ASTM D6329-98(2023)

(Guide)Standard Guide for Developing Methodology for Evaluating the Ability of Indoor Materials to Support Microbial Growth Using Static Environmental Chambers

Standard Guide for Developing Methodology for Evaluating the Ability of Indoor Materials to Support Microbial Growth Using Static Environmental Chambers

SIGNIFICANCE AND USE

4.1 The static chambers have several different applications:

4.1.1 The static chambers can be used to compare the susceptibility of different materials to the colonization and amplification of various microorganisms under defined conditions.

4.1.2 Chambers operated at high relative humidities may be used to perform worst case scenario screening tests on materials by providing an atmosphere where environmental conditions may be favorable for microbial growth.

4.1.3 Use of multiple chambers with different environmental parameters, such as a range of relative humidities, permits the evaluation of multiple microenvironments and allows investigation of materials under differing environmental conditions.

4.1.4 Drying requirements for wetted materials may also be investigated. This information may be relevant for determining material resistance to microbial growth after becoming wet. These conditions may simulate those where materials are subjected to water incursion through leaks as well as during remediation of a building after a fire.

4.1.5 Growth rates of microorganisms on the material may also be investigated. Once it has been established that organisms are able to grow on a particular material under defined conditions, investigations into the rate of organism growth may be performed. These evaluations provide base line information and can be used to evaluate methods to limit or contain amplification of microorganisms.

4.2 These techniques should be performed by personnel with training in microbiology. The individual must be competent in the use of sterile technique, which is critical to exclude external contamination of materials.

SCOPE

1.1 Many different types of microorganisms (for example, bacteria, fungi, viruses, algae) can occupy indoor spaces. Materials that support microbial growth are potential indoor sources of biocontaminants (for example, spores and toxins) that can become airborne indoor biopollutants. This guide describes a simple, relatively cost effective approach to evaluating the ability of a variety of materials to support microbial growth using a small chamber method.

1.2 This guide is intended to assist groups in the development of specific test methods for a definite material or groups of materials.

1.3 Static chambers have certain limitations. Usually, only small samples of indoor materials can be evaluated. Care must be taken that these samples are representative of the materials being tested so that a true evaluation of the material is performed.

1.4 Static chambers provide controlled laboratory microenvironment conditions. These chambers are not intended to duplicate room conditions, and care must be taken when interpreting the results. Static chambers are not a substitute for dynamic chambers or field studies.

1.5 A variety of microorganisms, specifically bacteria and fungi, can be evaluated using these chambers. This guide is not intended to provide human health effect data. However, organisms of clinical interest, such as those described as potentially allergenic, may be studied using this approach.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6329 − 98 (Reapproved 2023)

Standard Guide for

Developing Methodology for Evaluating the Ability of Indoor

Materials to Support Microbial Growth Using Static

Environmental Chambers

This standard is issued under the fixed designation D6329; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

1.1 Many different types of microorganisms (for example,

mine the applicability of regulatory limitations prior to use.

bacteria, fungi, viruses, algae) can occupy indoor spaces.

1.8 This international standard was developed in accor-

Materials that support microbial growth are potential indoor

dance with internationally recognized principles on standard-

sources of biocontaminants (for example, spores and toxins)

ization established in the Decision on Principles for the

that can become airborne indoor biopollutants. This guide

Development of International Standards, Guides and Recom-

describes a simple, relatively cost effective approach to evalu-

mendations issued by the World Trade Organization Technical

ating the ability of a variety of materials to support microbial

Barriers to Trade (TBT) Committee.

growth using a small chamber method.

1.2 This guide is intended to assist groups in the develop-

2. Referenced Documents

ment of specific test methods for a definite material or groups

2.1 ASTM Standards:

of materials.

D1193 Specification for Reagent Water

1.3 Static chambers have certain limitations. Usually, only

D1356 Terminology Relating to Sampling and Analysis of

small samples of indoor materials can be evaluated. Care must

Atmospheres

be taken that these samples are representative of the materials

E104 Practice for Maintaining Constant Relative Humidity

being tested so that a true evaluation of the material is

by Means of Aqueous Solutions

performed.

2.2 APHA Standards:

1.4 Static chambers provide controlled laboratory microen- Standard Methods for the Examination of Water and Waste-

vironment conditions. These chambers are not intended to water

duplicate room conditions, and care must be taken when

3. Terminology

interpreting the results. Static chambers are not a substitute for

dynamic chambers or field studies.

3.1 Definitions—For definitions of terms used in this guide,

refer to Terminology D1356.

1.5 A variety of microorganisms, specifically bacteria and

fungi, can be evaluated using these chambers. This guide is not

3.2 Definitions of Terms Specific to This Standard:

intended to provide human health effect data. However, organ-

3.2.1 amplification—the act or result of increasing the

isms of clinical interest, such as those described as potentially

quantity of microorganisms.

allergenic, may be studied using this approach.

3.2.2 CFU—colony forming unit, which may arise from a

1.6 The values stated in SI units are to be regarded as

single organism or multiple units, such as spores, in the case of

standard. No other units of measurement are included in this

the fungi.

standard.

3.2.3 colony—macroscopically visible growth.

1.7 This standard does not purport to address all of the

3.2.4 inoculation—the act of introducing a microorganism

safety concerns, if any, associated with its use. It is the

(inoculum) into the test material.

1 2

This guide is under the jurisdiction of ASTM Committee D22 on Air For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Quality and is the direct responsibility of Subcommittee D22.08 on Assessment, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Sampling, and Analysis of Microorganisms. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Jan. 1, 2023. Published February 2023. Originally the ASTM website.

approved in 1998. Last previous edition approved in 2015 as D6329 – 98 (2015). Available from American Public Health Association (APHA), 800 I St., NW,

DOI: 10.1520/D6329-98R23. Washington, DC 20001, http://www.apha.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6329 − 98 (2023)

3.2.5 inoculum—viable test microorganism introduced onto

a material by implanting a small amount on the surface or

substrate.

3.2.6 plate—petri dish containing microbiological agar me-

dia on which microorganism are grown.

3.2.7 static chamber—a small chamber (enclosed space)

with no internal forced air motion.

3.2.8 susceptibility—the vulnerability of a material or sur-

face to colonization by microorganisms.

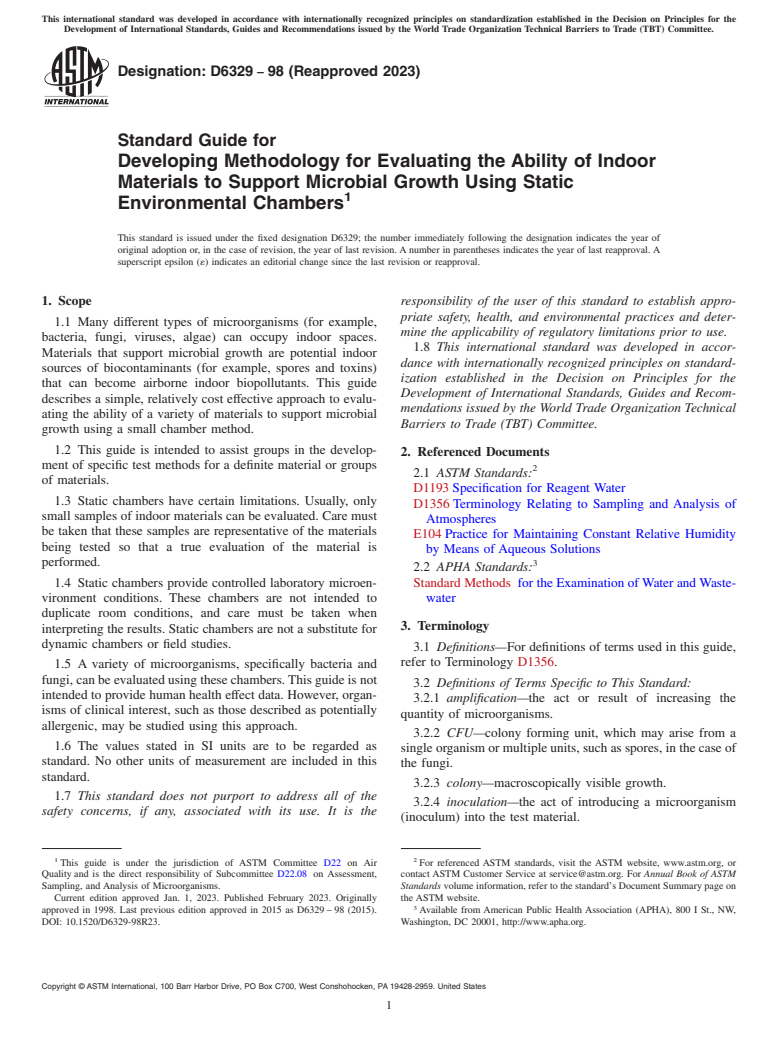

FIG. 1 Schematic of Example Static Chamber

4. Significance and Use

5.1.1 Relative Humidity—Maintain humidities through the

4.1 The static chambers have several different applications:

use of saturated salt solutions contained in trays on the bottom

4.1.1 The static chambers can be used to compare the

of the chambers (see Practice E104). It is essential that the

susceptibility of different materials to the colonization and

chambers be tightly sealed so that the desired humidity will be

amplification of various microorganisms under defined condi-

maintained. Place hygrometers in the chambers for confirma-

tions.

tion that humidities are being maintained, although saturated

4.1.2 Chambers operated at high relative humidities may be

salt solutions are themselves standards. Exercise care that the

used to perform worst case scenario screening tests on mate-

salts selected for use in the chamber are not inhibitory to the

rials by providing an atmosphere where environmental condi-

test organisms.

tions may be favorable for microbial growth.

5.1.2 Temperature—Control the temperature of the cham-

4.1.3 Use of multiple chambers with different environmen-

bers. The chambers may be externally controlled through the

tal parameters, such as a range of relative humidities, permits

use of constant temperature environments, such as a room or

the evaluation of multiple microenvironments and allows

incubator. Chart recorders or other data logging devices are

investigation of materials under differing environmental con-

recommended to confirm maintenance of temperature. Con-

ditions.

trolled temperature is critical for two reasons. First, it can have

4.1.4 Drying requirements for wetted materials may also be

a profound effect on the growth of microorganisms. Second,

investigated. This information may be relevant for determining

relative humidity is dependent upon temperature. The control

material resistance to microbial growth after becoming wet.

limits may be defined by consulting a psychometric chart and

These conditions may simulate those where materials are

determining the impact of temperature on a specific test RH.

subjected to water incursion through leaks as well as during

5.1.3 Characterize instrumentation for evaluating other pa-

remediation of a building after a fire.

rameters if the instruments are to be employed during material

4.1.5 Growth rates of microorganisms on the material may

testing. Conditions such as light need to be noted and con-

also be investigated. Once it has been established that organ-

trolled during the course of an experiment as these conditions

isms are able to grow on a particular material under defined

may have an effect on the growth of the test organism. Light

conditions, investigations into the rate of organism growth may

may be controlled externally by placing the chambers in a

be performed. These evaluations provide base line information

darkened room to remove light or in a continuously lighted

and can be used to evaluate methods to limit or contain

room for a constant light source.

amplification of microorganisms.

5.2 Provide ports, where needed, for the insertion of probes

4.2 These techniques should be performed by personnel

to monitor and record temperature and relative humidity, using

with training in microbiology. The individual must be compe-

externally located instrumentation as long as it is well sealed

tent in the use of sterile technique, which is critical to exclude

and contamination is avoided.

external contamination of materials.

5.3 Decontamination—Decontaminate the chamber before

initiating any analysis. Surface disinfection or vapor phase

5. Apparatus

disinfection may be appropriate. Glass may be autoclaved.

5.1 Static Chamber—Chambers should be relatively small Follow the manufacturers’ instructions, especially any safety

and portable, contain three or four shelves, and be easily precautions. If a chemical disinfectant is employed, clear the

decontaminated. In addition, transparent walls are desirable chambers of any residual disinfectant to prevent interference

because visual inspection of the test material and monitoring of with the growth of the microorganisms on the material being

instruments (that is, hygrometers) without opening the cham- evaluated. Thoroughly ventilate the chambers in a clean

ber is preferred. Fig. 1 is a schematic diagram of a possible environment. Decontaminate the salt solutions. The method

static chamber. Acrylic desiccators are readily available, easily used is dependent upon the composition of the salts selected.

adaptable, and relatively inexpensive. Other options, such as Any instrumentation to be used during the evaluations, such as

glass, are also acceptable. Glass has the advantage of being hygrometers, may be removed from the chambers during the

autoclavable; however, it is frequently much less portable. The decontamination procedure of the chamber surfaces and de-

chamber door must provide ready access to the materials but contaminated separately; however, it is generally more effec-

should be airtight when closed. tive for them to remain in the chambers. Verify the efficacy of

D6329 − 98 (2023)

the decontamination procedure as part of the Quality 8. Sample Preparation

Assurance/Quality Control (QA/QC) plan.

8.1 Specific details on the preparation of the samples will

5.4 Decontaminate the work area around the chambers

depend upon the characteristics of the material to be tested.

routinely, especially before opening the chamber door. The Generally, replicate small pieces of the test material should be

chambers should be kept in a clean room, functionally Class

used. Depending upon the material, pieces as small as 4 by 4

100 000 (M 6.5 or ISO 8) or better. cm may be used. Pieces should be placed on sterile petri dishes

or other appropriate holders on the shelves in the chamber.

6. Reagents

Include controls and blanks within the QA/QC framework.

6.1 Purity of Reagents—Reagent grade chemicals shall be

8.2 Common microbiological practice is to sterilize a sur-

used in all tests. Unless otherwise indicated, it is intended that

face or material before inoculation to ensure that the test

all reagents conform to the specifications of the Committee on

organism is the only source being evaluated. Autoclaving is an

Analytical Reagents of the American Chemical Society where

extremely effective method if such a procedure does not alter

such specifications are available. Other grades may be used,

the test material. Other methods, such as ionizing and non-

provided it is first ascertained that the reagent is of sufficiently

ionizing irradiation, ultraviolet, dry heat, and surface or vapor

high purity to permit its use without lessening the accuracy of

phase disinfection, are also acceptable if these methods do not

the determination.

harm the material and do not have residue effects or if all traces

6.2 Purity of Water—Unless otherwise indicated, references of the disinfectant can be removed prior to testing. Consult the

to water shall be understood to mean reagent water as certified test material manufacturer or conduct tests with the test

by Type II of Specification D1193. It should conform to the material to determine the best method of sterilization. Specific

Type A specifications for microbial classification. details for decontamination depend upon the method selected

and should be worked out before actual testing begins within

6.3 Microbiological Media—Choose appropriate media de-

the QA/QC framework.

pending upon the test microorganism selected. Commercially

prepared media may be acceptable, but it may be necessary to

8.3 Equilibrate or bring to near equilibrium samples in the

prepare organism specific media. References should be con- chamber before inoculation with the test organism. Equilibra-

sulted to determine the proper media for optimal growth of the

tion time will depend upon both the material to be tested and

test organism. the chamber relative humidity selected for the test. Determine

equilibration times for each material prior to testing.

7. Characterization of Static Chamber

8.3.1 Ascertain equilibration by determining when the bulk

7.1 Characterize static chambers for all environmental pa- moisture content of the material reaches a constant value. The

rameters being measured before any material evaluations are

use of a calibrated analytical balance is recommended.

performed. Chambers should be characterized for at least

8.3.2 Compute the bulk moisture content of the test material

relative humidity and temperature. Take sufficient readings to

as follows:

ensure that the conditions will be maintained throughout the

MC 5 M 2 M /M × 100 (1)

@~ ! #

b d d

course of the experiment and will meet the QA/QC standards

where:

developed for a specific test.

7.1.1 Equilibration—Equilibrate disinfected chambers con-

MC = bulk moisture content (%),

M = mass of the small piece (g), and

taining hygrometers before taking the first relative humidity

b

M = mass of the small piece after drying (g).

reading. Place the hygrometers on a shelf for ease of reading

d

through the walls of the chamber without opening the door.

M may be determined either by oven drying at 105 to

d

Take multiple sequential readings at appropriate intervals that

110 °C or desiccation to constant weight depending upon the

were determined experimentally. The variation of the instru-

test material. Time required for drying is determined experi-

mentation must be determined and taken into consideration.

mentally. A sample can be considered dry when no significant

For example, a minimum of four similar readings (65 %) over

weight change is detected in two consecutive weighings at least

an 8 h period may be determ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.