

Rheological Characterization of Architectural Coatings

using Three Rotational Bench Viscometers

This standard is issued under the fixed designation D7394; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D869 Test Method for Evaluating Degree of Settling of Paint

D1005 Test Method for Measurement of Dry-Film Thick-

1.1 This practice describes a popular industry protocol for

ness of Organic Coatings Using Micrometers

the rheological characterization of waterborne architectural

D1200 Test Method for Viscosity by Ford Viscosity Cup

coatings using three commonly used rotational bench viscom-

D2196 Test Methods for Rheological Properties of Non-

eters. Each viscometer operates in a different shear rate regime

Newtonian Materials by Rotational Viscometer

for determination of coating viscosity at low shear rate, mid

D2805 Test Method for Hiding Power of Paints by Reflec-

shear rate, and at high shear rate respectively as defined herein.

tometry

General guidelines are provided for predicting some coating

D4040 Test Method for Rheological Properties of Paste

performance properties from the viscosity measurements

Printing and Vehicles by the Falling-Rod Viscometer

made. With appropriate correlations and subsequent modifica-

D4062 Test Method for Leveling of Paints by Draw-Down

tion of the performance guidelines, this practice has potential

Method

for characterization of other types of aqueous and non-aqueous

D4287 Test Method for High-Shear Viscosity Using a Cone/

coatings.

Plate Viscometer

1.2 The values in common viscosity units (Krebs Units, KU

D4400 Test Method for Sag Resistance of Paints Using a

and Poise, P) are to be regarded as standard.

Multinotch Applicator

1.3 This standard does not purport to address all of the

D4414 Practice for Measurement of Wet Film Thickness by

safety concerns, if any, associated with its use. It is the Notch Gages

responsibility of the user of this standard to establish appro-

D4958 Test Method for Comparison of the Brush Drag of

priate safety, health, and environmental practices and deter- Latex Paints

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

3. Terminology

dance with internationally recognized principles on standard-

3.1 Definitions:

ization established in the Decision on Principles for the

3.1.1 coating rheology, n—the viscosity profile obtained for

Development of International Standards, Guides and Recom-

a fluid coating over a range of shear rates.

mendations issued by the World Trade Organization Technical

3.1.2 high-shear viscosity (HSV), n—the viscosity of a fluid

Barriers to Trade (TBT) Committee.

-1

coating at high shear rate (typically measured at 10,000 s or

-1

2. Referenced Documents 12,000 s ), and for architectural coatings, it is often referred to

as the “brush-drag” viscosity.

2.1 ASTM Standards:

D562 Test Method for Consistency of Paints Measuring

3.1.3 leveling, n—the ability of a wet coating to flow out to

Krebs Unit (KU) Viscosity Using a Stormer-Type Viscom-

a smooth dry film after application, thereby minimizing or

eter

eliminating coating surface irregularities that occur during

brushing, rolling or spraying (see also Test Method D4062).

3.1.4 low-shear viscosity (LSV), n—the viscosity of a coat-

This practice is under the jurisdiction of ASTM Committee D01 on Paint and

-1

ing fluid at low shear rate (typically in the range of 0.001 s to

Related Coatings, Materials, and Applications and is the direct responsibility of

-1

Subcommittee D01.24 on Physical Properties of Liquid Paints & Paint Materials.

1 s ), often referred to as the “leveling viscosity” or inversely

Current edition approved Feb. 1, 2023. Published February 2023. Originally

as the “suspension viscosity.”

approved in 2008. Last previous edition approved in 2018 as D7394 – 18. DOI:

10.1520/D7394-18R23.

3.1.5 mid-shear thickener effıciency (MSTE), n—the weight

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

of active thickener per unit volume of wet coating required to

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

give the target MSV, commonly expressed as lb active

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. thickener/100 gal wet coating (or in g/L units).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7394 − 18 (2023)

3.1.6 mid-shear viscosity (MSV), n—the viscosity of a example, it is quite common to have a specification for the

coating fluid at medium shear rate (typically in the range of 10 Krebs Unit viscosity in architectural coatings. In this case,

-1 -1

s to 1000 s ), often referred to as the “consistency” or the MSV would be the first viscosity measurement made, and any

“mixing viscosity.” coatings out of specification would be adjusted (usually with

the amount of thickener) to obtain the same or similar Krebs

3.1.7 newtonian, n—a rheological term describing a fluid

viscosity. With the Krebs viscosity constant, meaningful com-

that maintains constant viscosity over a range of shear rates

parisons between coatings can then be made in the extreme

(see also Test Method D1200 and Test Method D4040).

shear rate regimes for LSV and HSV where many coatings

3.1.8 rheometer, n—an instrument capable of continuously

properties are affected.

measuring fluid viscosity over a range of shear rates or shear

stresses, often capable of other types of rheological

5. Significance and Use

determinations, and ideally suited for research and well-

5.1 A significant feature of this practice is the ability to

defined characterization of fluid rheology.

survey coating rheology over a broad range of shear rates with

3.1.9 rotational viscometer, n—an instrument that uses one

the same bench viscometers and test protocol that paint

or more turning surfaces in contact with a fluid to measure the

formulators and paint quality control (QC) analysts routinely

fluid’s viscosity, is capable of operating at one or more

use. By using this procedure, measurement of the shear

rotational speeds to provide different shear rates, is typically

rheology of a coating is possible without using an expensive

limited to one speed per measurement, is relatively simple to

laboratory rheometer, and performance predictions can be

operate and ideally suited for quality control or routine lab

made based on those measurements.

determinations.

5.2 Low-Shear Viscosity (LSV)—The determination of low-

3.1.10 settling, n—the gradual sedimentation of pigment or

shear viscosity in this practice can be used to predict the

other disperse phase particles, or both, that may occur during

relative “in-can” performance of coatings for their ability to

storage of a coating (see also Test Method D869).

suspend pigment or prevent syneresis, or both. The LSV can

3.1.11 shear rate, n—the change in velocity of a fluid per also predict relative performance for leveling and sag resis-

unit gap between shearing surfaces.

tance after application by roll, brush or spray. Fig. 1 shows the

predictive low-shear viscosity relationships for several coat-

3.1.12 suspension, n—as defined in this practice, a coating

ings properties.

formulation’s ability to suspend pigment and other disperse

phase particles, thereby inhibiting or preventing settling or

5.3 Mid-Shear Viscosity (MSV)—The determination of

syneresis, or both. MSV (coating consistency) in this practice is often the first

viscosity obtained. This viscosity reflects the coatings resis-

3.1.13 syneresis, n—the separation of a clear liquid layer at

tance to flow on mixing, pouring, pumping, or hand stirring.

the top of coating in a container that may occur during storage.

Architectural coatings nearly always have a target specification

3.1.14 thixotropy, n—a rheological term describing a non-

for mid-shear viscosity, which is usually obtained by adjusting

newtonian fluid that decreases in viscosity with time at a given

the level of thickener in the coating. Consequently, mid-shear

shear rate, and then rebuilds viscosity with time when the

viscosity is ideally a constant for a given series of coatings

shearing stops (see also Test Methods D2196).

being tested to provide meaningful comparisons of low-shear

and high-shear viscosity. With viscosities at the same KU

4. Summary of Practice

value, MSV can also be used to obtain the relative Mid-Shear

4.1 This practice involves characterization of architectural Thickener Efficiency (MSTE) of different thickeners in the

coating rheology by measuring viscosity with three rotational

same coating expressed as lb thickener/100 gal wet coating or

bench viscometers to obtain low-shear viscosity (LSV), mid- g thickener/L wet coating.

shear viscosity (MSV) and high-shear viscosity (HSV), respec-

5.4 High-Shear Viscosity (HSV)—High-shear viscosity in

tively. LSV is obtained with a cylindrical- or disc-type spindle

this practice is a measure of the coatings resistance to flow on

viscometer operating at a low speed (at either 0.5 r/min (rpm)

application by brush or roller, which is often referred to as

or preferably 0.3 r/min (rpm)). The applicable shear rate for

brush-drag or rolling resistance respectively. This viscosity

-1

this viscometer/speed combination is in the range of 0.01 s to

-1

1 s . The MSV or coating consistency is obtained using an

analog or digital rotational paddle-type viscometer that mea-

sures viscosity in Krebs Units (KU). The applicable shear rate

-1 -1

for this instrument is in the range of 10 s to 200 s for most

architectural paints. The high-shear viscosity is obtained using

a cone/plate-type viscometer with a fixed shear rate of either

-1 -1

10,000 s or 12,000 s . If coatings are to be characterized

without any viscosity adjustments being made, measurements

with the three viscometers can be conducted in any order.

However, if a series of paints is being compared where it is

desirable to have one of the three viscosities a constant,

viscosity adjustments may be needed to achieve that. For FIG. 1 Low Shear Viscosity (LSV)

D7394 − 18 (2023)

relates to the coatings ability to provide one-coat hiding, its 8.1.1 A common practice in many architectural coatings

ease of application (brushing or rolling resistance), and its labs is the examination of coating viscosity in three shear rate

spread rate. Fig. 2 shows high-shear viscosity relationship regimes using three different rotational bench viscometers: a

predictions for relative coating performance. cylindrical- or disc-type spindle viscometer at low rotational

speed for low-shear viscosity (LSV), a fixed speed paddle-type

6. Reagents

viscometer for mid-shear viscosity (MSV), and a cone/plate-

6.1 Viscosity Standards—optional, for checking the accu- type viscometer for high-shear viscosity (HSV). This test

racy of each of the three viscometers used in this practice. protocol is described briefly in the ASTM Paint and Coatings

Testing Manual and in more detail in the Handbook of

7. Apparatus and Equipment

Coatings Additives. Although controlled shear rate and con-

7.1 Spatula or Lab Stirrer—optional, for mixing coating trolled shear stress rheometers do provide more complete

samples prior to viscosity measurements. coating rheology profiles, have well defined shear rates and

shear stresses, are often more accurate in their measurements,

7.2 Rotational Viscometer—with cylindrical- or disc-type

and can provide other rheological information such as elastic

spindle and torque constant between 65 μN-m and 720 μN-m to

properties etc., many routine decisions about relative coating

measure the low-shear viscosity of a coating at a low rotational

rheology performance predictions are made using the test

speed of 0.3 r/min (rpm) standard, or 0.5 r/min (rpm) optional).

protocol of this practice.

7.3 Paddle-Type Rotational Viscometer—digital or analog

8.1.2 The mid-shear Krebs Unit viscosity is a primary

instrument to measure the mid-shear viscosity of the coating in

specification for nearly all architectural coatings. Consequently

Krebs Units (KU).

this is usually the first viscosity measurement made. If the

Krebs Unit viscosity is not on target, a common practice is to

7.4 Cone/Plate-Type Viscometer—to measure the high-shear

-1

adjust thickener level to bring the coating into the correct KU

viscosity of the coating at a fixed shear rate of 10,000 s or

-1

specification range. Krebs Unit viscosity specifications for

12,000 s , depending on whether the electrical system is 50 Hz

architectural coatings can range from about 70 KU to 120 KU

or 60 Hz.

6 3 KU, depending on the type of coating and application. For

7.5 Thermometer (ASTM 49C or equivalent of 0.1 °C accu-

a typical house paint with a midpoint specification of 100 KU

racy per Test Method D562 or Test Methods D2196)—to record

viscosity, the specification range would be 63 %. Since MSV

and adjust the coating sample temperature.

is often a primary specification, a series of coatings being

7.6 Leveling Draw-Down Blade—optional, to determine the

compared for rheology will often have the same or similar KU

relative leveling of coatings for comparison and correlation

viscosity, and this is actually advantageous and important for

with low-shear viscosity measurements.

meaningful comparisons of LSV and HSV. The reason for this

is that an increase in MSV for a coating will result in a

7.7 Sag Bar—optional, to determine the sag resistance of

corresponding increase in its LSV and HSV. If the coatings do

coatings for comparison and correlation with low-shear viscos-

not have the same MSV, viscosity comparisons at low and high

ity measurements.

shear cannot be made on an equal basis.

7.8 Paint Brush—optional, for brushing out paints for rela-

8.1.3 In some protocols, LSV or HSV can be a primary

tive brush drag, wet film thickness, hiding power, and leveling

specification for a coating with MSV having secondary prior-

of brush marks for comparison and correlation with low-shear

ity. In those instances, LSV or HSV are adjusted to constant

and high-shear viscosity measurements.

value with thickeners or rheology modifiers, or both, and the

7.9 Paint Roller—optional, for rolling out paints for relative

other two viscosities are th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.