ASTM E104-02(2007)

(Practice)Standard Practice for Maintaining Constant Relative Humidity by Means of Aqueous Solutions

Standard Practice for Maintaining Constant Relative Humidity by Means of Aqueous Solutions

SCOPE

1.1 This practice describes one method for generating constant relative humidity (rh) environments in relatively small containers.

1.2 This practice is applicable for obtaining constant relative humidities ranging from dryness to near saturation at temperatures spanning from 0 to 50C.

1.3 This practice is applicable for closed systems such as environmental conditioning containers and for the calibration of hygrometers.

1.4 This practice is not recommended for the generation of continuous (flowing) streams of constant humidity unless precautionary criteria are followed to ensure source stability. (See Section 9 .)

1.5 Caution-Saturated salt solutions are extremely corrosive, and care should be taken in their preparation and handling. There is also the possibility of corrosive vapors in the atmospheres over the saturated salt solutions.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For more specific safety precautionary information see 1.5 and 10.1 .

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E104–02 (Reapproved 2007)

Standard Practice for

Maintaining Constant Relative Humidity by Means of

Aqueous Solutions

This standard is issued under the fixed designation E104; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D1356 Terminology Relating to Sampling and Analysis of

Atmospheres

1.1 This practice describes one method for generating con-

2.2 Other Document:

stant relative humidity (rh) environments in relatively small

DIN50008 “Konstantklimate uber waesserigen Loseungen”

containers.

(Constant Climates Over Aqueous Solutions).

1.2 This practice is applicable for obtaining constant rela-

Part 1: Saturated Salt and Glycerol Solutions.

tive humidities ranging from dryness to near saturation at

temperatures spanning from 0 to 50°C.

3. Terminology

1.3 This practice is applicable for closed systems such as

3.1 non-hygroscopic material—material which neither ab-

environmental conditioning containers and for the calibration

sorbs nor retains water vapor.

of hygrometers.

3.2 For definitions of other terms used in this practice refer

1.4 This practice is not recommended for the generation of

to Terminology D1356.

continuous (flowing) streams of constant humidity unless

precautionary criteria are followed to ensure source stability.

4. Summary of Practice

(See Section 9.)

4.1 Standard value relative humidity environments are gen-

1.5 Caution—Saturated salt solutions are extremely corro-

erated using selected aqueous saturated salt solutions.

sive, and care should be taken in their preparation and

handling.Thereisalsothepossibilityofcorrosivevaporsinthe

5. Significance and Use

atmospheres over the saturated salt solutions.

5.1 Standard value relative humidity environments are im-

1.6 This standard does not purport to address all of the

portant for conditioning materials in shelf-life studies or in the

safety concerns, if any, associated with its use. It is the

testing of mechanical properties such as dimensional stability

responsibility of the user of this standard to establish appro-

and strength. Relative humidity is also an important operating

priate safety and health practices and determine the applica-

variable for the calibration of many species of measuring

bility of regulatory limitations prior to use. For more specific

instruments.

safety precautionary information see 1.5 and 10.1.

6. Interferences

2. Referenced Documents

6.1 Temperature regulation of any solution-head space en-

2.1 ASTM Standards:

vironment to 60.1°C is essential for realizing generated

D1193 Specification for Reagent Water

relative humidity values within 60.5 % (expected).

6.2 Some aqueous saturated salt solutions change composi-

This practice is under the jurisdiction ofASTM Committee D22 onAir Quality

tion following preparation by hydrolysis or by reaction with

and is the direct responsibility of Subcommittee D22.11 on Meteorology.

environmental components (for example, carbon dioxide ab-

Current edition approved Oct. 1, 2007. Published December 2007. Originally

sorption by alkaline materials). These solutions should be

approved in 1951. Last previous edition approved in 2002 as E104 - 02. DOI:

10.1520/E0104-02R07.

freshly prepared on each occasion of use.

Opila, R., Jr., Weschler, C. J., and Schubert, R., “Acidic Vapors Above

Saturated Salt Solutions Commonly Used for Control of Humidity,” IEEE Trans.

Components, Hybrids and Manufacturing Technology, Vol 12, No. 1, March 1989,

pp. 114–120.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Published by Deutsches Institut für Normung, 4-10 Burggrzfenstrasse Postfach

Standards volume information, refer to the standard’s Document Summary page on 1107, D-1000 Berlin, Federal Republic of Germany. Also available from ANSI

the ASTM website. Publication Office, New York, NY.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E104–02 (2007)

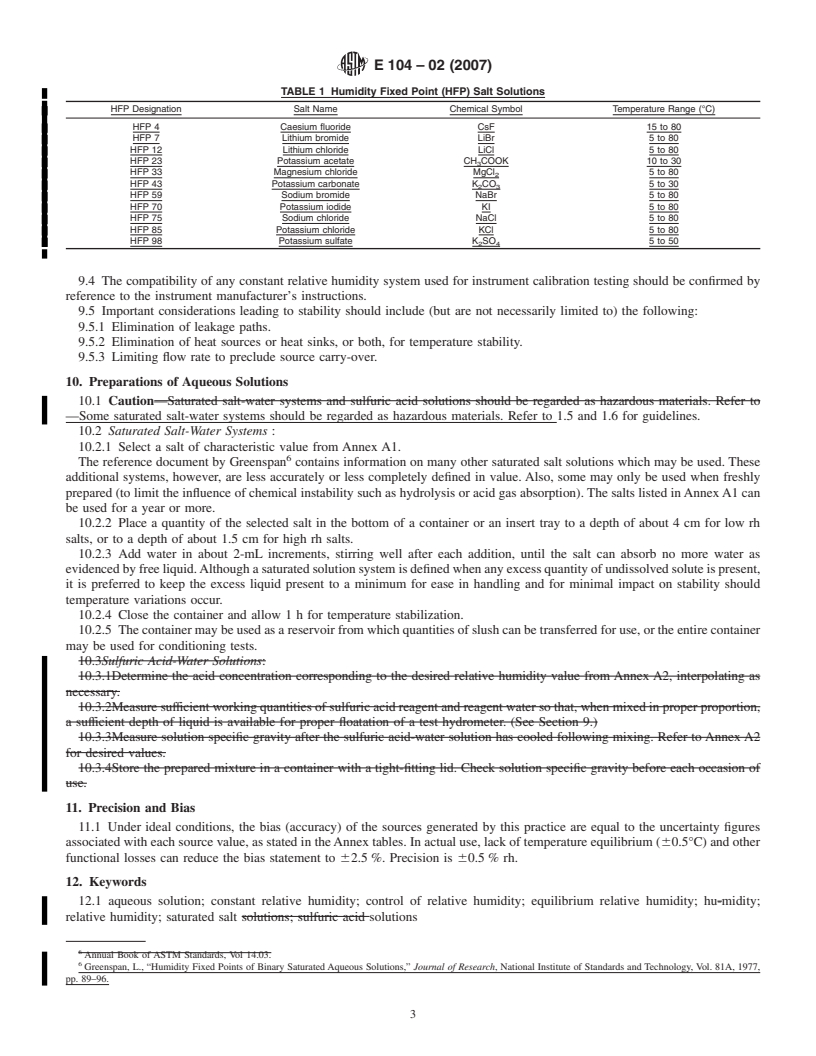

TABLE 1 Humidity Fixed Point (HFP) Salt Solutions

HFP Designation Salt Name Chemical Symbol Temperature Range (°C)

HFP 4 Caesium fluoride CsF 15 to 80

HFP 7 Lithium bromide LiBr 5 to 80

HFP 12 Lithium chloride LiCl 5 to 80

HFP 23 Potassium acetate CH COOK 10 to 30

HFP 33 Magnesium chloride MgCl 5to80

HFP 43 Potassium carbonate K CO 5to30

2 3

HFP 59 Sodium bromide NaBr 5 to 80

HFP 70 Potassium iodide KI 5 to 80

HFP 75 Sodium chloride NaCl 5 to 80

HFP 85 Potassium chloride KCl 5 to 80

HFP 98 Potassium sulfate K SO 5to50

2 4

7. Apparatus typesofcontainers).Theventshouldbeassmallaspracticalto

minimize loss of desired equilibrium conditions when in use.

7.1 Container—The container, including a cover or lid

9.2 The container should be small to minimize the influence

which can be secured airtight, should be made of corrosion

of any temperature variations acting upon the container and

resistant, non-hygroscopic material such as glass. A metal or

3 2

contents. A maximum proportion of 25 cm volume/cm of

plastic container is acceptable if the solution is retained in a

solution surface area is suggested, and overall container

dish or tray made of appropriate material. Refer also to 9.2 for

headspace volume should be no larger than necessary to

size restrictions.

confine a stored item.

8. Reagents and Materials 9.3 Measurement accuracy is strongly dependent on the

ability to achieve and maintain temperature stability during

8.1 Purity of Reagents—Reagent grade chemicals shall be

actual use of any solution system. Temperature instability of

used for preparation of all standard solutions. Unless otherwise

60.1°C can cause corresponding instabilities in generated

indicated, it is intended that all reagents conform to the

values of relative humidity of 60.5 %.

specifications of the Committee on Analytical Reagents of the

9.4 The compatibility of any constant relative humidity

American Chemical Society where such specifications are

system used for instrument calibration testing should be

available. Other grades may be used, provided it is first

confirmed by reference to the instrument manufacturer’s in-

ascertained that the reagent is of sufficiently high purity to

structions.

permit its use without lessening the accuracy of the determi-

9.5 Important considerations leading to stability should

nation.

include (but are not necessarily limited to) the following:

8.1.1 Saturated salt solutions may be prepared using either

9.5.1 Elimination of leakage paths.

amorphous or hydrated reagents (that is, reagents containing

9.5.2 Elimination of heat sources or heat sinks, or both, for

water of crystallization). Hydrated reagents are often preferred

temperature stability.

to amorphous forms for their solvating characteristics.

9.5.3 Limiting flow rate to preclude sour

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E104–85 (Reapproved 1996) Designation:E104–02 (Reapproved 2007)

Standard Practice for

Maintaining Constant Relative Humidity by Means of

Aqueous Solutions

This standard is issued under the fixed designation E 104; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This practice describes two methodsone method for generating constant relative humidity (rh) environments in relatively

small containers.

1.2 This practice is applicable for obtaining constant relative humidities ranging from dryness to near saturation at temperatures

spanning from 0 to 50°C.

1.3 This practice is applicable for closed systems such as environmental conditioning containers and for the calibration of

hygrometers.

1.4 This practice is not recommended for the generation of continuous (flowing) streams of constant humidity unless

precautionary criteria are followed to ensure source stability. (See Section 9.)

1.5 Caution—Both saturated —Saturated salt solutions and sulfuric acid-water solutions are extremely corrosive, and care

should be taken in their preparation and handling. There is also the possibility of corrosive vapors in the atmospheres over the

saturated salt solutions. and over the sulfuric acid solution.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For more specific safety precautionary information see 1.5 and 10.1.

2. Referenced Documents

2.1 ASTM Standards:

D 1193 Specification for Reagent Water

D4023Terminology Relating to Humidity Measurements

E126Test Method for Inspection and Verification of Hydrometers

2.2 1356 Terminology Relating to Sampling and Analysis of Atmospheres

2.2 Other Document:

DIN50008 “Konstantklimate uber waesserigen Loseungen” (Constant Climates Over Aqueous Solutions).

Part 1: Saturated Salt and Glycerol Solutions. Part 2: Sulfuric Acid Solutions. (1981)

3. Terminology

3.1 non-hygroscopic material—material which neither absorbs nor retains water vapor.

3.2 For definitions of other terms used in this practice refer to Terminology D4023D 1356.

This practice is under the jurisdiction of ASTM Committee D-22 on Sampling and Analysis of Atmospheres and is the direct responsibility of Subcommittee D22.11

on Meteorology.

Current edition approved Feb. 22, 1985. Published June 1985.

This practice is under the jurisdiction of ASTM Committee D22 on Air Quality and is the direct responsibility of Subcommittee D22.11 on Meteorology.

Current edition approved Oct. 1, 2007. Published December 2007. Originally approved in 1951. Last previous edition approved in 2002 as E104 - 02.

Opila, R., Jr., Weschler, C. J., and Schubert, R., “Acidic Vapors Above Saturated Salt Solutions Commonly Used for Control of Humidity,” IEEE Trans. Components,

Hybrids and Manufacturing Technology, Vol 12, No. 1, March 1989, pp. 114–120.

Kawasaki, K., and Kanou, K., “Control ofAtmospheric Humidity forAqueous SulfuricAcid Solutions,” Vol. III (A. Wexler, ed.), Reinhold Publishing Corporation, NY,

1964, pp. 531–534.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 11.01.

PublishedbyDeutschesInstitutfürNormung,4-10BurggrzfenstrassePostfach1107,D-1000Berlin,FederalRepublicofGermany.AlsoavailablefromANSIPublication

Office, New York, NY.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E104–02 (2007)

4. Summary of Practice

4.1Standard value relative humidity environments are generated using selected aqueous saturated salt solutions or various

strength sulfuric acid-water systems.

4.1 Standard value relative humidity environments are generated using selected aqueous saturated salt solutions.

5. Significance and Use

5.1 Standard value relative humidity environments are important for conditioning materials in shelf-life studies or in the testing

of mechanical properties such as dimensional stability and strength. Relative humidity is also an important operating variable for

the calibration of many species of measuring instruments.

6. Interferences

6.1Temperature regulation of any solution-head space environment to 60.1°C is essential for realizing generated relative

humidity values within 60.5 % (expected).

6.2Sulfuric Acid—Water systems are strongly hygroscopic and can substantially change value by absorption and desorption if

storedinanopencontainer.Onlyfreshlypreparedsolutions,orsolutionswhichvalueshavebeenindependentlytestedforstrength,

should be used.

6.3Some aqueous saturated salt solutions change composition following preparation by hydrolysis or by reaction with

environmental components (for example, carbon dioxide absorption by alkaline materials). These solutions should be freshly

prepared on each occasion of use. Interferences

6.1 Temperature regulation of any solution-head space environment to 60.1°C is essential for realizing generated relative

humidity values within 60.5 % (expected).

6.2 Some aqueous saturated salt solutions change composition following preparation by hydrolysis or by reaction with

environmental components (for example, carbon dioxide absorption by alkaline materials). These solutions should be freshly

prepared on each occasion of use.

7. Apparatus

7.1 Container—The container, including a cover or lid which can be secured airtight, should be made of corrosion resistant,

non-hygroscopic material such as glass.Ametal or plastic container is acceptable if the solution is retained in a dish or tray made

of appropriate material. Refer also to 9.2 for size restrictions.

7.2Hydrometers—One or more hydrometers may be used to test sulfuric acid solution specific gravities for the range of

humidities concerned. The hydrometer(s) should have a minimum scale division of 0.001. (Refer to Test Method E126.)

8. Reagents and Materials

8.1 Purity of Reagents—Reagent grade chemicals shall be used for preparation of all standard solutions. Unless otherwise

indicated, it is intended that all reagents conform to the specifications of the Committee on Analytical Reagents of the American

Chemical Society where such specifications are available. Other grades may be used, provided it is first ascertained that the

reagent is of sufficiently high purity to permit its use without lessening the accuracy of the determination.

8.1.1 Saturated salt solutions may be prepared using either amorphous or hydrated reagents (that is, reagents containing water

of crystallization). Hydrated reagents are often preferred to amorphous forms for their solvating characteristics.

8.2 Purity of Water—Reagent water produced by distillation, or by ion exchange, or reverse osmosis followed by distillation

shall be used. See Specification D 1193.

8.3 Nomenclature for Salts—The proper nomenclature for the Humidity Fixed Point (HFP) salt chemicals and the

corresponding acceptable temperature ranges are provided in Table 1. The scale encompasses relative humidity ranges from 2 %

to 98.5 % and a temperature range from 5°C to 80°C. When the salt solutions are used at temperatures above 40°C, the risk of

salt crystals settling on the surface rather than being immersed in the solution must be taken into account.

9. Technical Precautions

9.1 Although a container capable of airtight closure is described in Section 7, it may be desirable to have a vent under certain

conditions of test or with some kinds of containers (changes in pressure may produce undesirable cracks in some types of

containers). The vent should be as small as practical to minimize loss of desired equilibrium conditions when in use.

9.2 The container should be small to minimize the influence of any temperature variations acting upon the container and

3 2

contents. A maximum proportion of 25 cm volume/cm of solution surface area is suggested, and overall container headspace

volume should be no larger than necessary to confine a stored item.

9.3 Measurement accuracy is strongly dependent on the ability to achieve and maintain temperature stability during actual use

of any solution system. Temperature instability of 60.1°C can cause corresponding instabilities in generated values of relative

humidity of 60.5 %.

Annual Book of ASTM Standards, Vol 11.03.Reagent Chemicals, American Chemical Society Specifications , American Chemical Society, Washington, DC. For

suggestions on the testing of reagents not listed by the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and

the United States Pharmacopeia and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville, MD.

------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.