ASTM D4912-89(1994)

(Test Method)Standard Test Method for Fabric Stability of Vinyl-Coated Glass Yarn Insect Screening and Louver Cloth

Standard Test Method for Fabric Stability of Vinyl-Coated Glass Yarn Insect Screening and Louver Cloth

SCOPE

1.1 This test method provides a procedure for evaluating fabric stability by measuring the resistance to yarn slippage of filling yarns over warp yarns, or warp yarns over filling yarns in vinyl-coated glass yarn insect screening and louver cloth.

1.2 This test method shows the values in both SI units and inch-pound units. "SI units" is the technically correct name for a system of metric units known as the International System of Units. "Inch-pound units" is the technically correct name for the customary units used in the United States. The values stated in inch-pound units are to be regarded as the standard. The values in SI units are provided for information only.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

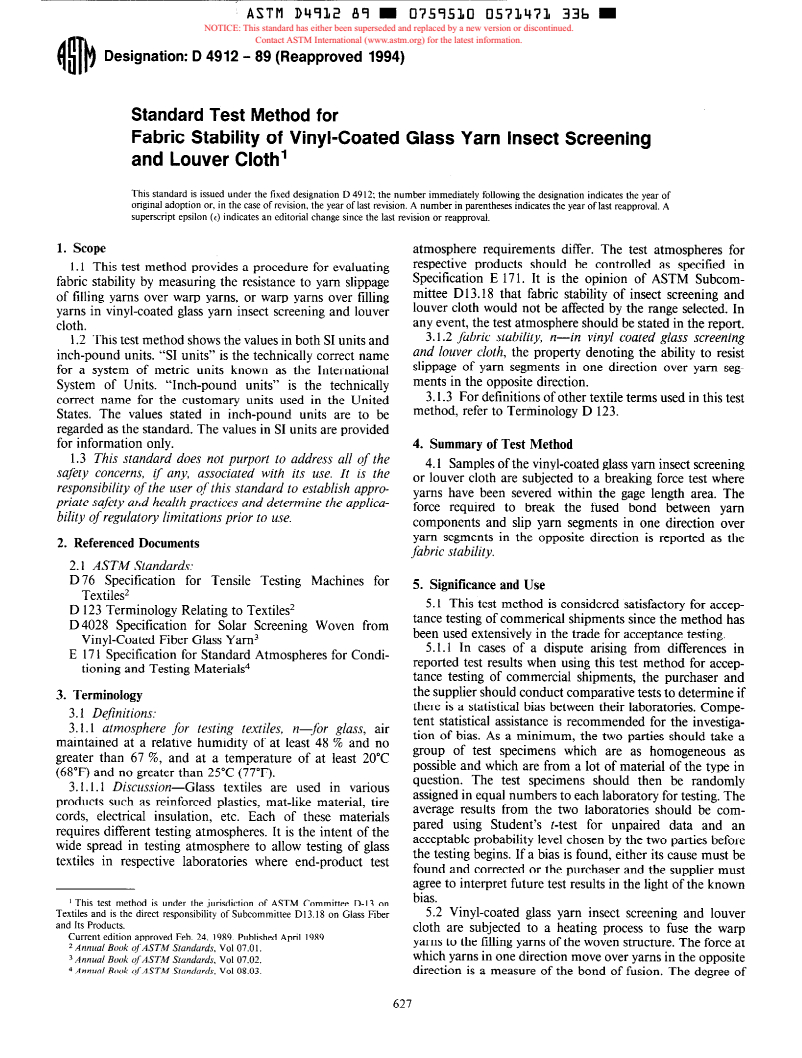

ASTM D4922 89 - 0759530 057L47L 336 -

Designation: D 4912 - 89 (Reapproved 1994)

Standard Test Method for

Fabric Stability of Vinyl-Coated Glass Yarn Insect Screening

and Louver Cloth’

This standard is issued under the fixed designation D 49 12; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (r) indicates an editorial change since the last revision or reapproval.

atmosphere requirements differ. The test atmospheres for

1. Scope

respective products should be controlled as specified in

1.1 This test method provides a procedure for evaluating

Specification E 17 1. It is the opinion of ASTM Subcom-

fabric stability by measuring the resistance to yam slippage

mittee D13.18 that fabric stability of insect screening and

of filling yarns over warp yarns, or warp yarns over tilling

louver cloth would not be affected by the range selected. In

yarns in vinyl-coated glass yarn insect screening and louver

any event, the test atmosphere should be stated in the report.

cloth.

3.1.2 fabric stability, n-in vinyl coated glass screening

1.2 This test method shows the values in both SI units and

and louver cloth, the property denoting the ability to resist

inch-pound units. ‘91 units” is the technically correct name

slippage of yarn segments in one direction over yam seg-

for a system of metric units known as the International

ments in the opposite direction.

System of Units. “Inch-pound units” is the technically

3.1.3 For definitions of other textile terms used in this test

correct name for the customary units used in the United

method, refer to Terminology D 123.

States. The values stated in inch-pound units are to be

regarded as the standard. The values in SI units are provided

4. Summary of Test Method

for information only.

1.3 This standard does not purport to address all of the

4.1 Samples of the vinyl-coated glass yam insect screening

safety concerns, if any, associated with its use. It is the

or louver cloth are subjected to a breaking force test where

responsibility qf the user qf this standard to establish appro-

yarns have been severed within the gage length area. The

priate safety and health practices and determine the applica-

force required to break the fused bond between yarn

bility of regulatory limitations prior to use.

components and slip yarn segments in one direction over

yarn segments in the opposite direction is reported as the

2. Referenced Documents

fabric stability.

2.1 ASTM Standards:

D76 Specification for Tensile Testing Machines for

5. Significance and Use

Textiles2

5.1 This test method is considered satisfactory for accep-

D 123 Terminology Relating to Textiles2

tance testing of commerical shipments since the method has

D4028 Specification for Solar Screening Woven from

been used extensively in the trade for acceptance testing.

Vinyl-Coated Fiber Glass Yarn3

5.1.1 In cases of a dispute arising from differences in

E 17 1 Specification for Standard Atmospheres for Condi-

reported test results when using this test method for accep-

tioning and Testing Materials4

tance testing of commercial shipments, the purchaser and

the supplier should conduct comparative tests to determine if

3. Terminology

there is a statistical bias between their laboratories. Compe-

3.1 Definitions:

tent statistical assistance is recommended for the investiga-

3.1.1 atmosphere for testing textiles, n:for glass, air

tion of bias. As a minimum, the two parties should take a

maintained at a relative humidity of at least 48 % and no

group of test specimens which are as homogeneous as

greater than 67 %, and at a temperature of at least 20°C

possible and which are from a lot of material of the type in

(68°F) and no greater than 25°C (77°F).

question. The test specimens should then be randomly

3. I. 1.1 Discussion-Glass textiles are used in various

assigned in equal numbers to each laboratory for testing. The

products such as reinforced plastics, mat-like material, tire

average results from the two laboratories should be com-

cords, electrical insulation, etc. Each of these materials

pared using Student’s t-test for unpaired data and an

requires different testing atmospheres. It is the intent of the

acceptable probability level chosen by the two parties before

wide spread in testing atmosphere to allow testing of glass

the testing begins. If a bias is found, either its cause must be

textiles in respective laboratories where end-product test

found and corrected or the purchaser and the supplier must

agree to interpret future test results in the light of the known

bias.

’ This test method is under the jurisdiction of ASTM Committee D-13 on

5.2 Vinyl-coated glass yarn insect screening and louver

Textiles and is the direct responsibility of Subcommittee D13.18 on Glass Fiber

and Its Products.

cloth are subjected to a heating process to fuse the warp

Current edition approved Feb. 24, 1989. Published April 1989.

yarns to the filling yarns of the woven structure. The force at

= Annrtal Book gj’ASTh4 Standa& Vol 07.01.

which yarns in one direction move over yarns in the opposite

3 Annual Book oI‘ASTM StandardJ, Vol 07.02.

direction is a measure of the bond of fusion. The degree of

4 Annun/ Book qfAST.44 Smndrrrds, Vol 08.03.

ASTM D49L2 89 - 0759530 0573472 272 -

the bond of fusion on the vinyl-coated glass yarn insect

screening and louver cloth is used for process control. Fabric

stability was formerly called resistance to yarn slippage.

6. Apparatus

6.1 Tensile Testing Machine-In case of dispute a con-

stant-rate-of-extension, CRE, tensile testing machine as de-

scribed in Specification D 76 will be used. When agreed

upon between the purchaser and the supplier, a constant-

rate-of-traverse tensile, CRT, testing machine can be used.

6.1.1 The clamp faces shall be rubber or smooth metallic

faced at least 10 mm (0.4 in.) wider than the specimen width CUT “A”

and with a minimum of 25 mm (1 in.) in the direction of

CUT “B”

application of force.

NOTE l-The covering of the metallic faces with approximately a

3-mm (0. I l-in.) thick cardboard or other suitable material has been

found useful for preventing crushing of the specimen.

7. Sampling and Number of Specimens

7.1 Lot Size-A lot is defined as a single shipment of a

single type of glass textile. A lot may constitute all or part of

a single customer order.

7.2 Lot Sample-As a lot sample for acceptance testing,

take the number of rolls of insect screening or louver cloth

directed in an applicable material specification or other

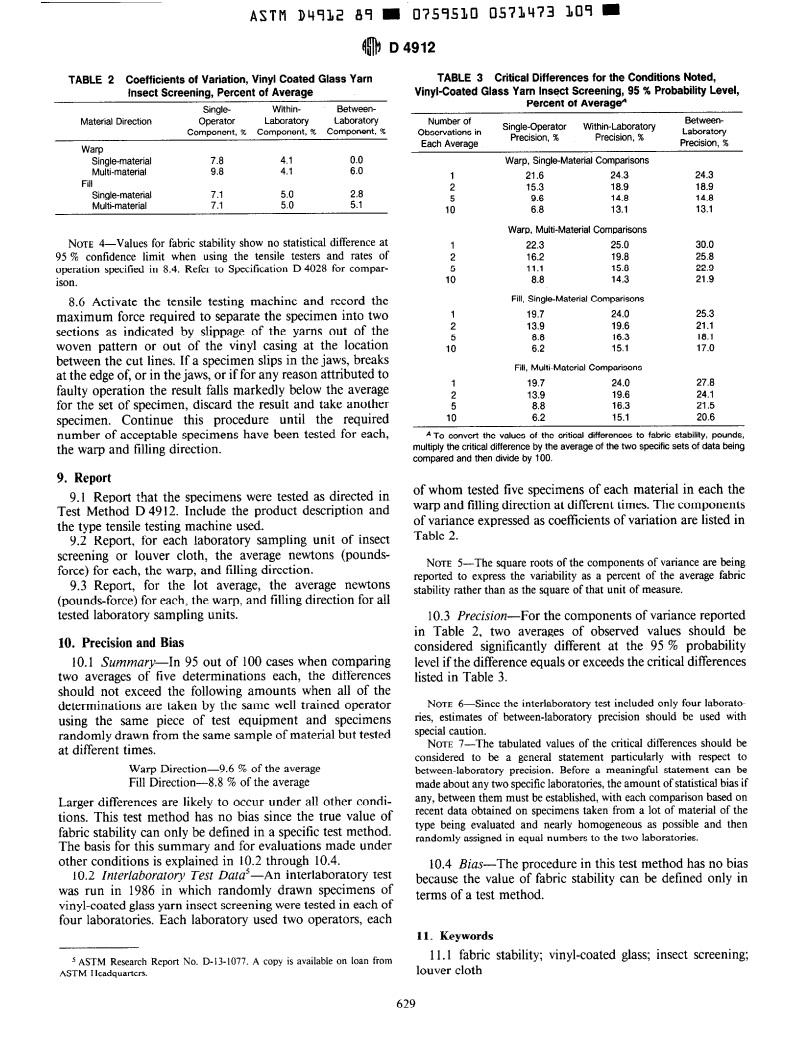

FIG. 1 Screening, Nonmetallic, Insert; Cut Pattern of Specimen

agreement between the purchaser and the supplier. Consider

rolls of insect screening or louver cloth to be the primary

test. Take test specimens from each swatch in the laboratory

sampling unit. In the absence of such an agreement, take the

sample in such a-way that no specimen is closer than one

number of rolls specified in Table 1.

tenth the width of the swatch from the selvage with no two

NOTE 2-An adequate specification or other agreement between the

specimens cut parallel to the warp containing the same set of

purchaser and the supplier requires taking into account the variability

warp ends or if cut parallel to the tilling, containing the same

between rolls of insect screening or louver cloth and between test

set of tilling picks, and the specimens from different swatches

specimens from a swatch or roll of insect screening or louver cloth to

produce a sampling plan with meaningful producer’s risk, consumer’s

are each taken from a different part of the width of the

risk, acceptable quality level, and limiting quality level.

swatches.

7.3 Laboratory Sample-As a laboratory sample for ac-

8. Procedure

ceptance testing, proceed as directed in an applicable mate-

8.1 Condition the laboratory samples without precondi-

rial specification or other agreement between the purchaser

and the supplier. In the absence of such an agreement, use tioning for period of at least 5 h in the atmosphere for testing

the lot sampling units for the laboratory sampling units. glass textiles, unless otherwise specified.

Take a full width swatch, 2 m (2 yd) long, from each selected

NOTE 3-In any event, 24 h is considered ample exposure to bring

lot sam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.