ASTM E810-94(2000)

(Test Method)Standard Test Method for Coefficient of Retroreflection of Retroreflective Sheeting Utilizing the Coplanar Geometry

Standard Test Method for Coefficient of Retroreflection of Retroreflective Sheeting Utilizing the Coplanar Geometry

SCOPE

1.1 This test method describes the instrument measurement of the retroreflective performance of retroreflective sheeting.

1.2 The user of this test method must specify the entrance and observation angles to be used.

1.3 This test method is intended as a laboratory test and requires a facility that can be darkened sufficiently so that stray light does not affect the test results.

1.4 Portable and bench retroreflection measuring equipment may be used to determine RA values provided the geometry and appropriate substitutional standard reference panels, measured in accordance with this test method, are utilized. In this case the methods of Procedure B in Practice E809 apply. Additional information on the use of portable retroreflectometers may be found in Test Method E 1709.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 810 – 94 (Reapproved 2000)

Standard Test Method for

Coefficient of Retroreflection of Retroreflective Sheeting

This standard is issued under the fixed designation E 810; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 coeffıcient of retroreflection, R —of a plane retrore-

A

flecting surface, the ratio of the coefficient of luminous

1.1 This test method describes the instrument measurement

intensity (R ) of a plane retroreflecting surface to its area (A),

I

of the retroreflective performance of retroreflective sheeting.

−1 −2

expressed in candelas per lux per square metre (cd·lx ·m ).

1.2 The user of this test method must specify the entrance

R = R /A.

A I

and observation angles to be used.

3.2.1.1 Discussion—The equivalent inch–pound units for

1.3 This test method is intended as a laboratory test and

coefficient of retroreflection are candelas per foot candle per

requires a facility that can be darkened sufficiently so that stray

square foot. The SI and inch pound units are numerically equal.

light does not affect the test results.

An equivalent term used for coefficient of retroreflection is

1.4 Portable and bench retroreflection measuring equipment

specific intensity per unit area, with symbol SIA or the CIE

may be used to determine R values provided the appropriate

A

symbol R8. The term coefficient of retroreflection and the

substitutional standard reference panels, measured in accor-

symbol R along with the SI units of candelas per lux per

A

dance with this test method, are used. In this case the methods

square meter are recommended by ASTM.

of Procedure B in Practice E 809 apply.

3.2.1.2 Discussion—R is a useful engineering quantity for

A

1.5 This standard does not purport to address all of the

determining the photometric performance of such retroreflec-

safety concerns, if any, associated with its use. It is the

tive surfaces as highway delineators or warning devices. R

A

responsibility of the user of this standard to establish appro-

may also be used to determine the minimum area of retrore-

priate safety and health practices and determine the applica-

flective sheeting necessary for a desired level of photometric

bility of regulatory limitations prior to use.

performance. R has been used intensively in the specification

A

2. Referenced Documents

of retroreflective sheeting.

3.2.2 datum mark, n—in retroreflection, an indication on the

2.1 ASTM Standards:

retroreflector that is used to define the orientation of the

E 284 Terminology of Appearance

retroreflector with respect to rotation about the retroreflector

E 308 Practice for Computing the Colors of Objects by

axis.

Using the CIE System

3.2.2.1 Discussion—The datum mark must not lie on the

E 691 Practice for Conducting an Interlaboratory Study to

retroreflector axis.

Determine the Precision of a Test Method

3.2.3 entrance angle, n— in retroreflection, angle between

E 808 Practice for Describing Retroreflection

the illumination axis and the retroreflector axis.

E 809 Practice for Measuring Photometric Characteristics

3.2.3.1 Discussion—The entrance angle is usually no larger

of Retroreflectors

than 90°, but for completeness its full range is defined as 0° #

2.2 Other Document:

b # 180°. To completely specify the orientation, this angle is

CIE Publication No 54 Retroreflection—Definition and

characterized by two components, b and b .

Measurement 1 2

3.2.4 goniometer, n—an instrument for measuring or setting

3. Terminology

angles.

3.2.5 illumination axis, n— in retroflection, a line from the

3.1 The terms and definitions in Terminology E 284 apply to

centroid of the effective source aperture to the retroreflector

this test method.

center.

3.2 Definitions:

3.2.6 observation angle, n—angle between the axes of the

incident beam and the observed (reflected) beam ( in retrore-

This method is under the jurisdiction of ASTM Committee E12 on Color and

flection, a, between the illumination axis and the observation

Appearance and is the direct responsibility of Subcommittee E12.10 on Retrore-

flection.

axis).

Current edition approved Feb. 15, 1994. Published April 1994. Originally

3.2.6.1 Discussion—The observation angle is always posi-

published as E 810 – 81. Last previous edition E 810 – 93b.

2 tive and in the context of retroreflection is restricted to small

Annual Book of ASTM Standards, Vol 06.01.

acute angles. Range: 0° # a < 180°.

Annual Book of ASTM Standards, Vol 14.02.

Available from USNC/CIE Publications Office, TLA Lighting Consultants, Inc.

3.2.7 observation axis, n— in retroreflection, a line from the

77 Pond St, Salem, MA 01970.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 810

centroid of the effective receiver aperture to the retroreflector area. The specimen holder is separated from the light source by

center. 15 m.

3.2.8 receiver, n— the portion of a photometric instrument 4.2 The general procedure involved is to determine the ratio

that receives the viewing beam from the specimen, including a of the light retroreflected from the test surface to that incident

collector such as an integrating sphere, if used, often the on the test surface.

monochromator or spectral filters, the detector, and associated

4.3 The photometric quantity, coefficient of retroreflection,

optics and electronics. is calculated from these measurements.

3.2.9 retroreflection, n—reflection in which the reflected

rays are preferentially returned in directions close to the 5. Significance and Use

opposite of the direction of the incident rays, this property

5.1 Measurements made by this test method are related to

being maintained over wide variations of the direction of the

visual observations of retroreflective sheeting as seen by the

B

incident rays. [CIE]

human eye when illuminated by tungsten-filament light sources

3.2.10 retroreflective device, n—deprecated term; use ret-

such as a motor vehicle headlamp.

roreflector.

5.2 The values determined relate to the visual effects for a

3.2.11 retroreflective material, n—a material that has a thin

given geometric configuration as specified by the user of the

continuous layer of small retroreflective elements on or very

test method. This test method has been found useful for tests at

near its exposed surface (for example, retroreflective sheeting,

observation angles between 0.1 and 2.0° (observation angles

retroreflective fabrics, transfer films, beaded paint, highway

between 0.1° and 0.2° may be achieved by careful design of

surface signs, or pavement striping).

source and receiver aperture configuration), and at entrance

3.2.12 retroreflective sheeting—a retroreflective material

angles up to 60°. It has been used to determine coefficient of

−1 −2

preassembled as a thin film ready for use. Retroreflective

retroreflection values as low as 0.1 cd·lx ·m , but for values

−1 −2

sheeting is a commonly used surfacing material for highway

less than 1 cd·lx ·m special attention must be given to the

signs.

responsivity of the receiver and to the elimination of very small

3.2.13 retroreflector, n—a reflecting surface or device from

amounts of stray light.

which, when directionally irradiated, the reflected rays are

preferentially returned in directions close to the opposite of the

6. Apparatus

direction of the incident rays, this property being maintained

6.1 Light Source—The light source shall be of the projector

over wide variations of the direction of the incident rays. [CIE,

type and shall meet the following requirements (an illuminance

B

1982]

at the 15-m specimen distance of about 10 lx is commonly

3.2.14 retroreflector axis, n—a designated line segment

available within these restrictions):

from the retroreflector center that is used to describe the

6.1.1 The spectral energy distribution of the source shall be

angular position of the retroreflector.

proportional to CIE standard Source A (a correlated color

3.2.14.1 Discussion—The direction of the retroreflector axis

temperature of 2856 K, see Practice E 308). The projection

is usually chosen centrally among the intended directions of

lamp together with the projection optics shall be operated such

illumination; for example, the direction of the road on which or

that it illuminates the test specimen with this spectral power

with respect to which the retroreflector is intended to be

distribution.

positioned. In testing horizontal road markings the retroreflec-

6.1.2 A nonpolarizing light source shall be used.

tor axis is usually the normal to the test surface.

6.1.3 At observation angles between 0.2° and 2.0°, the exit

3.2.15 retroreflector center, n—a point on or near a retrore-

aperture of the source shall be circular and 26 mm (65%) in

flector that is designated to be the center of the device for the

diameter. This corresponds to 0.1° angular aperture at the 15 m

purpose of specifying its performance.

test distance. At observation angles between 0.1° and 0.2°, the

3.2.16 rotation angle, e, n—in retroreflection, angle indicat-

exit aperture of the source shall be circular and 13 mm (65%)

ing the orientation of the specimen when it is rotated about the

in diameter. This corresponds to 0.05° angular aperture at the

retroreflector axis.

15 m test distance.

3.2.16.1 Discussion—The rotation angle is the dihedral

6.1.4 The illumination at the sample produced by the

angle from the half-plane originating on the retroreflector axis

projector shall be such that the test specimen and only a

and containing the positive part of the second axis to the half

minimum of the background is illuminated. This is commonly

plane originating on the retroreflector axis and containing the

accomplished by placing a restrictive aperture in the projector

datum mark. Range: −180° # e # 180°.

slide port.

3.2.17 source, n—an object that produces light or other

6.1.5 The source shall be regulated such that the illumi-

radiant flux.

nance at the test surface does not change by more than 61%

3.2.18 viewing angle, n, n—in retroreflection, the angle

for the duration of the test.

between the retroreflector axis and the observation axis.

6.1.6 The illuminance produced on the sample surface shall

be uniform within 65 % of the average illuminance normal to

4. Summary of Test Method

the source at the distance of 15 m.

4.1 This test method involves the use of a light projector 6.2 Receiver—The receiver shall meet the requirements that

−1 −2

source, a receiver, a device to position the receiver with respect follow. (In this test, for 10 lx incident upon a 1 cd·lx ·m

to the source and a test specimen holder in a suitable darkened retroreflective sheeting test specimen with area of 0.04 m , the

E 810

incident normal illuminance at the receiver will be about

−3

1.8 3 10 lx).

6.2.1 The responsivity and range of the receiver shall be

sufficient so that readings of both the incident normal illumi-

nance (at the specimen) and the retroreflected light at the

observation position can be measured with a resolution of at

least 1 part in 50 on the readout scale.

6.2.2 The spectral responsivity of the receiver shall match

that of the 1931 CIE Standard Photopic Observer (see Annex

A1 of Practice E 809).

6.2.3 The receiver shall be insensitive to the polarization of

light.

6.2.4 The linearity of the photometric scale over the range

of readings to be taken shall be within 61 %. Correction

factors may be used to ensure a linear response. Linearity

verification tests must be made utilizing the entire receiver

readout device including the detector, load, range selection

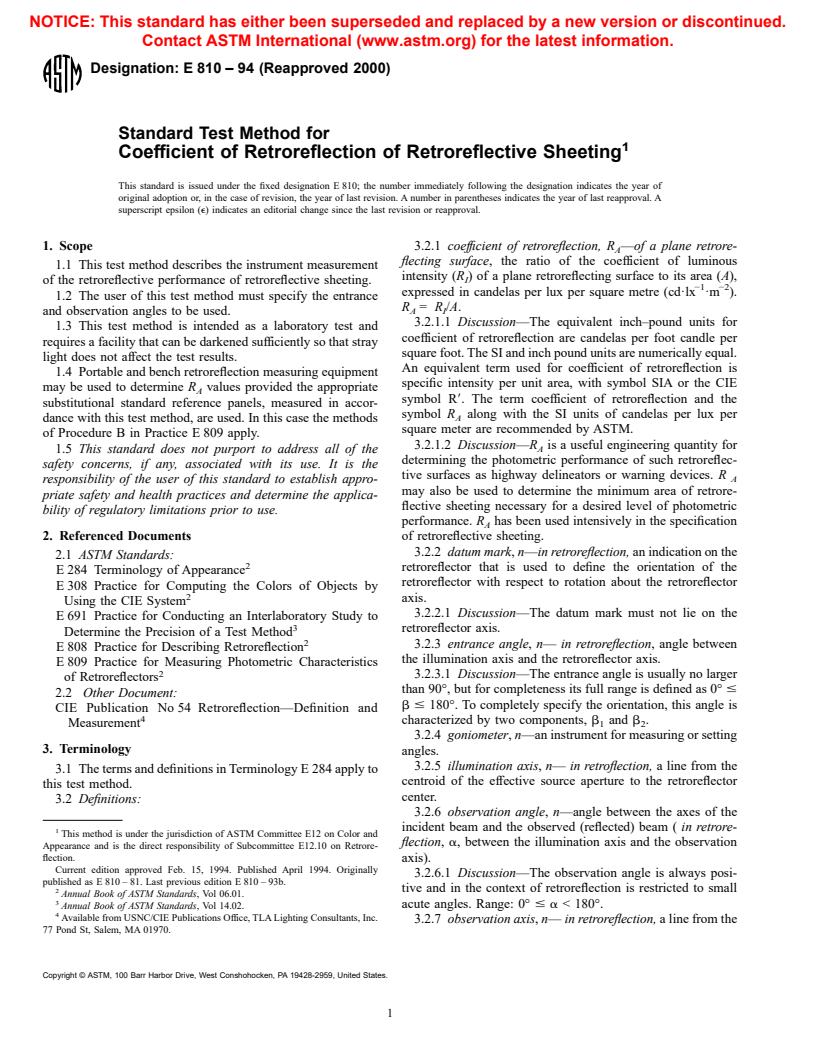

NOTE 1—This view shows the source-receiver in a horizontal plane and

system and readout display device.

the entrance angle b(= b ) as a rotation about a vertical axis. The rotation

6.2.5 The stability of the receiver shall be such that readings angle e is shown at +45° for illustration purposes— default position is

e = 0°.

from a constant source do not vary any more than 1 % for the

FIG. 1 Pictorial View of a Goniometer—Specimen Holder

duration of the test.

Assembly

6.2.6 The field of view shall be limited by use of light

the receiver can easily be substituted for the specimen (re-

baffles or a field aperture on the instrument so that the entire

quired when incident light measurements are taken).

test sample is fully within the field of view, rejecting stray light

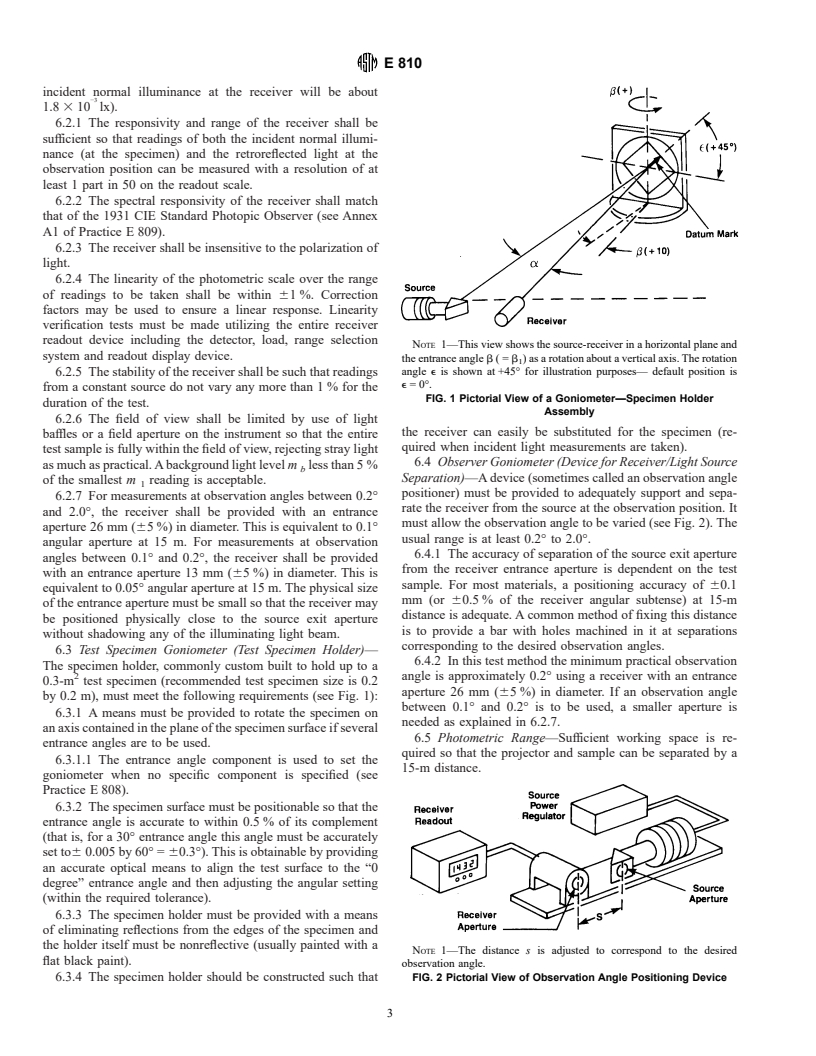

6.4 Observer Goniometer (Device for Receiver/Light Source

as much as practical. A background light level m less than 5 %

b

Separation)—A device (sometimes called an observation angle

of the smallest m reading is acceptable.

positioner) must be provided to adequately support and sepa-

6.2.7 For measurements at observation angles between 0.2°

rate the receiver from the source at the observation position. It

and 2.0°, the receiver shall be provided with an entrance

must allow the observation angle to be varied (see Fig. 2). The

aperture 26 mm (65 %) in diameter. This is equivalent to 0.1°

usual range is at least 0.2° to 2.0°.

angular aperture at 15 m. For measurements at observation

6.4.1 The accuracy of separation of the source exit aperture

angles between 0.1° and 0.2°, the receiver shall be provided

from the receiver entrance aperture is dependent on the test

with an entrance aperture 13 mm (65 %) in diameter. This is

sample. For most materials, a positioning accuracy of 60.1

equivalent to 0.05° angular aperture at 15 m. The physical size

mm (or 60.5 % of the receiver angular subtense) at 15-m

of the entrance aperture must be small so that the receiver may

distance is adequate. A common method of fixing this distance

be positioned physically close to the source exit aperture

is to provide a bar with holes machined in it at separations

without shadowing any of the illuminating light beam.

corresponding to the desired observation angles.

6.3 Test Specimen Goniometer (Test Specimen Holder)—

6.4.2 In this test method the minimum practical observation

The specimen holder, commonly custom built to hold up to a

angle is approximately 0.2° using a receiver with an entrance

0.3-m test specimen (recommended test specimen size is 0.2

aperture 26 mm (65 %) in diameter. If an observation angle

by 0.2 m), must meet the following requirements (see Fig. 1):

between 0.1° and 0.2° is to be used, a smaller aperture is

6.3.1 A means must be provided to rotate the specimen on

needed as explained in 6.2.7.

an axis contained in the plane of the specimen surface if several

6.5 Photometric Range—Sufficient working space is re-

entrance angles are to be used.

quired so that the projector and sample can

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.