ASTM E1317-97a

(Test Method)Standard Test Method for Flammability of Marine Surface Finishes

Standard Test Method for Flammability of Marine Surface Finishes

SCOPE

1.1 This fire-test-response standard describes a procedure for measuring fire properties associated with flammable behavior of surface finishes used on noncombustible substrates aboard ship (Note 1). In particular, these include surface finishes intended for use in ship construction such as deck surfacing materials, bulkhead and ceiling veneers including any adhesives used to fasten the veneers to the bulkheads and ceilings, paints, and exposed treatment of insulating materials. Note 1-This test method has been prepared to closely follow the test procedure of IMO Resolution A.653(16) (1). Optional provisions not applicable to the domestic use of this test method have been deleted.

1.2 Tests performed according to this test method are intended to yield fire properties that, when appropriately interpreted, can be used to select materials and surface treatments that will limit the rapid growth and spread of fire.

1.3 This test method requires a specific range of specimen radiant thermal exposure for measuring fire properties.

1.4 This standard should be used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions and should not be used to describe or appraise the fire-hazard or fire-risk of materials, products, or assemblies under actual fire conditions. However, results of the test may be used as elements of a fire-hazard assessment or a fire-risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard or fire risk of a particular end use.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1317 – 97a An American National Standard

Standard Test Method for

Flammability of Marine Surface Finishes

This standard is issued under the fixed designation E 1317; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 84 Test Method for Surface Burning Characteristics of

Building Materials

1.1 This fire-test-response standard covers a procedure for

E 162 Test Method for Surface Flammability of Materials

measuring fire properties associated with flammable behavior

Using a Radiant Heat Energy Source

of surface finishes used on noncombustible substrates aboard

E 176 Terminology of Fire Standards

ship (Note 1). In particular, these include surface finishes

E 286 Test Method for Surface Flammability of Building

intended for use in ship construction such as deck surfacing

Materials Using an 8-ft (2.44-m) Tunnel Furnace

materials, bulkhead and ceiling veneers including any adhe-

E 648 Test Method for Critical Radiant Flux of Floor-

sives used to fasten the veneers to the bulkheads and ceilings,

Covering Systems Using a Radiant Heat Energy Source

paints, and exposed treatment of insulating materials.

E 970 Test Method for Critical Radiant Flux of Exposed

NOTE 1—This test method has been prepared to closely follow the test

Attic Floor Insulation Using a Radiant Heat Energy

procedure of IMO Resolution A.653(16) (1). Optional provisions not

Source

applicable to the domestic use of this test method have been deleted.

E 1321 Test Method for Determining Material Ignition and

1.2 Tests performed according to this test method are 3

Flame Spread Properties

intended to yield fire properties that, when appropriately

2.2 Code of Federal Regulations (CFR):

interpreted, can be used to select materials and surface treat- 5

CFR Title 46, Part 164.009, Noncombustible Materials

ments that will limit the rapid growth and spread of fire.

2.3 ASTM Adjuncts:ASTM

1.3 This test method requires a specific range of specimen

Detailed drawings (19), construction information, and parts

radiant thermal exposure for measuring fire properties.

list (Adjunct to E1317)

1.4 This standard should be used to measure and describe

3. Terminology

the response of materials, products, or assemblies to heat and

flame under controlled conditions and should not be used to

3.1 Definitions—For definitions of general terms used in

describe or appraise the fire-hazard or fire-risk of materials,

this test method, refer to Terminology E 176.

products, or assemblies under actual fire conditions. However,

3.2 Definitions of Terms Specific to This Standard:

results of the test may be used as elements of a fire-hazard

3.2.1 compensating thermocouple, n—a thermocouple for

assessment or a fire-risk assessment which takes into account

the purpose of generating an electrical signal representing

all of the factors which are pertinent to an assessment of the

long-term changes in the stack metal temperatures wherein a

fire hazard or fire risk of a particular end use.

fraction of the signal generated is subtracted from the signal

1.5 This standard does not purport to address all of the

developed by the stack-gas thermocouples.

safety concerns, if any, associated with its use. It is the

3.2.2 critical flux at extinguishment, n— a flux level at the

responsibility of the user of this standard to establish appro-

specimen surface corresponding to the distance of farthest

priate safety and health practices and determine the applica-

advance and subsequent self-extinguishment of the flame on

bility of regulatory limitations prior to use. For specific hazard

the centerline of a specimen.

statements, see Section 7.

3.2.2.1 Discussion—The flux reported is based on calibra-

tion tests with a special calibration dummy specimen.

2. Referenced Documents

3.2.3 dummy specimen—a noncombustible (as defined by

2.1 ASTM Standards:

46 CFR 164.009) specimen used for standardizing the operat-

ing condition of the equipment, roughly 20 mm in thickness

with a density of 7506 100 kg/m .

This test method is under the jurisdiction of ASTM Committee E-5 on Fire

Standards and is the direct responsibility of Subcommittee E05.22 on Surface

Annual Book of ASTM Standards, Vol 04.07.

Burning.

Discontinued; see 1992 Annual Book of ASTM Standards, Vol 04.07.

Current edition approved June 10, 1997. Published August 1997. Originally

Available from Superintendent of Documents, U.S. Government Printing

published as E 1317 – 90. Last previous edition E 1317 – 97.

Office, Washington, DC 20402.

The boldface numbers in parentheses refer to a list of references at the end of

Detailed drawings are available from ASTM Headquarters. Request

this standard.

ADJE1317.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1317

3.2.4 fume stack—a box-like duct with thermocouples and thermocouples as the burning progresses. Results are reported

baffles through which flames and hot fumes from a burning in terms of heat for ignition, heat for sustained burning, critical

specimen pass whose purpose is to permit measurement of the flux at extinguishment, and heat release of the specimen during

heat release from the burning specimen. burning.

3.2.5 heat for ignition—the product of time from initial

5. Significance and Use

specimen exposure until the flame front reaches the 150-mm

position and the flux level at this position, the latter obtained in 5.1 This test method provides a means for evaluation of the

flammable performance of surface finish materials used in

prior calibration of the apparatus.

constructing and outfitting ships.

3.2.6 heat for sustained burning—the product of time from

5.2 A specimen of the surface finish of concern is mounted

initial specimen exposure until the arrival of the flame front,

on the support material contemplated for use and subjected to

and the incident flux level at that same location as measured

a controlled significant radiant-flux exposure.

with a dummy specimen during calibration.

5.3 All specimens are tested while mounted in a vertical

3.2.7 marine board—an insulation board of 750 6 100

plane.

kg/m density that meets the noncombustibility criteria of 46

5.4 The following surfaces are exposed to test:

CFR 164.009.

5.4.1 Bulkhead specimens having surface veneers, fabrics,

3.2.8 measured heat release of specimen—the observed heat

or painted finishes are tested on one or both exposed sides.

release under the variable flux field imposed on the specimen

5.4.2 Ceiling finish materials shall be tested on the lower

and measured as defined by this test method.

exposed surface.

3.2.9 mirror assembly—a mirror, marked and aligned with

the viewing rakes, used as an aid in quickly identifying and 5.4.3 For ceiling finish materials which are perforated and

air backed, tests also shall be conducted on the back (upper)

tracking the flame front progress.

3.2.10 reverberatory wires—a wire mesh located in front of, surface of the material.

5.4.4 Deck finish and flooring materials are tested on the

but close to, the radiating surface of the panel heat source

which serves to enhance the combustion efficiency and in- upper exposed surface.

5.4.5 Protective membranes or finishes on insulation mate-

crease the radiance of the panel.

3.2.11 special calibration dummy specimen—a dummy rials are tested on the air-exposed face or faces.

5.5 This test method provides fire properties that relate to

specimen as defined by Fig. 1, made of the same material as the

the flammability of the specimens tested. These include ignit-

dummy specimen, intended only for use in calibration of flux

ability, heat exposure for continued burning, critical flux at

gradient along the specimen.

extinguishment, and heat-release behavior under varying flux-

3.2.12 viewing rakes—a set of bars with wires spaced at

exposure conditions applied.

50-mm intervals for the purpose of increasing the precision of

5.6 This test method does not provide:

timing the flame front progress along the specimen.

5.6.1 Full information on fire properties of surface-finish

4. Summary of Test Method

materials supported by backing materials other than those

tested.

4.1 This test provides methods for evaluating the flamma-

5.6.2 Full information on surface-finish materials when

bility characteristics of 155 by 800-mm specimens in a vertical

used in other thicknesses than those tested.

orientation. The specimens are exposed to a graded radiant-flux

5.6.3 Methods for using the fire property measurements as a

field supplied by a gas-fired radiant panel. Means are provided

measure for classifying the fire risk or hazard of the specimens

for observing the times to ignition, spread, and extinguishment

tested.

of flame along the length of the specimen as well as for

measuring the compensated millivolt signal of the stack gas

6. Apparatus

6.1 Test Equipment— Figs. 2-6 show photographs of the

equipment as assembled ready for test. Detailed drawings and

a parts list are available from ASTM. These provide engineer-

ing information necessary for the fabrication of the main

frame, specimen holders, stack, and other parts of the equip-

ment. Some commercially available units have added safety

features that are not described in the drawings. Brief parts list

for the test equipment assembly includes:

6.1.1 Main Frame (see Fig. 2(a) and Fig. 2(b) consisting of

two separate sections; the burner frame and the specimen

support frame. These two units are bolted together with

threaded rods permitting flexibility in mechanical alignment.

6.1.2 Specimen Holders that provide for support of the

specimen during test. At least two of these are required. Using

three of these will prevent delays resulting from required

cooling of holders prior to mounting specimens.

NOTE 1—All dimensions are in millimetres.

FIG. 1 Dummy Specimen for Flux Gradient Calibration 6.1.3 Specimen Fume Stack, fabricated of stainless sheet

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1317

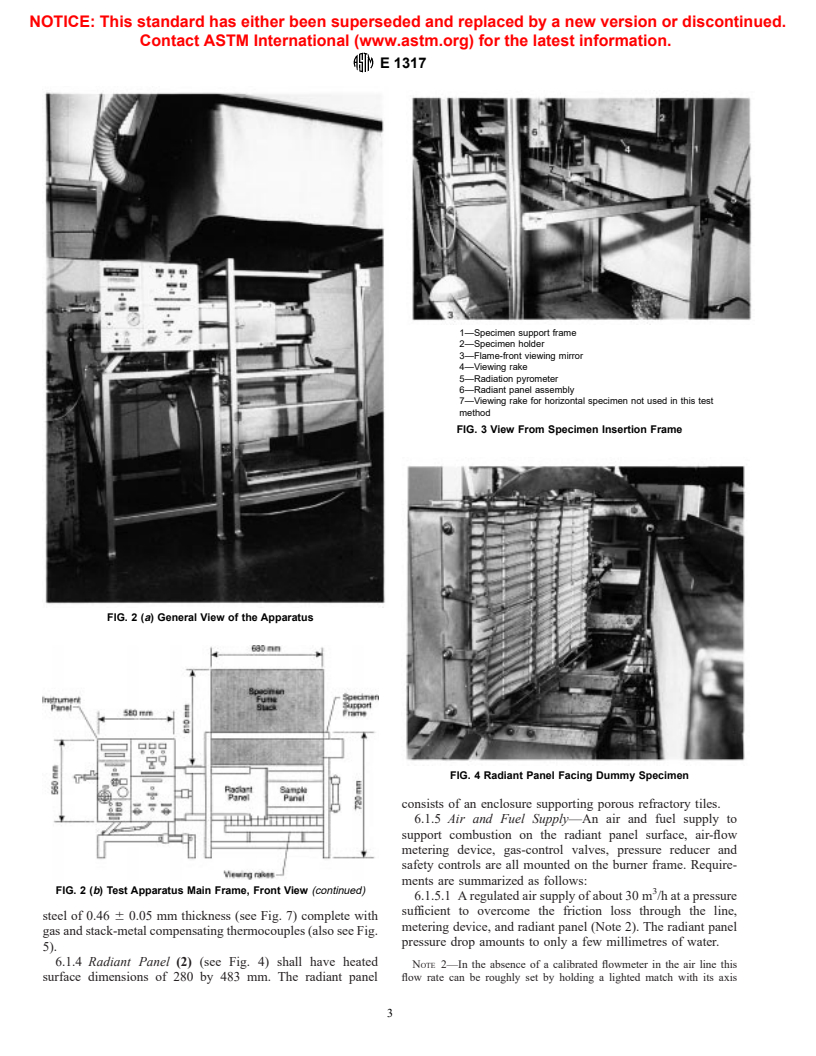

1—Specimen support frame

2—Specimen holder

3—Flame-front viewing mirror

4—Viewing rake

5—Radiation pyrometer

6—Radiant panel assembly

7—Viewing rake for horizontal specimen not used in this test

method

FIG. 3 View From Specimen Insertion Frame

FIG. 2 (a) General View of the Apparatus

FIG. 4 Radiant Panel Facing Dummy Specimen

consists of an enclosure supporting porous refractory tiles.

6.1.5 Air and Fuel Supply—An air and fuel supply to

support combustion on the radiant panel surface, air-flow

metering device, gas-control valves, pressure reducer and

safety controls are all mounted on the burner frame. Require-

ments are summarized as follows:

FIG. 2 (b) Test Apparatus Main Frame, Front View (continued) 3

6.1.5.1 A regulated air supply of about 30 m /h at a pressure

sufficient to overcome the friction loss through the line,

steel of 0.46 6 0.05 mm thickness (see Fig. 7) complete with

metering device, and radiant panel (Note 2). The radiant panel

gas and stack-metal compensating thermocouples (also see Fig.

pressure drop amounts to only a few millimetres of water.

5).

6.1.4 Radiant Panel (2) (see Fig. 4) shall have heated

NOTE 2—In the absence of a calibrated flowmeter in the air line this

surface dimensions of 280 by 483 mm. The radiant panel flow rate can be roughly set by holding a lighted match with its axis

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1317

1—Pilot flame

FIG. 5 Rear View of Specimen Supported in Equipment Showing

2—Viewing rake

Specimen Clamp, Stack and Handle of Stack Thermocouple

Assembly

NOTE 1—Two burners are provided; only one for the non-contracting

pilot is operating.

horizontal and close to the panel tile face. The match flame should deviate

FIG. 6 Pilot Flame and Dummy Assembly

from the vertical by about 10°.

6.1.5.2 The fuel gas used shall be either natural gas or

methane. A pressure regulator shall be provided to maintain a

constant supply pressure. The gas shall be controlled either by

a manually adjusted needle valve or a venturi mixer. The

venturi mixer will allow control of the flux level of the panel

by adjusting only the air valve. Safety devices shall include an

electrically operated shutoff valve to prevent gas flow in the

event of electric power failure, air pressure failure, or loss of

heat at the burner surface. The fuel gas flow requirements shall

be 1.0 to 3.7 m /h at a pressure sufficient to overcome pressure

losses.

6.1.6 The specimen holder, pilot-flame holder, fume stack,

flame-front viewing rakes, radiation pyrometer, and mirror are

all assembled on the specimen support frame. The arrangement

FIG. 7 Stack—Specimen Position Dimensions

of parts on this frame is evident in Fig. 2(a), Fig. 2(b), and Fig.

3. the apparatus in the position of the specimen except during

6.1.7 A dummy specimen of marine board of the thickness actual testing.

and density specified in the test procedure shall be mounted on 6.2 Instrumentation:

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1317

6.2.1 Total Radiation Pyrometer—This instrument shall be least 1-m separation between it and the walls of the test room.

compensated for its temperature variation and shall have a No combustible finish material of ceiling, floor, or walls shall

sensitivity between the thermal wavelengths of 1 and 9 μm that be located within2mofthe radiant heat source.

is nominally constant and shall view a centrally located area on 6.3.4 Air Supply—Access to an exterior supply of air, to

the radiant panel of about 150 by 300 mm. The instrument shall

replace that removed by the exhaust system, is required. This

be rigidly mounted on the specimen support frame in such a shall be arranged in such a way that the ambient temperature

manner that it will be directed at the radiant panel surface

remains reasonably stable (for example, the air might be taken

oriented for specimens in the vertical positions. from an adjoining heated building).

6.3.5 Room Draughts—Measurement

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.