ASTM C892-00

(Specification)Standard Specification for High-Temperature Fiber Blanket Thermal Insulation

Standard Specification for High-Temperature Fiber Blanket Thermal Insulation

SCOPE

1.1 This specification covers high-temperature fiber blanket thermal insulation for use at various temperatures from 1350oF (732oC) up to 3000oF (1649oC), except when used in high-temperature furnaces.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.2 When the installation or use of thermal insulation materials, accessories, and systems may pose safety or health problems, the manufacturers shall provide the user with appropriate current information regarding any known problems associated with the recommended use of the company's products, and shall also recommend protective measures to be employed in their safe utilization. The user shall establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units which are provided for information only and are not considered standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 892 – 00

Standard Specification for

1

High-Temperature Fiber Blanket Thermal Insulation

This standard is issued under the fixed designation C892; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C201 Test Method for Thermal Conductivity of Refracto-

2

ries

1.1 This specification covers high-temperature fiber blanket

3

C209 Test Methods for Cellulosic Fiber Insulating Board

thermalinsulationforuseatvarioustemperaturesfrom1350°F

C356 Test Method for Linear Shrinkage of Preformed

(732°C) up to 3000°F (1649°C), except when used in high-

High-Temperature Thermal Insulation Subjected to Soak-

temperature furnaces.

3

ing Heat

1.2 This standard does not purport to address all of the

C390 Criteria for Sampling and Acceptance of Preformed

safety concerns, if any, associated with its use. It is the

3

Thermal Insulation Lots

responsibility of the user of this standard to establish appro-

C1058 Practice for Selecting Temperatures for Evaluating

priate safety and health practices and determine the applica-

3

and Reporting Thermal Properties of Thermal Insulation

bility of regulatory limitations prior to use.

C1335 TestMethodforMeasuringNon-FibrousContentof

1.3 When the installation or use of thermal insulation

3

Man-Made Rock and Slag Mineral Fiber Insulation

materials, accessories, and systems may pose safety or health

problems, the manufacturers shall provide the user with appro-

3. Terminology

priate current information regarding any known problems

3.1 Definitions—Terminology C71 andTerminology C168

associated with the recommended use of the company’s

shall be considered as applying to the terms used in this

products, and shall also recommend protective measures to be

standard.

employed in their safe utilization. The user shall establish

3.2 Definitions of Terms Specific to This Standard:

appropriate safety and health practices and determine the

3.2.1 fibers—thefibersshallberefractoryoxides,processed

applicability of regulatory requirements prior to use.

from a molten state into fibrous form.

1.4 The values stated in inch-pound units are to be regarded

3.2.2 high-temperature fiber thermal insulation— a thermal

asthestandard.Thevaluesgiveninparenthesesaremathemati-

insulation, varying in flexibility, composed of refractory inor-

cal conversions to SI units which are provided for information

ganic fibers, with or without binder added, and furnished in

only and are not considered standard.

either flat sheets or rolls.

2. Referenced Documents

4. Classification

2.1 ASTM Standards:

2 4.1 The general-type product governed by this specification

C71 Terminology Relating to Refractories

is blanket or batt composed of inorganic refractory fibers.

C167 Test Methods for Thickness and Density of Blanket

3 4.2 Types—The product is separated into types based upon

or Batt Thermal Insulation

temperatures of use:

C168 Terminology Relating to Thermal Insulating Materi-

3

Type Temperature of use, °F (°C), maximum

als

I 1350 (732)

C177 Test Method for Steady-State Heat Flux Measure-

II 1600 (871)

ments and Thermal Transmission Properties by Means of III 2400 (1316)

3

IV 2600 (1427)

the Guarded Hot Plate Apparatus

V 3000 (1649)

4.3 Grades—The product is separated into grades based

upon its density:

1

This specification is under the jurisdiction of ASTM Committee C16 on

3 3

Grade Density, lb/ft (kg/m ), nominal

Thermal Insulation and is the direct responsibility of Subcommittee C16.23 on

3 3 (48)

Blanket and Loose Fill Insulation.

4 4 (64)

Current edition approved Oct. 10, 2000. Published January 2001. Originally

6 6 (96)

published as C892–78. Last previous edition C892–93.

2 8 8 (128)

Annual Book of ASTM Standards, Vol 15.01.

3 12 12 (192)

Annual Book of ASTM Standards, Vol 04.06.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

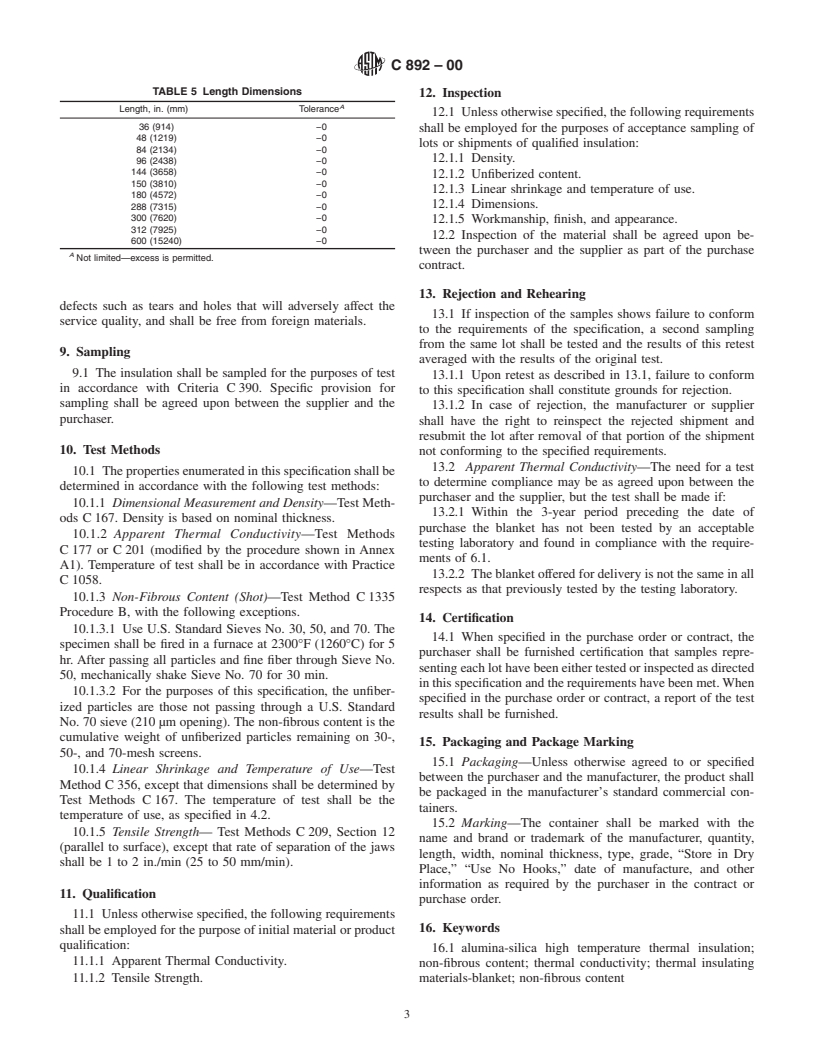

---------------------- Page: 1 ----------------------

C892–00

TABLE 2 Physical and Mechanical Requirements

5. Ordering Information

Properties Requirements

5.1 High-temperature fiber blanket thermal insulation is

Non-fibrous content (shot), maximum, % (by weight) 30

normally purchased on the basis of brand name, grade, length,

Linear shrinkage, maximum, % (at maximum use 5

width, thickness, and total square footage as specified in the

temperature)

2

purchase order. Tensile strength, minimum, lb/in (KPa)

Grade 3 1.0 (6.9)

5.2 The type and grade for the intended service shall be as

Grade 4 1.5 (10.3)

specified by the user with the assistance of the supplier where

Grade 6 2.0 (13.8)

desirable. Grade 8 3.0 (20.7)

Grade 12 5.0 (34.5)

5.3 Ins

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.