ASTM E2786-10(2015)

(Test Method)Standard Test Methods for Measuring Expansion of Intumescent Materials Used in Firestop and Joint Systems

Standard Test Methods for Measuring Expansion of Intumescent Materials Used in Firestop and Joint Systems

SIGNIFICANCE AND USE

5.1 These test methods are intended to measure the material’s expansion after heating.

5.2 The test methods also provide a means to determine the expansion factor.

SCOPE

1.1 These test methods determine, by measurement, the expansion of intumescent materials used in firestop and joint systems under specified conditions.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The text of these test methods references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the fire test response standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2786 − 10 (Reapproved 2015)

Standard Test Methods for

Measuring Expansion of Intumescent Materials Used in

1

Firestop and Joint Systems

This standard is issued under the fixed designation E2786; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions of Terms Specific to This Standard:

3.3 expansion, n—anincreaseinthedimensionsastheresult

1.1 These test methods determine, by measurement, the

of heating.

expansion of intumescent materials used in firestop and joint

systems under specified conditions.

3.4 expansion factor, n—the ratio of the material height

before and after heating, under test conditions that allow

1.2 The values stated in inch-pound units are to be regarded

expansion only in the vertical direction.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

3.5 intumescent, adj—characterized by swelling when ex-

and are not considered standard.

posed to high surface temperatures or flames.

1.3 The text of these test methods references notes and

4. Summary of Test Method

footnotes which provide explanatory material. These notes and

4.1 These test methods place a material of a specified

footnotes (excluding those in tables and figures) shall not be

considered as requirements of the fire test response standard. thickness or volume into a specific device that is capable of

heating the material.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4.2 After the material is heated, its dimensional or volumet-

responsibility of the user of this standard to establish appro- ric change is measured.

priate safety and health practices and determine the applica-

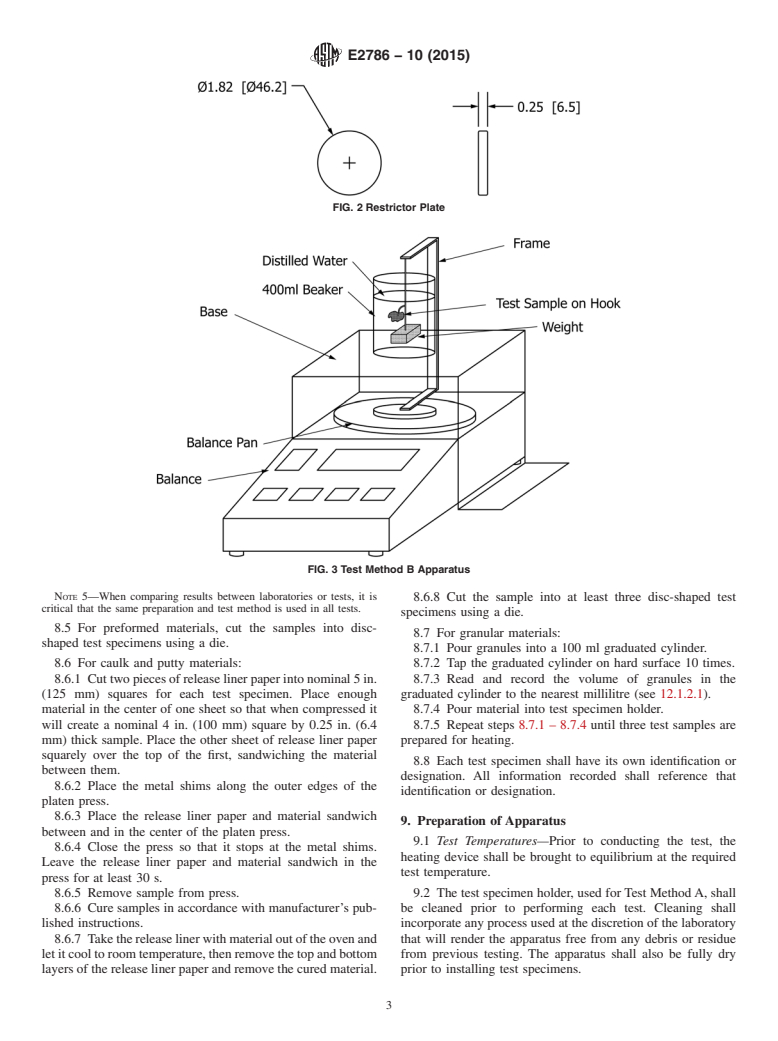

4.3 Two test methods are provided, one using a test speci-

bility of regulatory limitations prior to use.

men holder (Test Method A) and the other using a water

displacement method (Test Method B).

2. Referenced Documents

4.4 Test MethodAmay be used for measuring expansion of

2

2.1 ASTM Standards:

any material.

E176 Terminology of Fire Standards

4.5 Test Method B may be used for measuring expansion of

E631 Terminology of Building Constructions

any material, except for those materials that are granular, that

are susceptible to absorbing paraffin in conditioned pre-

3. Terminology

expandedstateorpost-expandedstate,orthataresusceptibleto

3.1 Definitions—Definitions in the following standards will

damage or deformation in a post-expanded state.

prevail for terms not defined in these test methods.

4.6 The test method used must be reported, as use of

3.1.1 For definitions of general terms used in these test

different test methods will result in different expansion factors.

methods related to building construction, refer to Terminology

E631.

5. Significance and Use

3.1.2 For definitions of general terms used in these test

methods related to fire standards, refer to Terminology E176.

5.1 These test methods are intended to measure the materi-

al’s expansion after heating.

5.2 The test methods also provide a means to determine the

1

These test methods are under the jurisdiction of ASTM Committee E06 on

expansion factor.

Performance of Buildings and is the direct responsibility of Subcommittee E06.21

on Serviceability.

Current edition approved Jan. 1, 2015. Published January 2015. Originally 6. Apparatus

approved in 2010. Last previous edition approved in 2010 as E2786–10. DOI:

6.1 Heating Device—An enclosed furnace or oven or simi-

10.1520/E2786-10R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or lar equipment capable of maintaining the temperature specified

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

herein and large enough to contain the test specimen holder.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 6.2 Test Method A—Test Specimen Holder Method:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2786 − 10 (2015)

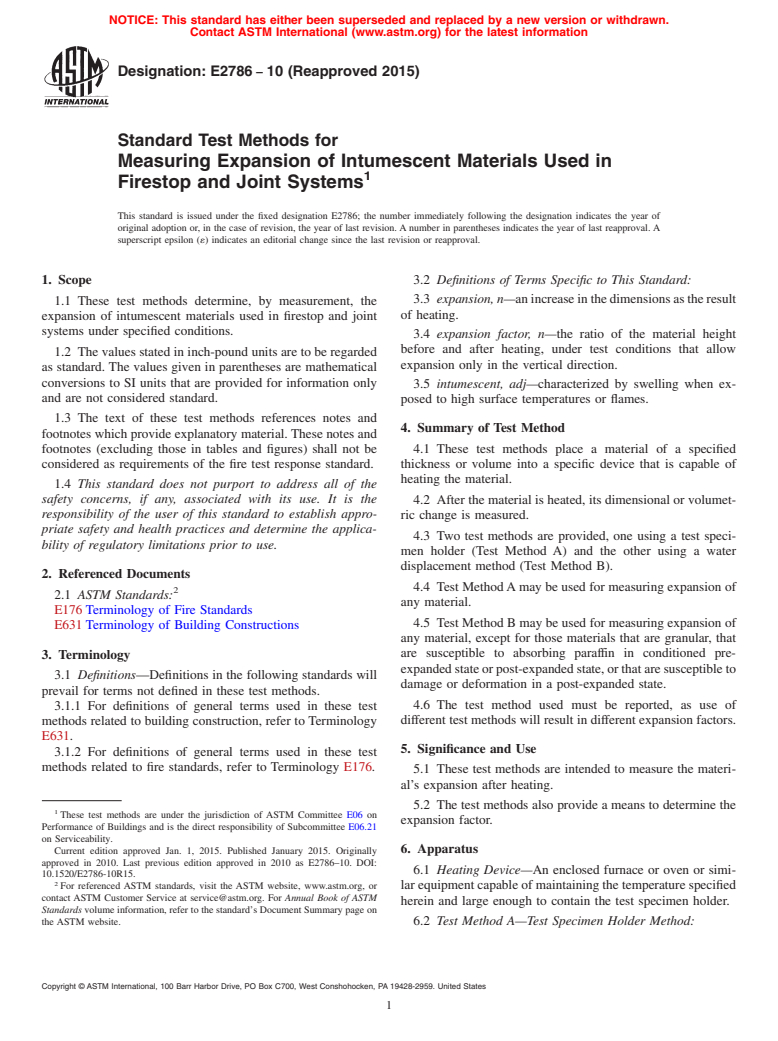

6.2.1 Test Specimen Holder—A Series 300 stainless steel 6.3.7 Paraffın wax with Melting Point of 132.8°F – 134.6°F

assembly consisting of at least two cylinders contained in a (56°C – 57°C), or equivalent.

frame into which the material is placed. Each cylinder shall be 6.3.8 Distilled Water.

nominally 5 in. (130 mm) high with a nominal 2 in. (50 mm)

7. Hazards

outside diameter. Fig. 1 is an example of a test specimen

holder. Wall thickness shall be nominal 0.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2786 − 10 E2786 − 10 (Reapproved 2015)

Standard Test Methods for

Measuring Expansion of Intumescent Materials Used in

1

Firestop and Joint Systems

This standard is issued under the fixed designation E2786; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods determine, by measurement, the expansion of intumescent materials used in firestop and joint systems

under specified conditions.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 The text of these test methods references notes and footnotes which provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of the fire test response standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E176 Terminology of Fire Standards

E631 Terminology of Building Constructions

3. Terminology

3.1 Definitions—Definitions in the following standards will prevail for terms not defined in these test methods.

3.1.1 For definitions of general terms used in these test methods related to building construction, refer to Terminology E631.

3.1.2 For definitions of general terms used in these test methods related to fire standards, refer to Terminology E176.

3.2 Definitions of Terms Specific to This Standard:

3.3 expansion, n—an increase in the dimensions as the result of heating.

3.4 intumescent, adj—characterized by swelling when exposed to high surface temperatures or flames.

3.4 expansion factor, n—the ratio of the material height before and after heating, under test conditions that allow expansion only

in the vertical direction.

3.5 intumescent, adj—characterized by swelling when exposed to high surface temperatures or flames.

4. Summary of Test Method

4.1 These test methods place a material of a specified thickness or volume into a specific device that is capable of heating the

material.

4.2 After the material is heated, its dimensional or volumetric change is measured.

4.3 Two test methods are provided, one using a test specimen holder (Test Method A) and the other using a water displacement

method (Test Method B).

1

These test methods are under the jurisdiction of ASTM Committee E06 on Performance of Buildings and is the direct responsibility of Subcommittee E06.21 on

Serviceability.

Current edition approved Oct. 1, 2010Jan. 1, 2015. Published November 2010January 2015. Originally approved in 2010. Last previous edition approved in 2010 as

E2786–10. DOI: 10.1520/E2786-10.10.1520/E2786-10R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2786 − 10 (2015)

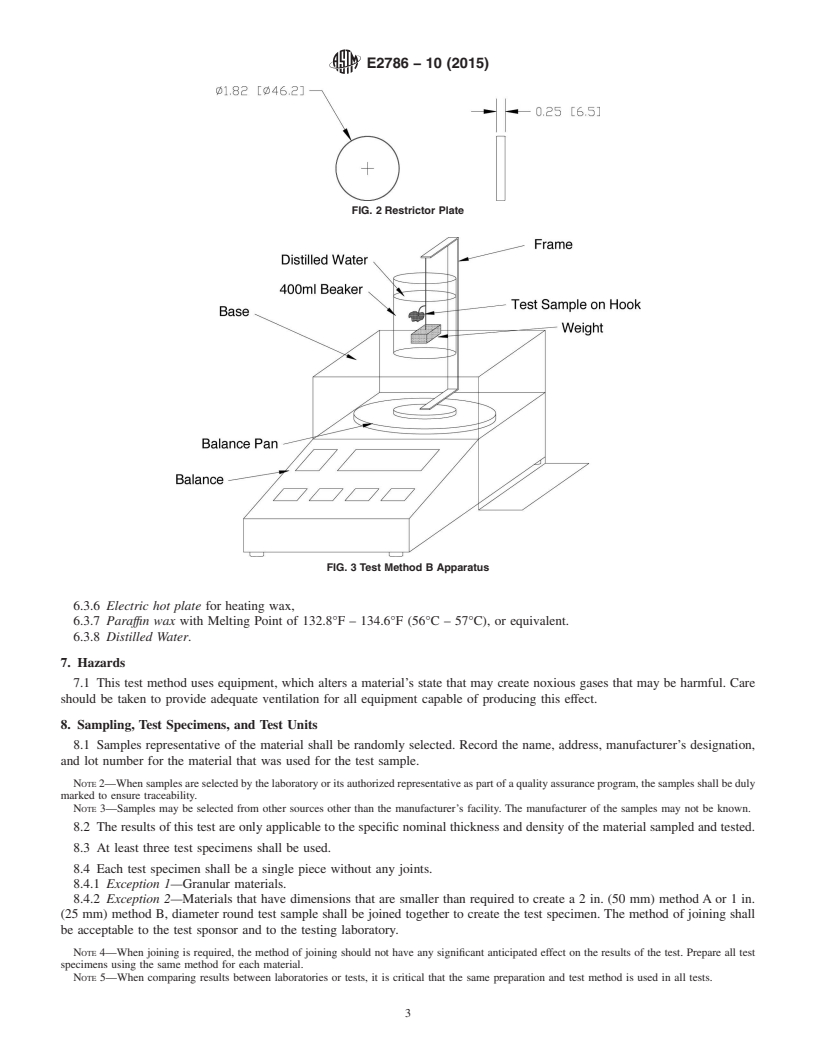

4.4 Test Method A may be used for measuring expansion of any material.

4.5 Test Method B may be used for measuring expansion of any material, except for those materials that are granular, that are

susceptible to absorbing paraffin in conditioned pre-expanded state or post-expanded state, or that are susceptible to damage or

deformation in a post-expanded state.

4.6 The test method used must be reported, as use of different test methods will result in different expansion factors.

5. Significance and Use

5.1 These test methods are intended to measure the material’s expansion after heating.

5.2 The test methods also provide a means to determine the expansion factor.

6. Apparatus

6.1 Heating Device—An enclosed furnace or oven or similar equipment capable of maintaining the temperature specified herein

and large enough to contain the test specimen holder.

6.2 Test Method A—Test Specimen Holder Method:

6.2.1 Test Specimen Holder—A

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.