ASTM E1695-95

(Test Method)Standard Test Method for Measurement of Computed Tomography (CT) System Performance

Standard Test Method for Measurement of Computed Tomography (CT) System Performance

SCOPE

1.1 This test method provides instruction for determining the spatial resolution and contrast sensitivity in X-ray and -ray computed tomography (CT) images. The determination is based on examination of the CT image of a uniform disk of material. The spatial resolution measurement is derived from an image analysis of the sharpness at the edge of the disk. The contrast sensitivity measurement is derived from an image analysis of the statistical noise at the center of the disk.

1.2 This test method is more quantitative and less susceptible to interpretation than alternative approaches because the required disk is easy to fabricate and the analysis is immune to cupping artifacts. This test method may not yield meaningful results if the disk image occupies less than a significant fraction of the field of view.

1.3 This test method may also be used to evaluate other performance parameters. Among those characteristics of a CT system that are detectable with this test method are: the mid-frequency enhancement of the reconstruction kernel, the presence (or absence) of detector crosstalk, the undersampling of views, and the clipping of unphysical (that is, negative) CT numbers (see Air Force Technical Report WL-TR-94-4021). It is highly likely that other characteristics as well can be detected with this test method.

1.4 The values stated in SI units are to be regarded as the standard. Inch-pound units are provided for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1695 – 95 An American National Standard

Standard Test Method for

Measurement of Computed Tomography (CT) System

Performance

This standard is issued under the fixed designation E 1695; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 1570 Practice for Computed Tomographic (CT) Exami-

nation

1.1 This test method provides instruction for determining

the spatial resolution and contrast sensitivity in X-ray and

3. Terminology

g-ray computed tomography (CT) images. The determination

3.1 Definitions—The definitions of terms relating to

is based on examination of the CT image of a uniform disk of

Gamma- and X-Radiology, which appear in Terminology

material. The spatial resolution measurement is derived from

E 1316 and Guide E 1441, shall apply to the terms used in this

an image analysis of the sharpness at the edge of the disk. The

test method.

contrast sensitivity measurement is derived from an image

3.2 Definitions of Terms Specific to This Standard:

analysis of the statistical noise at the center of the disk.

3.2.1 phantom—a part or item being used to quantify CT

1.2 This test method is more quantitative and less suscep-

system performance.

tible to interpretation than alternative approaches because the

3.2.2 test object—a part or specimen being subjected to CT

required disk is easy to fabricate and the analysis is immune to

examination.

cupping artifacts. This test method may not yield meaningful

3.3 Acronyms:

results if the disk image occupies less than a significant fraction

3.3.1 ERF—edge response function.

of the field of view.

3.3.2 PSF—point spread function.

1.3 This test method may also be used to evaluate other

3.3.3 MTF—modulation transfer function.

performance parameters. Among those characteristics of a CT

3.3.4 CDF—contrast discrimination function.

system that are detectable with this test method are: the

mid-frequency enhancement of the reconstruction kernel, the

4. Significance and Use

presence (or absence) of detector crosstalk, the undersampling

4.1 Two factors affecting the quality of a CT image are

of views, and the clipping of unphysical (that is, negative) CT

2 geometrical unsharpness and random noise. Geometrical un-

numbers (see Air Force Technical Report WL-TR-94-4021 ). It

sharpness limits the spatial resolution of a CT system, that is,

is highly likely that other characteristics as well can be detected

its ability to image fine structural detail in an object. Random

with this test method.

noise limits the contrast sensitivity of a CT system, that is, its

1.4 The values stated in SI units are to be regarded as the

ability to detect the presence or absence of features in an

standard. Inch-pound units are provided for information only.

object. Spatial resolution and contrast sensitivity may be

1.5 This standard does not purport to address all of the

measured in various ways. ASTM specifies spatial resolution

safety concerns, if any, associated with its use. It is the

be quantified in terms of the modulation transfer function

responsibility of the user of this standard to establish appro-

(MTF) and contrast sensitivity be quantified in terms of the

priate safety and health practices and determine the applica-

contrast discrimination function (CDF) (see Guide E 1441 and

bility of regulatory limitations prior to use.

Practice E 1570). This test method allows the purchaser or the

provider of CT systems or services, or both, to measure and

2. Referenced Documents

specify spatial resolution and contrast sensitivity.

2.1 ASTM Standards:

E 1316 Terminology for Nondestructive Examinations

5. Apparatus

E 1441 Guide for Computed Tomography (CT) Imaging

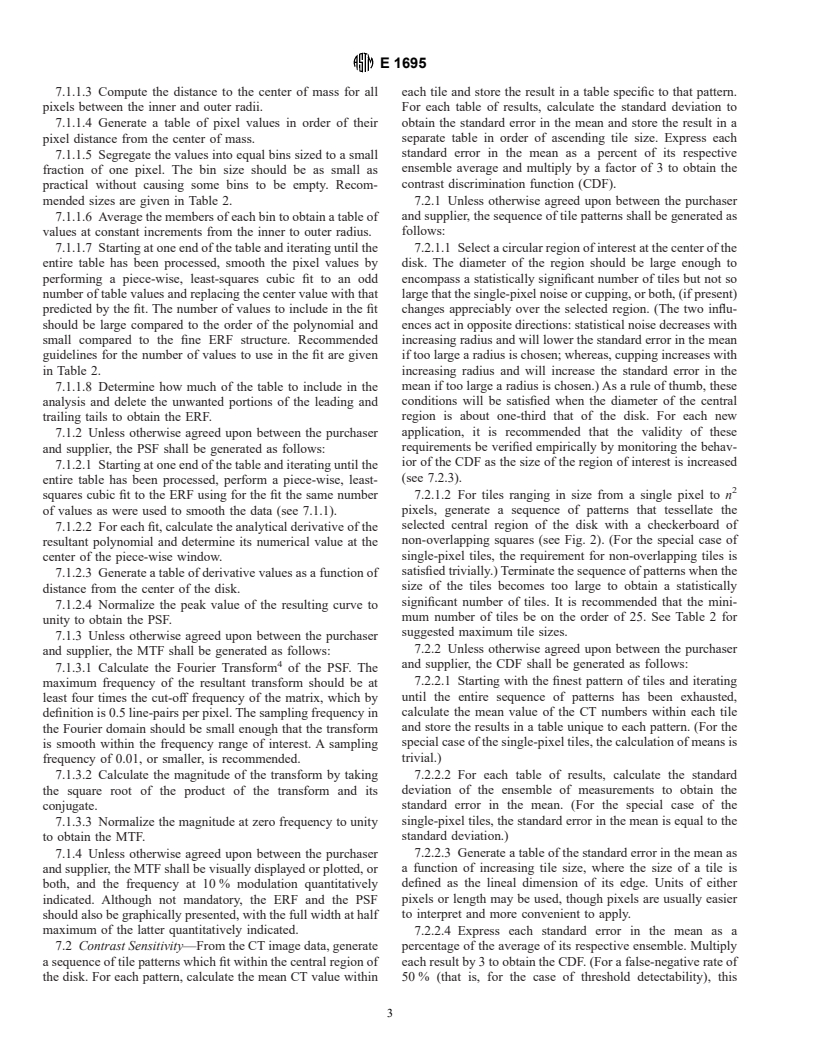

5.1 Disk Phantom—The disk phantom shall be a right

cylinder of uniform material conforming to the design and

This test method is under the jurisdiction of ASTM Committee E-7 on

material requirements in Table 1 and Fig. 1. Since spatial

Nondestructive Testing and is the direct responsibility of Subcommittee E07.01 on

resolution and contrast sensitivity depend on the examination

Radiology (X and Gamma) Method.

Current edition approved March 15, 1995. Published May 1995. task (that is, the test object and the specified CT parameters),

X-Ray Computed Tomography Standards (WL-TR-94-4021). Bossi, R. H. and

the application requirements must be fixed before the phantom

Nelson, J. M. Air Force Contract No. F33615-88-C-5404.

can be designed. In general, each examination task will require

Annual Book of ASTM Standards, Vol 03.03.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 1695

TABLE 1 Disk Phantom Design Requirements

Material The material, in conjunction with the diameter of the disk,

shall be such that the phantom approximates the

attenuation range of the test object. The material should

preferably be the same as that of the test object.

Diameter The diameter shall be such that the reconstruction of the disk

occupies a significant fraction of the resulting image. In

conjunction with the material, the diameter shall be such

that the phantom approximates the attenuation range of the

test object.

Thickness The thickness of the disk shall be greater than the slice

thickness used to inspect the test object.

Shape The perpendicularity of the axis of revolution with respect to

the surface used to mount the phantom on the CT system

shall not compromise the measurement of geometrical

unsharpness.

Finish The surface texture roughness of the curved surface shall not

compromise the measurement of geometrical unsharpness.

requirements take precedence and may dictate the selection of

another material. The design of the disk phantom is a matter of

agreement between the purchaser and the supplier.

6. Procedure

6.1 The phantom shall be mounted on the CT system with

the orientation of the axis of revolution of the disk normal to

the scan plane. The alignment shall not compromise the

measurement of geometrical unsharpness. Unless otherwise

agreed upon between purchaser and supplier, the phantom shall

be placed at the center of the field of view used for the test

object.

6.2 Unless otherwise agreed upon between purchaser and

supplier, the data acquisition parameters shall be identical to

those used for test object scans. The slice plane shall intercept

the phantom approximately midway between the flat faces of

the disk.

6.3 Unless otherwise agreed upon between purchaser and

supplier, the reconstruction parameters shall be identical to

those used for test object reconstructions.

6.4 Unless otherwise agreed upon between purchaser and

supplier, the display parameters shall be identical to those used

for test object display. It shall be verified by examination that

the disk image occupies an image at least two-thirds of the

FIG. 1 Disk Phantom

image matrix. Recommended guidelines are given in Table 2.

a separate phantom. The diameter of the disk relative to the

7. Interpretation of Results

field of view shall be such that the reconstructed image of the

7.1 Spatial Resolution—From the CT image data, generate

disk occupies a significant fraction of the image matrix.

the composite profile of the edge of the disk to obtain the edge

Recommended sizes are given in Table 2. The diameter and

response function (ERF). Calculate the derivative of the ERF

opacity of the disk shall be such that the phantom approximates

to obtain the point spread function (PSF). Calculate the

the attenuation range of the test object. If possible, the phantom 4

amplitude of the Fourier Transform of the PSF and normalize

should be of the same material as the test object, but the other

the results to unity at zero frequency to obtain the modulation

transfer function (MTF).

TABLE 2 Suggested Measurement Parameters

7.1.1 Unless otherwise agreed upon between the purchaser

and supplier, the ERF shall be generated as follows:

Image Matrix Disk Image Maximum Tile ERF Bin Number

7.1.1.1 Calculate the center of mass of the disk.

Size Diameter Size Size of Fit

7.1.1.2 Select the inner and outer radii with respect to the

(Pixels) (Pixels) (Pixels) (Pixels) Points

center of mass that comfortably bracket the edge.

256 235 12 0.100 11

512 470 24 0.050 21

The Fourier Transform and Its Applications, Ronald M. Bracewell, McGraw-

1024 940 48 0.025 41

Hill, NY, ISBN 0-07-007013-X.

E 1695

7.1.1.3 Compute the distance to the center of mass for all each tile and store the result in a table specific to that pattern.

pixels between the inner and outer radii. For each table of results, calculate the standard deviation to

obtain the standard error in the mean and store the result in a

7.1.1.4 Generate a table of pixel values in order of their

pixel distance from the center of mass. separate table in order of ascending tile size. Express each

standard error in the mean as a percent of its respective

7.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.