ASTM E3414-23

(Test Method)Standard Test Method for Constant Torque Thermal Cycling of Cylindrical Shape Memory Alloy Specimens

Standard Test Method for Constant Torque Thermal Cycling of Cylindrical Shape Memory Alloy Specimens

SIGNIFICANCE AND USE

4.1 Constant torque thermal cycling tests determine the effect of shear stress on the transformation properties such as transformation temperatures, actuation shear strain and residual shear strain of a shape memory alloy. This test is done to provide data for the characterization selection of shape memory alloy materials, quality control, design allowables and actuator design (1-3).5 The tests should be used for one thermal cycle but may be used for repeated thermal cycles as agreed upon between supplier and customer.

4.2 Measurement of the specimen's motion closely parallels many shape memory actuator applications and provides a result that is applicable to the function of the material.

4.3 This test method may be used for cylindrical specimens such as wire, round tube or bar forms. Thus, it is able to provide an assessment of the product in its semi-finished form.

4.4 This test method provides a simple method for determining transformation temperatures by heating and cooling specimens through their full thermal transformation under torque.

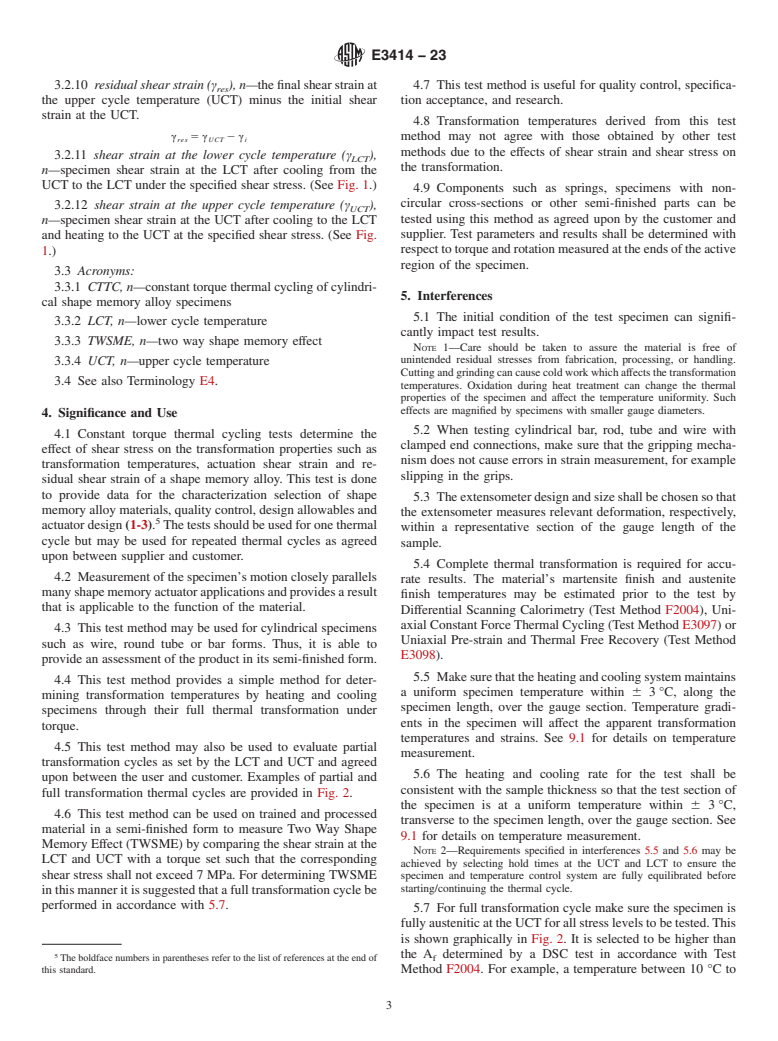

4.5 This test method may also be used to evaluate partial transformation cycles as set by the LCT and UCT and agreed upon between the user and customer. Examples of partial and full transformation thermal cycles are provided in Fig. 2.

FIG. 2 Effects of Shear Stress and Upper Cycle Temperature on Test Results

Note 1: A) UCT sufficient for complete Austenitic transformation. B) UCT not sufficient for complete Austenitic transformation. “τ” is the applied shear stress.

4.6 This test method can be used on trained and processed material in a semi-finished form to measure Two Way Shape Memory Effect (TWSME) by comparing the shear strain at the LCT and UCT with a torque set such that the corresponding shear stress shall not exceed 7 MPa. For determining TWSME in this manner it is suggested that a full transformation cycle be performed in accordance with 5.7.

4.7 This test method is useful for quality control, sp...

SCOPE

1.1 This test method will define procedures for thermomechanical cycling of shape memory alloys (SMA) material and components with circular cross-sections under constant torque. This test method will measure the transformation properties such as transformation temperatures, actuation shear strain and residual shear strain, when a shape memory alloy is thermally cycled through the phase transformation under a constant applied torque. This test is done to provide data for the characterization selection of shape memory alloy materials, quality control, design allowables and actuator design.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E3414 − 23

Standard Test Method for

Constant Torque Thermal Cycling of Cylindrical Shape

1

Memory Alloy Specimens

This standard is issued under the fixed designation E3414; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E83 Practice for Verification and Classification of Exten-

someter Systems

1.1 This test method will define procedures for thermome-

E209 Practice for Compression Tests of Metallic Materials at

chanical cycling of shape memory alloys (SMA) material and

Elevated Temperatures with Conventional or Rapid Heat-

components with circular cross-sections under constant torque.

ing Rates and Strain Rates

This test method will measure the transformation properties

E606/E606M Test Method for Strain-Controlled Fatigue

such as transformation temperatures, actuation shear strain and

Testing

residual shear strain, when a shape memory alloy is thermally

E691 Practice for Conducting an Interlaboratory Study to

cycled through the phase transformation under a constant

Determine the Precision of a Test Method

applied torque. This test is done to provide data for the

E1169 Practice for Conducting Ruggedness Tests

characterization selection of shape memory alloy materials,

E2207 Practice for Strain-Controlled Axial-Torsional Fa-

quality control, design allowables and actuator design.

tigue Testing with Thin-Walled Tubular Specimens

1.2 The values stated in SI units are to be regarded as

E2368 Practice for Strain Controlled Thermomechanical

standard. No other units of measurement are included in this

Fatigue Testing

standard.

E3097 Test Method for Uniaxial Constant Force Thermal

1.3 This standard does not purport to address all of the Cycling of Shape Memory Alloys

safety concerns, if any, associated with its use. It is the

E3098 Test Method for Mechanical Uniaxial Pre-strain and

responsibility of the user of this standard to establish appro- Thermal Free Recovery of Shape Memory Alloys

priate safety, health, and environmental practices and deter-

F2004 Test Method for Transformation Temperature of

mine the applicability of regulatory limitations prior to use. Nickel-Titanium Alloys by Thermal Analysis

1.4 This international standard was developed in accor-

F2005 Terminology for Nickel-Titanium Shape Memory

dance with internationally recognized principles on standard-

Alloys

ization established in the Decision on Principles for the

2.2 Other Standards:

Development of International Standards, Guides and Recom-

IEEE/ASTM SI 10 American National Standard for Metric

2

mendations issued by the World Trade Organization Technical

Practice

Barriers to Trade (TBT) Committee. 3

ASQ C1 General Requirements for a Quality Program

4

ISO 9001 Quality Management Systems—Requirements

2. Referenced Documents

2

3. Terminology

2.1 ASTM Standards:

E4 Practices for Force Calibration and Verification of Test-

3.1 Definitions—The terms specific to this test method are

ing Machines

defined in this section. All other terms used in this test method

E21 Test Methods for Elevated Temperature Tension Tests of

are in accordance with Terminologies in Terminology F2005,

Metallic Materials

Practice E2207, Test Method E3097 and Test Method E3098.

All shear stress and shear strain defined in this test method are

determined on the outer diameter in accordance with Practice

1

E2207, unless otherwise stated.

This test method is under the jurisdiction of ASTM Committee E08 on Fatigue

and Fracture and is the direct responsibility of Subcommittee E08.05 on Cyclic

Deformation and Fatigue Crack Formation.

Current edition approved Nov. 1, 2023. Published November 2023. DOI:

3

10.1520/E3414–23 Available from American Society for Quality (ASQ), 600 N. Plankinton Ave.,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Milwaukee, WI 53203, http://www.asq.org.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from International Organization for Standardization (ISO), ISO

Standards volume information, refer to the standard’s Document Summary page on Central Secretariat, Chemin de Blandonnet 8, CP 401, 1214 Vernier, Geneva,

the ASTM website. Switzerland, https://www.iso.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E3414 − 23

3.1.1 Discussion—During thermomechanical cycling of 3.2.4 cooling trans

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.