ASTM F994-86(1996)e1

(Specification)Standard Specification for Design and Installation of Overboard Discharge Hull Penetration Connections

Standard Specification for Design and Installation of Overboard Discharge Hull Penetration Connections

General Information

Standards Content (Sample)

e1

Designation: F 994 – 86 (Reapproved 1996) An American National Standard

Standard Specification for

Design and Installation of Overboard Discharge Hull

Penetration Connections

This standard is issued under the fixed designation F 994; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords were added editorially in November 1996.

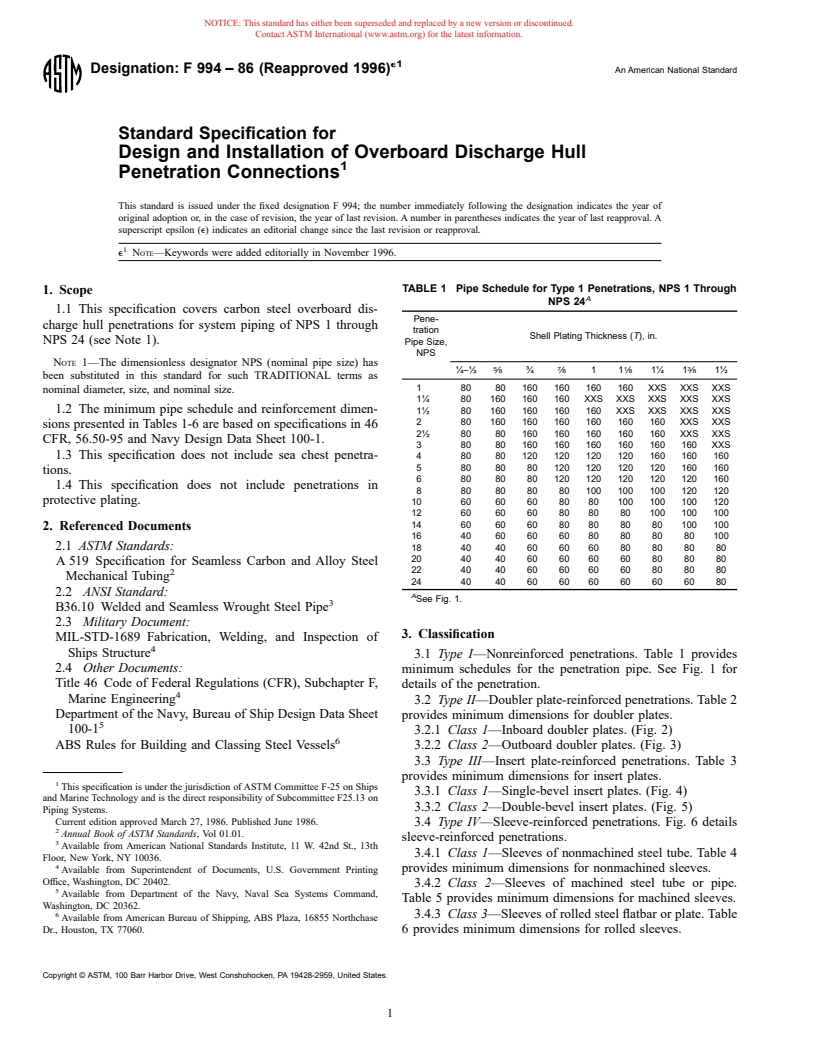

TABLE 1 Pipe Schedule for Type 1 Penetrations, NPS 1 Through

1. Scope

A

NPS 24

1.1 This specification covers carbon steel overboard dis-

Pene-

charge hull penetrations for system piping of NPS 1 through

tration

Shell Plating Thickness (T), in.

NPS 24 (see Note 1). Pipe Size,

NPS

NOTE 1—The dimensionless designator NPS (nominal pipe size) has

5 7 1 3

¼–½ ⁄8 ¾ ⁄8 11 ⁄8 1¼ 1 ⁄8 1½

been substituted in this standard for such TRADITIONAL terms as

1 80 80 160 160 160 160 XXS XXS XXS

nominal diameter, size, and nominal size.

1¼ 80 160 160 160 XXS XXS XXS XXS XXS

1.2 The minimum pipe schedule and reinforcement dimen-

1½ 80 160 160 160 160 XXS XXS XXS XXS

2 80 160 160 160 160 160 160 XXS XXS

sions presented in Tables 1-6 are based on specifications in 46

2½ 80 80 160 160 160 160 160 XXS XXS

CFR, 56.50-95 and Navy Design Data Sheet 100-1.

3 80 80 160 160 160 160 160 160 XXS

1.3 This specification does not include sea chest penetra-

4 80 80 120 120 120 120 160 160 160

5 80 80 80 120 120 120 120 160 160

tions.

6 80 80 80 120 120 120 120 120 160

1.4 This specification does not include penetrations in

8 80 80 80 80 100 100 100 120 120

protective plating. 10 60 60 60 80 80 100 100 100 120

12 60 60 60 80 80 80 100 100 100

14 60 60 60 80 80 80 80 100 100

2. Referenced Documents

16 40 60 60 60 80 80 80 80 100

2.1 ASTM Standards: 18 40 40 60 60 60 80 80 80 80

20 40 40 60 60 60 60 80 80 80

A 519 Specification for Seamless Carbon and Alloy Steel

22 40 40 60 60 60 60 80 80 80

Mechanical Tubing

24 40 40 60 60 60 60 60 60 80

2.2 ANSI Standard:

A

See Fig. 1.

B36.10 Welded and Seamless Wrought Steel Pipe

2.3 Military Document:

3. Classification

MIL-STD-1689 Fabrication, Welding, and Inspection of

Ships Structure

3.1 Type I—Nonreinforced penetrations. Table 1 provides

2.4 Other Documents: minimum schedules for the penetration pipe. See Fig. 1 for

Title 46 Code of Federal Regulations (CFR), Subchapter F,

details of the penetration.

Marine Engineering

3.2 Type II—Doubler plate-reinforced penetrations. Table 2

Department of the Navy, Bureau of Ship Design Data Sheet

provides minimum dimensions for doubler plates.

100-1

3.2.1 Class 1—Inboard doubler plates. (Fig. 2)

ABS Rules for Building and Classing Steel Vessels

3.2.2 Class 2—Outboard doubler plates. (Fig. 3)

3.3 Type III—Insert plate-reinforced penetrations. Table 3

provides minimum dimensions for insert plates.

This specification is under the jurisdiction of ASTM Committee F-25 on Ships

3.3.1 Class 1—Single-bevel insert plates. (Fig. 4)

and Marine Technology and is the direct responsibility of Subcommittee F25.13 on

3.3.2 Class 2—Double-bevel insert plates. (Fig. 5)

Piping Systems.

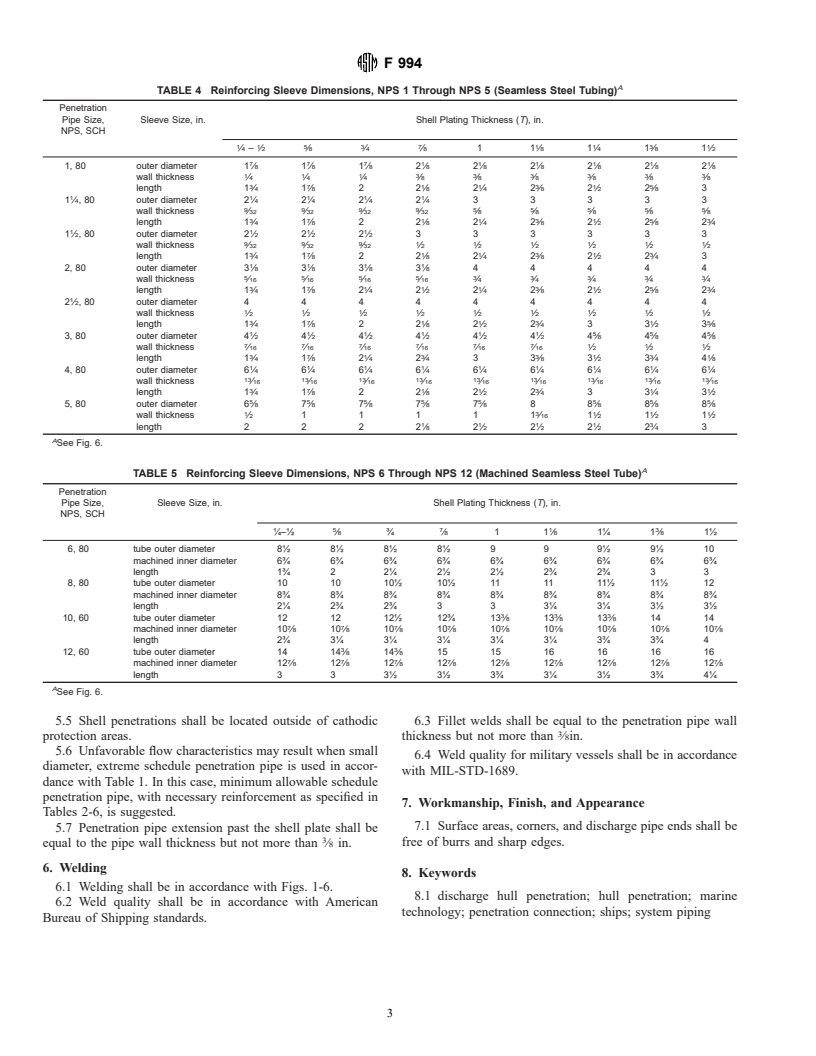

Current edition approved March 27, 1986. Published June 1986. 3.4 Type IV—Sleeve-reinforced penetrations. Fig. 6 details

Annual Book of ASTM Standards, Vol 01.01.

sleeve-reinforced penetrations.

Available from American National Standards Institute, 11 W. 42nd St., 13th

3.4.1 Class 1—Sleeves of nonmachined steel tube. Table 4

Floor, New York, NY 10036.

provides minimum dimensions for nonmachined sleeves.

Available from Superintendent of Documents, U.S. Government Printing

Office, Washington, DC 20402.

3.4.2 Class 2—Sleeves of machined steel tube or pipe.

Available from Department of the Navy, Naval Sea Systems Command,

Table 5 provides minimum dimensions for machined sleeves.

Washington, DC 20362.

3.4.3 Class 3—Sleeves of rolled steel flatbar or plate. Table

Available from American Bureau of Shipping, ABS Plaza, 16855 Northchase

Dr., Houston, TX 77060. 6 provides minimum dimensions for rolled sleeves.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 994

A

TABLE 2 Doubler Plate Dimensions (T 3 D) Type II Penetration, NPS 1 Through NPS 24 (in. 3 in.)

D

Penetrating

Pipe Size, Shell Plating Thickness (T), in.

NPS, SCH

5 7 1 3

¼to½ ⁄8 ¾ ⁄8 11 ⁄8 1¼ 1 ⁄8 1½

3 5

1, 80 ¼ 3 5 ⁄8 35½ 3 5 ⁄8 35¾ 35¾ 351 351 351¼ 3 5

3 5

1¼, 80 ¼ 3 6 ⁄8 36½ 3 6 ⁄8 36¾ 36¾ 361 361 361¼ 3 6

3 5

1½, 80 ¼ 3 6 ⁄8 36½ 3 6 ⁄8 36¾ 36¾ 361 361 361¼ 3 6

3 5

2, 80 ¼ 3 7 ⁄8 37½ 3 7 ⁄8 37¾ 37¾ 371 371 371¼ 3 7

3 5

2½, 80 ¼ 3 7 ⁄8 37½ 3 7 ⁄8 37¾ 37¾ 371 371 371¼ 3 7

3 5

3, 80 ¼ 3 8 ⁄8 38½ 3 8 ⁄8 38¾ 38¾ 381 381 381¼ 3 8

3 5

4, 80 ¼ 3 9 ⁄8 39½ 3 9 ⁄8 39¾ 39¾ 391 391 391¼ 3 9

3 5

5, 80 ¼ 3 10 ⁄83 10 ½ 3 10 ⁄8 3 10 ¾ 3 10 ¾ 3 10 1 3 10 1 3 10 1¼ 3 10

3 5

6, 80 ¼ 3 12 ⁄83 12 ½ 3 12 ⁄8 3 12 ¾ 3 12 ¾ 3 12 1 3 12 1 3 12 1¼ 3 12

3 5

8, 80 ¼ 3 14 ⁄83 14 ½ 3 14 ⁄8 3 14 ¾ 3 14 ¾ 3 14 1 3 14 1 3 14 1¼ 3 14

3 5

10, 60 ¼ 3 16 ⁄8 3 16 ½ 3 16 ⁄8 3 16 ¾ 3 16 ¾ 3 16 1 3 16 1 3 16 1¼ 3 16

3 5

12, 60 ¼ 3 18 ⁄8 3 18 ½ 3 18 ⁄8 3 18 ¾ 3 18 ¾ 3 18 1 3 18 1 3 18 1¼ 3 18

3 5

14, 60 ¼ 3 20 ⁄8 3 20 ½ 3 20 ⁄8 3 20 ¾ 3 20 ¾ 3 20 1 3 20 1 3 20 1¼ 3 20

3 5

16, 40 ¼ 3 22 ⁄8 3 22 ½ 3 22 ⁄8 3 22 ¾ 3 22 ¾ 3 23 1 3 22 1 3 23 1¼ 3 24

3 5

18, 40 ¼ 3 24 ⁄8 3 24 ½ 3 24 ⁄8 3 24 ¾ 3 24 ¾ 3 25 1 3 24 1 3 25 1¼ 3 28

3 5

20, 40 ¼ 3 26 ⁄8 3 26 ½ 3 26 ⁄8 3 26 ¾ 3 26 ¾ 3 27 1 3 26 1 3 27 1¼ 3 30

3 5

22, 60 ¼ 3 28 ⁄8 3 28 ½ 3 28 ⁄8 3 28 ¾ 3 28 ¾ 3 29 1 3 28 1 3 29 1¼ 3 32

3 5

24, 40 ¼ 3 30 ⁄8 3 30 ½ 3 30 ⁄8 3 30 ¾ 3 30 ¾ 3 31 1 3 30 1 3 31 1¼ 3 33

A

See Fig. 2 and Fig. 3.

A

TABLE 3 Insert Plate Dimensions (T 3 D), NPS 1 Through NPS 24 (in. 3 in.)

I

Penetrating

Pipe Size, Shell Plating Thickness (T), in.

NPS, SCH

5 7 1 3

¼to½ ⁄8 ¾ ⁄8 11 ⁄8 1¼ 1 ⁄8 1½

1 3 5 7

1, 80 1 381 ⁄8 3 8¼ 1¼ 3 8½ 1 ⁄8 3 8¾ 1½ 391 ⁄8 3 9¼ 1¾ 3 9½ 1 ⁄8 3 9¾ 2 3 10

1 3 5 7

1¼, 80 1 3 8¼ 1 ⁄8 3 8½ 1¼ 3 8¾ 1 ⁄8 391½ 3 9¼ 1 ⁄8 3 9½ 1¾ 3 10 1 ⁄8 3 10¼ 2 3 10½

1 3 5 7

1½, 80 1 3 8¾ 1 ⁄8 3 8¾ 1¼ 391 ⁄8 3 9¼ 1½ 3 9½ 1 ⁄8 3 10 1¾ 3 10 1 ⁄8 3 10½ 2 3 10¾

1 3 5 7

2, 80 1 391 ⁄8 3 9¼ 1¼ 3 9½ 1 ⁄8 3 9¾ 1½ 3 10 1 ⁄8 3 10¼ 1¾ 3 10½ 1 ⁄8 3 11 2 3 11

1 3 5 7

2½, 80 1 3 10 1 ⁄8 3 10 1¼ 3 10 1 ⁄8 3 10¼ 1½ 3 10½ 1 ⁄8 3 10¾ 1¾ 3 11 1 ⁄8 3 11¼ 2 3 11½

1 3 5 7

3, 80 1 3 10½ 1 ⁄8 3 10¾ 1¼ 3 10¾ 1 ⁄8 3 11 1½ 3 11¼ 1 ⁄8 3 11½ 1¾ 3 11¾ 1 ⁄8 3 12 2 3 12¼

1 3 5 7

4, 80 1 3 11 1 ⁄8 3 11½ 1¼ 3 11¾ 1 ⁄8 3 12 1½ 3 12¼ 1 ⁄8 3 12½ 1¾ 3 12¾ 1 ⁄8 3 13 2 3 13¼

1 3 5 7 1

5, 80 1 3 12 1 ⁄8 3 12½ 1¼ 3 13 1 ⁄8 3 13 1½ 3 13¼ 1 ⁄8 3 13½ 1¾ 3 13¾ 1 ⁄8 3 14 2 ⁄8 3 15

1 3 5 7 1

6, 80 1 3 13 1 ⁄8 3 13½ 1¼ 3 14 1 ⁄8 3 14 1½ 3 14¼ 1 ⁄8 3 14½ 1¾ 3 14¾ 1 ⁄8 3 15 2 ⁄8 3 16¼

1 3 5

8, 80 1 3 14 1 ⁄8 3 14½ 1¼ 3 15 1 ⁄8 3 16 1½ 3 16¼ 1 ⁄8 3 16½ 1¾ 3 17 2 3 18 2½ 3 19¼

1 3 5 3

10, 60 1 3 16 1 ⁄8 3 17 1¼ 3 18 1 ⁄8 3 18¼ 1½ 3 18½ 1 ⁄8 3 18¾ 2 3 20¾ 2 ⁄8 3 22¾ 2¼ 3 23

1 3 5 3

12, 60 1 3 18 1 ⁄8 3 18½ 1¼ 3 19 1 ⁄8 3 20 1½ 3 20½ 1 ⁄8 3 20¾ 2 3 22¾ 2 ⁄8 3 24¾ 2½ 3 25

1 3 5 3 5

14, 60 1 3 21 1 ⁄8 3 21 1¼ 3 21 1 ⁄8 3 21½ 1½ 3 21¾ 1 ⁄8 3 22 2 3 24 2 ⁄8 3 26 2 ⁄8 3 25¾

1 3 1 3 5 7

16, 40 1 3 23 1 ⁄8 3 23 1¼ 3 23¼ 1 ⁄8 3 24¼ 1¾ 3 26½ 2 ⁄8 3 27½ 2 ⁄8 3 28½ 2 ⁄8 3 29¾ 2 ⁄8 3 31

1 3 1 3 5 7

18, 40 1 3 25 1 ⁄8 3 25 1¼ 3 25¼ 1 ⁄8 3 25½ 1¾ 3 27½ 2 ⁄8 3 29½ 2 ⁄8 3 30½ 2 ⁄8 3 31¾ 2 ⁄8 3 33

1 3 7 1 3 5 7

20, 40 1 3 27 1 ⁄8 3 27¼ 1¼ 3 27¼ 1 ⁄8 3 28¼ 1 ⁄8 3 30½ 2 ⁄8 3 31½ 2 ⁄8 3 32½ 2 ⁄8 3 33¾ 2 ⁄8 3 35

1 3 7 1 3 5 7

22, 60 1 3 29 1 ⁄8 3 29 1¼ 3 29 1 ⁄8 3 30 1 ⁄8 3 30 2 ⁄8 3 30 2 ⁄8 3 33½ 2 ⁄8 3 34½ 2 ⁄8 3 36

1 3 7 1 3 5 7

24, 40 1 3 31 1 ⁄8 3 31 1¼ 3 31¼ 1 ⁄8 3 31½ 1 ⁄8 3 34½ 2 ⁄8 3 35½ 2 ⁄8 3 36½ 2 ⁄8 3 38 2 ⁄8 3 39

A

See Fig. 4 and Fig. 5.

4. Materials 5. General Requirements

4.1 Discharge pipe shall be of an acceptable material as 5.1 Overboard discharges shall be combined to the maxi-

specified by Title 46 CFR, 56.60-1. mum extent practicable to minimize the number of shell

penetrations.

4.2 Doubler and insert plates shall be of material with

physical properties equal to or better than the reinforced shell 5.2 A minimum of 3 in. shall be maintained between the

edge of penetrations an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.