ASTM E1569-09

(Test Method)Standard Test Method for Determination of Oxygen in Tantalum Powder by Inert Gas Fusion Technique (Withdrawn 2018)

Standard Test Method for Determination of Oxygen in Tantalum Powder by Inert Gas Fusion Technique (Withdrawn 2018)

SIGNIFICANCE AND USE

This test method is primarily intended as a test for compliance with compositional specifications. It is assumed that all who use this method will be trained analysts capable of performing common laboratory procedures skillfully and safely. It is expected that the work will be performed in a properly equipped laboratory.

SCOPE

1.1 This test method covers the determination of oxygen in tantalum powder in concentrations from 0.05 % to 0.50 %.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covered the determination of oxygen in tantalum powder in concentrations from 0.05 % to 0.50 %.

Formerly under the jurisdiction of Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials, this test method was withdrawn in January 2018 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1569 − 09

Standard Test Method for

Determination of Oxygen in Tantalum Powder by Inert Gas

1

Fusion Technique

This standard is issued under the fixed designation E1569; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope from the crucible to form carbon monoxide (CO) that is swept

by the inert gas stream into either an infrared or thermal

1.1 This test method covers the determination of oxygen in

conductivity detector. The detector output is compared to that

tantalum powder in concentrations from 0.05 % to 0.50 %.

of calibration reference materials and the result is displayed as

1.2 The values stated in SI units are to be regarded as

percent oxygen.

standard. No other units of measurement are included in this

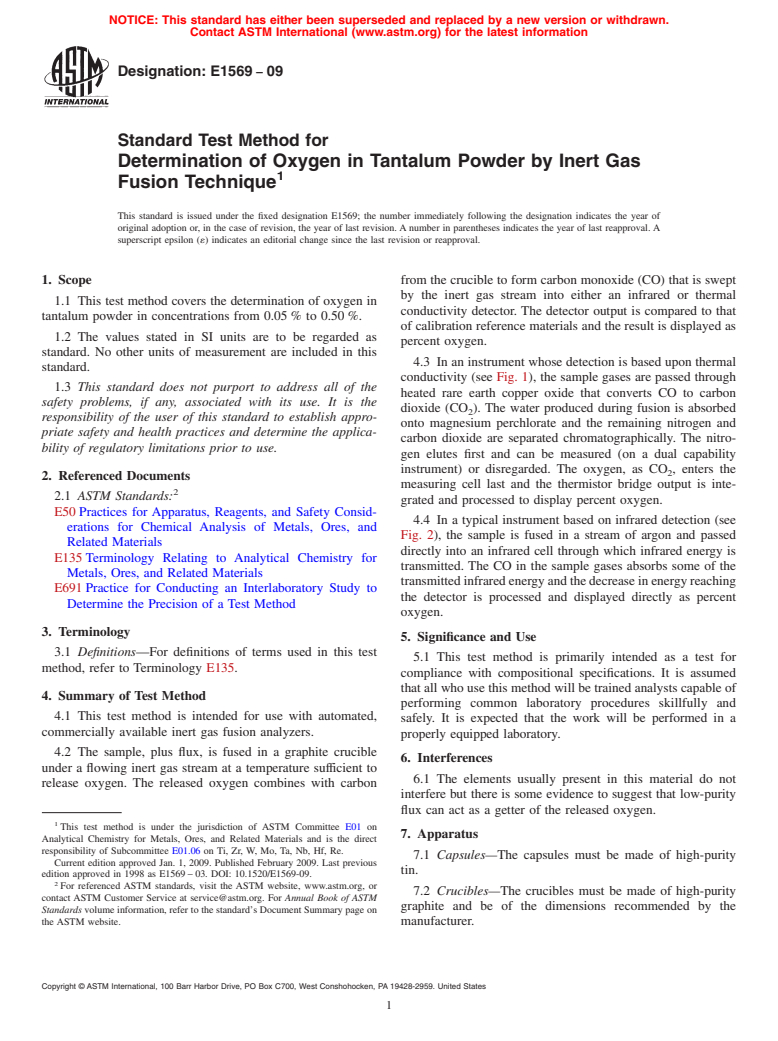

4.3 In an instrument whose detection is based upon thermal

standard.

conductivity (see Fig. 1), the sample gases are passed through

1.3 This standard does not purport to address all of the

heated rare earth copper oxide that converts CO to carbon

safety problems, if any, associated with its use. It is the

dioxide (CO ). The water produced during fusion is absorbed

2

responsibility of the user of this standard to establish appro-

onto magnesium perchlorate and the remaining nitrogen and

priate safety and health practices and determine the applica-

carbon dioxide are separated chromatographically. The nitro-

bility of regulatory limitations prior to use.

gen elutes first and can be measured (on a dual capability

instrument) or disregarded. The oxygen, as CO , enters the

2

2. Referenced Documents

measuring cell last and the thermistor bridge output is inte-

2

2.1 ASTM Standards:

grated and processed to display percent oxygen.

E50 Practices for Apparatus, Reagents, and Safety Consid-

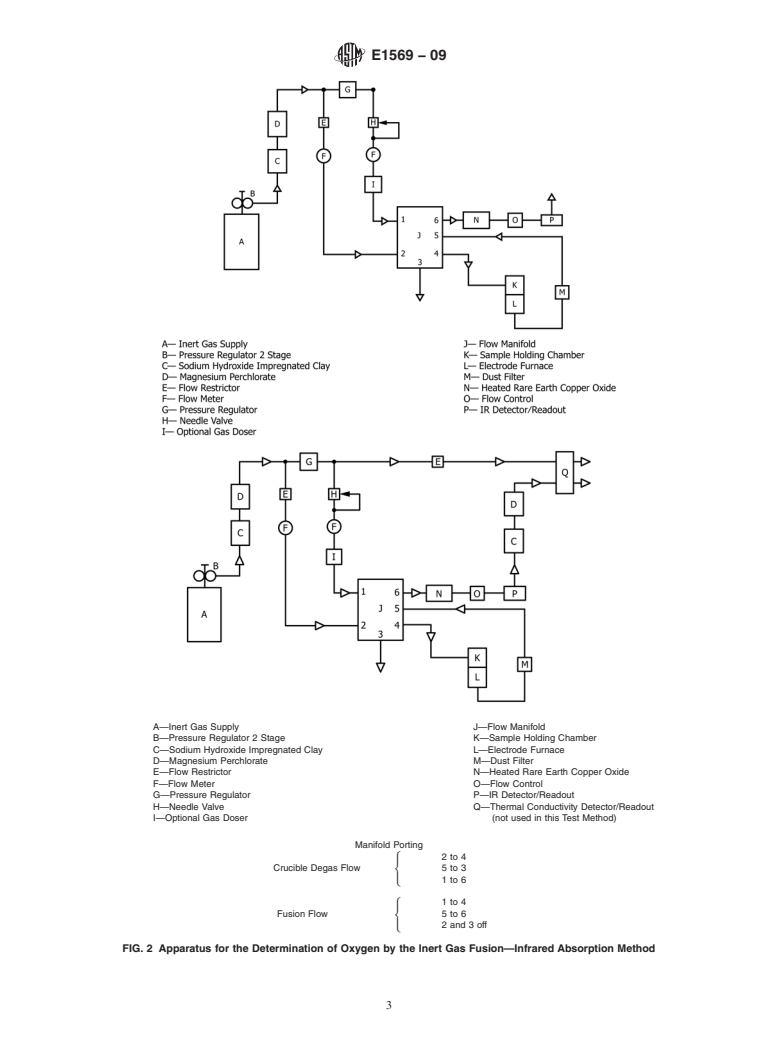

4.4 In a typical instrument based on infrared detection (see

erations for Chemical Analysis of Metals, Ores, and

Fig. 2), the sample is fused in a stream of argon and passed

Related Materials

directly into an infrared cell through which infrared energy is

E135 Terminology Relating to Analytical Chemistry for

transmitted. The CO in the sample gases absorbs some of the

Metals, Ores, and Related Materials

transmittedinfraredenergyandthedecreaseinenergyreaching

E691 Practice for Conducting an Interlaboratory Study to

the detector is processed and displayed directly as percent

Determine the Precision of a Test Method

oxygen.

3. Terminology

5. Significance and Use

3.1 Definitions—For definitions of terms used in this test

5.1 This test method is primarily intended as a test for

method, refer to Terminology E135.

compliance with compositional specifications. It is assumed

that all who use this method will be trained analysts capable of

4. Summary of Test Method

performing common laboratory procedures skillfully and

4.1 This test method is intended for use with automated,

safely. It is expected that the work will be performed in a

commercially available inert gas fusion analyzers.

properly equipped laboratory.

4.2 The sample, plus flux, is fused in a graphite crucible

6. Interferences

under a flowing inert gas stream at a temperature sufficient to

6.1 The elements usually present in this material do not

release oxygen. The released oxygen combines with carbon

interfere but there is some evidence to suggest that low-purity

flux can act as a getter of the released oxygen.

1

This test method is under the jurisdiction of ASTM Committee E01 on

7. Apparatus

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct

responsibility of Subcommittee E01.06 on Ti, Zr, W, Mo, Ta, Nb, Hf, Re.

7.1 Capsules—The capsules must be made of high-purity

Current edition approved Jan. 1, 2009. Published February 2009. Last previous

tin.

edition approved in 1998 as E1569 – 03. DOI: 10.1520/E1569-09.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

7.2 Crucibles—The crucibles must be made of high-purity

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

graphite and be of the dimensions recommended by the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. manufacturer.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1569 − 09

A—Inert Gas Supply I—Sample Holding Chamber

B—Pressure Regulator J—Electrode Furnace

C—Heated Copper K—Dust Filter

D—Sodium Hydroxide Impregnated Clay L—Heated Rare Earth Copper Oxide

E—Magnesium Perchlorate M—Magnesium Perchlorate

F—Flow Control N—Silica Column

G—Flow Manifold O—

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.